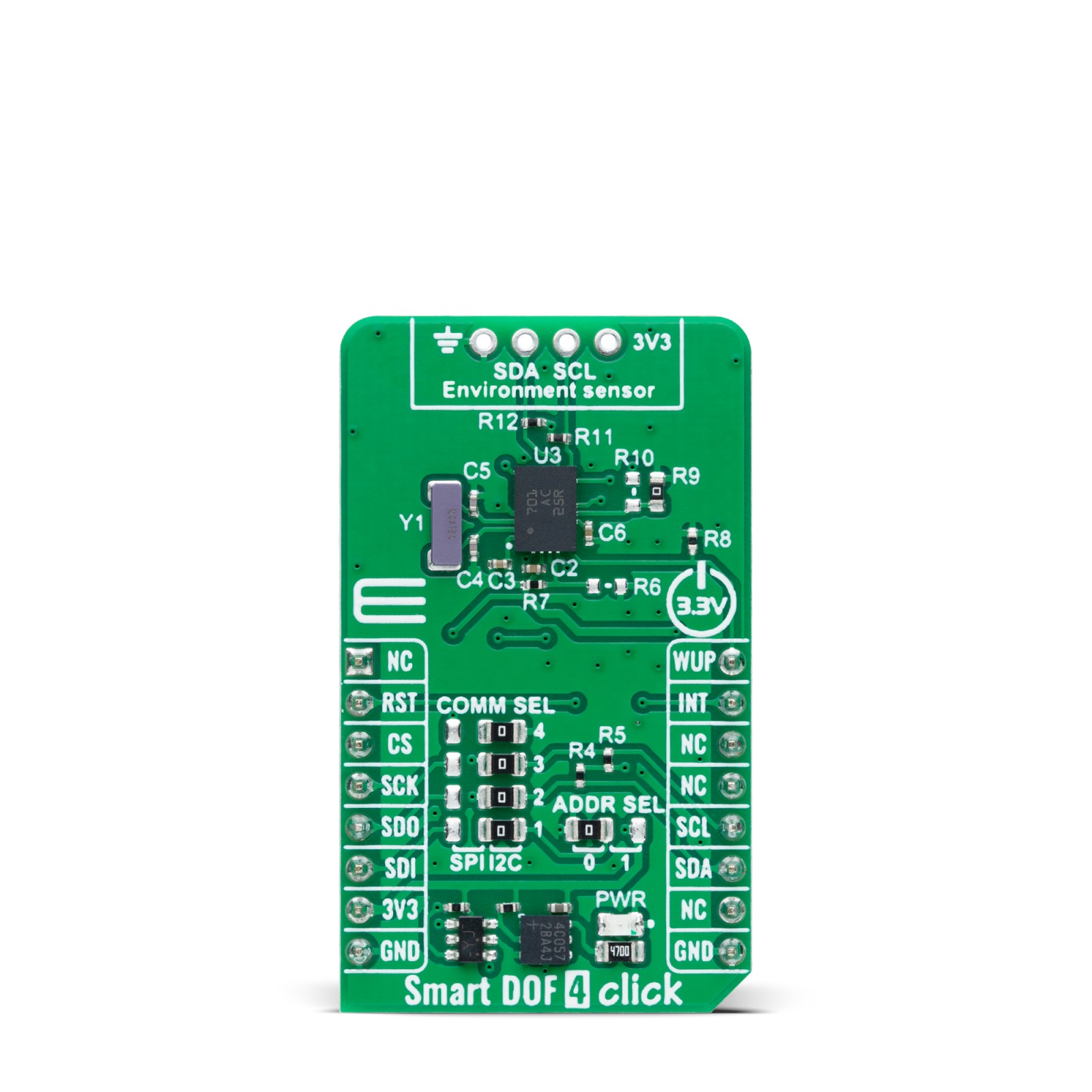

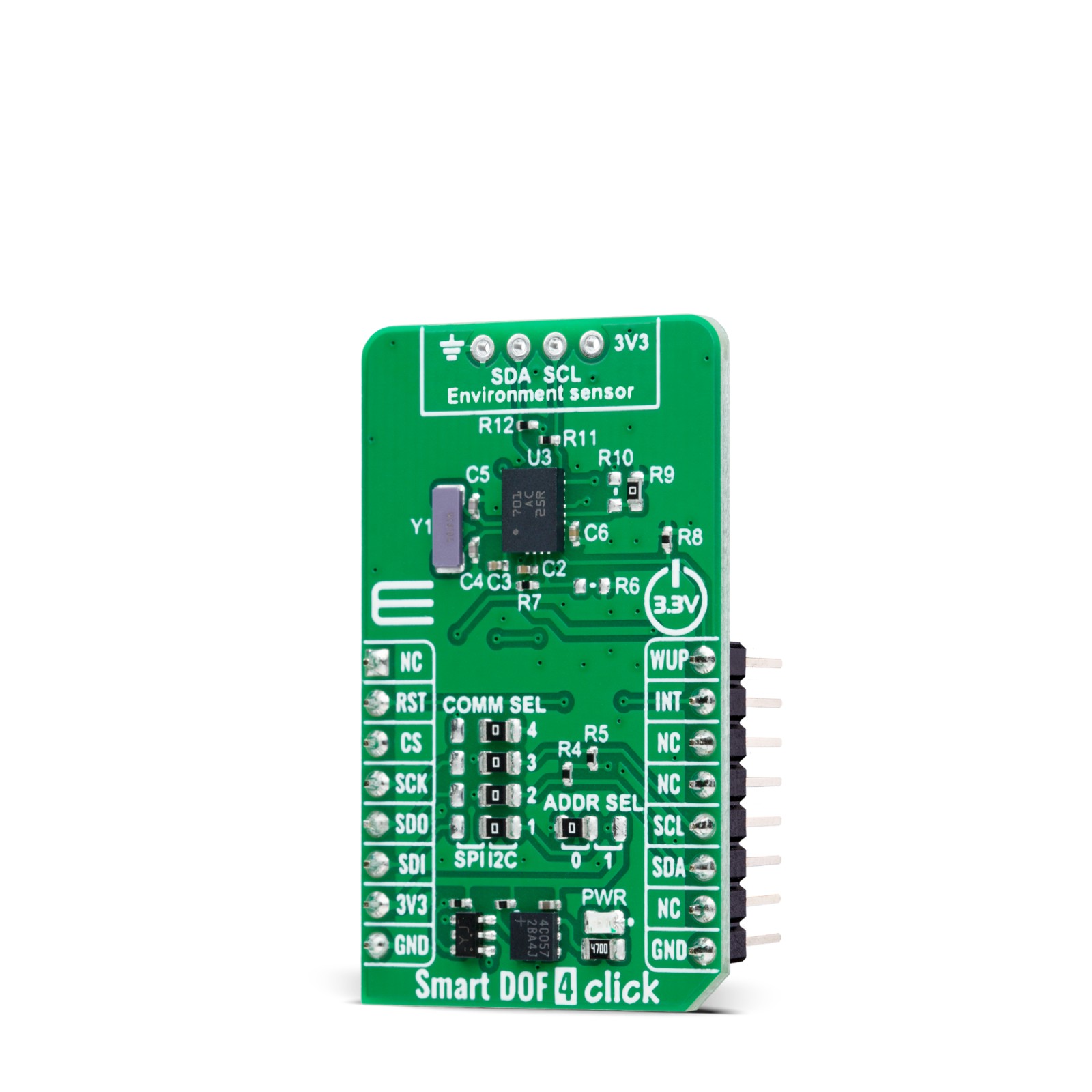

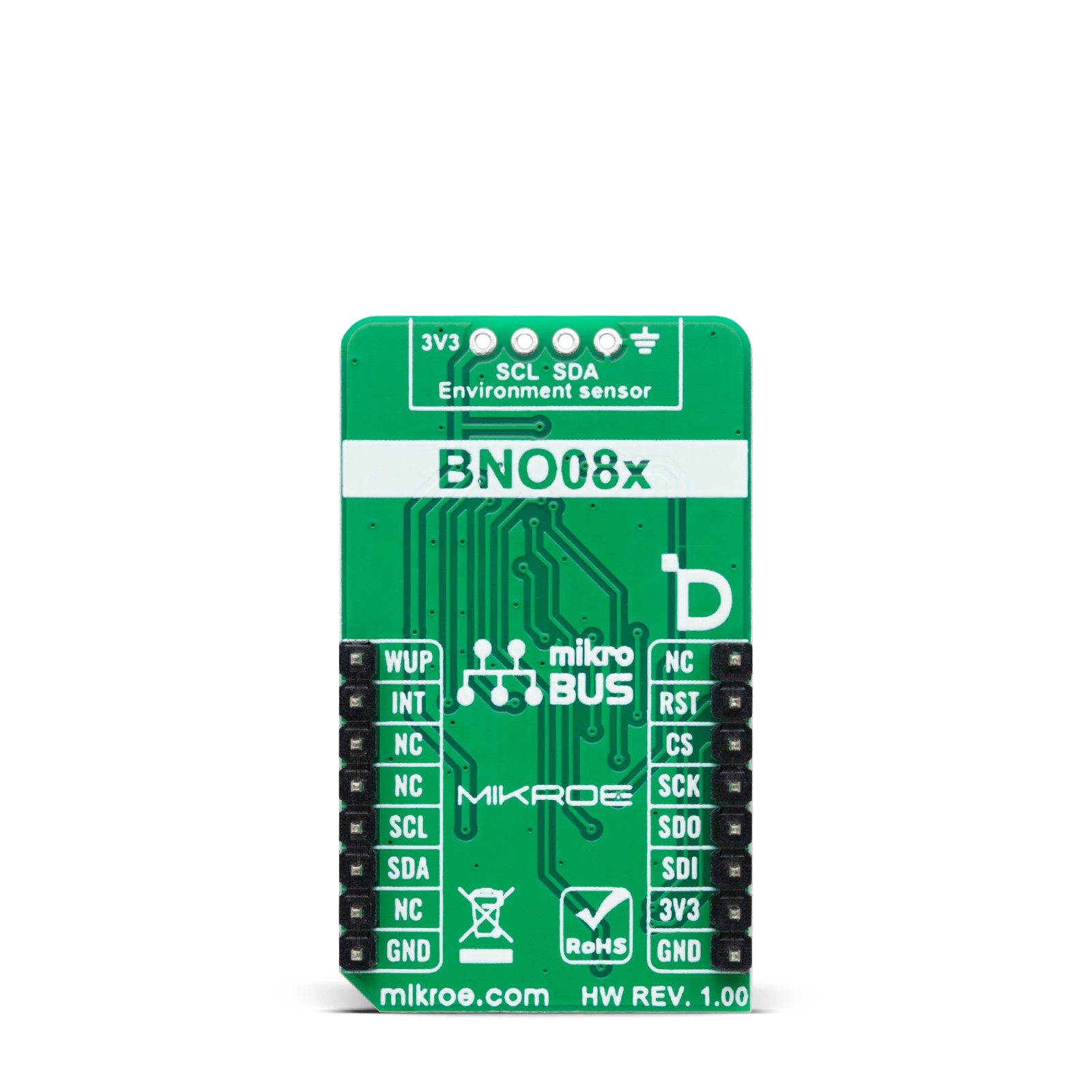

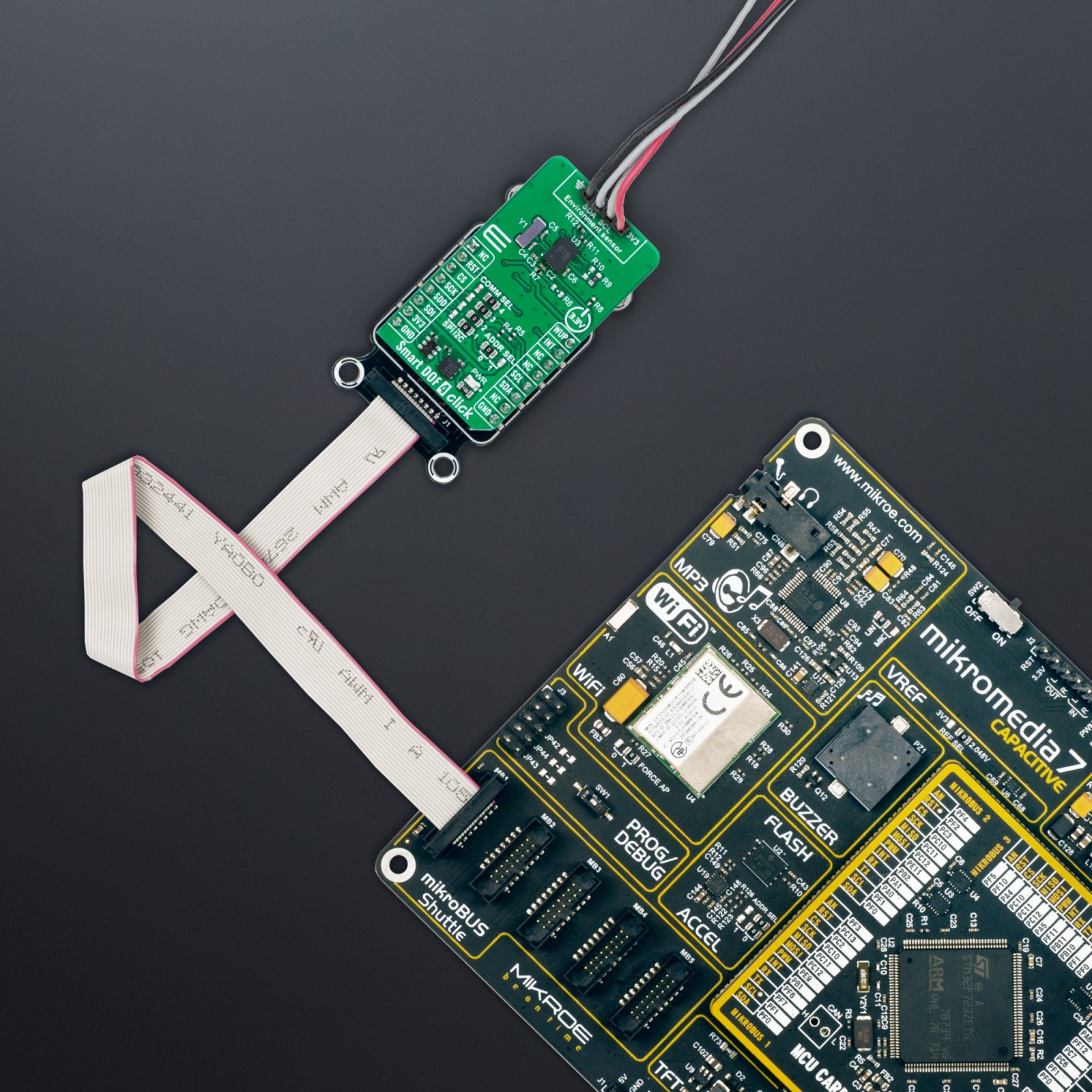

