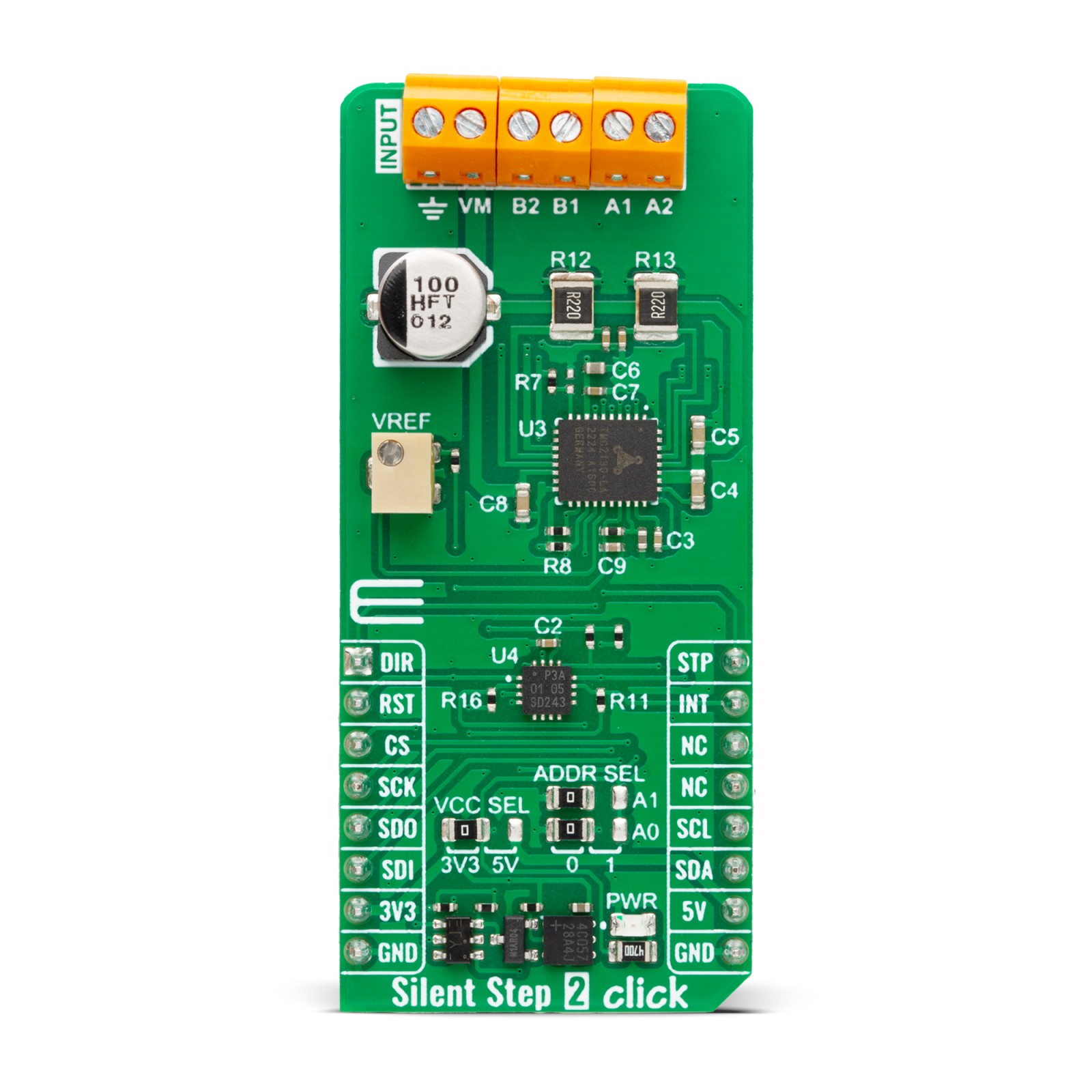

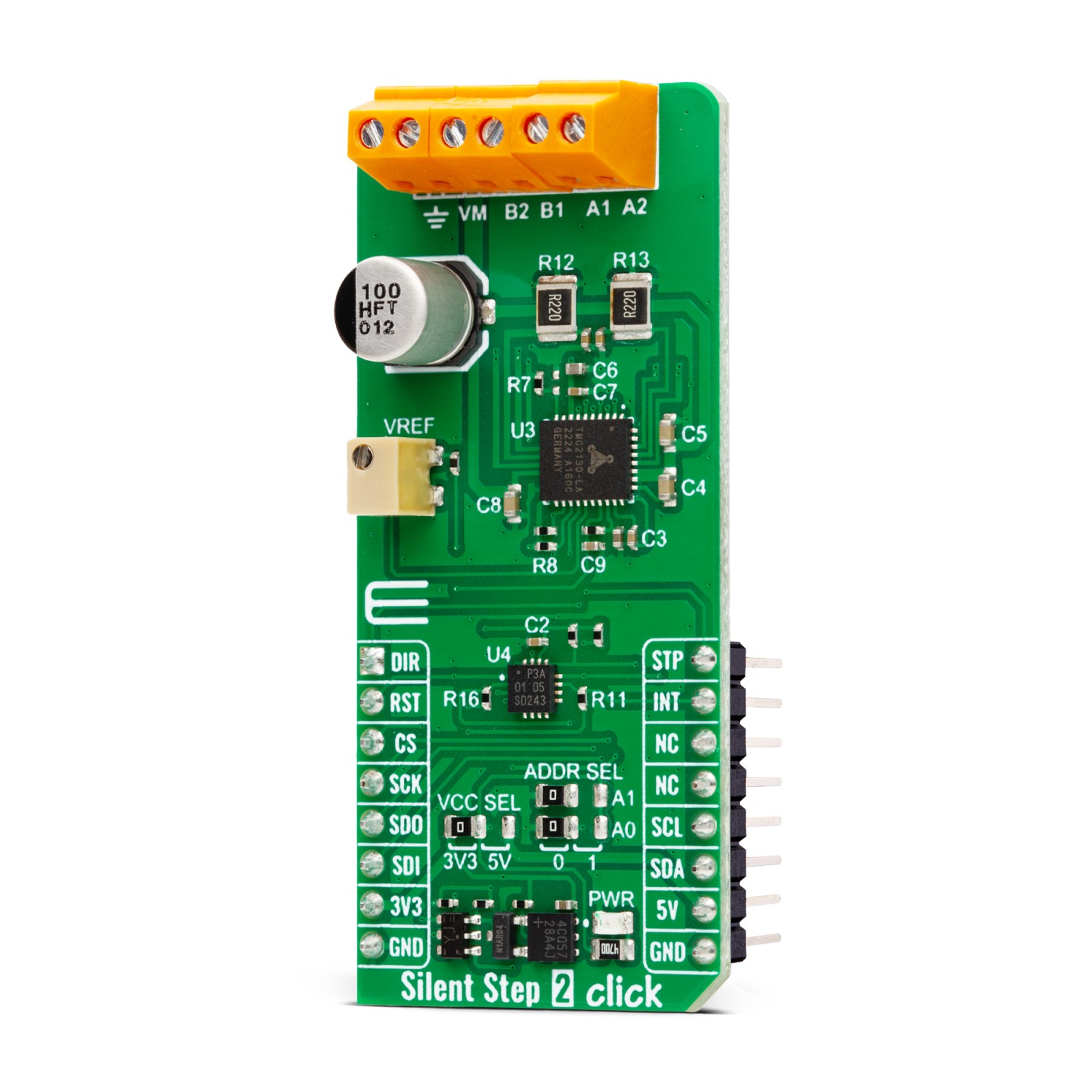

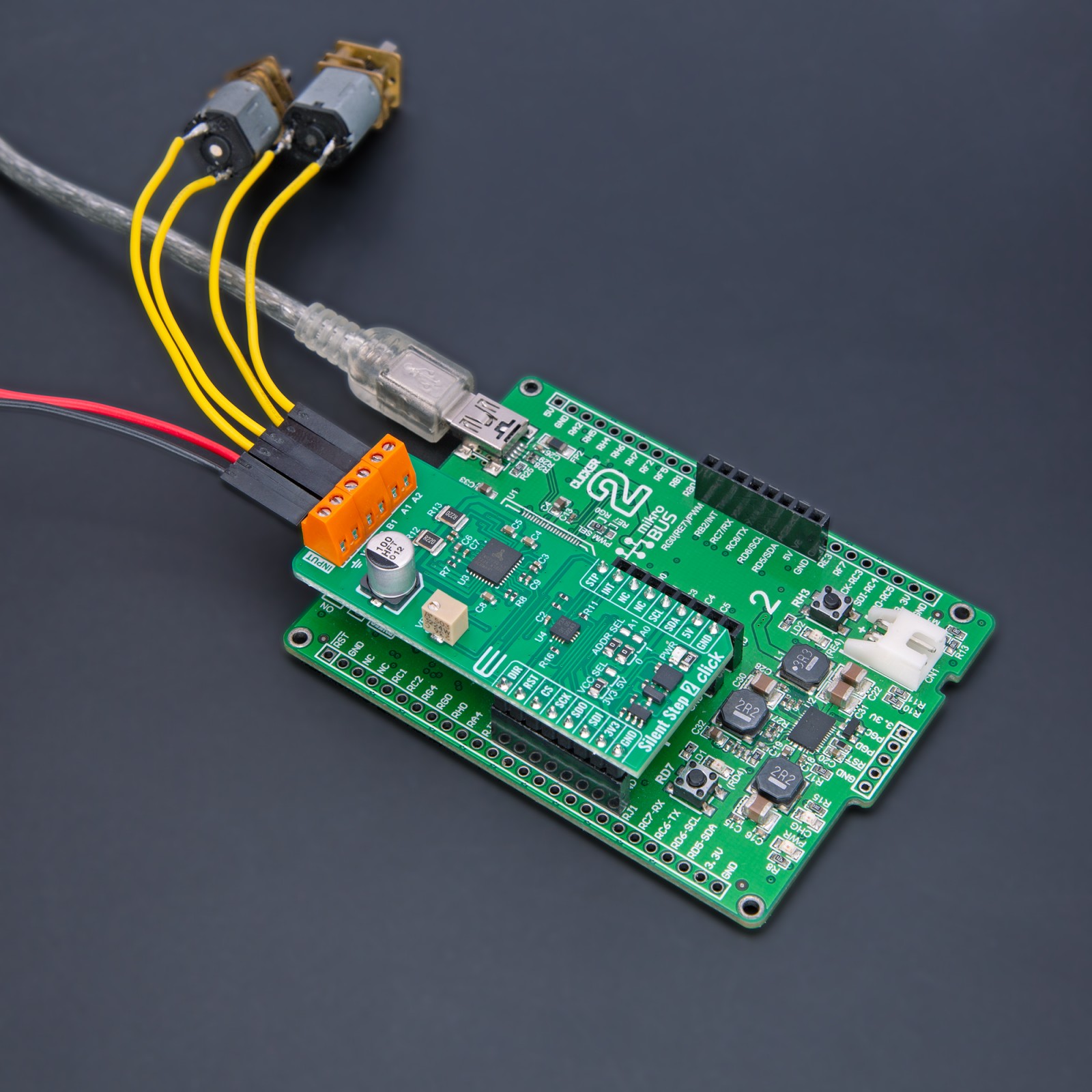

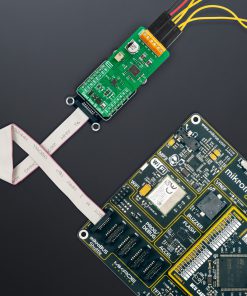

