Piezo Accel 2 Click – 25g

R5,850.00 ex. VAT

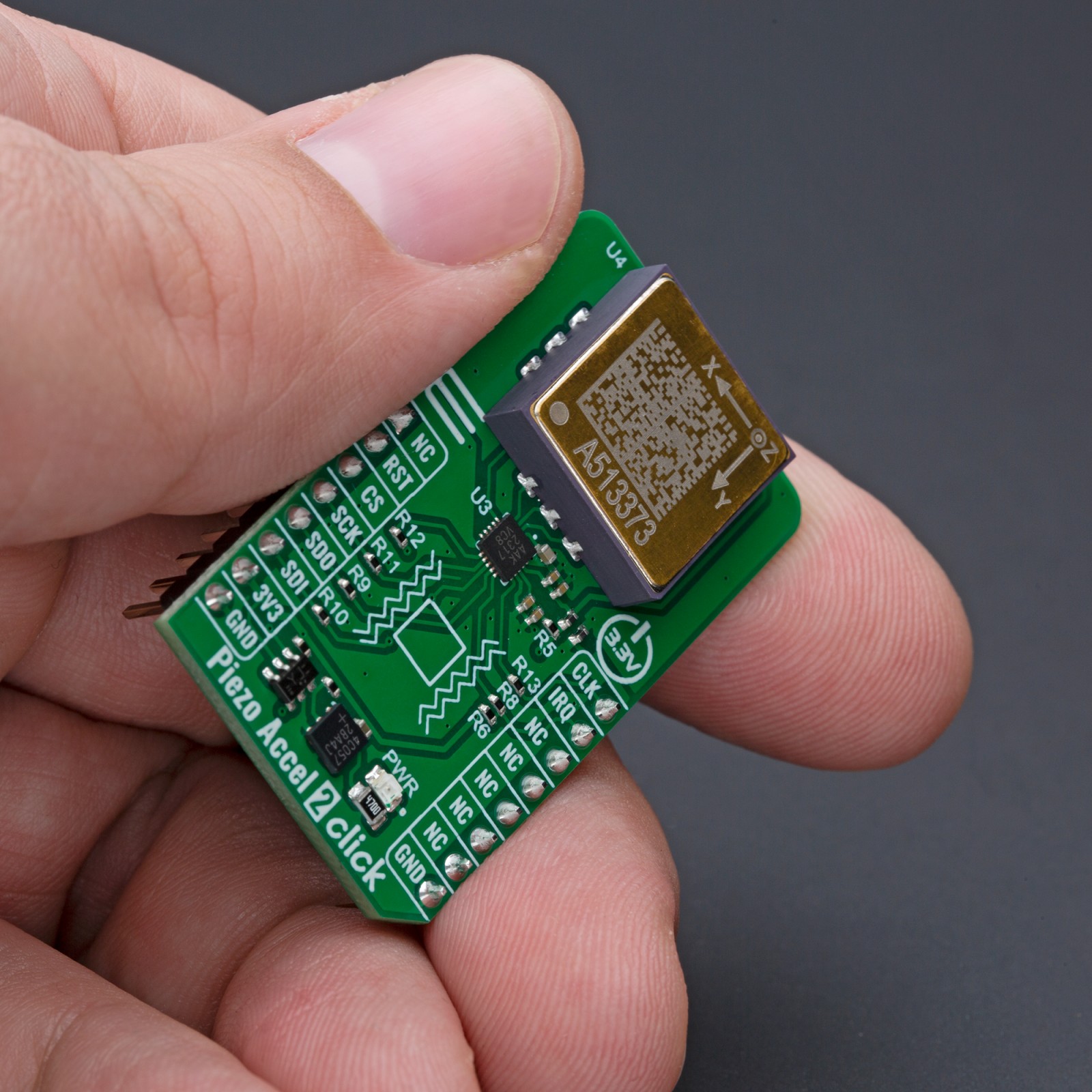

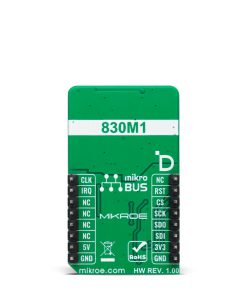

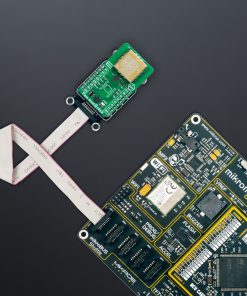

Piezo Accel 2 Click – 25g is a compact add-on board for precise vibration and motion monitoring in condition-based maintenance applications. This board features the 830M1-0025, a triaxial piezoelectric accelerometer from TE Connectivity, capable of detecting motion and acceleration along all three axes (X, Y, Z). The 830M1-0025 offers a ±25g range with a sensitivity of 50mV/g, providing reliable and accurate analog voltage outputs. It integrates a built-in RTD temperature sensor for simultaneous vibration and temperature monitoring, and the onboard MCP3562R 24-bit ADC converts these signals into high-resolution digital data. Communication is made through an SPI interface with additional interrupt and clock functionality for easy integration with a host MCU. Piezo Accel 2 Click is ideal for machine health monitoring, predictive maintenance, impact and shock detection, and embedded vibration monitoring, ensuring reliable performance in demanding environments.

