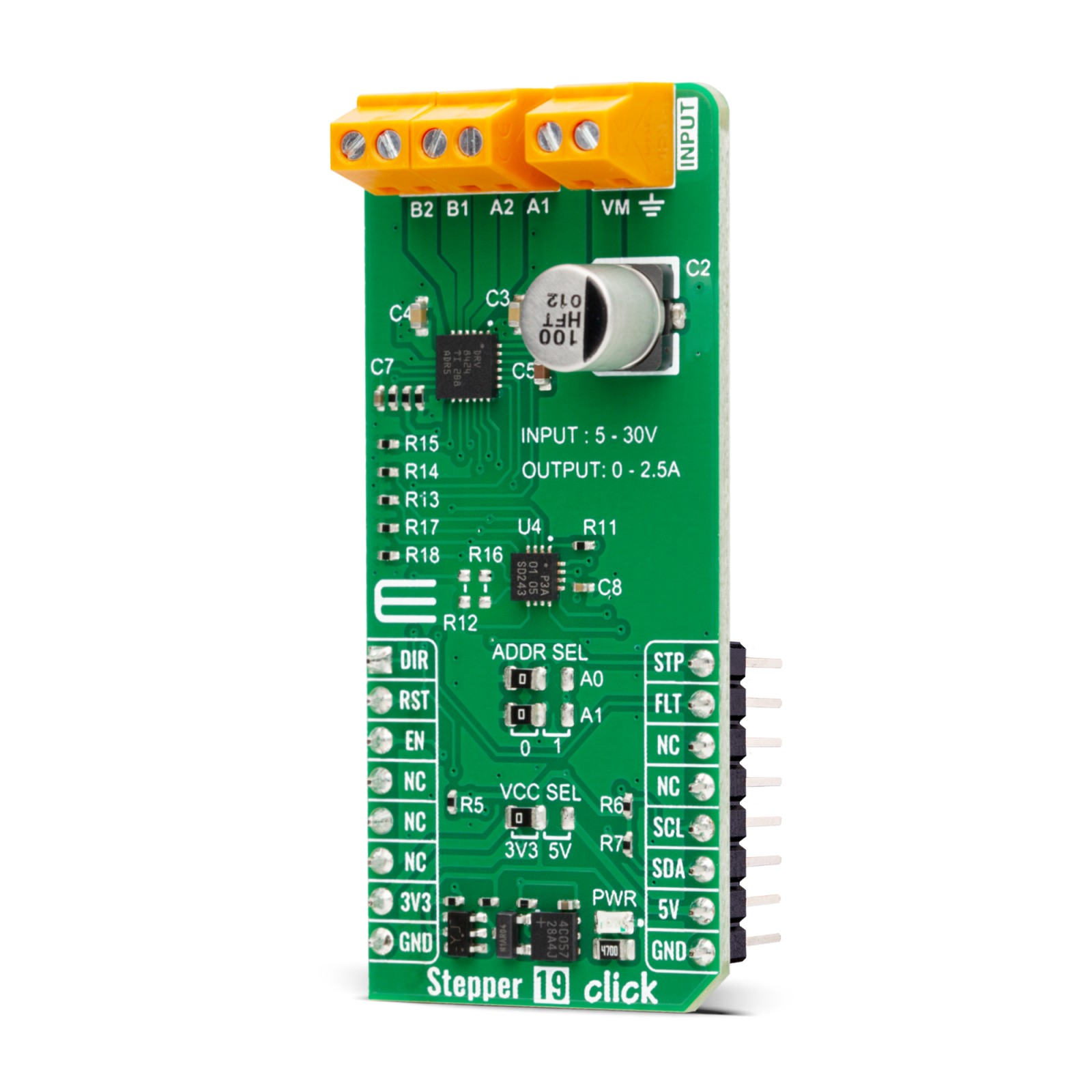

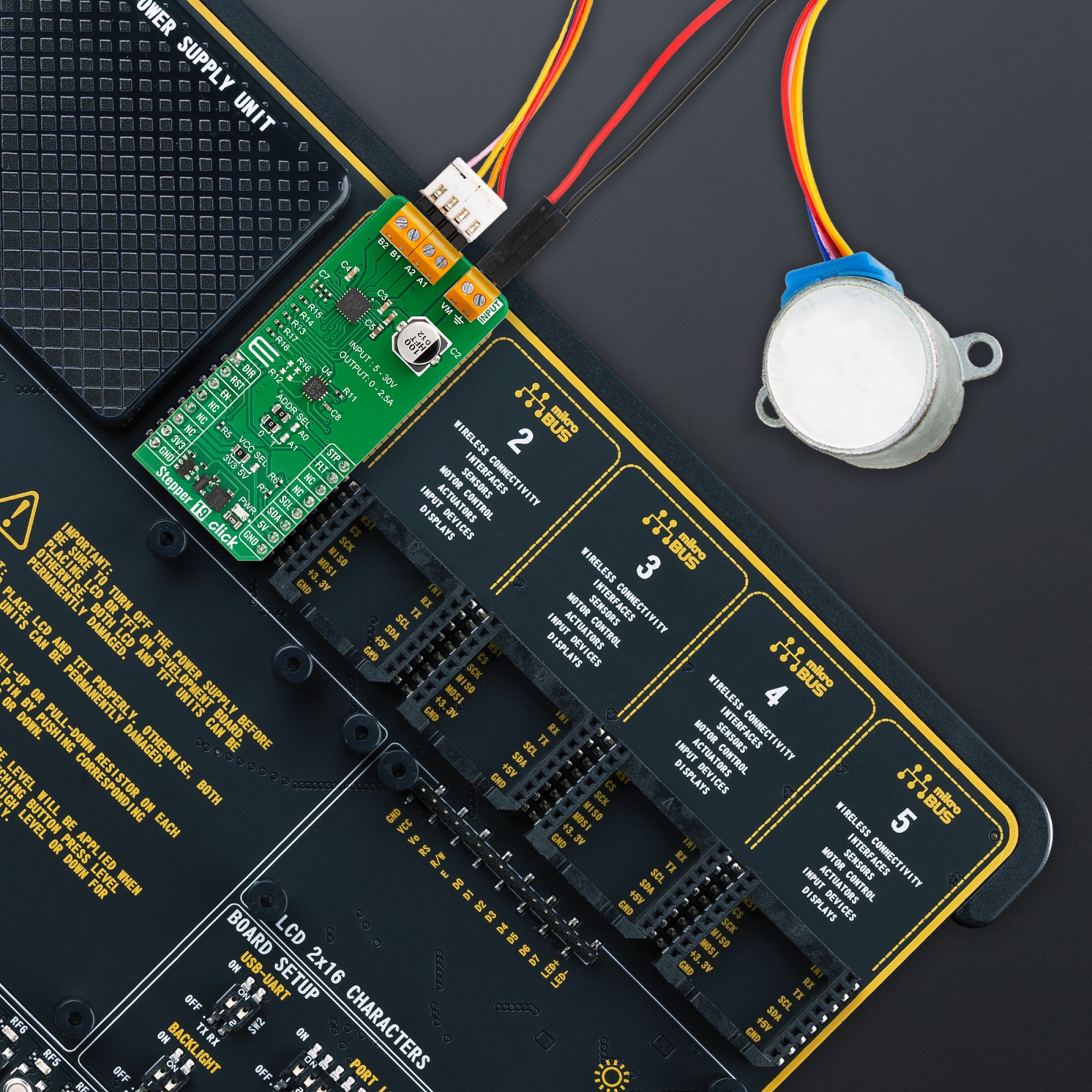

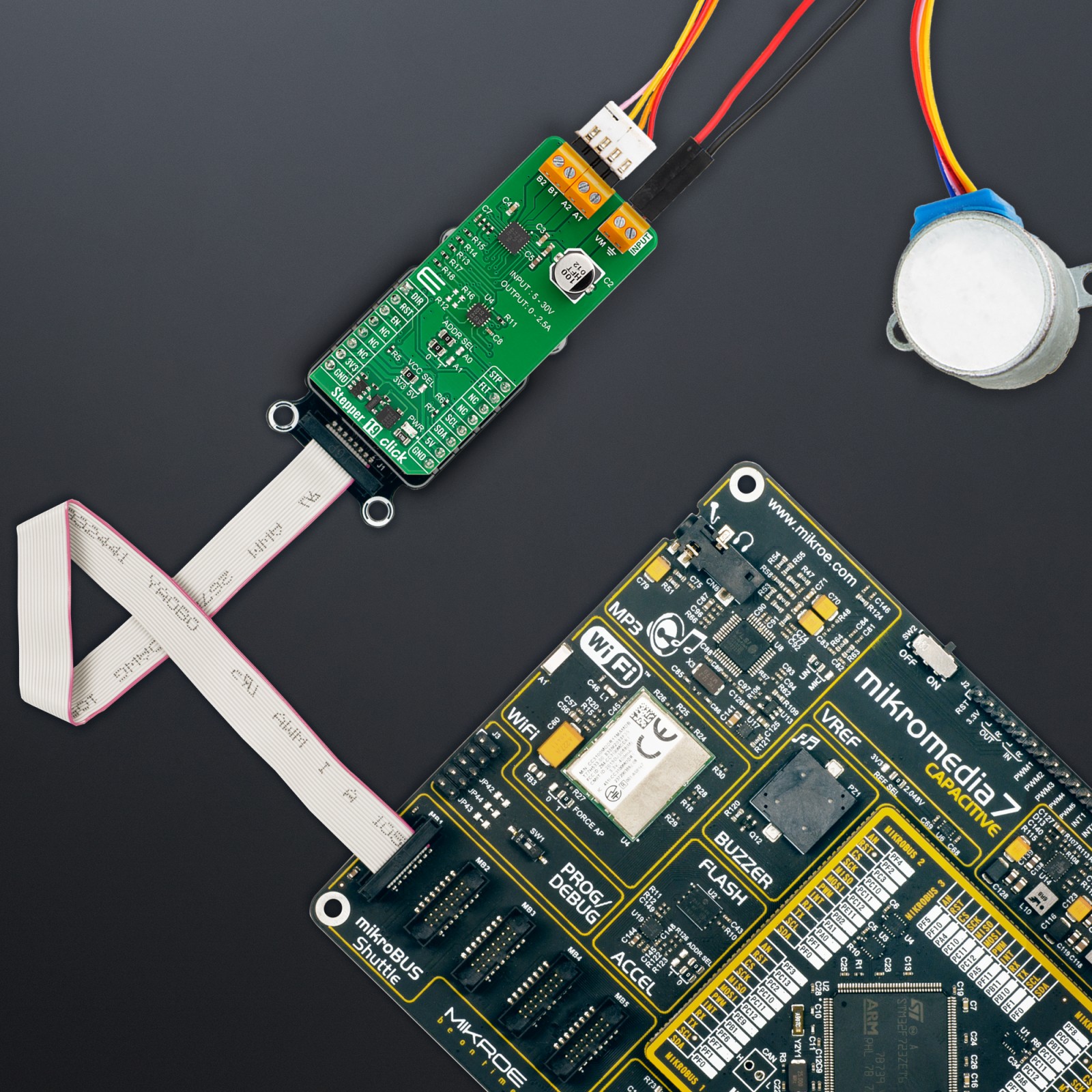

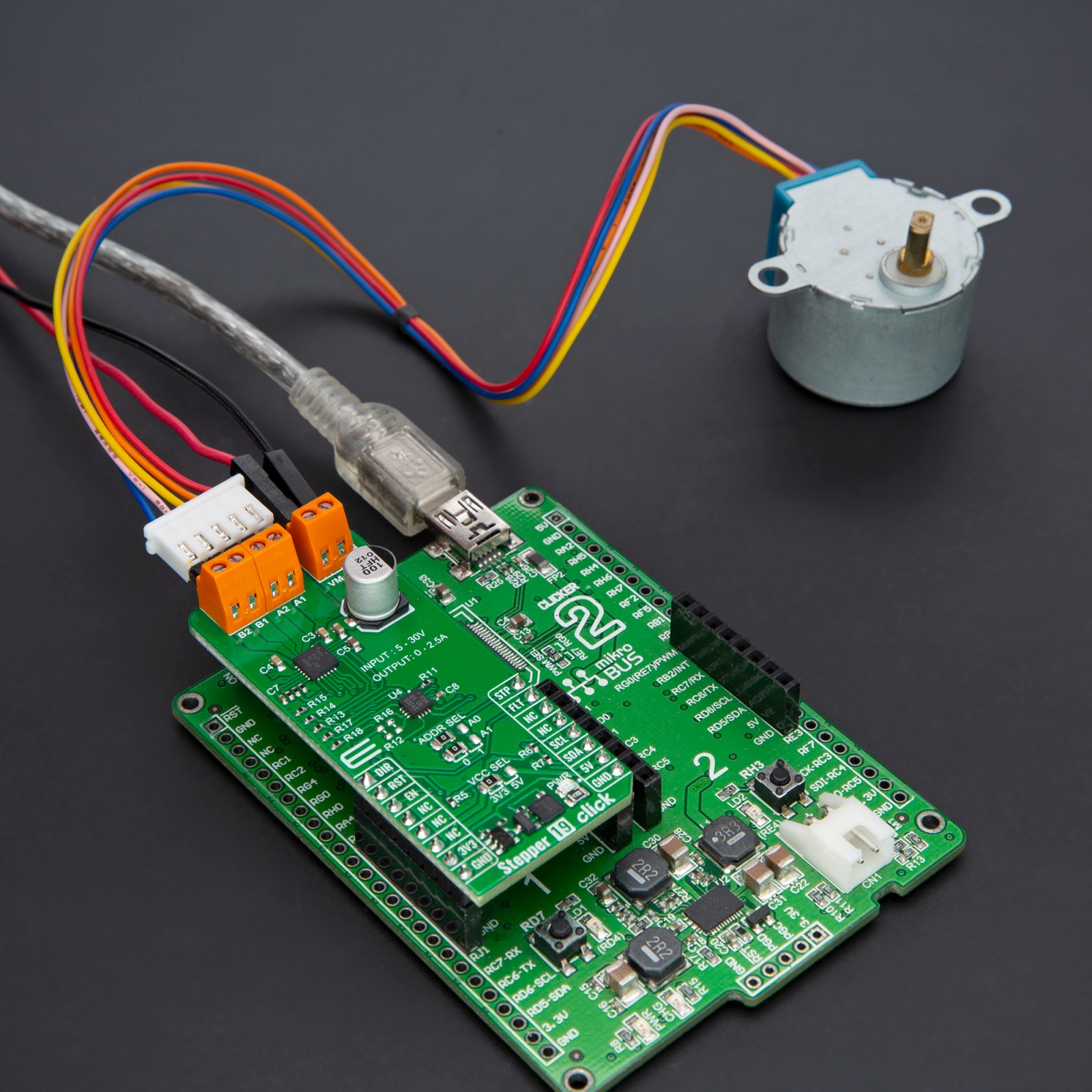

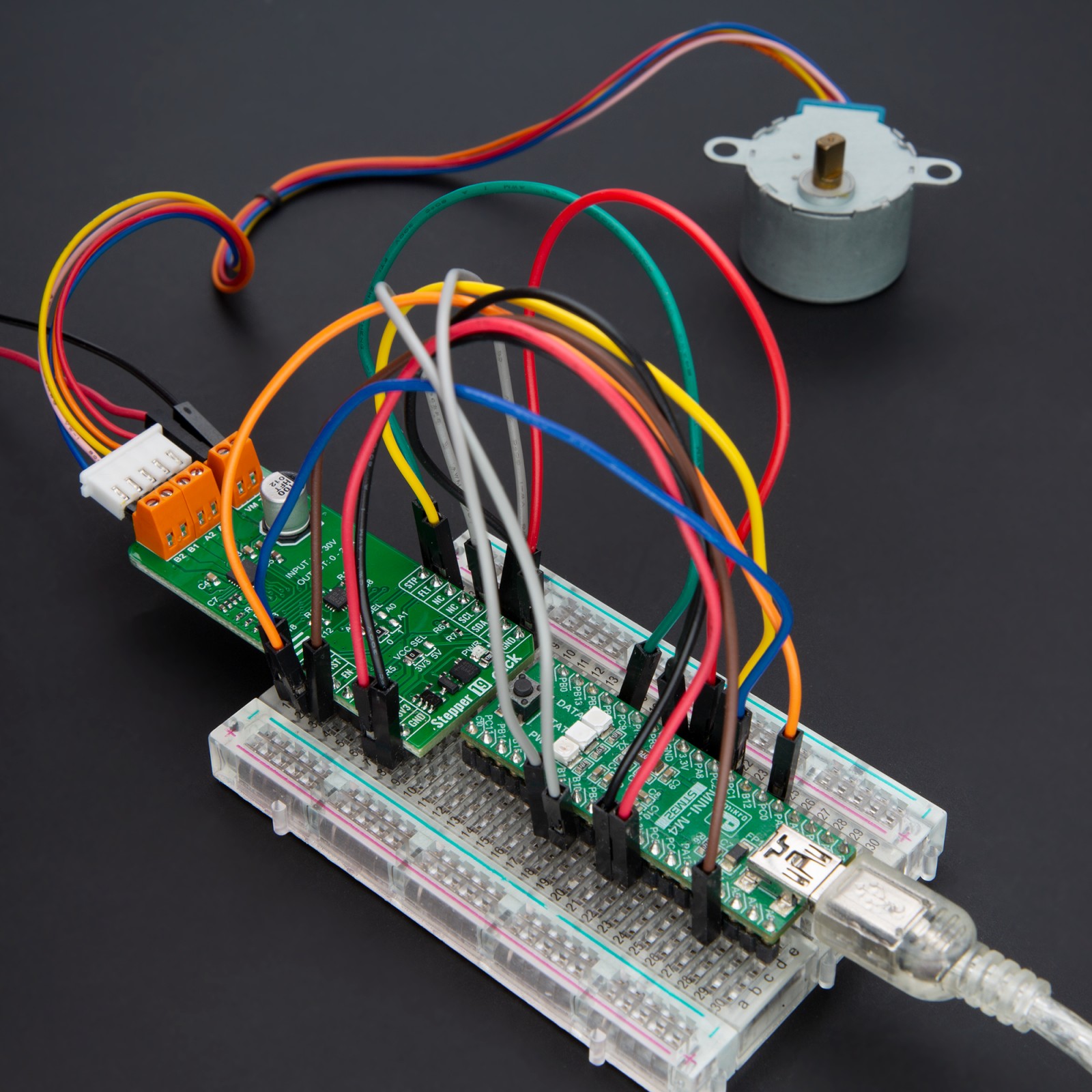

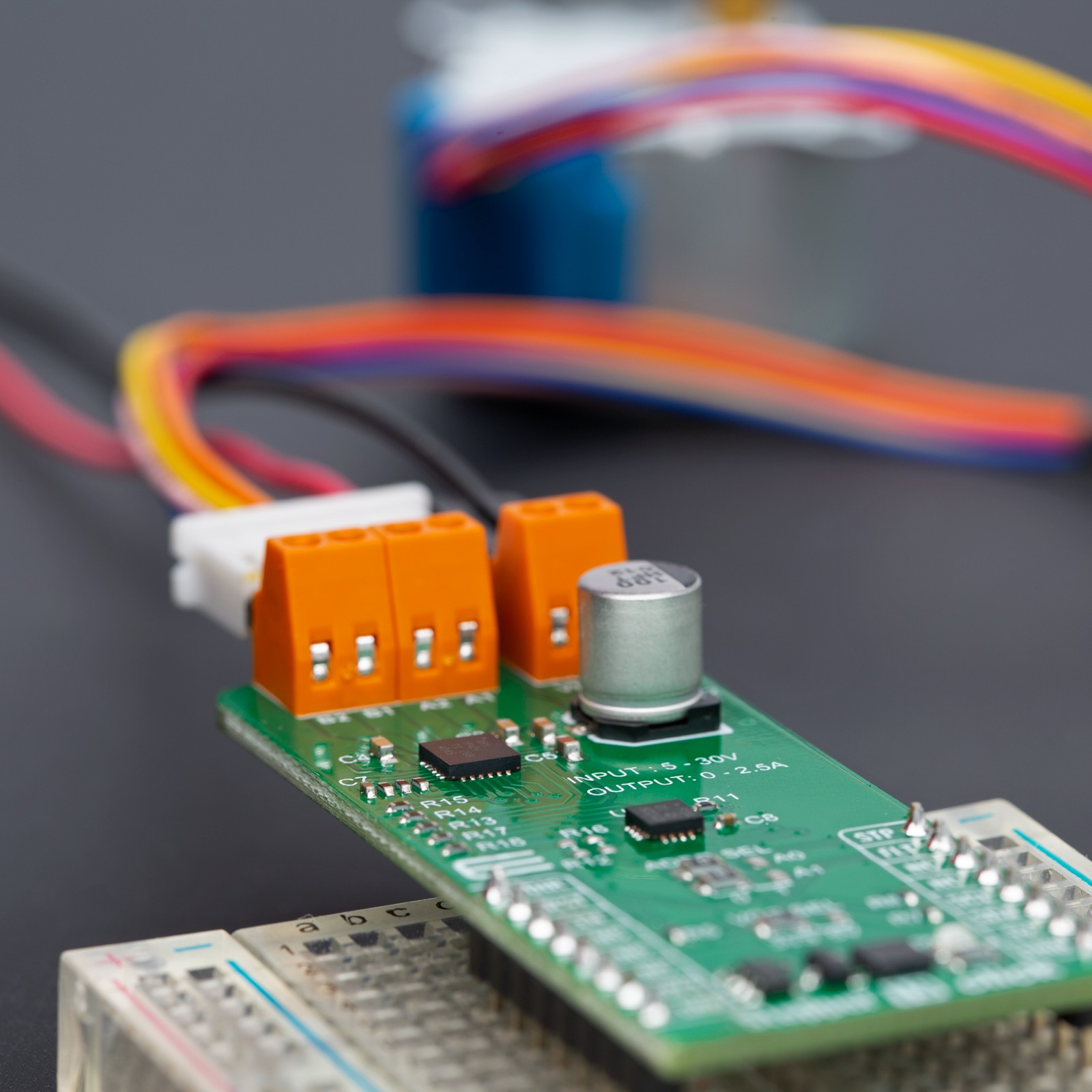