Silent Step 2 Click

R740.00 ex. VAT

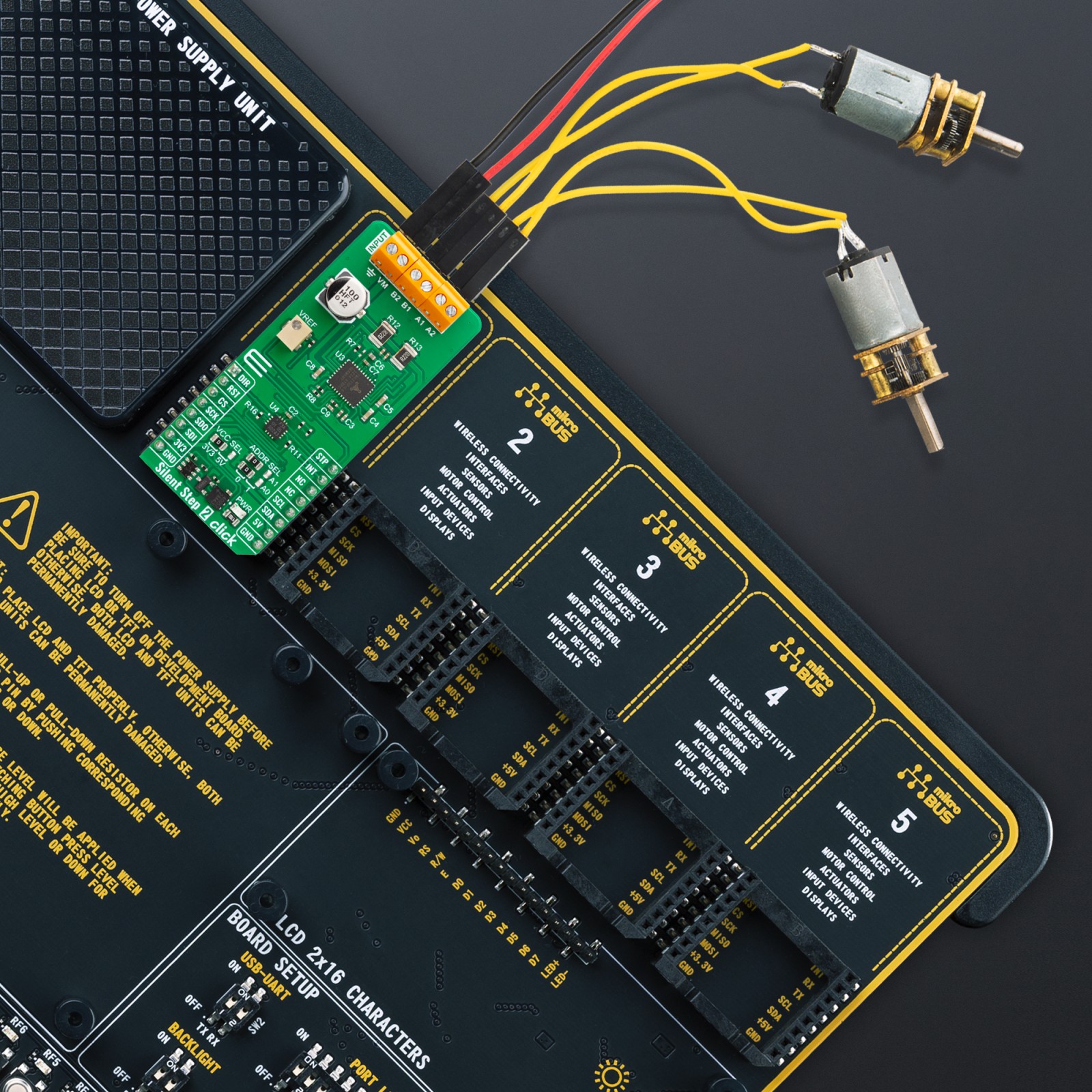

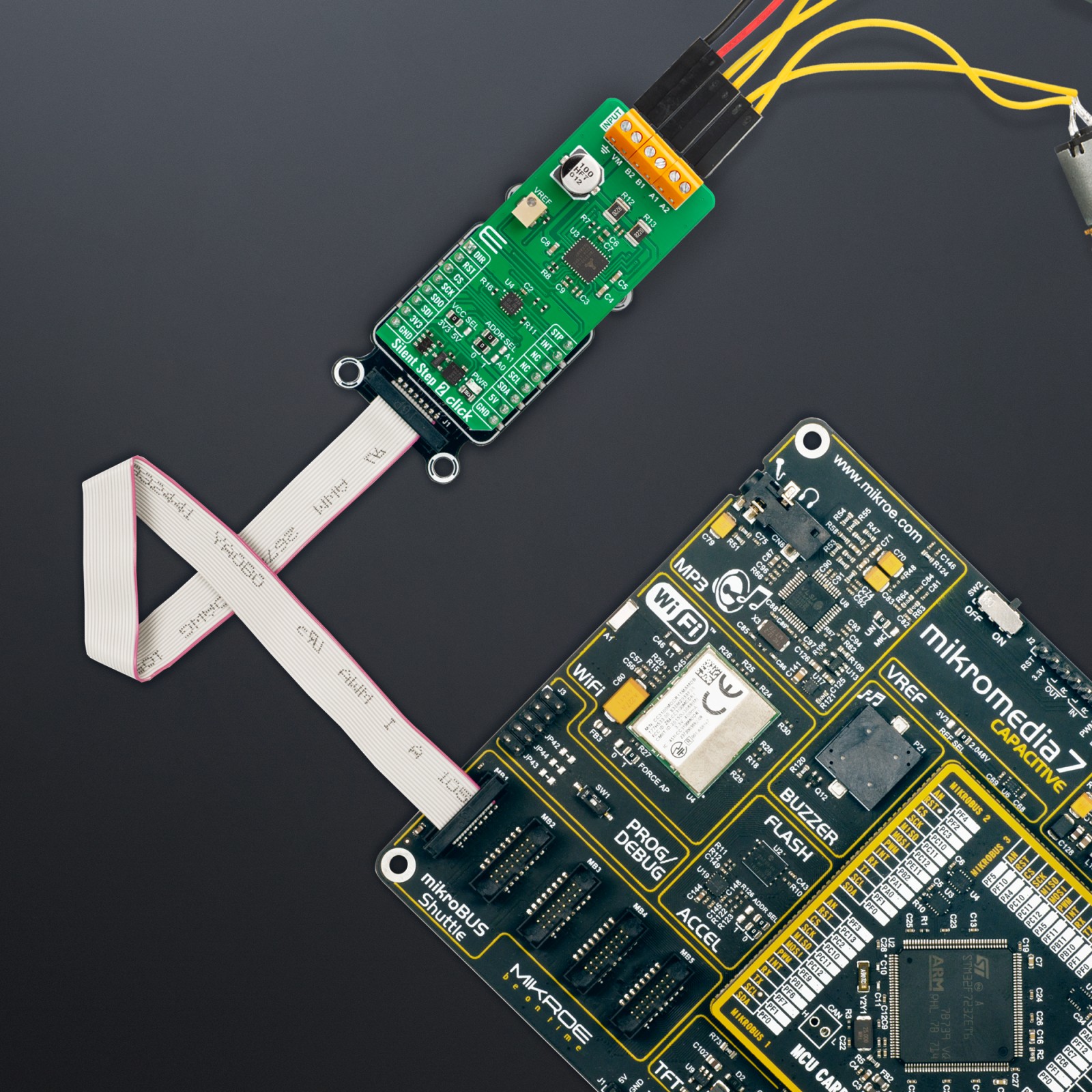

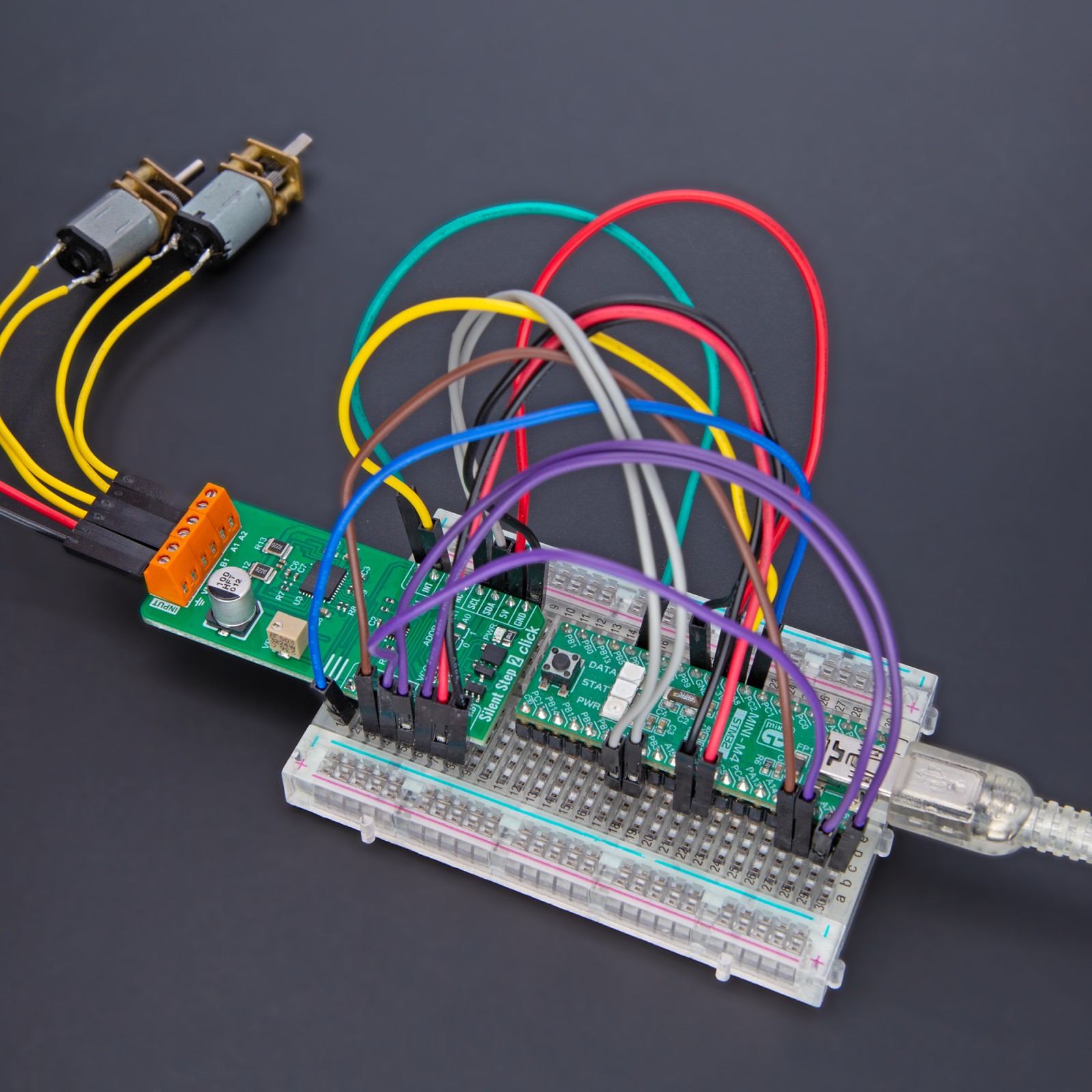