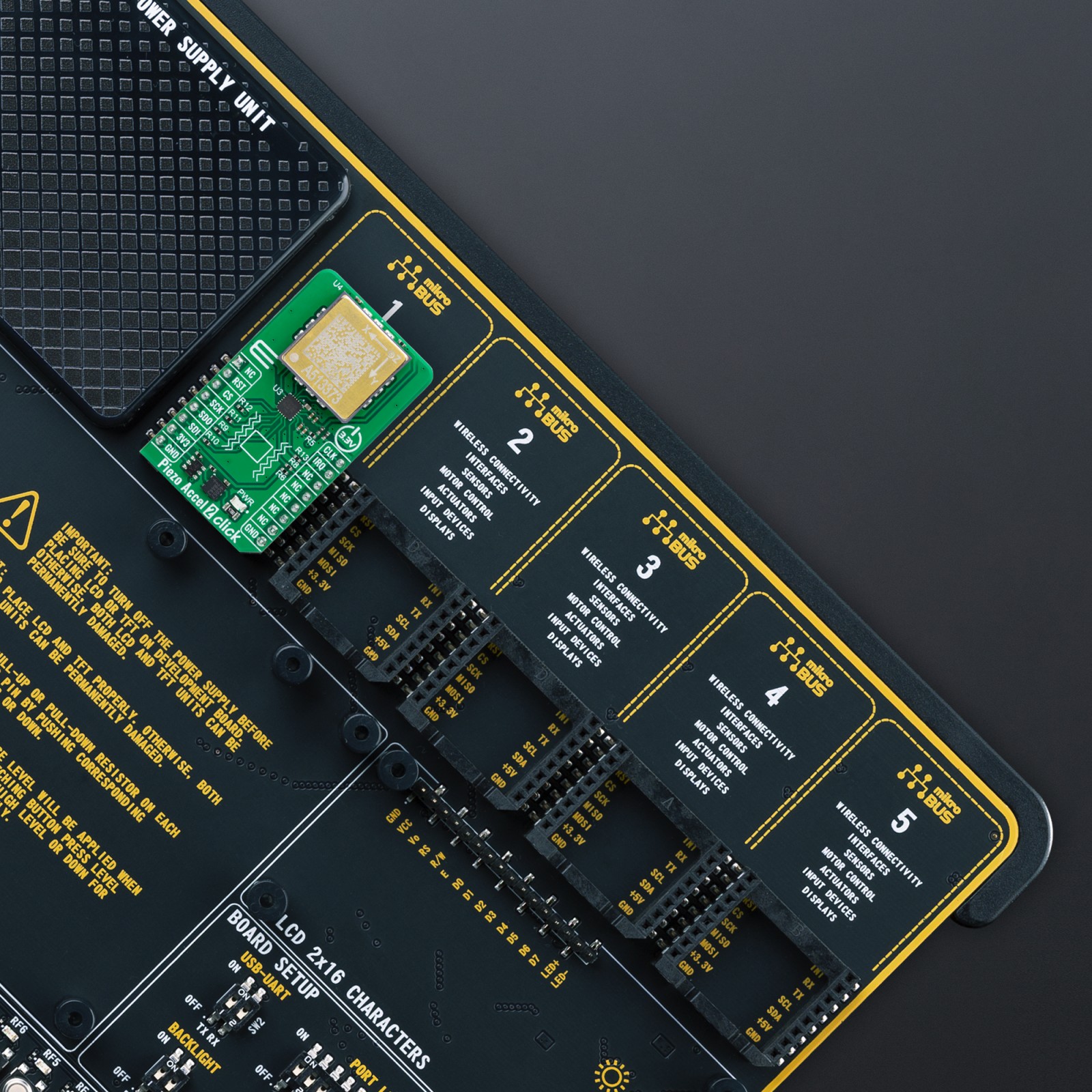

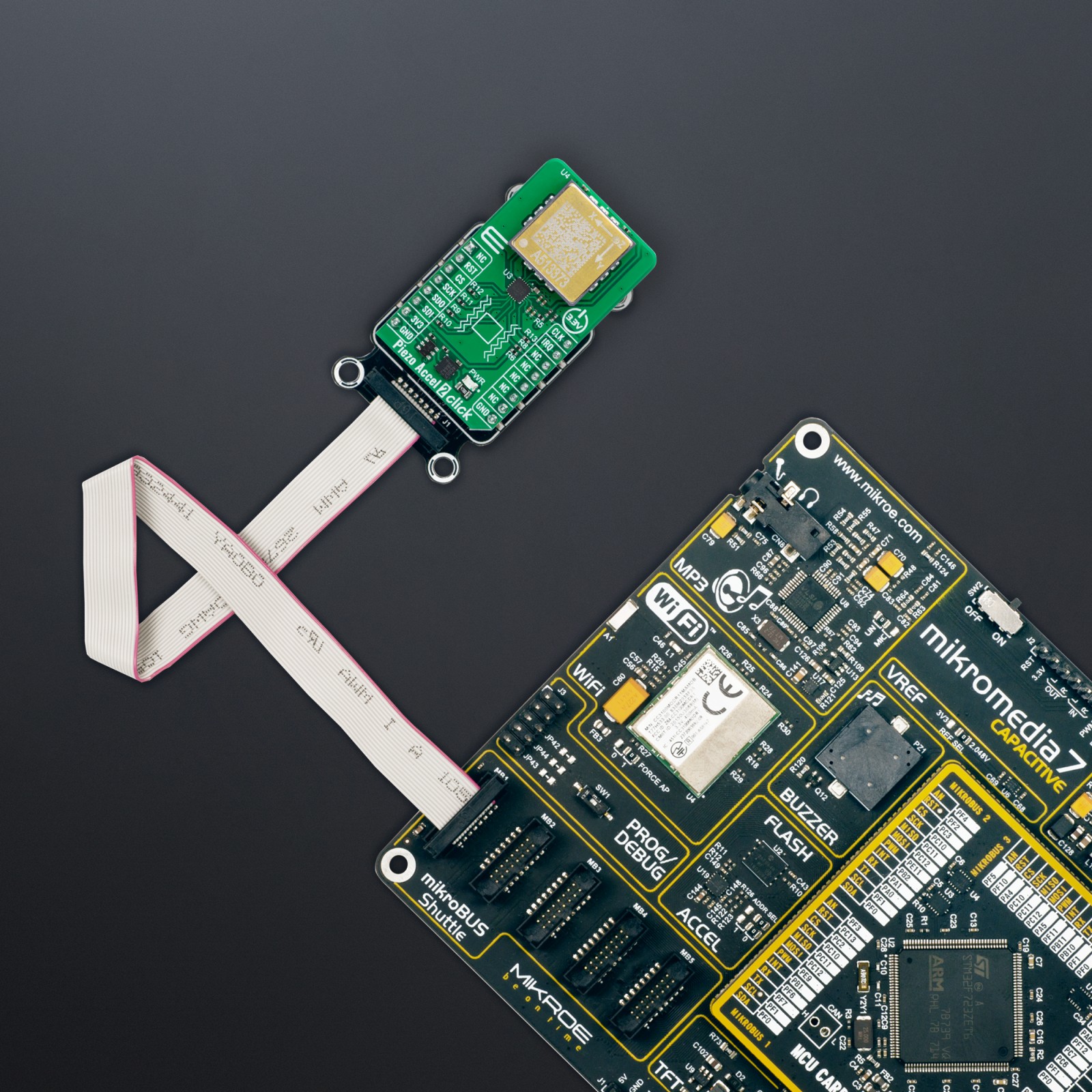