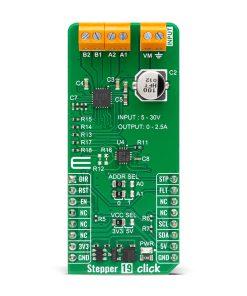

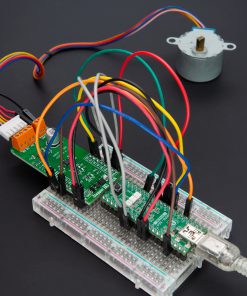

Stepper 19 Click is a compact add-on board for precise control over stepper motors. This board features the DRV8424, a stepper motor driver from Texas Instruments designed to drive both industrial and consumer stepper motors. The DRV8424 has dual N-channel power MOSFET H-bridge drivers, a microstepping indexer, and integrated current sensing, eliminating the need for external power sense resistors. Operating on a 5V to 30V external power supply, the DRV8424 can deliver up to 2.5A of full-scale output current, with an internal PWM current regulation scheme that includes smart tune, slow, and mixed decay options to optimize performance. Ideal for applications in multichannel system monitoring, robotics, precision positioning, and automated manufacturing processes, this Click board™ appears as a versatile solution for sophisticated stepper motor control.

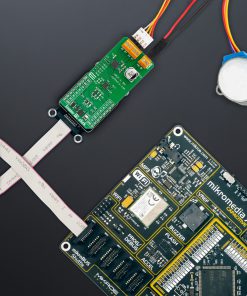

Stepper 19 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

WiFi Plus Click

1 × R2,100.00

WiFi Plus Click

1 × R2,100.00  RTC Click

1 × R370.00

RTC Click

1 × R370.00  GSM Click

3 × R1,000.00

GSM Click

3 × R1,000.00  RN4678 Click

2 × R805.00

RN4678 Click

2 × R805.00  EXPAND Click

1 × R245.00

EXPAND Click

1 × R245.00  tRF Click

1 × R1,000.00

tRF Click

1 × R1,000.00