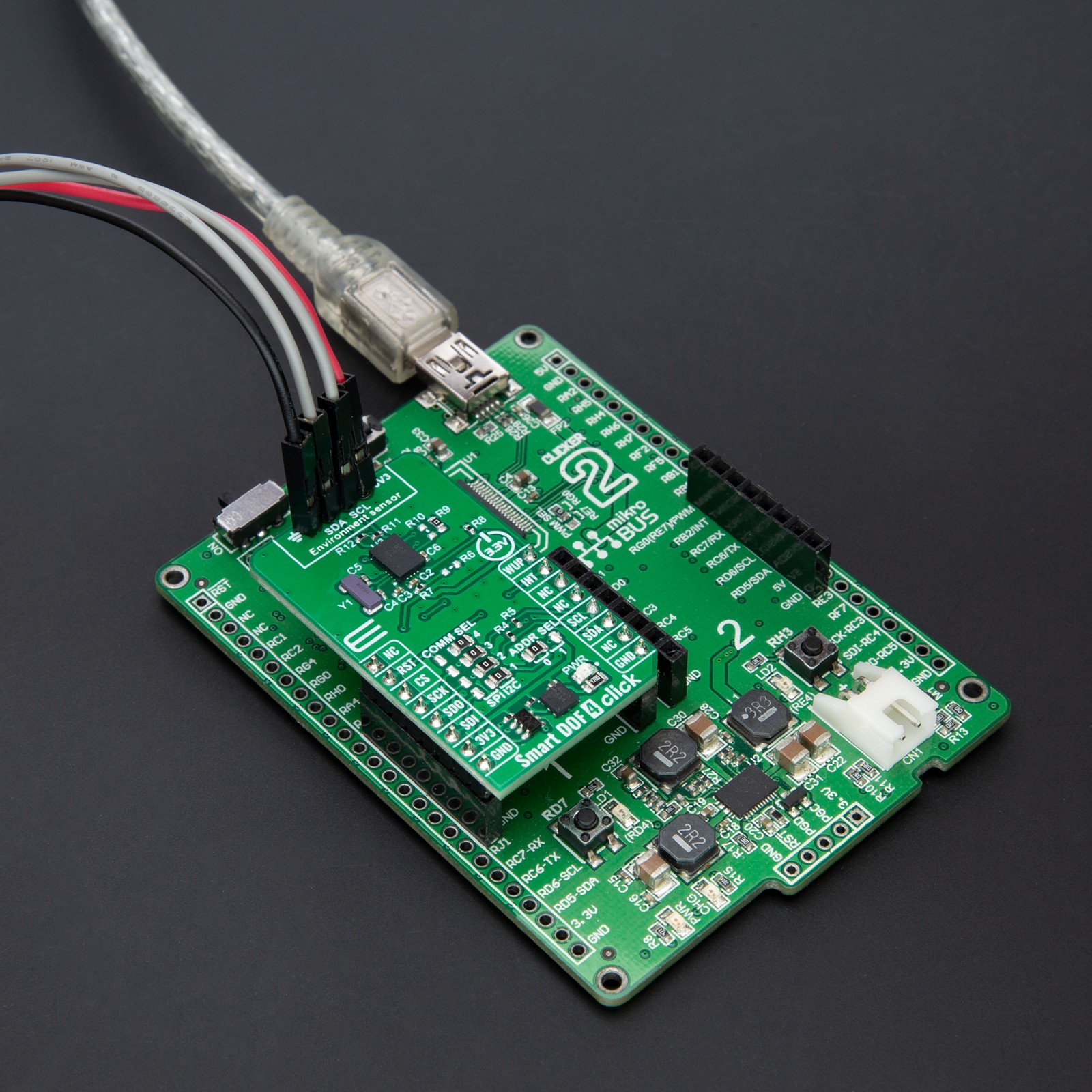

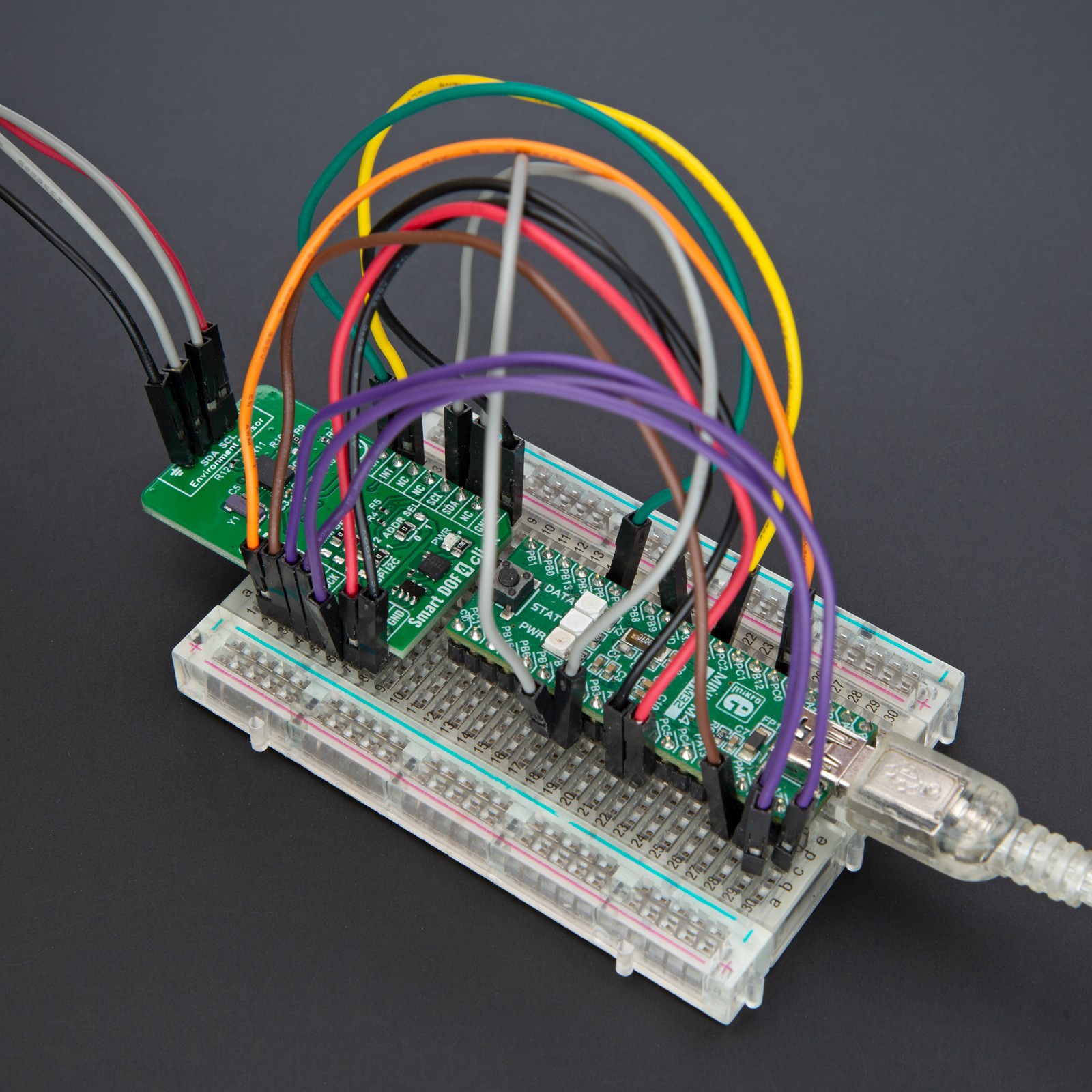

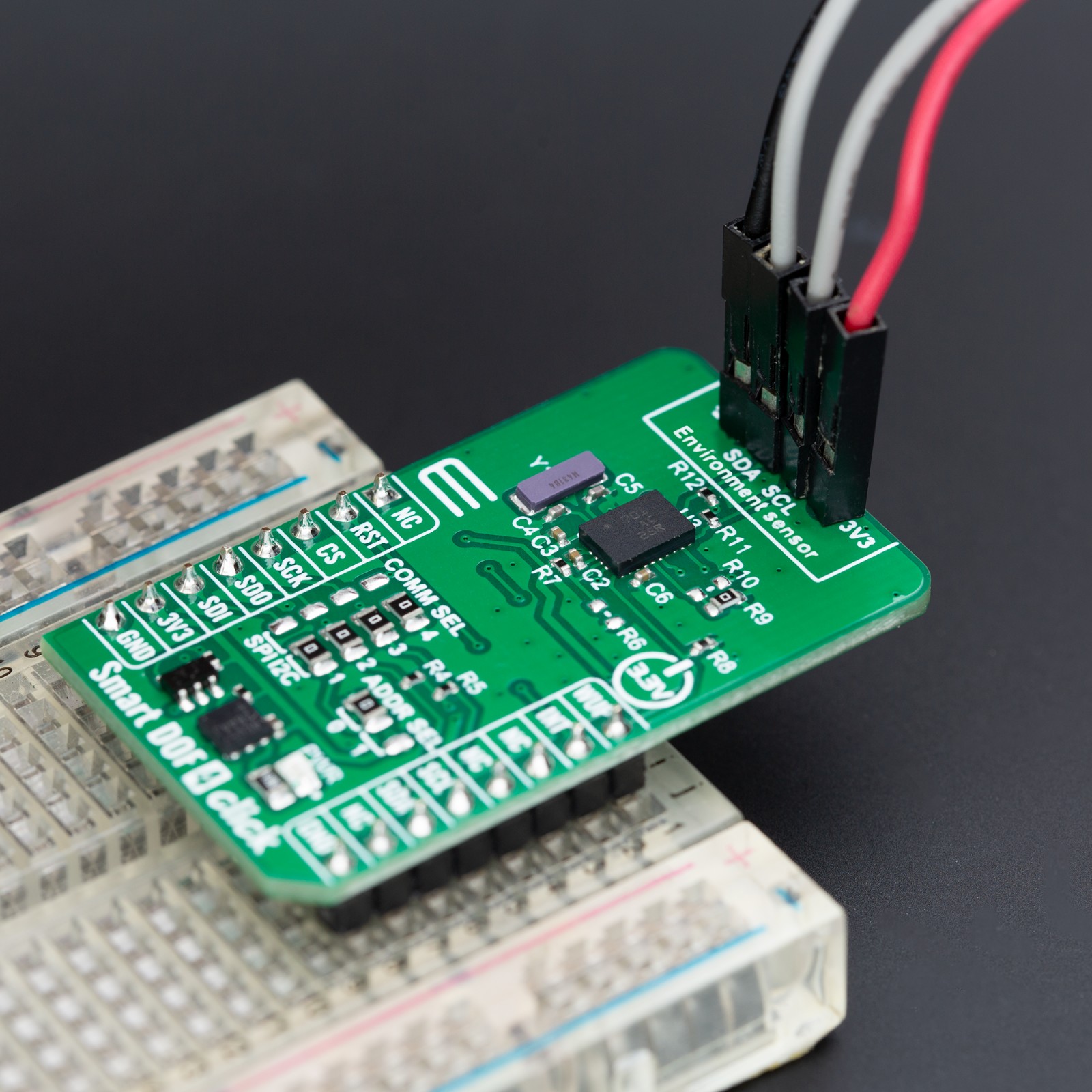

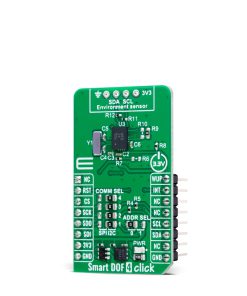

Smart DOF 4 Click

R740.00 ex. VAT

Smart DOF 4 Click is a compact add-on board for high-precision motion tracking and contextual sensing. This board features the BNO085, a 9-axis IMU System in Package (SiP) from CEVA, combining an accelerometer, gyroscope, and geomagnetic sensor with a 32-bit microcontroller running CEVA’s SH-2 firmware. The board provides real-time, calibrated 3D orientation, linear acceleration, and angular velocity while dynamically compensating for temperature changes and sensor aging. It supports I2C and SPI interfaces, features advanced MotionEngine™ technology for gesture detection and activity monitoring, and includes ‘Always-On’ capabilities like step counting and stability detection. Smart DOF 4 Click is ideal for AR/VR head trackers, robotics, IoT devices, and other motion-controlled applications.