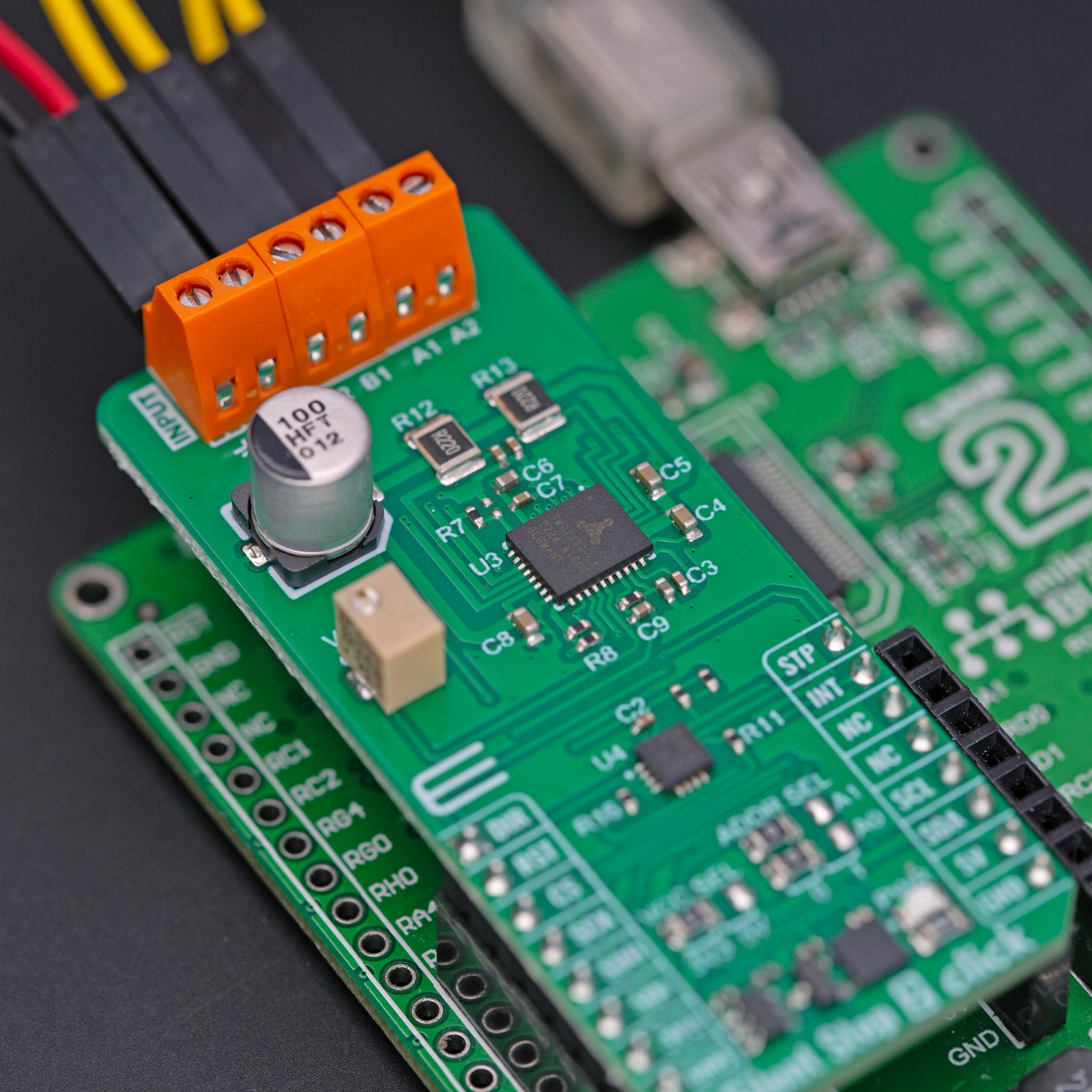

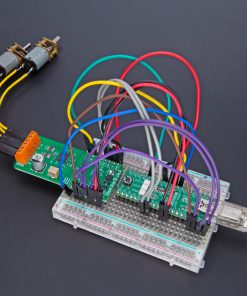

Silent Step 2 Click is a compact add-on board that allows extremely smooth and silent operation of the connected motor. This board features the TMC2130, a high-performance two-phase stepper motor driver from Analog Devices. The driver uses an external motor power supply of 4.75 up to 43V to power a 2-phase stepper motor up to 2A coil current (2.5A peak). In addition, its sophisticated StealthChop chopper ensures noiseless operation combined with maximum efficiency and the best motor torque. This Click board™ makes the perfect solution for the development of a direct substitution for many complex motion controllers for various industrial purposes.

Silent Step 2 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R703.00 |

| 10+ | R666.00 |

| 15+ | R629.00 |

| 20+ | R605.32 |

.jpg)