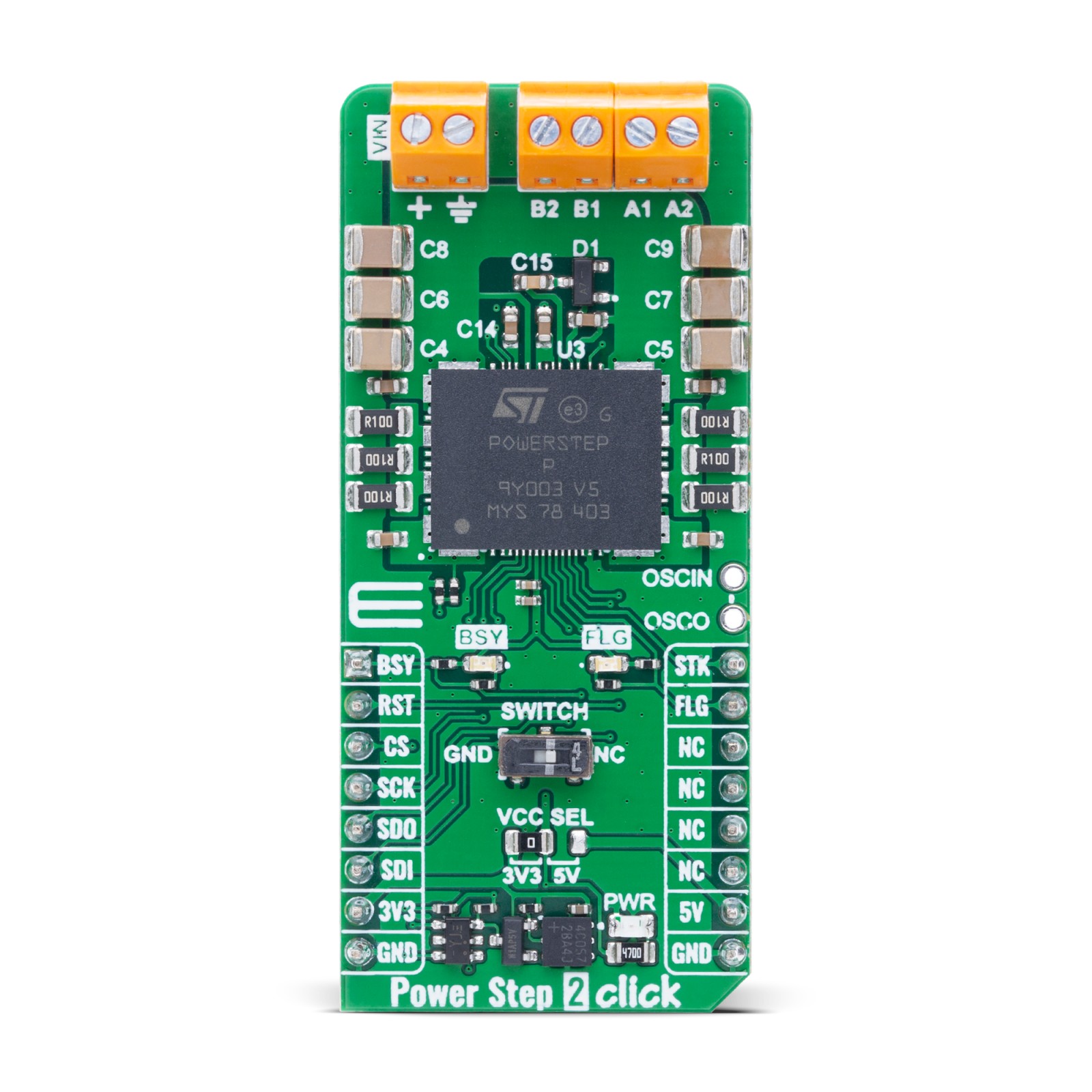

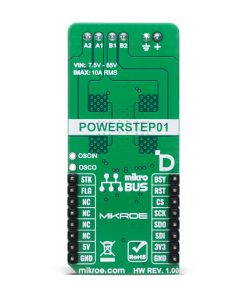

Power Step 2 Click

R965.00 ex. VAT

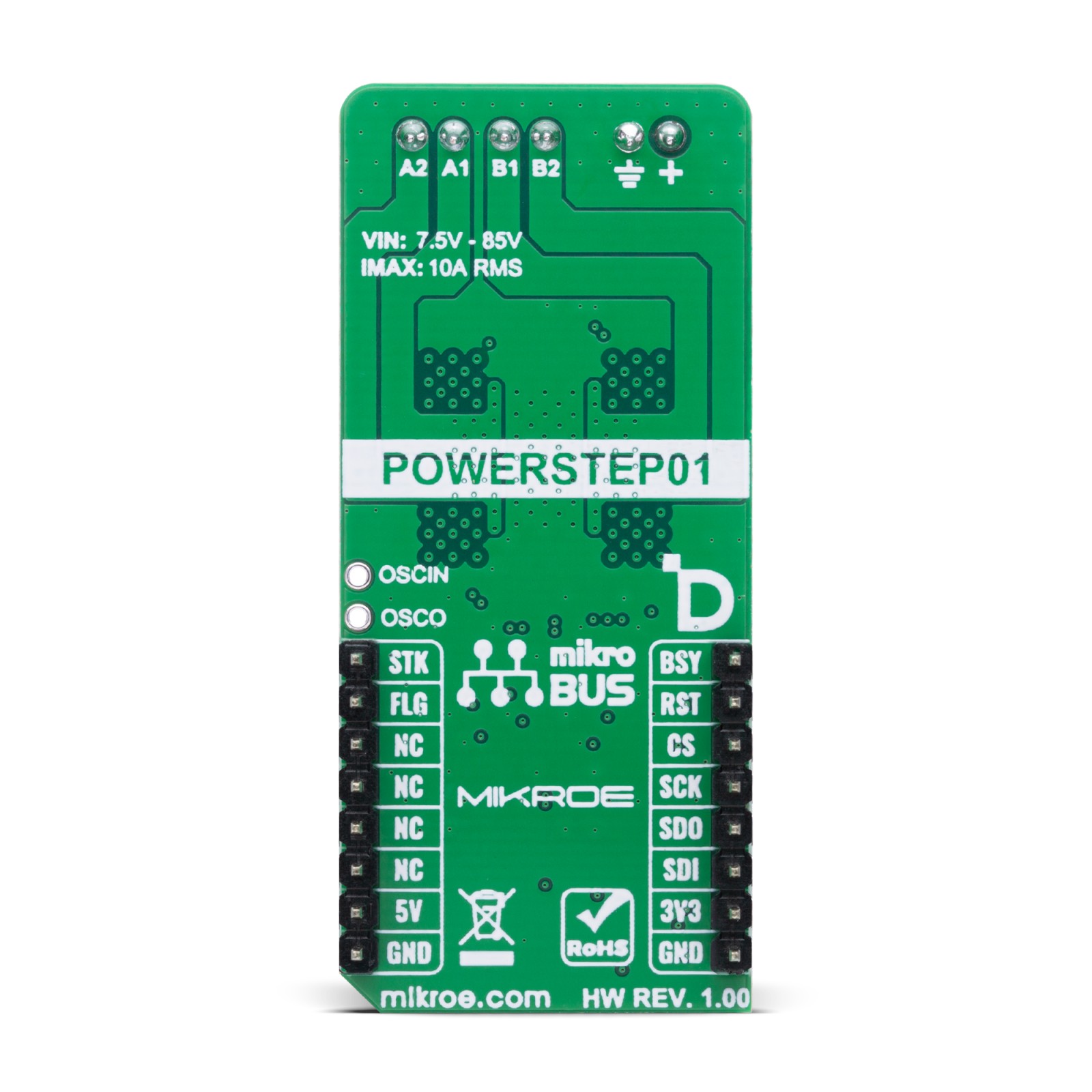

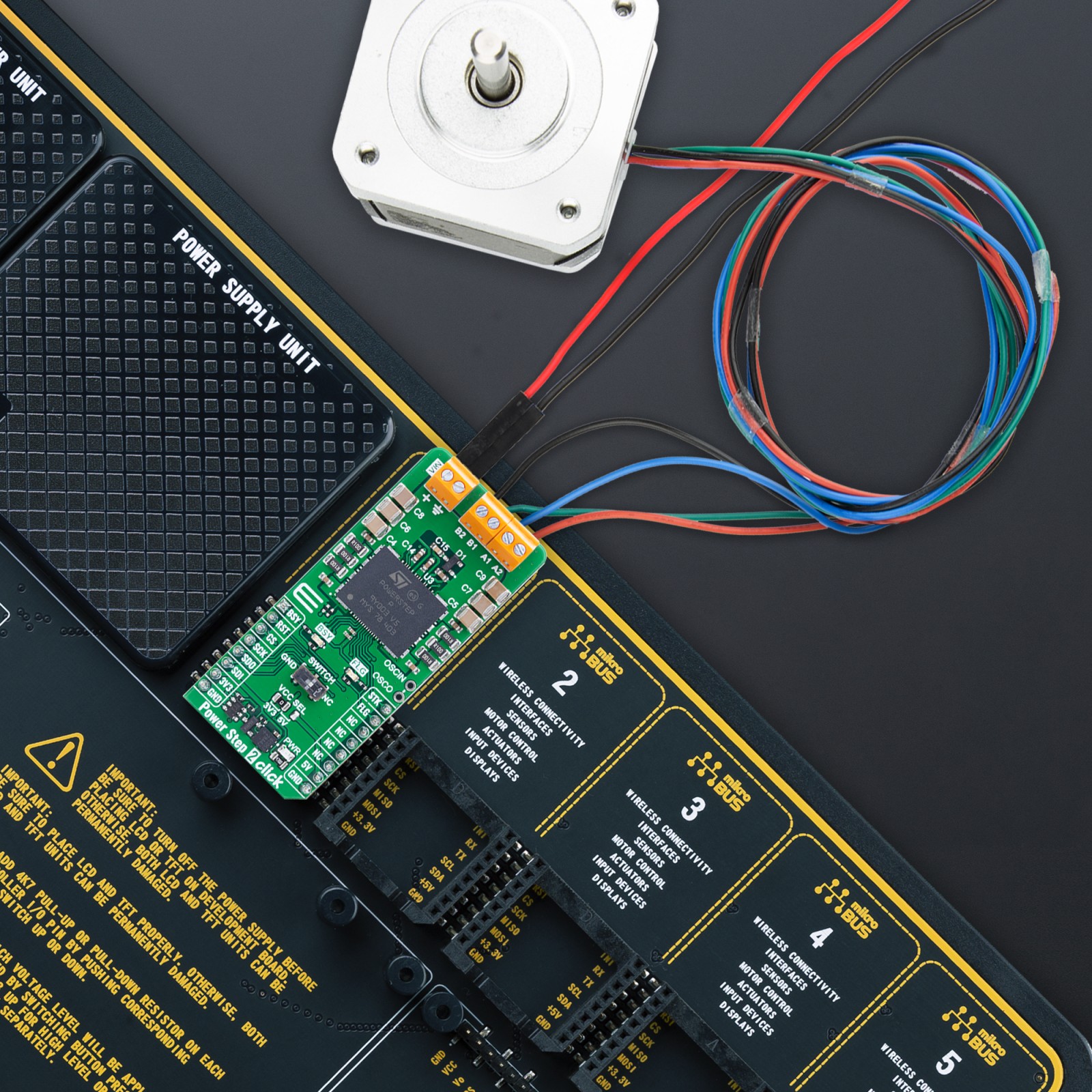

