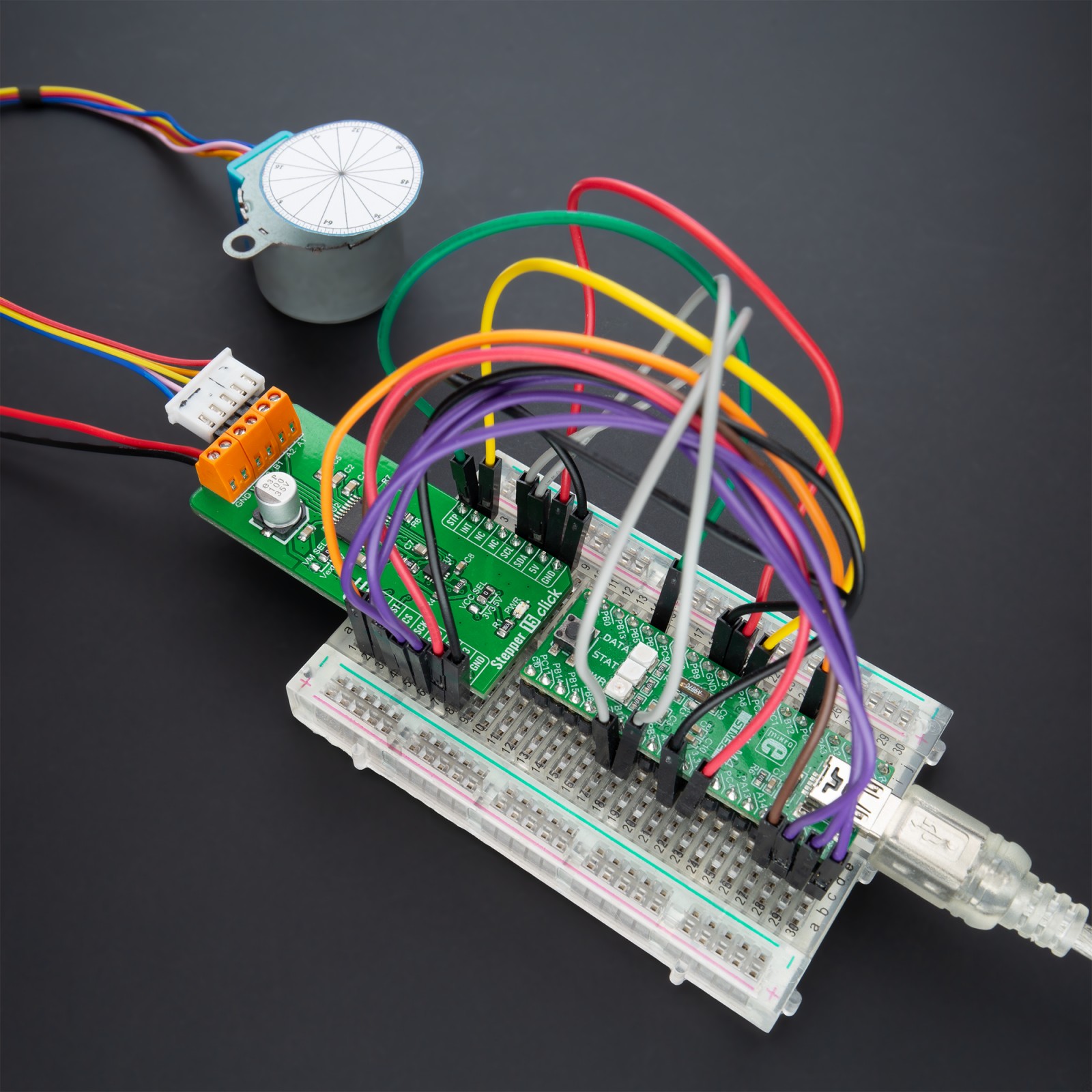

Stepper 15 Click

R640.00 ex. VAT

Stepper 15 Click is a compact add-on board that contains a bipolar stepper motor driver. This board features the DRV8889A, an automotive stepper driver with integrated current sense and stall detection from Texas Instruments. It supports up to 1.5A full-scale current with an internal microstepping indexer, smart tune decay technology, advanced stall detection algorithm, and integrated current sensing, eliminating the need for power sense resistors. With a simple STEP/DIR interface, the device supports up to 1/256 levels of microstepping to enable a smooth motion profile. Also, an advanced stall detection algorithm allows users to detect if the motor stopped and take action as needed, improving efficiency and reducing noise. This Click board™ is suitable for driving motors in any application that demands a precise and safe step motor driver.

Stepper 15 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

NOTE: Due to the current component shortage on the electronic market lead time and pricing for this product can vary

Stock: Lead-time applicable.

| 5+ | R608.00 |

| 10+ | R576.00 |

| 15+ | R544.00 |

| 20+ | R523.52 |