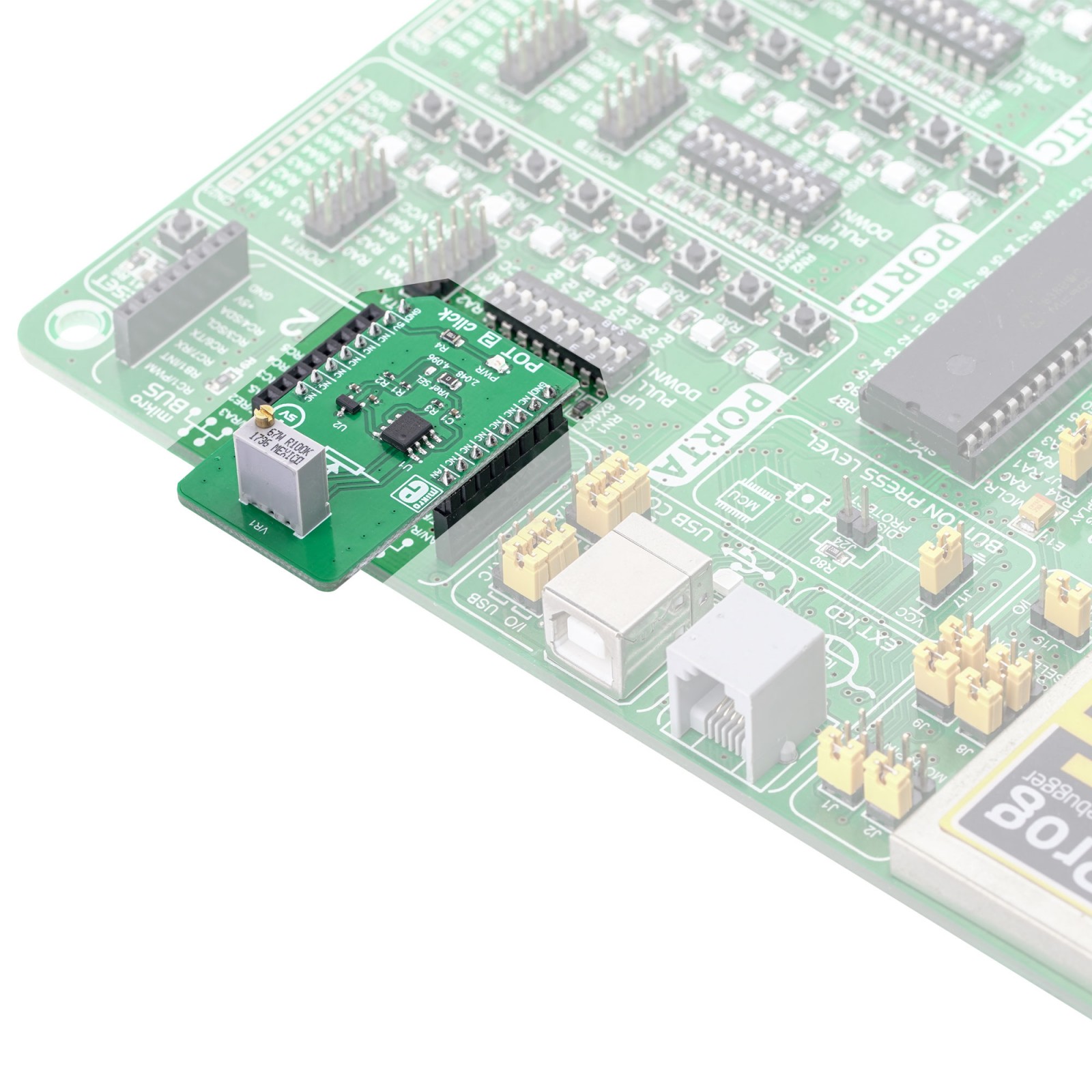

POT 2 Click

R245.00 ex. VAT

POT 2 click is a Click board™ with the accurate selectable reference voltage output. By utilizing a multi-turn precision potentiometer, this Click board™ can provide very accurate voltage output on the AN pin of the mikroBUS™. POT 2 click is also equipped with the SMD jumper, which allows the maximum reference voltage to be selected between two typically used values: 2.048V or 4.096V. Using a rail-to-rail buffering operational amplifier which provides constant input and output impedance, this Click board™ is an ideal solution when accurately controlled voltage reference is required.

POT 2 click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R232.75 |

| 10+ | R220.50 |

| 15+ | R208.25 |

| 20+ | R200.41 |

.jpg)