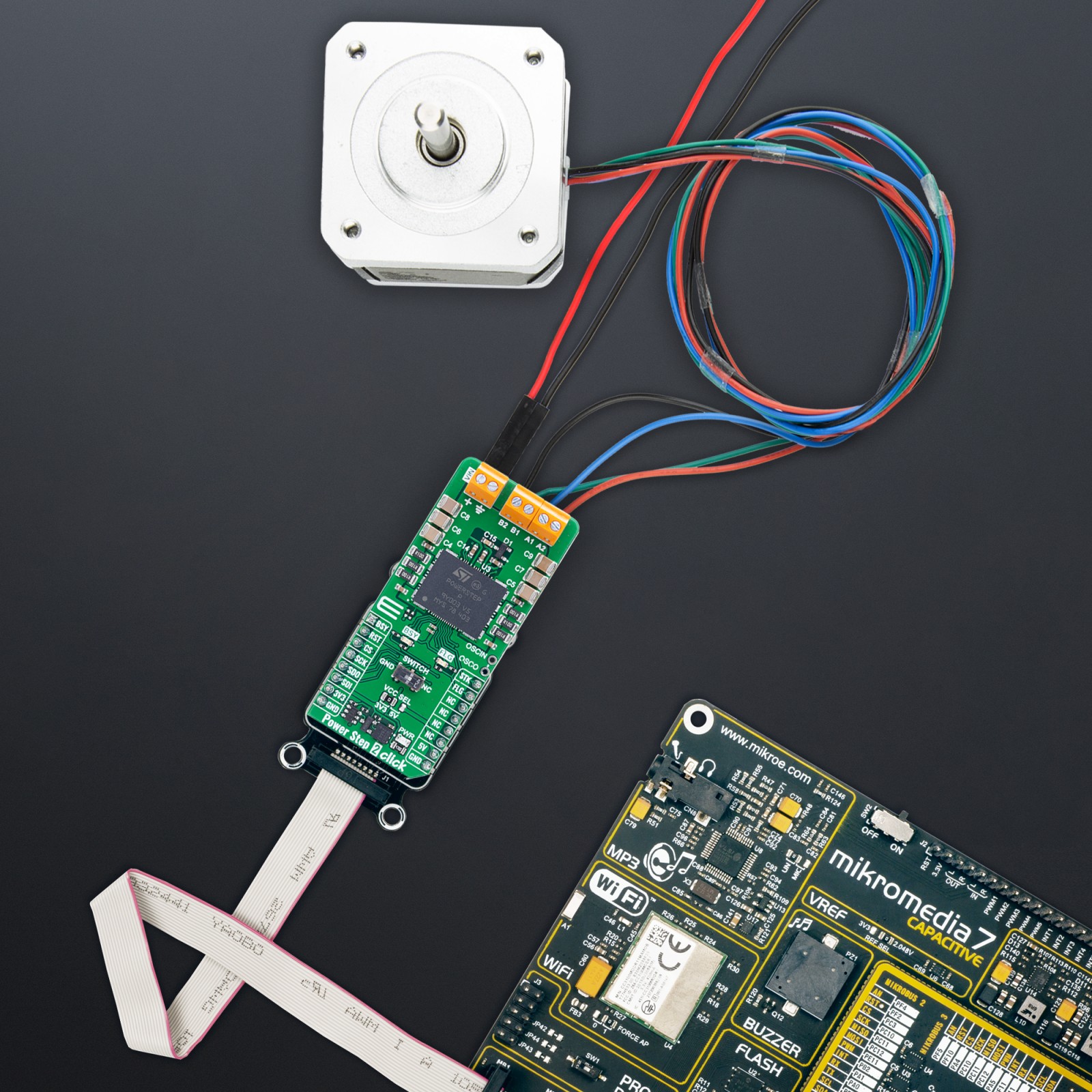

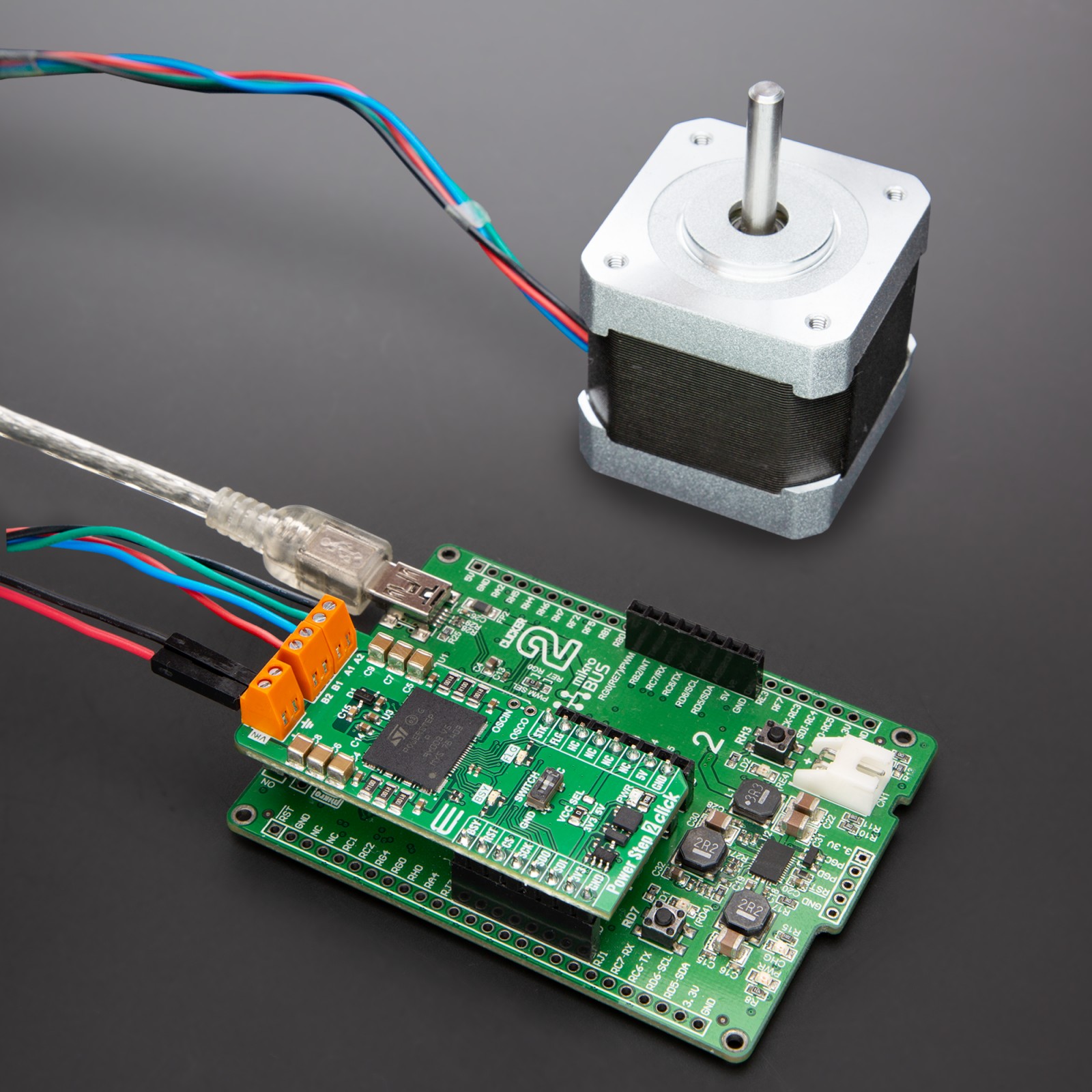

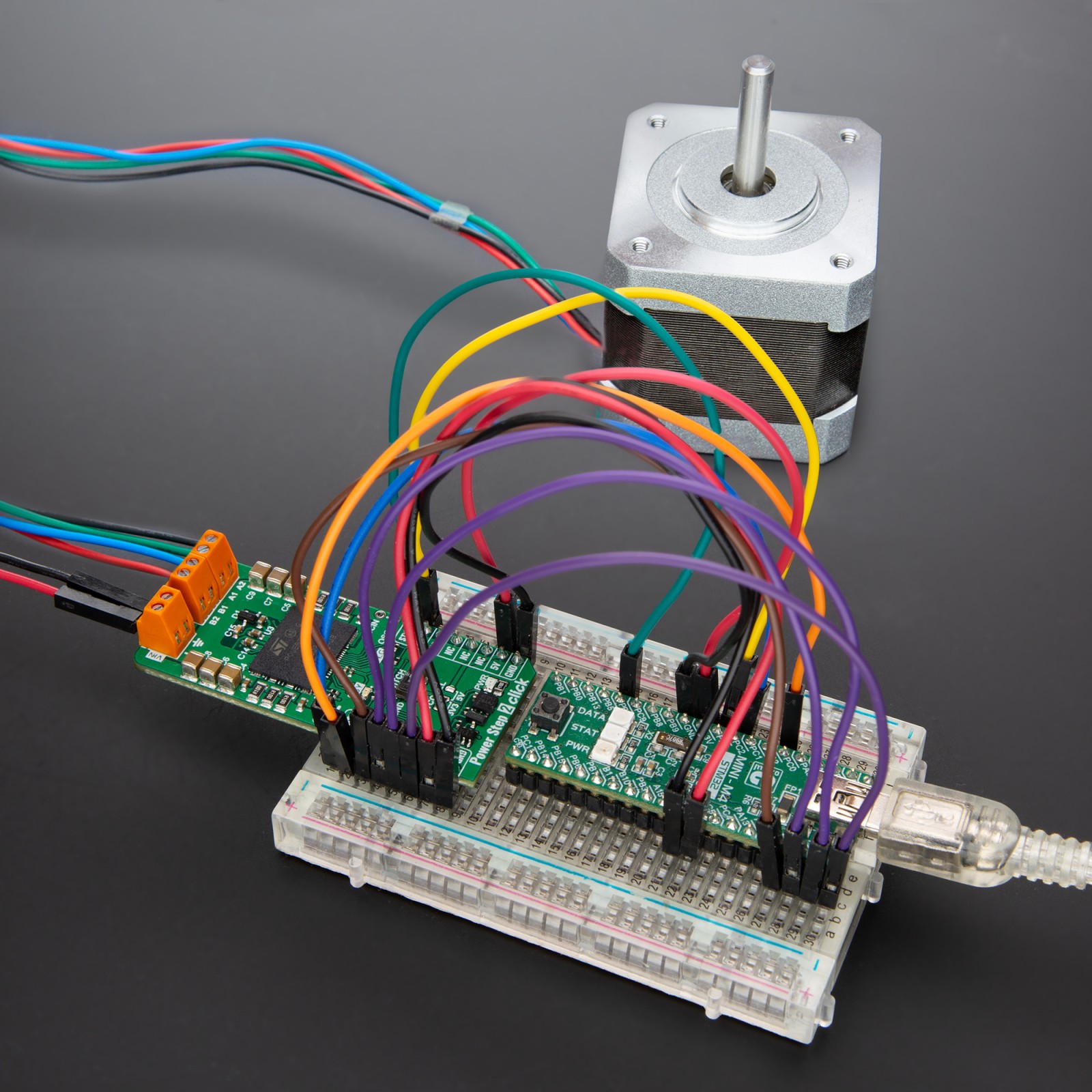

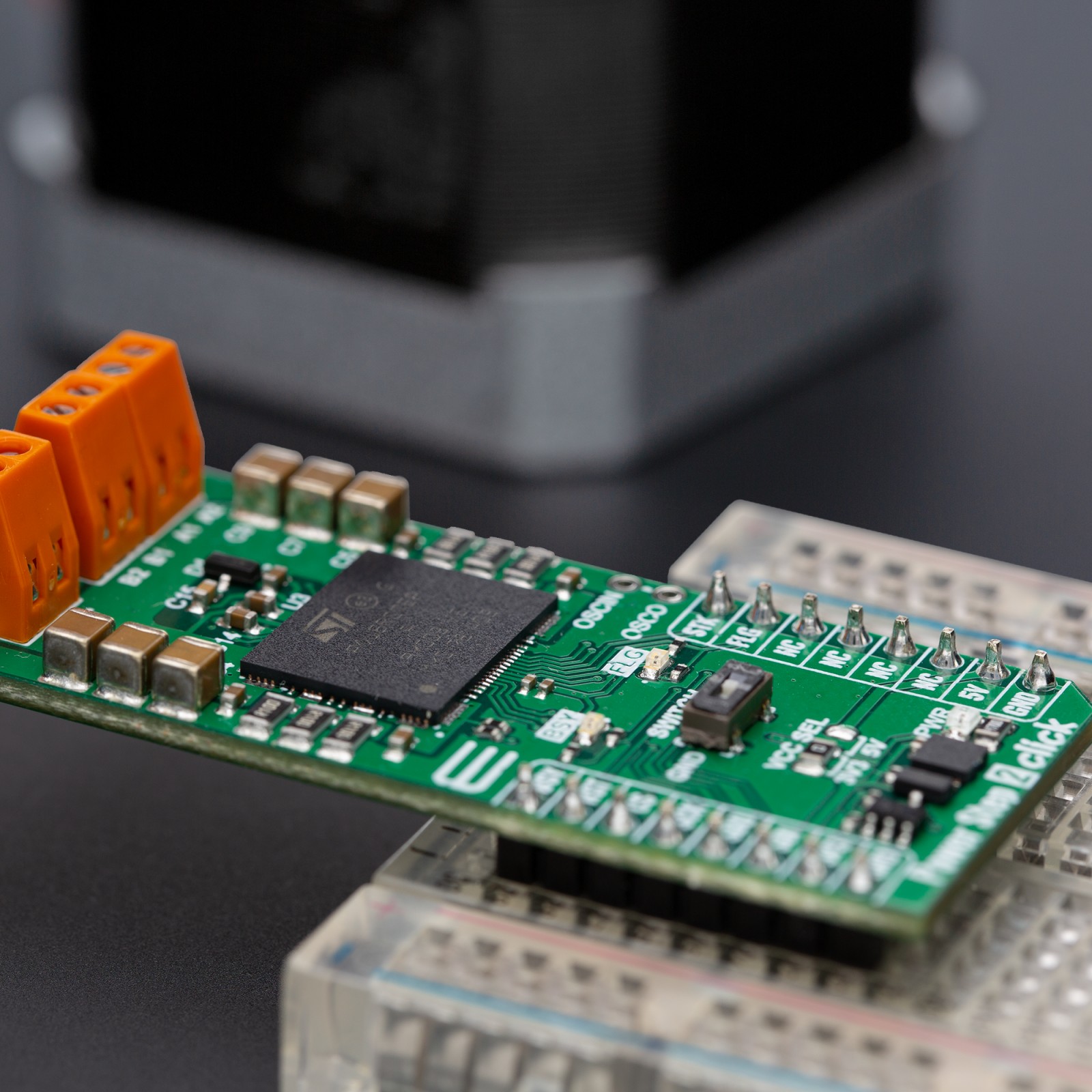

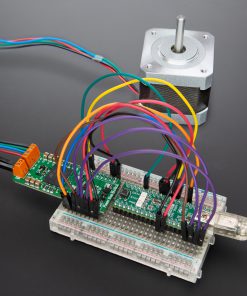

Power Step 2 Click is a compact add-on board for precise motion control applications. It is based on the powerSTEP01, a powerful 1/128 microstepping controller from STMicroelectronics, that integrates eight N-channel MOSFETs with ultra-low RDS(on). This board operates at voltages up to 85V, delivering up to 10A RMS output current while supporting both voltage mode driving and advanced current control. It features a high-speed 5MHz SPI interface, multiple safety protections, and additional control pins for enhanced functionality, including step clock input and motor initialization. The board also provides LED indicators for quick status monitoring and supports external clock synchronization. With its robust design and precise microstepping capabilities, Power Step 2 Click is ideal for industrial automation, medical equipment, robotics, antenna positioning, CCTV and security systems, and dome cameras.

Power Step 2 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R916.75 |

| 10+ | R868.50 |

| 15+ | R820.25 |

| 20+ | R789.37 |