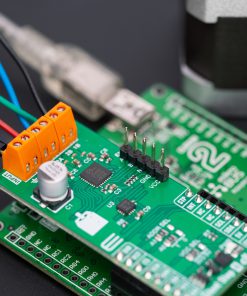

Silent Step 4 Click

R620.00 ex. VAT

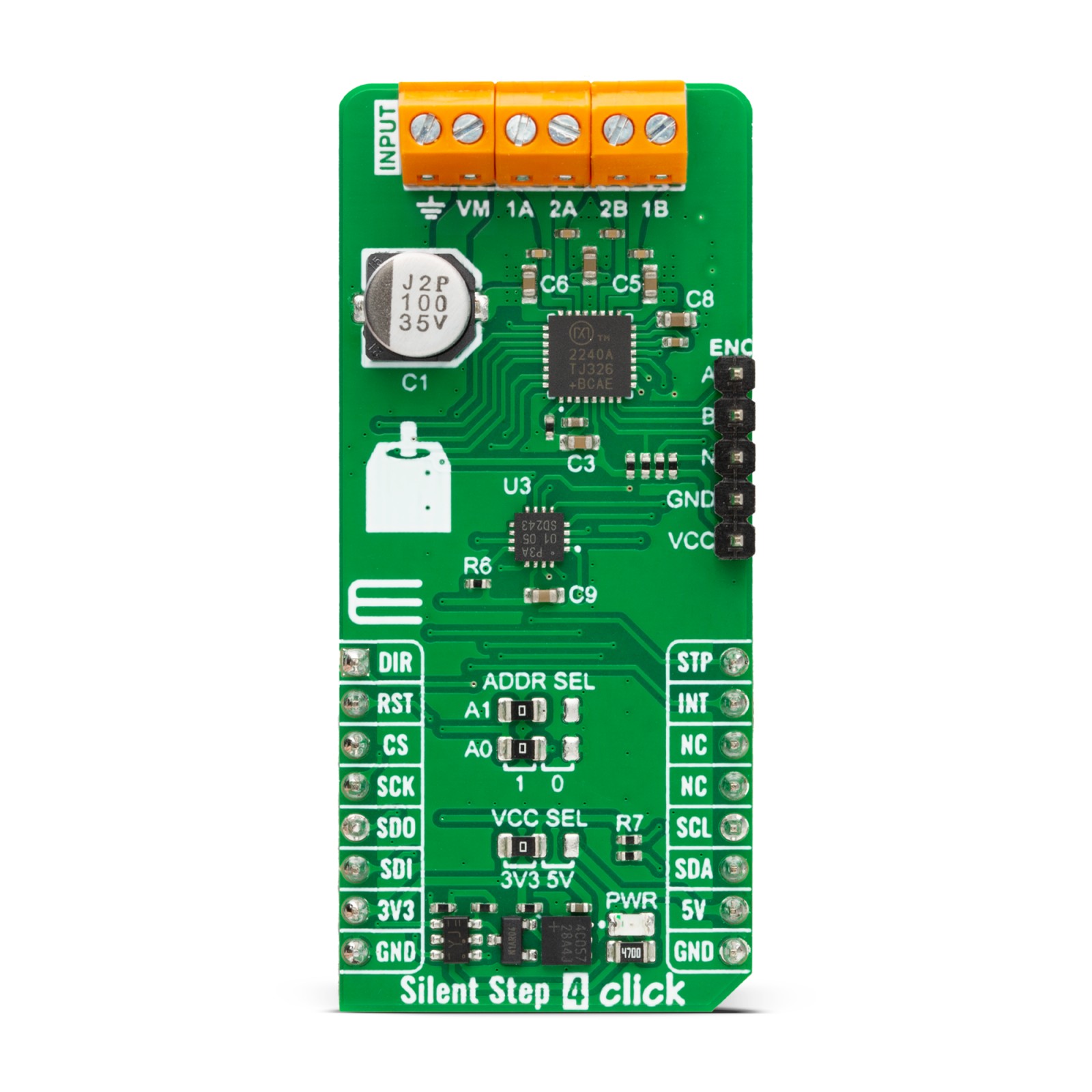

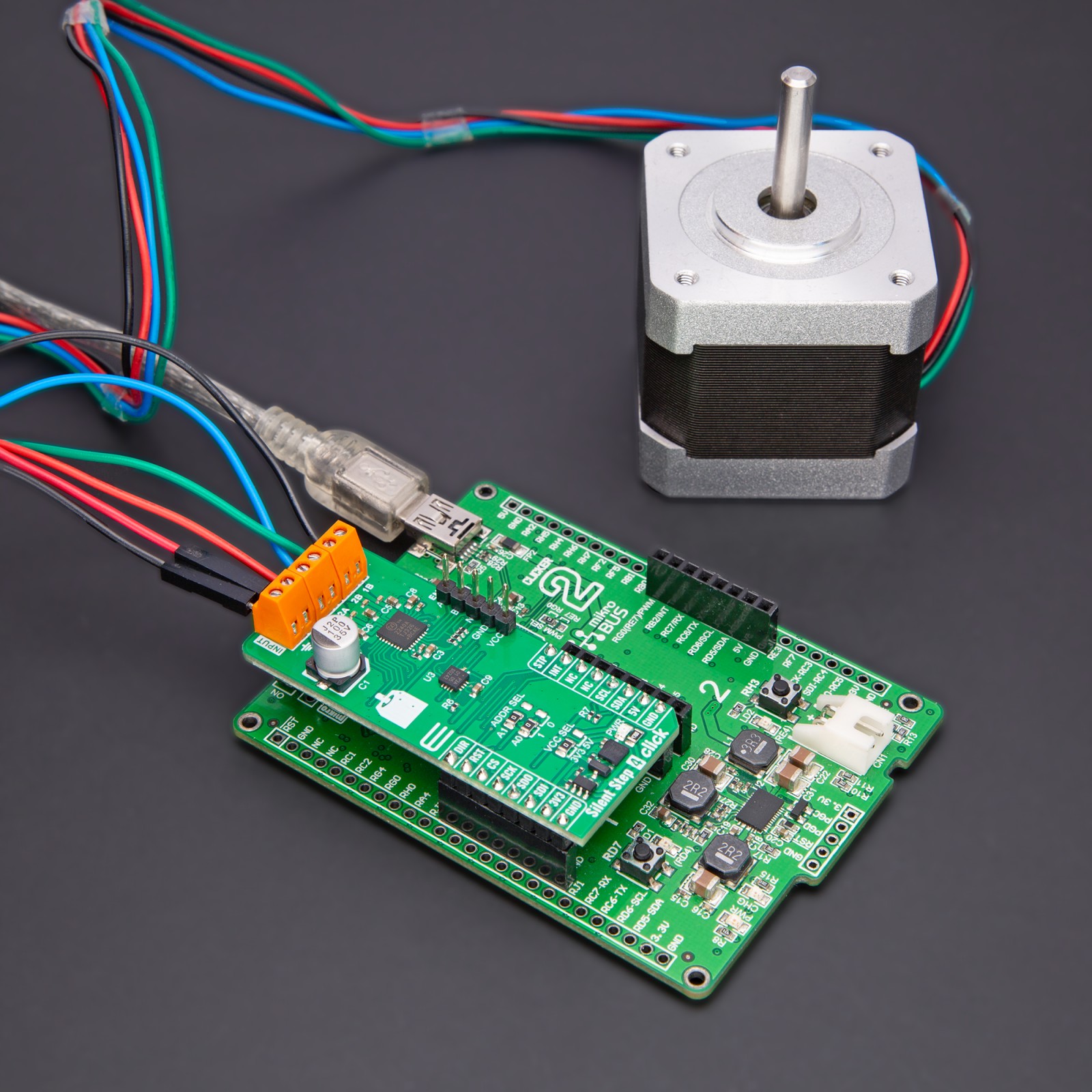

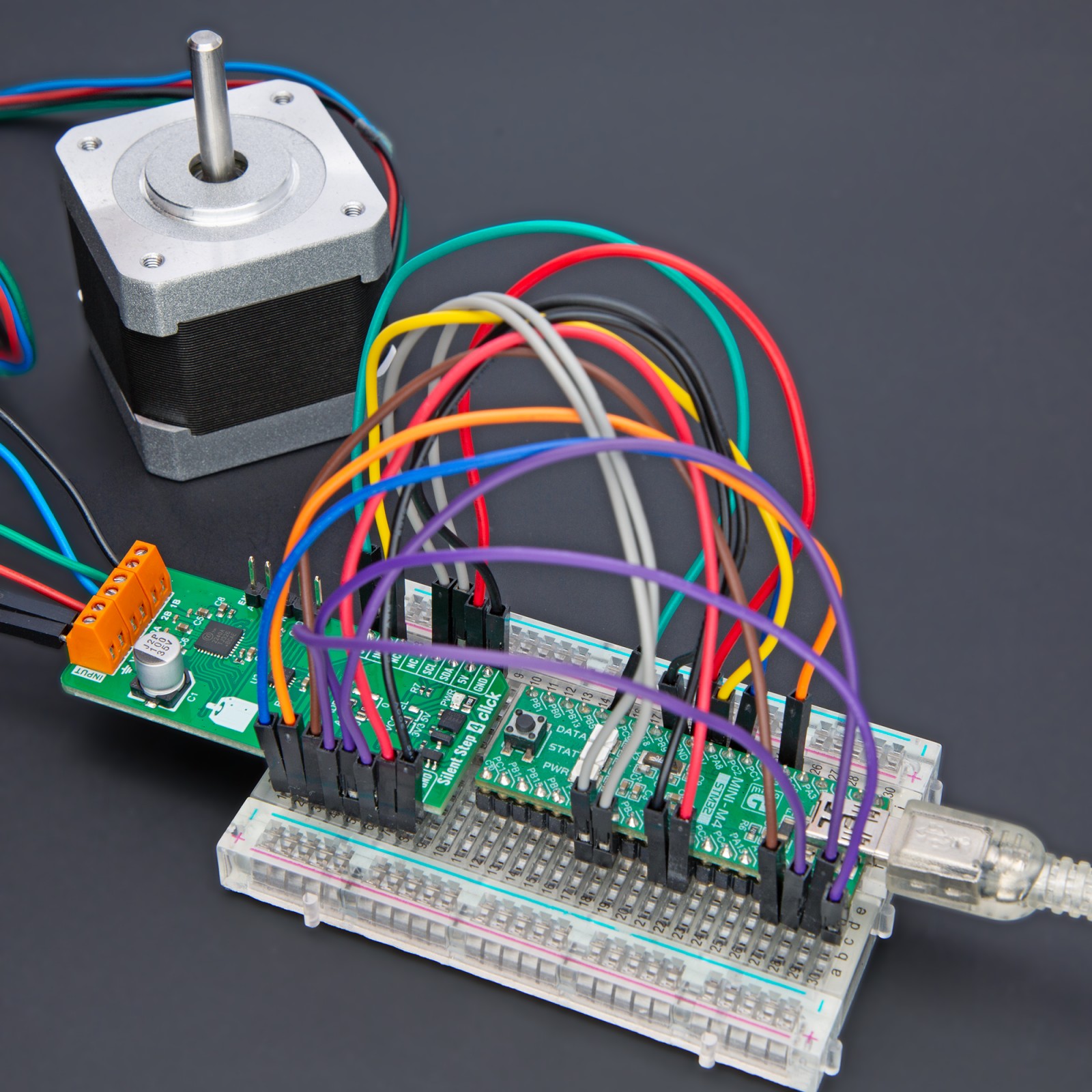