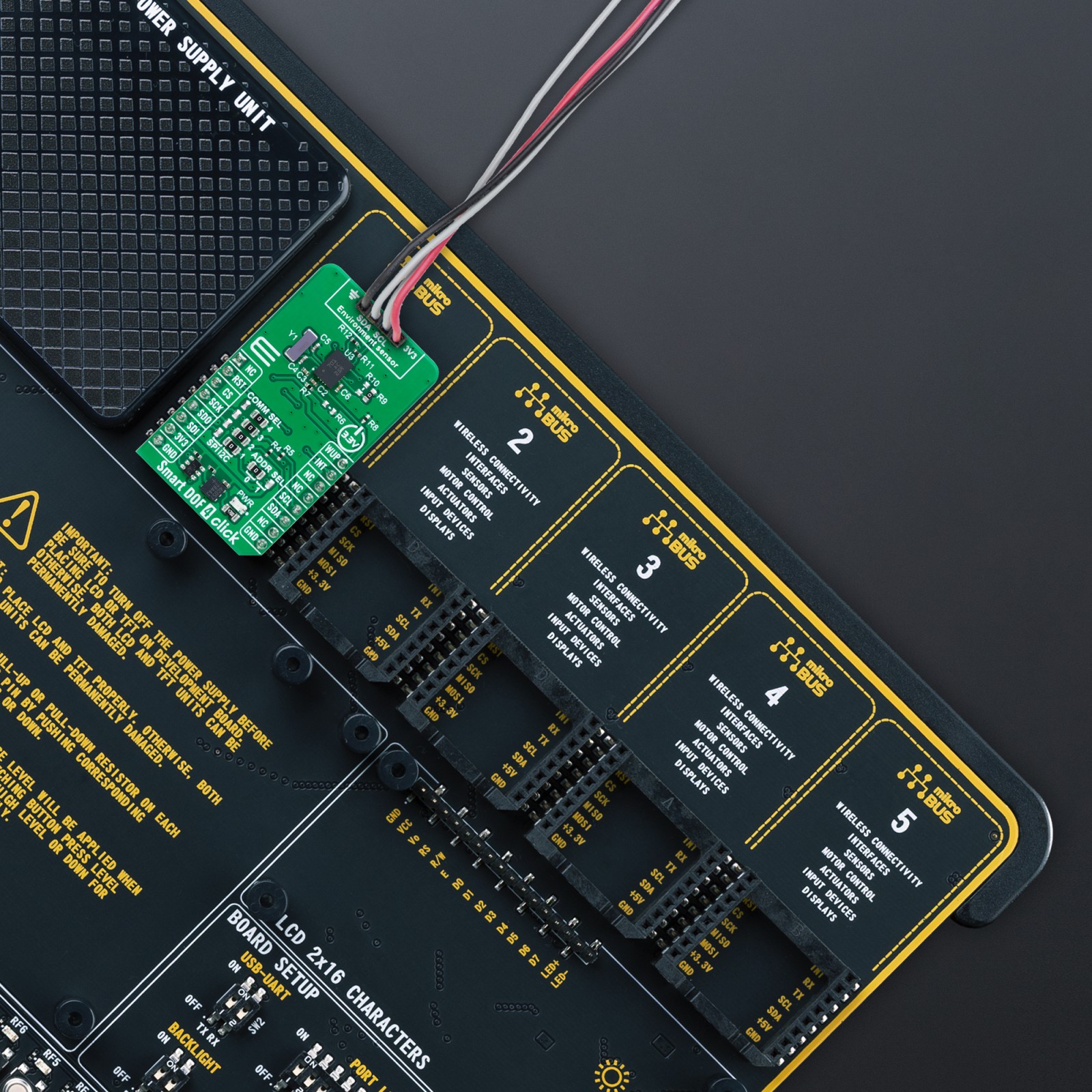

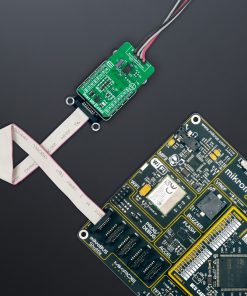

Smart DOF 4 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R703.00 |

| 10+ | R666.00 |

| 15+ | R629.00 |

| 20+ | R605.32 |