Printer Click

R1,100.00 ex. VAT

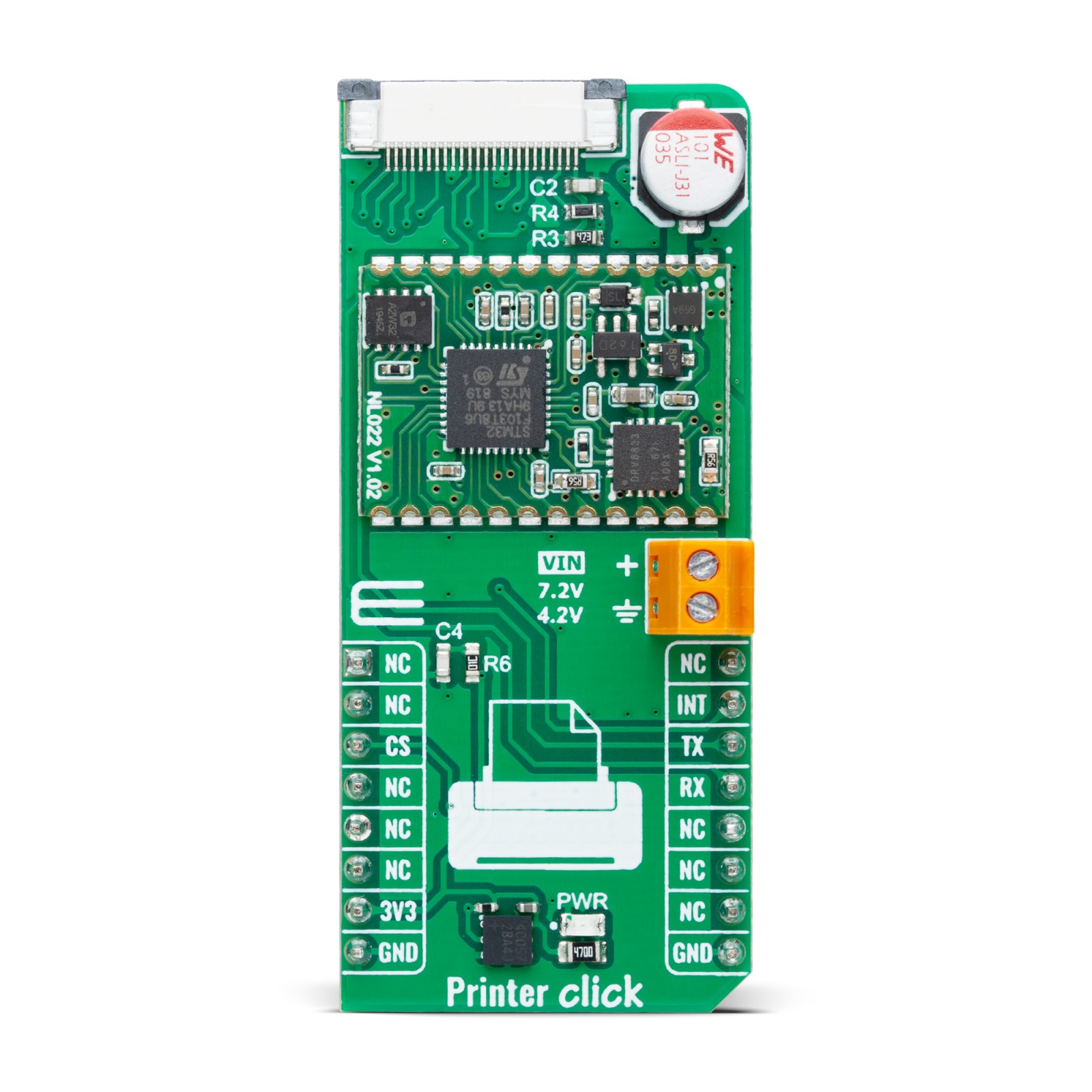

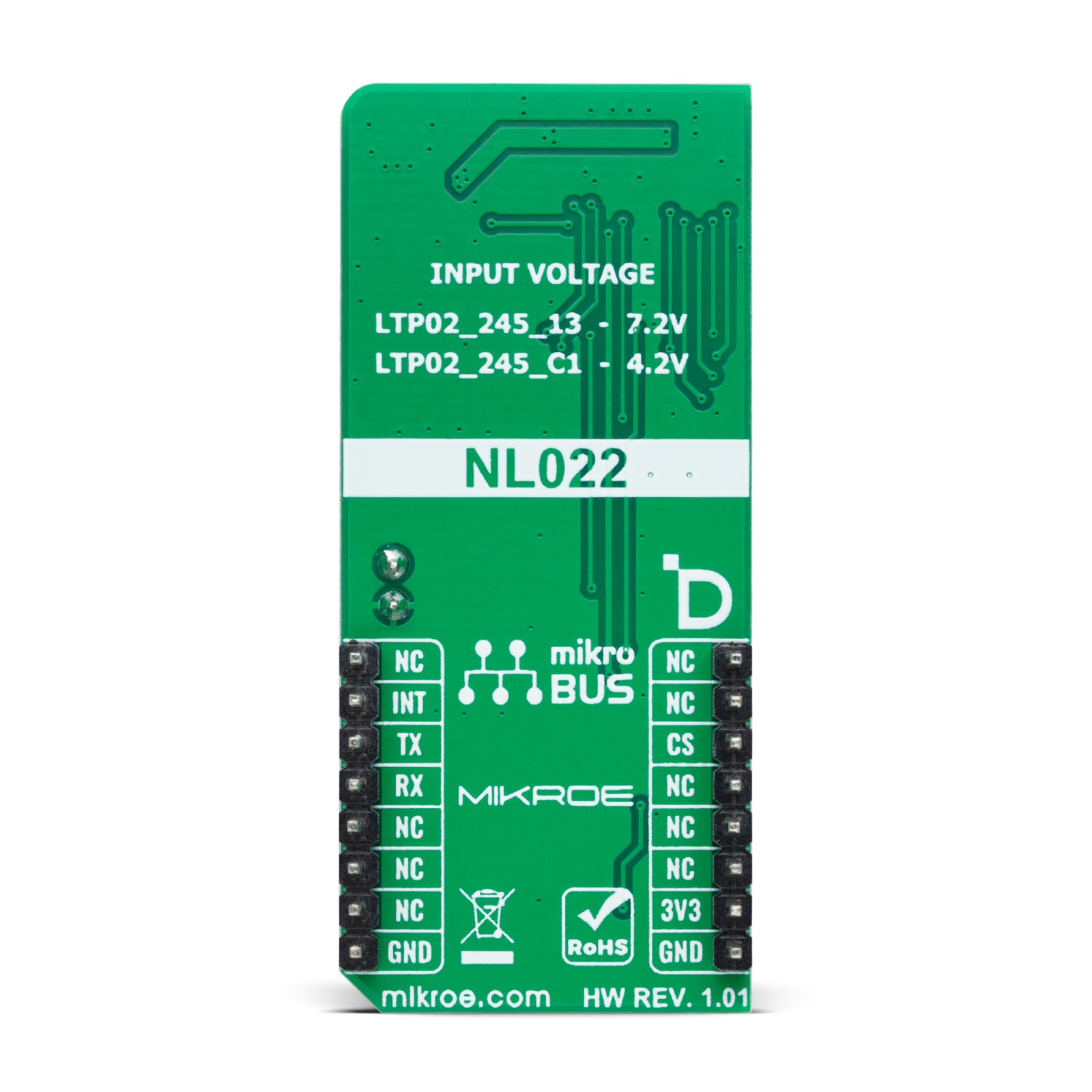

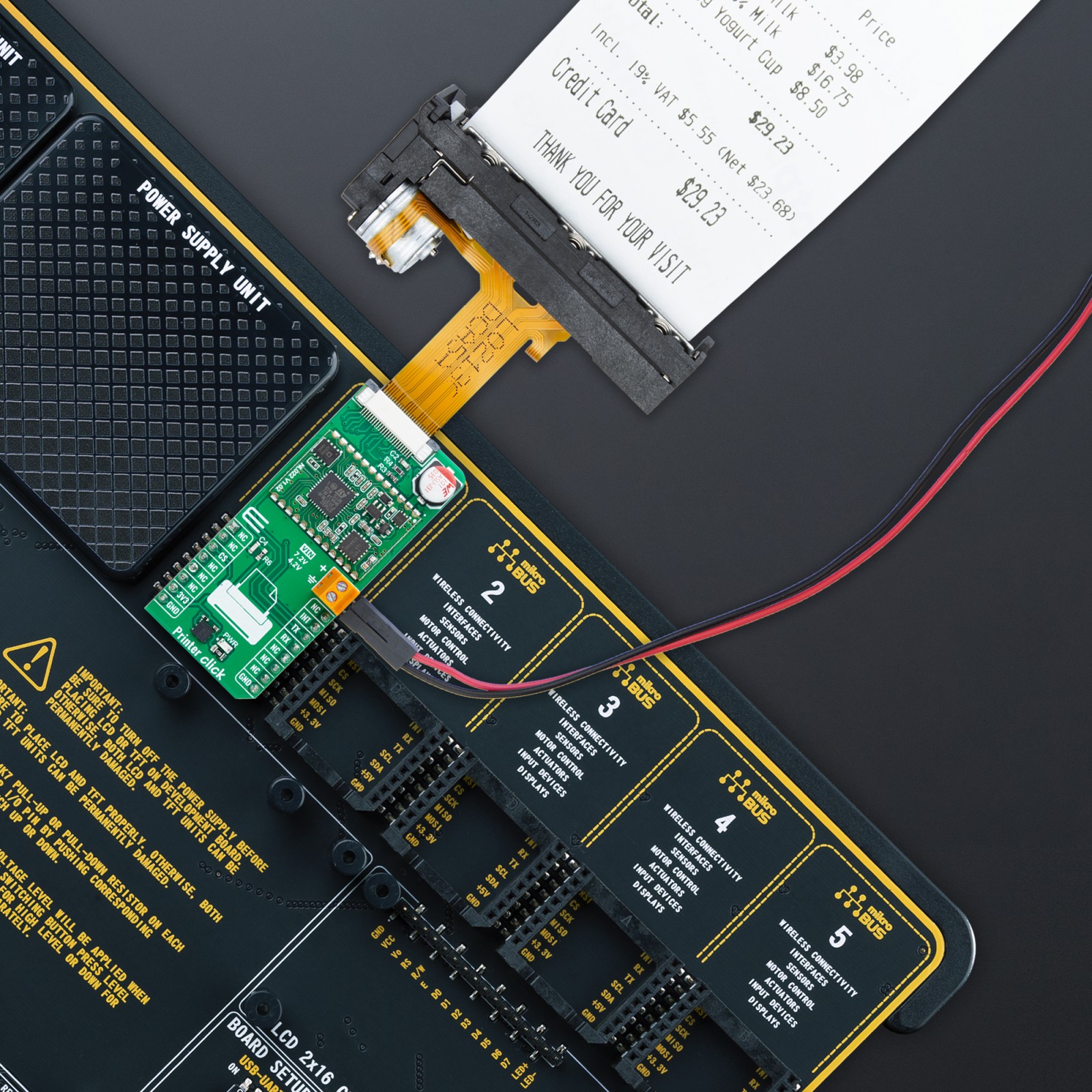

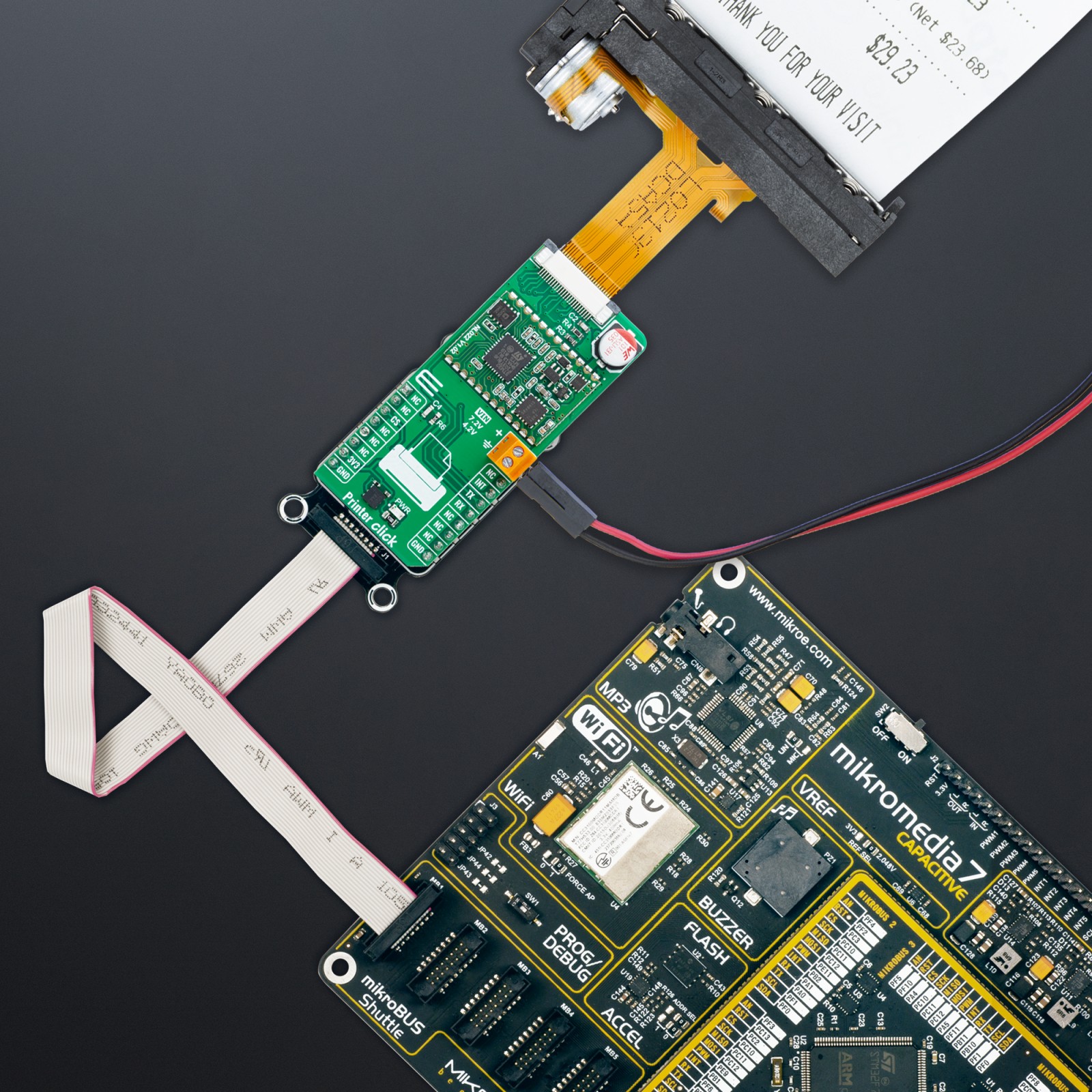

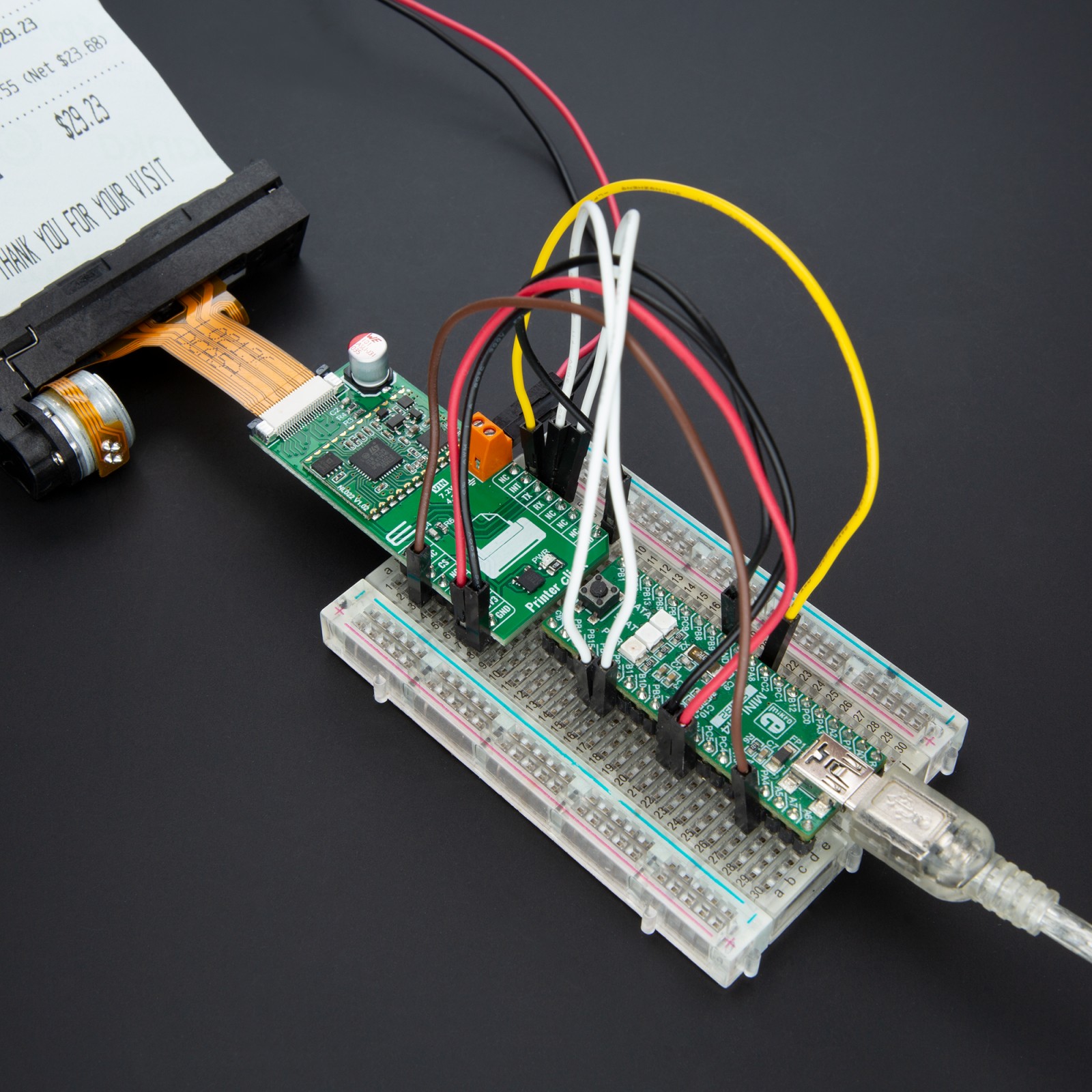

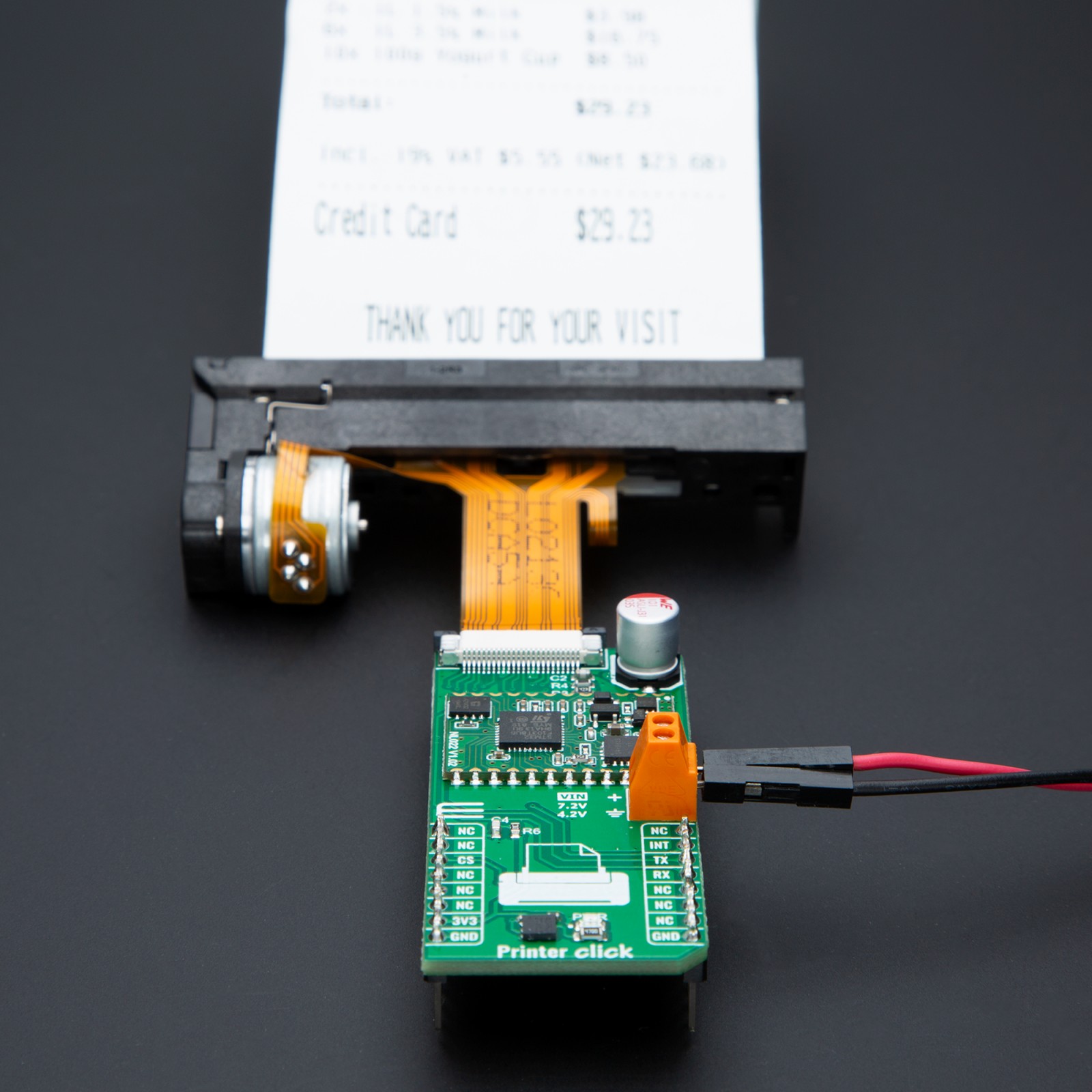