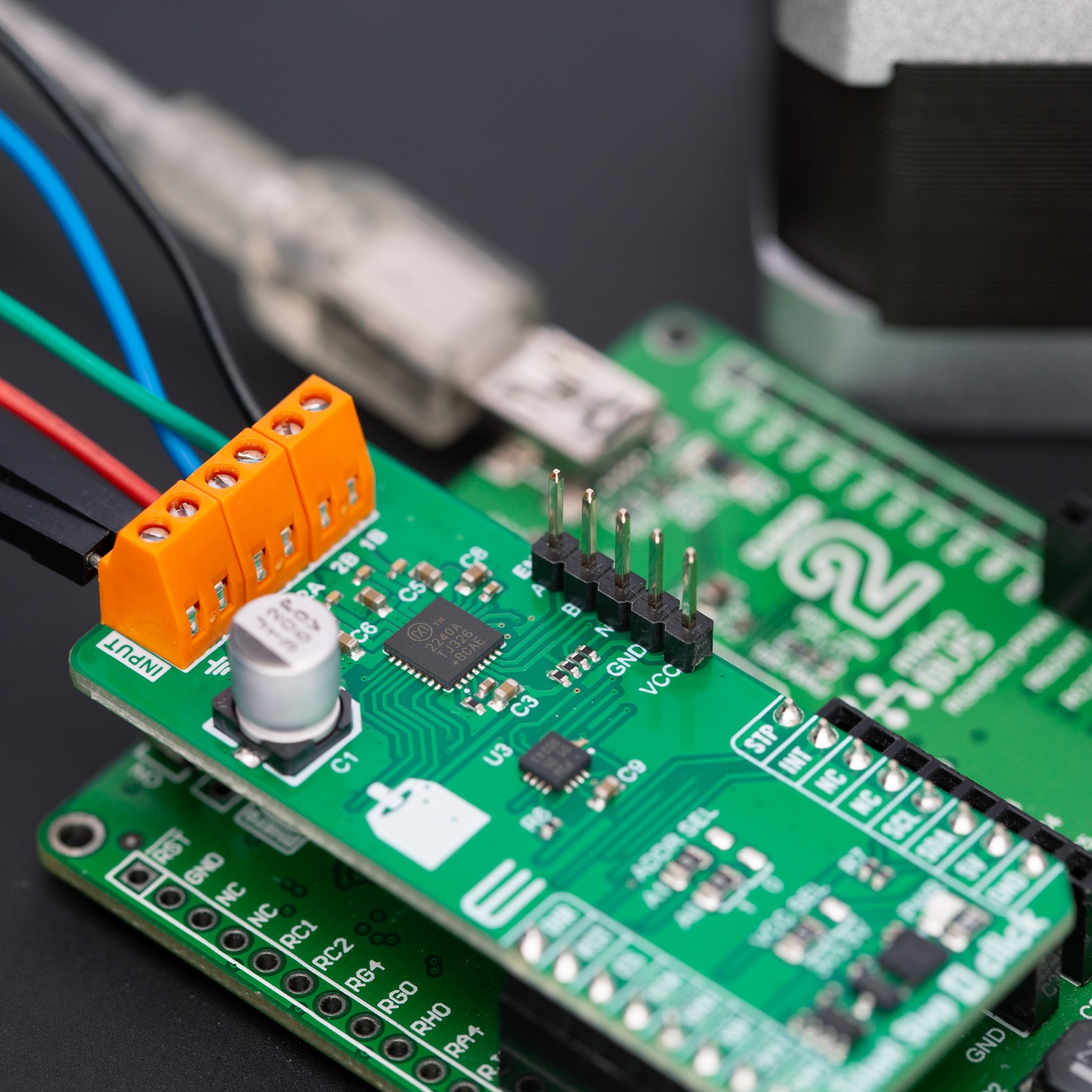

Silent Step 4 Click is a compact add-on board representing a completely integrated step motor driver solution. This board features the TMC2240, a smart integrated stepper driver from Analog Devices. The driver is based on a 256 micro-steps built-in indexer, two fully integrated H-Bridges, and non-dissipative integrated current sensing (ICS). The two H-Bridges can drive motors of up to 36V and 3A at max. This Click board™ makes the perfect solution for the development of textile industry machines, lab and factory automation, 3D printers, and more.

