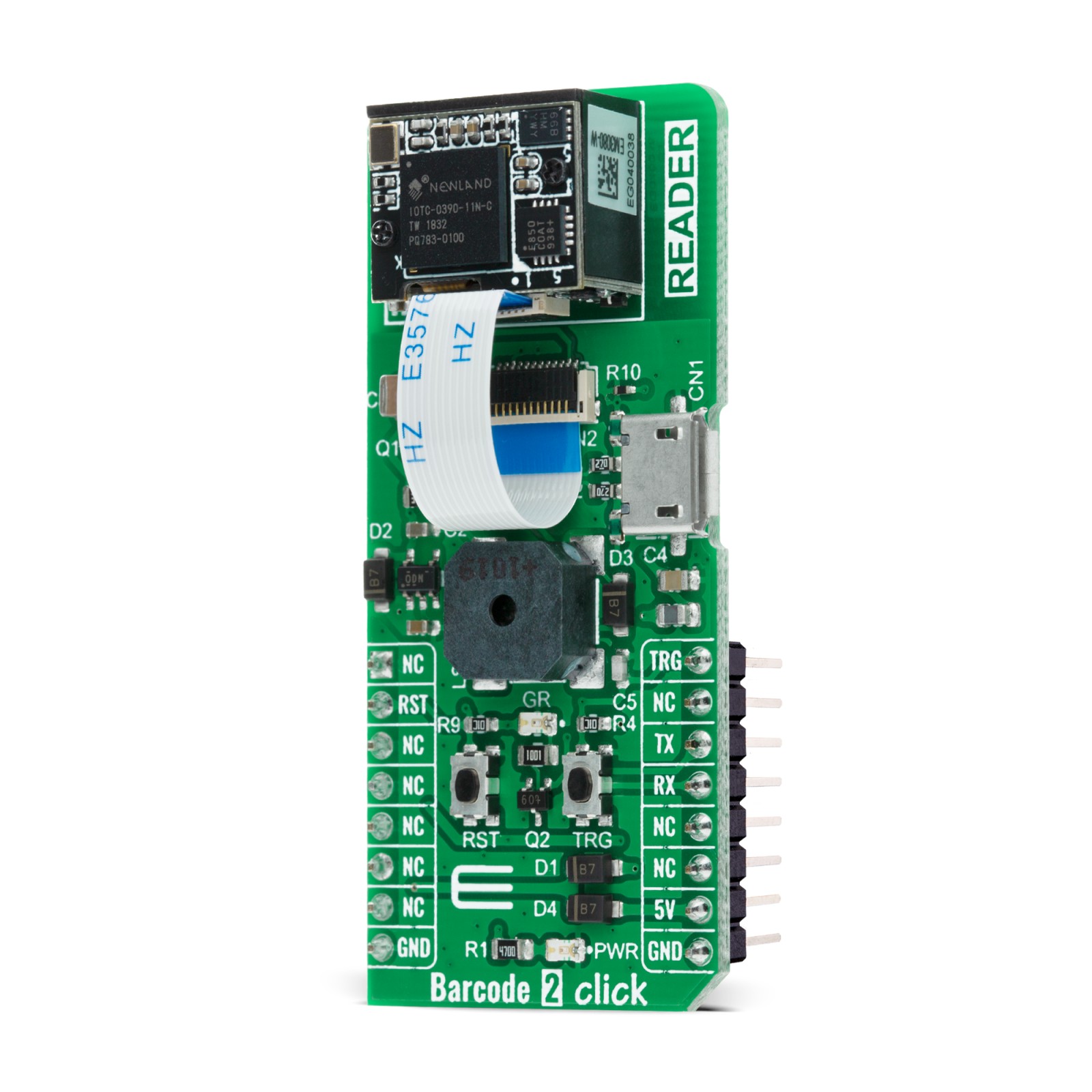

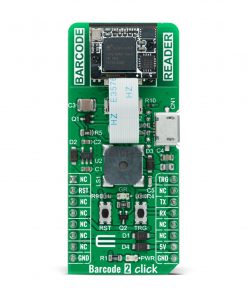

Barcode 2 Click

R2,350.00 ex. VAT

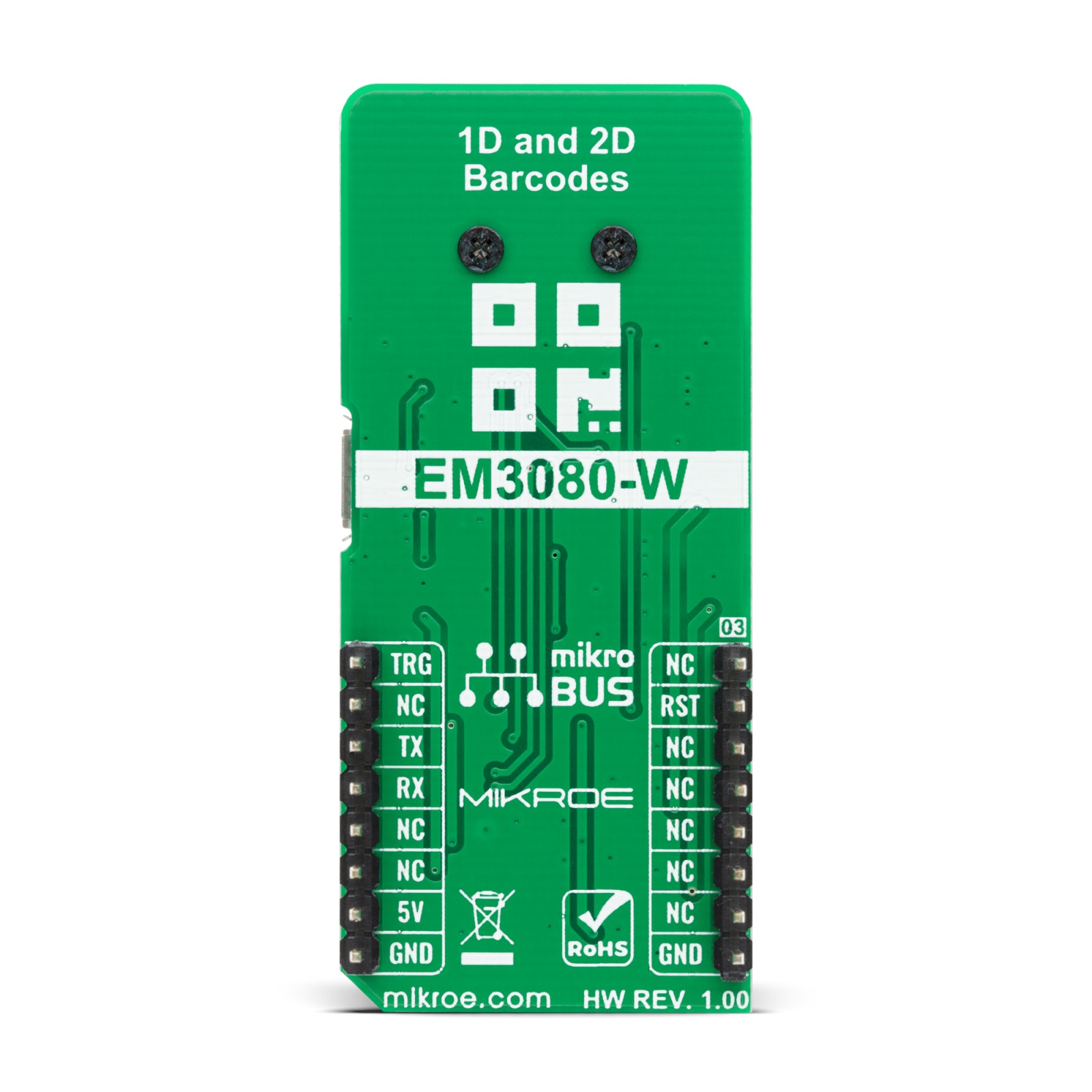

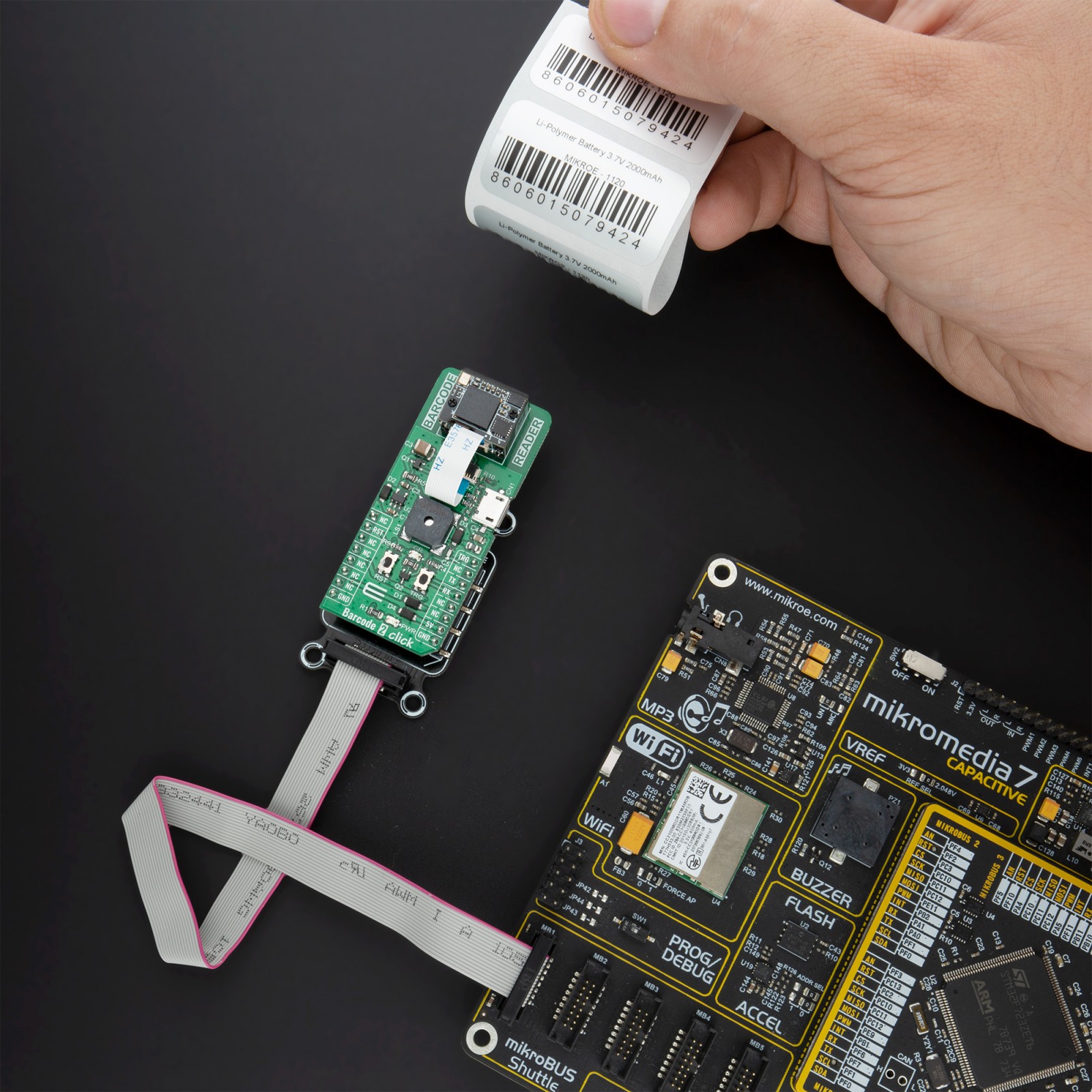

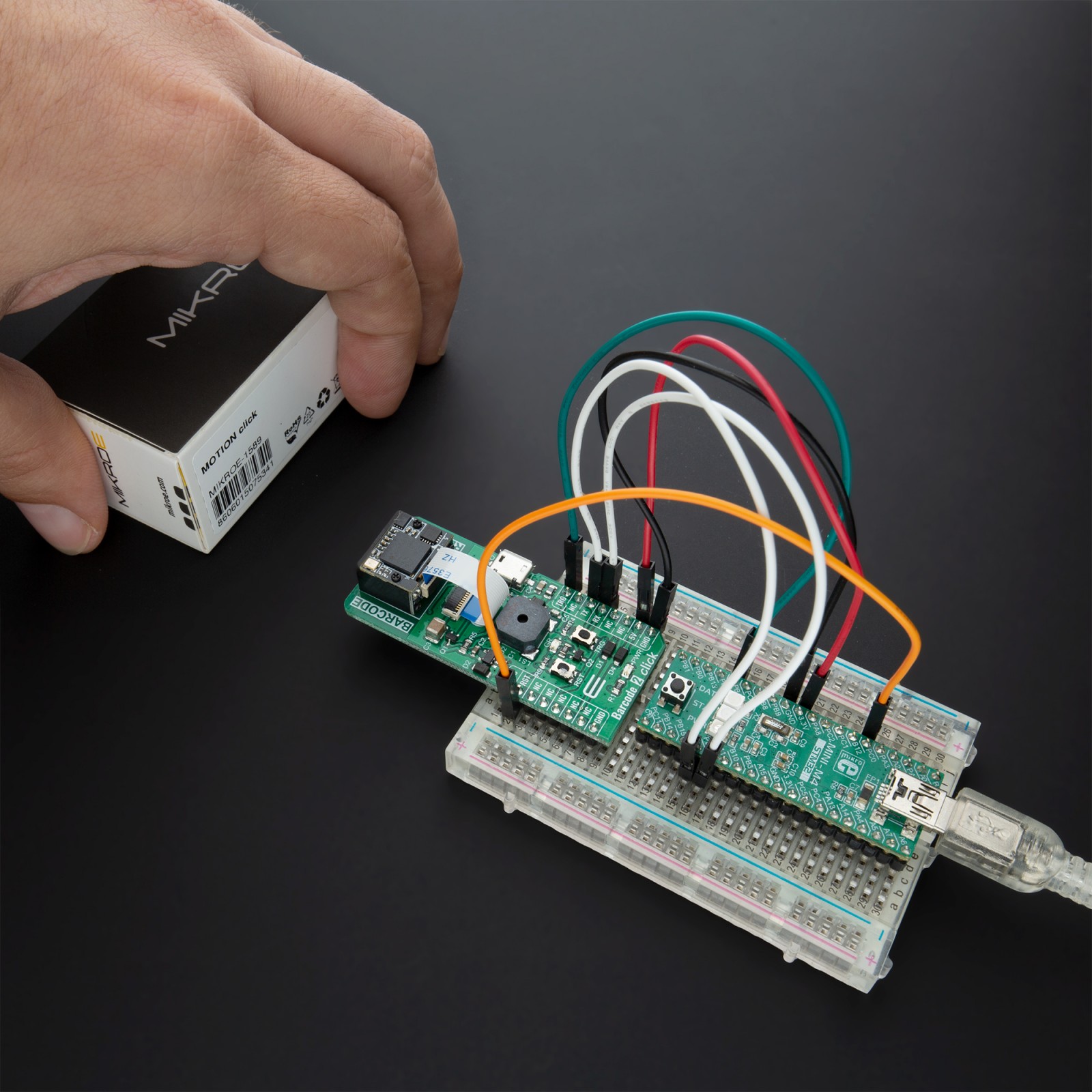

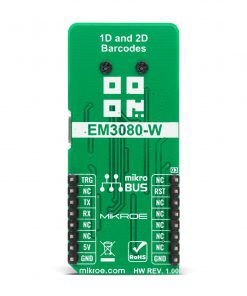

Barcode 2 Click is an adapter add-on board that contains a computerized image recognition system that is compliant with a wide range of different 1D and 2D barcode protocols. This board features the EM3080-W, a barcode decoder chip that delivers superior performance and solid reliability with low power consumption from Newland Auto-ID Tech. Co., Ltd. Featuring excellent near-field reading, wide-viewing angle, and snappy reading, the EM3080-W also offer stunning performance on decoding poor-quality and damaged barcodes which brings greater efficiency and convenience in barcode scanning. This Click board™ represents an ideal solution for both emerging mobile phone-based barcode applications, like coupons, e-tickets and boarding passes, and traditional applications.

Barcode 2 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R2,232.50 |

| 10+ | R2,115.00 |

| 15+ | R1,997.50 |

| 20+ | R1,922.30 |