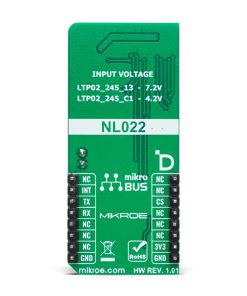

Printer Click is a compact add-on board designed for high-performance control of thermal printer heads. This board features the NL022, a thermal printer head controller from Norden Logic optimized for managing thermal print heads with various voltage ratings and configurations, compatibility with 24-pin MOLEX connector and diverse flat cable widths. The NL022 features an ARM-based architecture with vast RAM and Flash memory, real-time head temperature monitoring, and a responsive paper-out detection system. It supports ESC/POS commands, 170 languages including UTF-8 and UTF-16, and generates both 1D barcodes (UPC, EAN, CODE128) and on-chip 2D QR codes. Communication with the host MCU is established through a UART interface with an INT pin indicating ready-to-send status for smooth data exchange. This board is ideal for applications such as medical devices, taxi meters, ticket machines, handheld POS terminals, industrial meters, and cash registers, offering reliable and customizable thermal printing solutions.

Printer Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

NOTE: A compatible Thermal Printer Head – 7.2V (LTP02_245_13) is also available in the MIKROE shop. This thermal printer head works with the Printer Click and can be purchased directly from our store. For more details and specifications, please visit the product page.

Stock: Lead-time applicable.

| 5+ | R1,045.00 |

| 10+ | R990.00 |

| 15+ | R935.00 |

| 20+ | R899.80 |

.jpg)