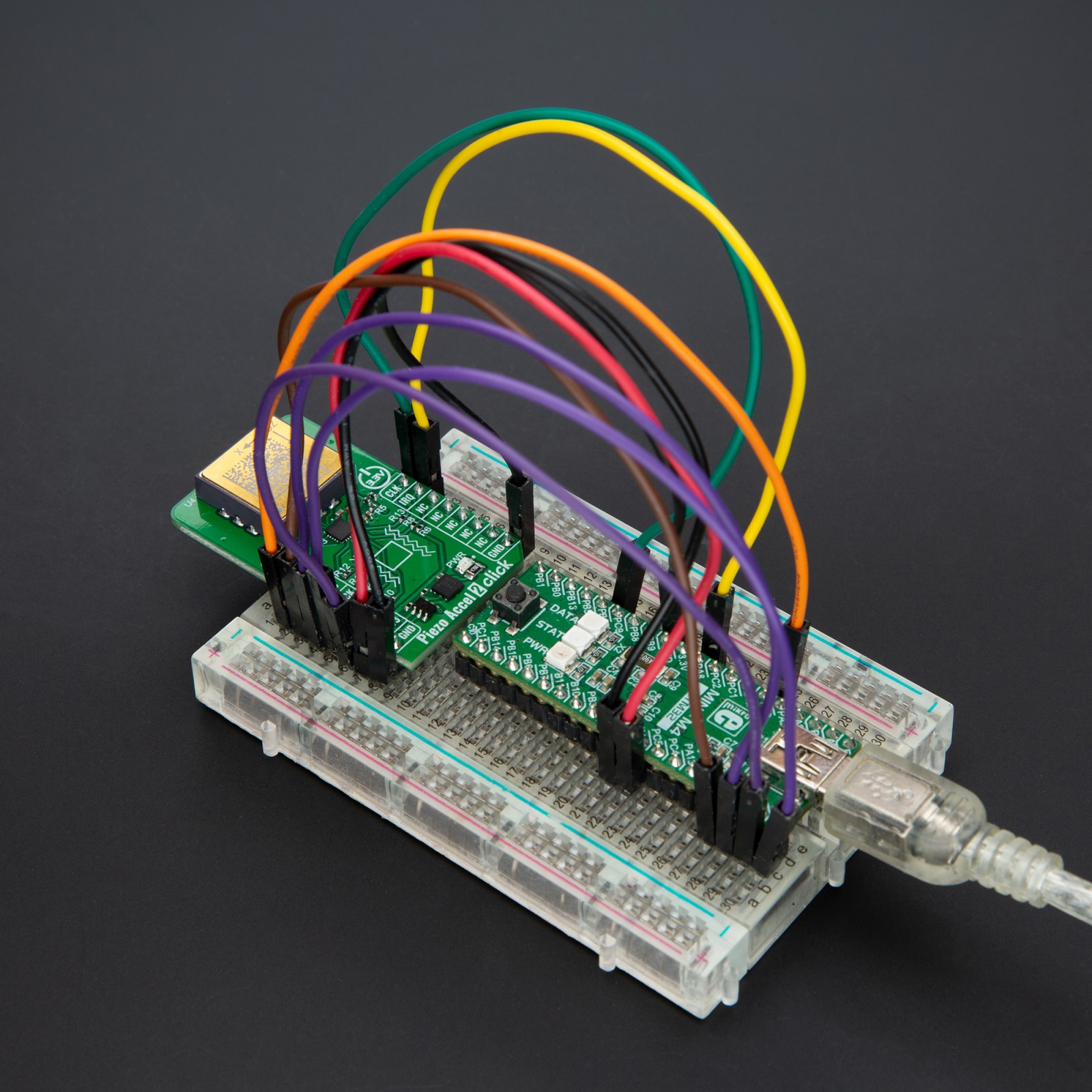

Piezo Accel 2 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R5,557.50 |

| 10+ | R5,411.25 |

| 15+ | R5,265.00 |

| 20+ | R5,118.75 |