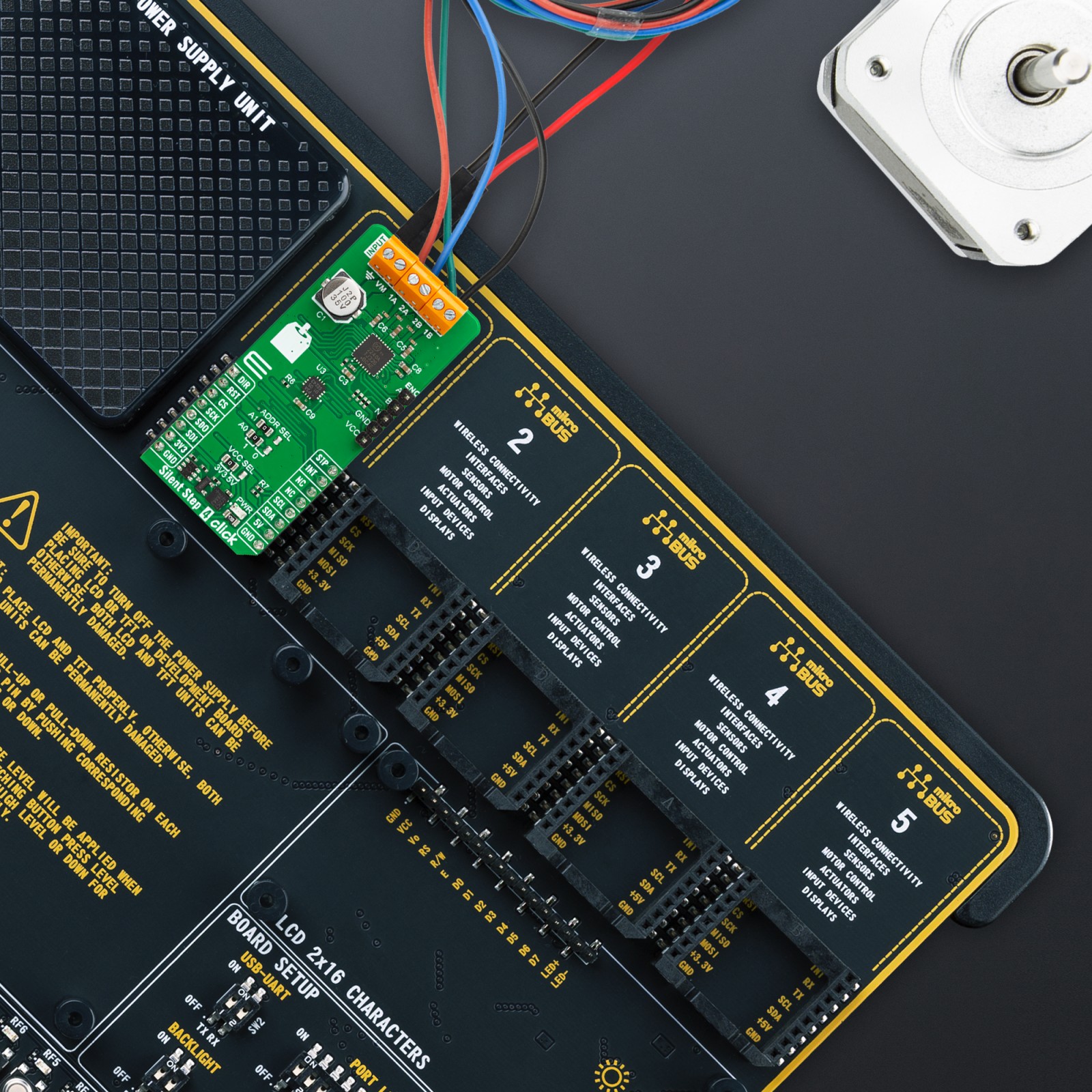

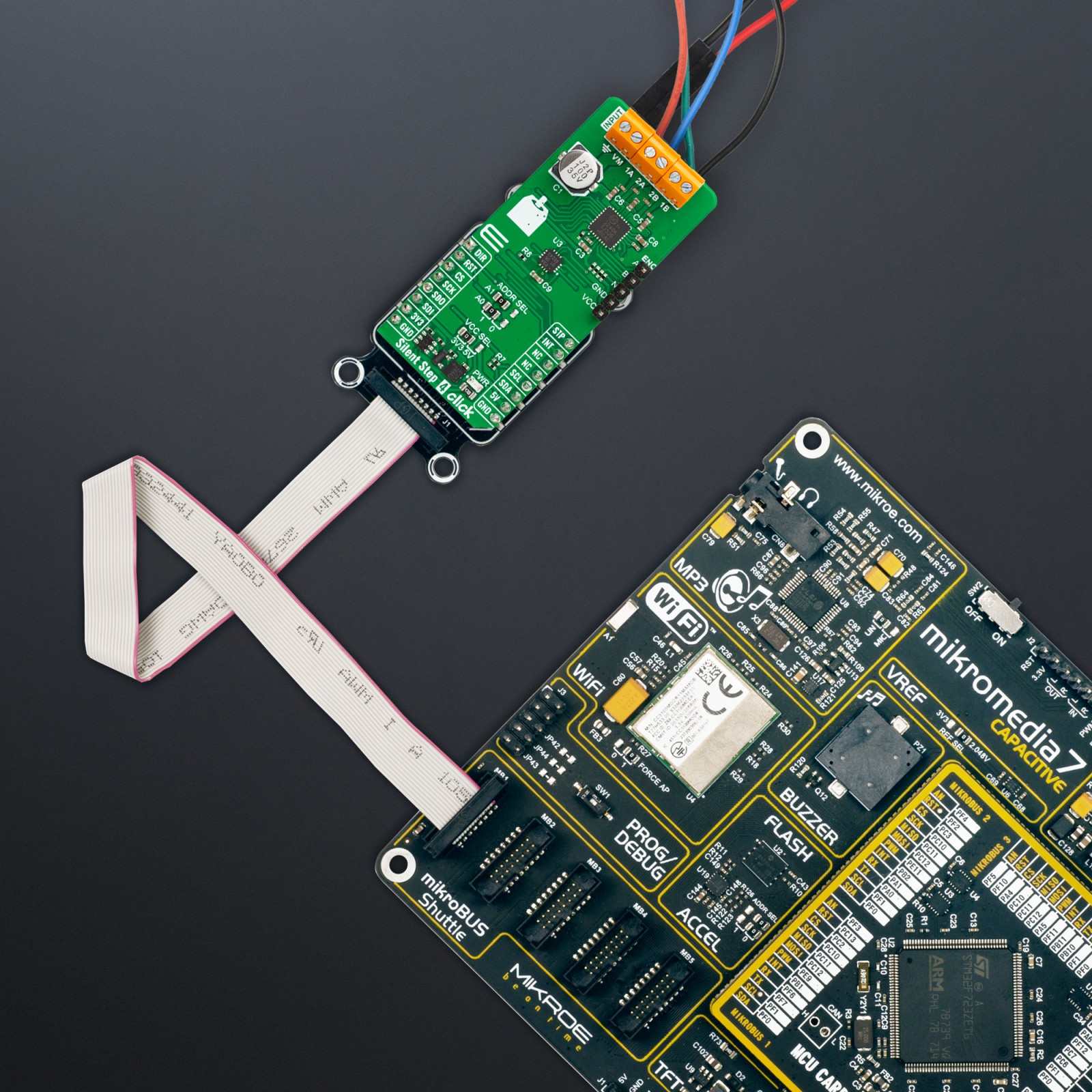

Silent Step 4 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R589.00 |

| 10+ | R558.00 |

| 15+ | R527.00 |

| 20+ | R507.16 |