Vibro Motor 4 Click

R435.00 ex. VAT

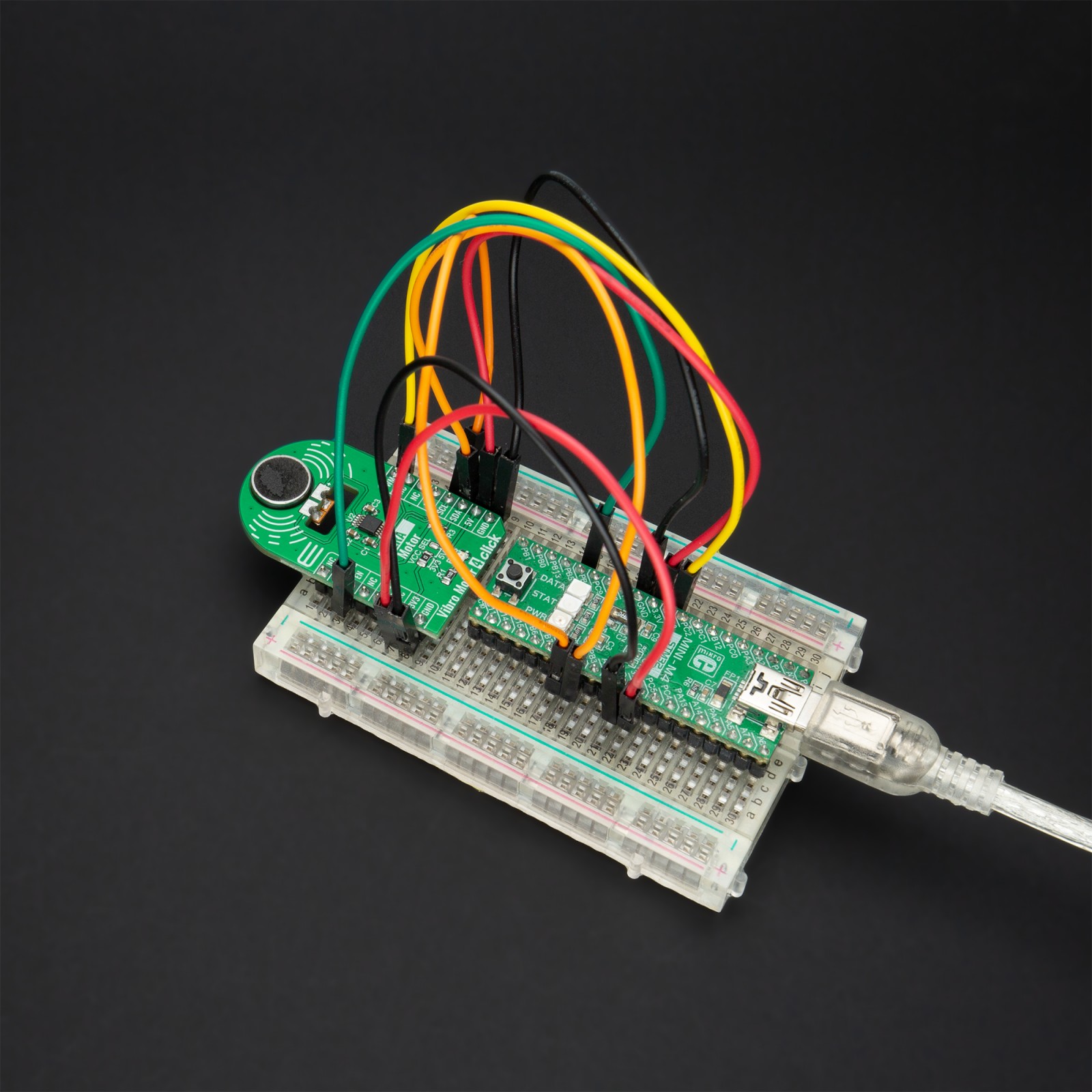

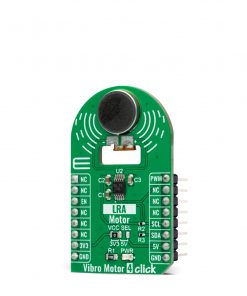

Vibro Motor 4 Click is a compact add-on board that makes an ideal solution for adding simple haptic feedback in any design. This board features the VG1040003D , a coin-sized linear resonant actuator (LRA) that generates vibration/haptic feedback from Vybronics. Driven by a flexible Haptic/Vibra driver, the DRV2605, VG1040003D vibrates in the Z-axis, which is perpendicular to the face of the vibration motor. It draws a maximum of 170mA while producing the highest G force/vibration energy of 2 GRMS. This Click board™ makes an excellent choice for devices with limited battery capacity and for users who require crisp haptic feedback and low power consumption.

Vibro Motor 4 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R413.25 |

| 10+ | R391.50 |

| 15+ | R369.75 |

| 20+ | R355.83 |