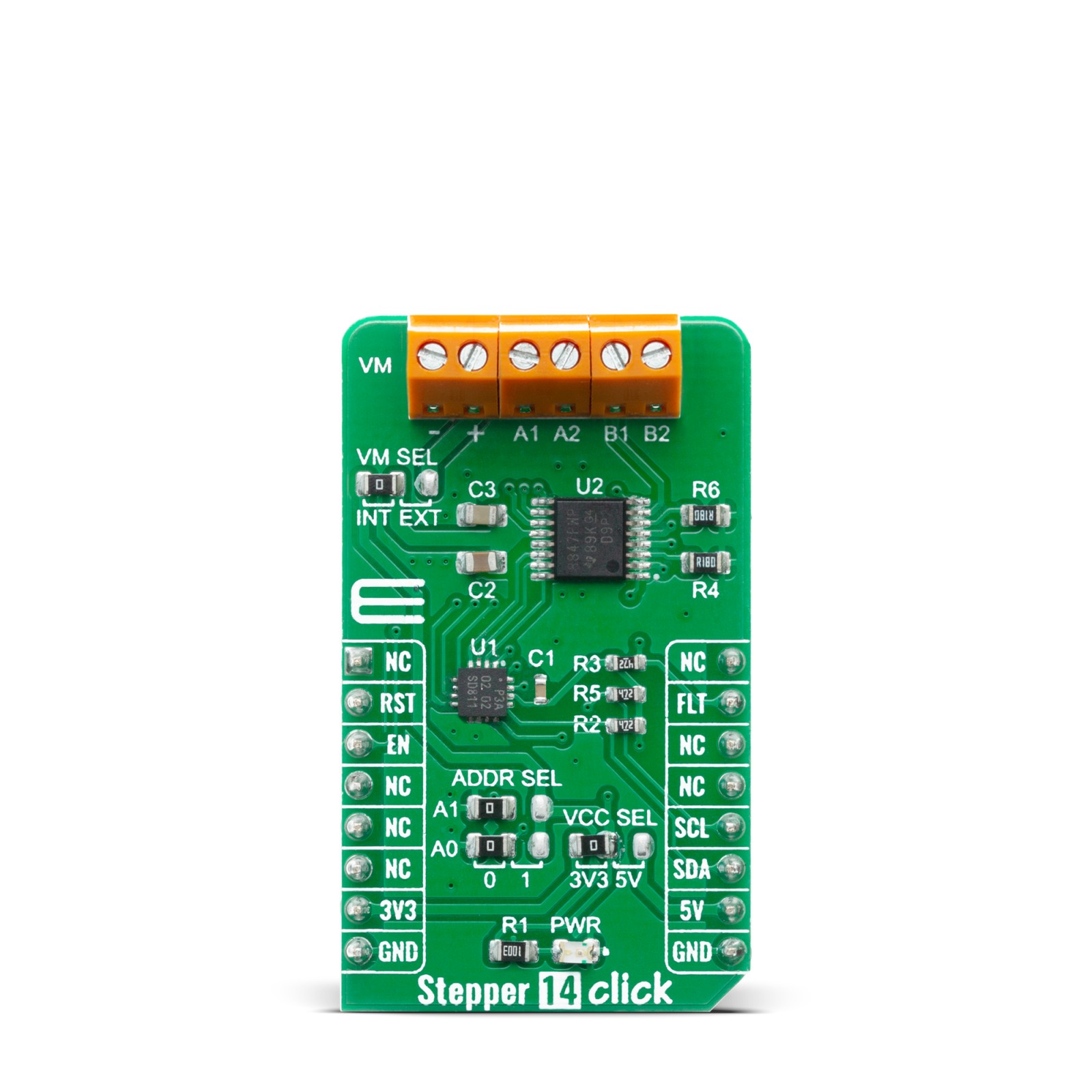

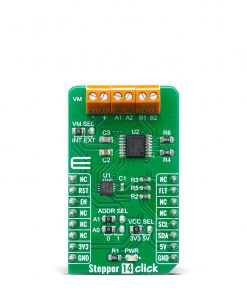

Stepper 14 Click

R440.00 ex. VAT

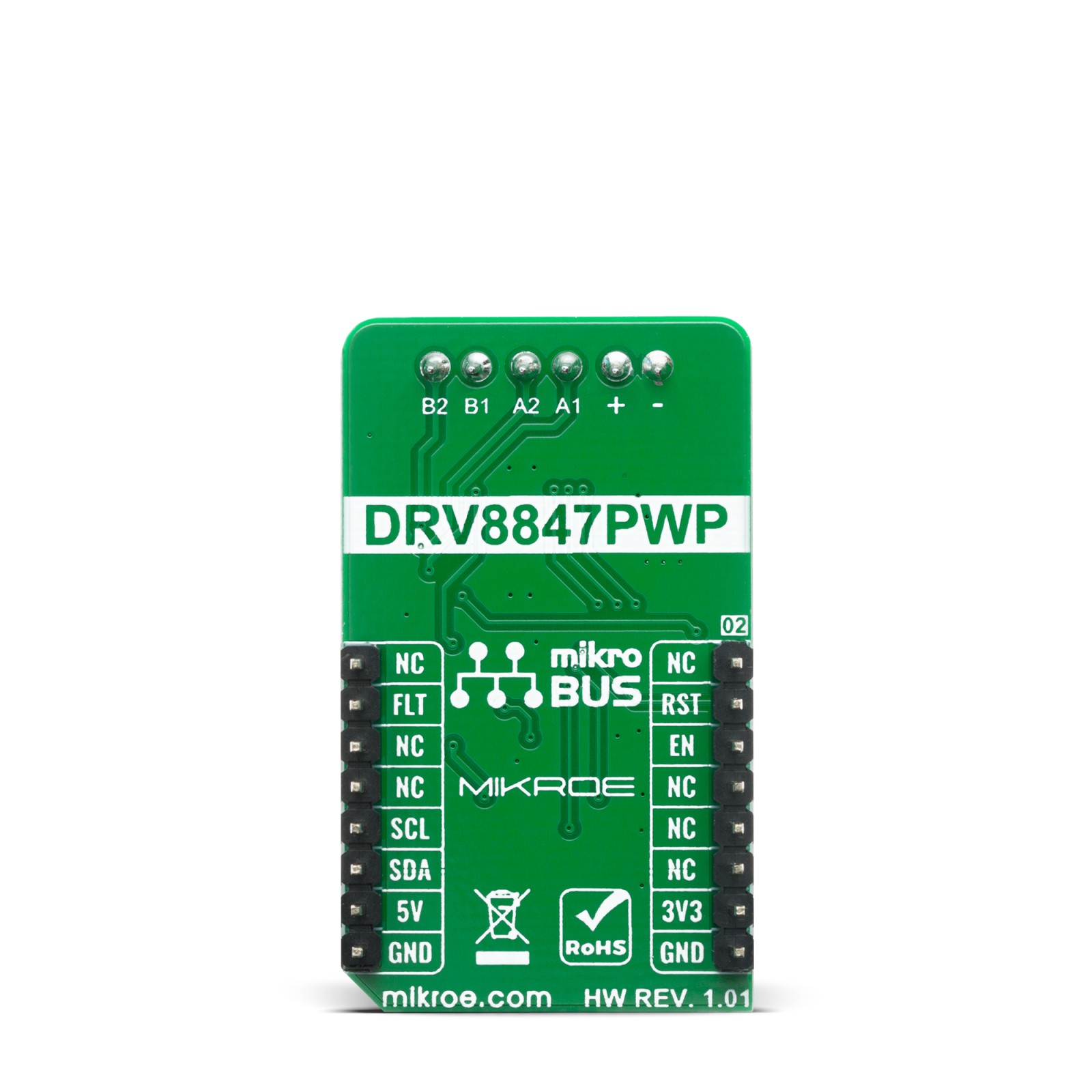

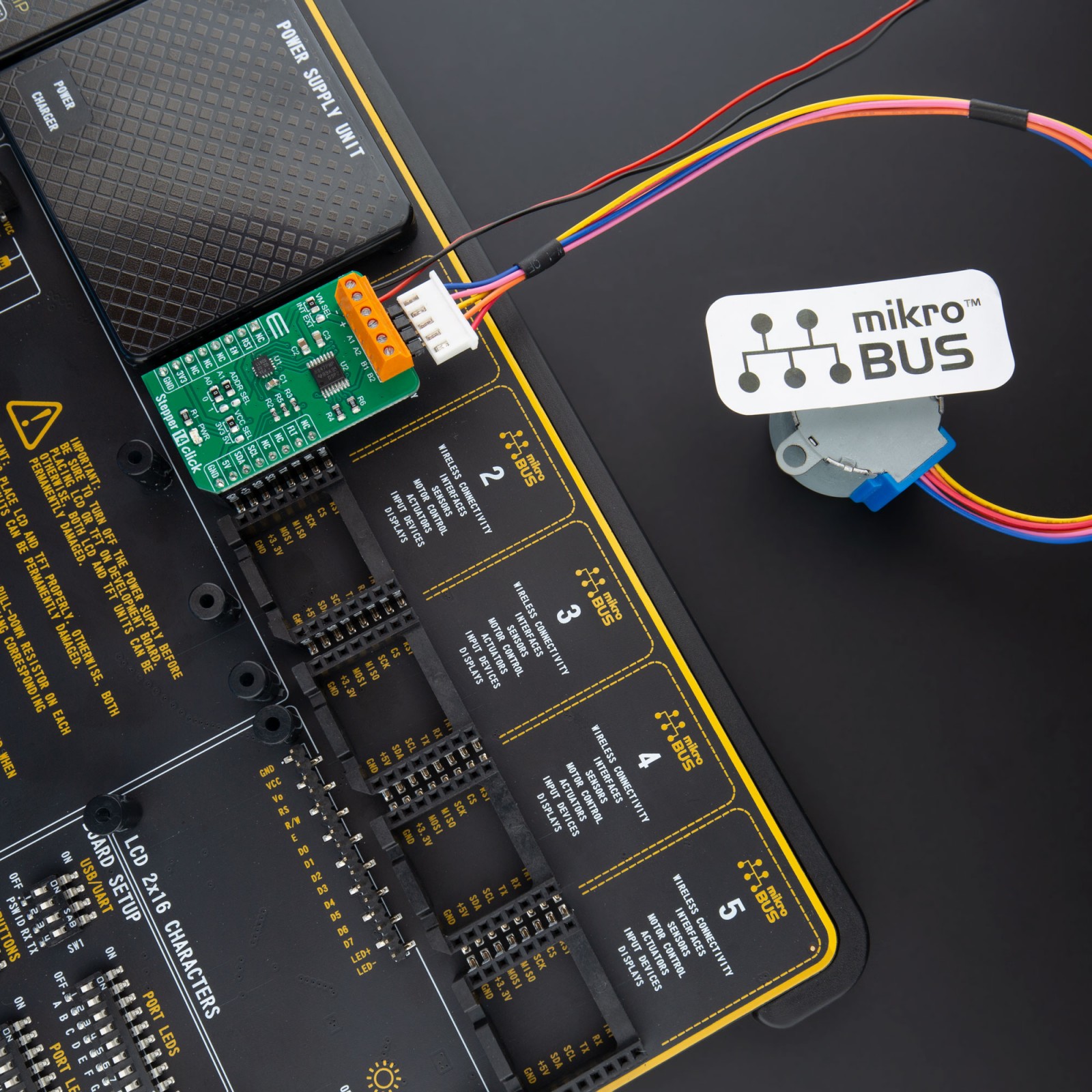

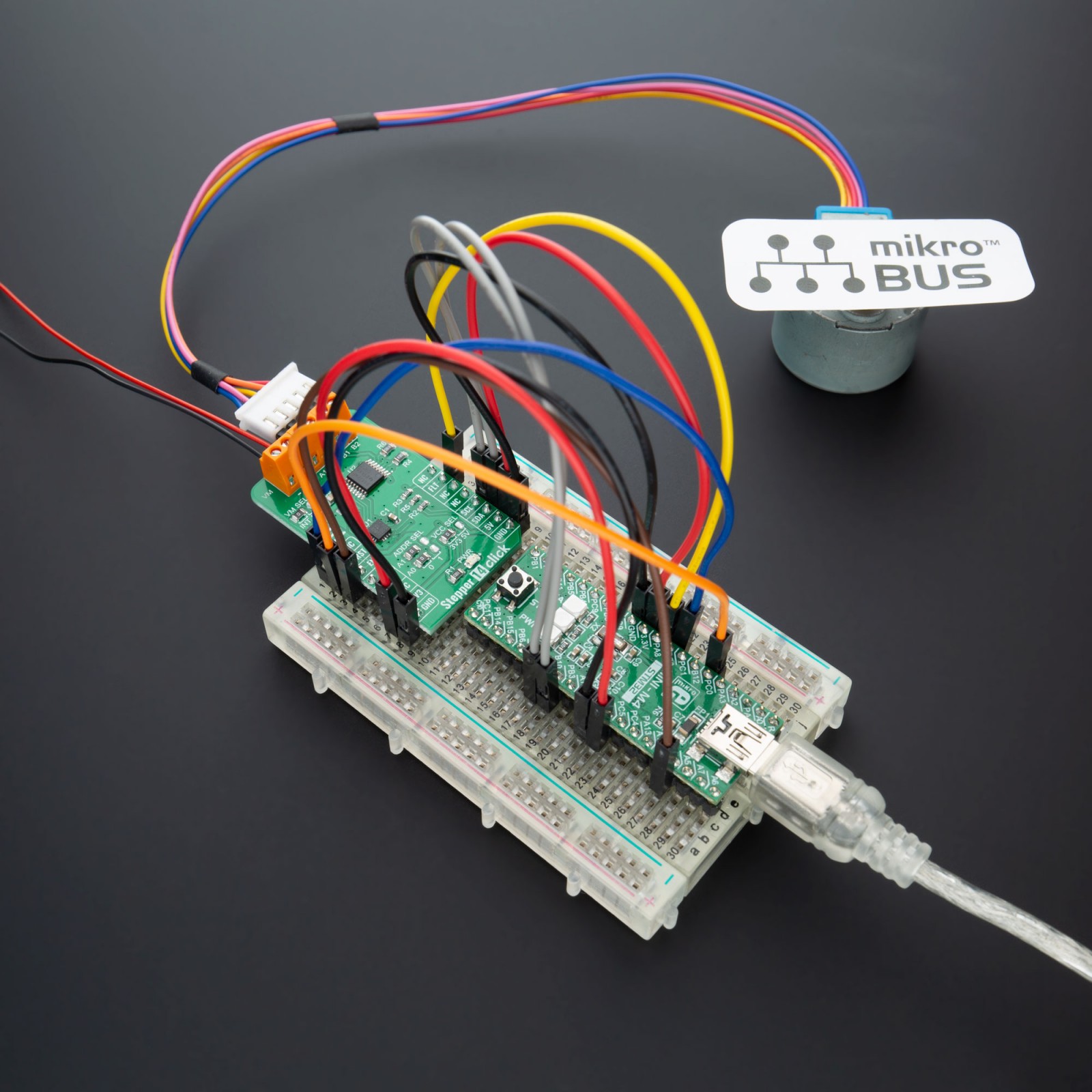

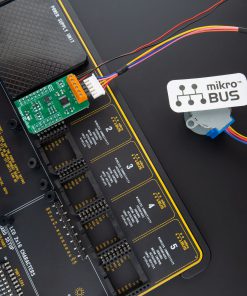

The Stepper 14 Click is a Click board™ that features the DRV8847PWPR, a step motor driver, from Texas Instruments. This Click board™ provides a bipolar step motor controle, It features an H-bridge bipolar step motor driver, which supports full-, half-, quarter-, or eighth-step modes. This click board™ also carries a port expander so that the communication can be done with a minimal number of pins, through the mikroBUS™ I2C bus. This click board™ offers thermal protection, integrated kickback voltage protection, it has a wide range of input voltage, protection against current shoot-through the H-Bridge and high current capability. These features make Stepper 14 click an ideal solution for driving motors in any application that demands a precise and safe step motor driver.

Stepper 14 click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R418.00 |

| 10+ | R396.00 |

| 15+ | R374.00 |

| 20+ | R359.92 |

.jpg)