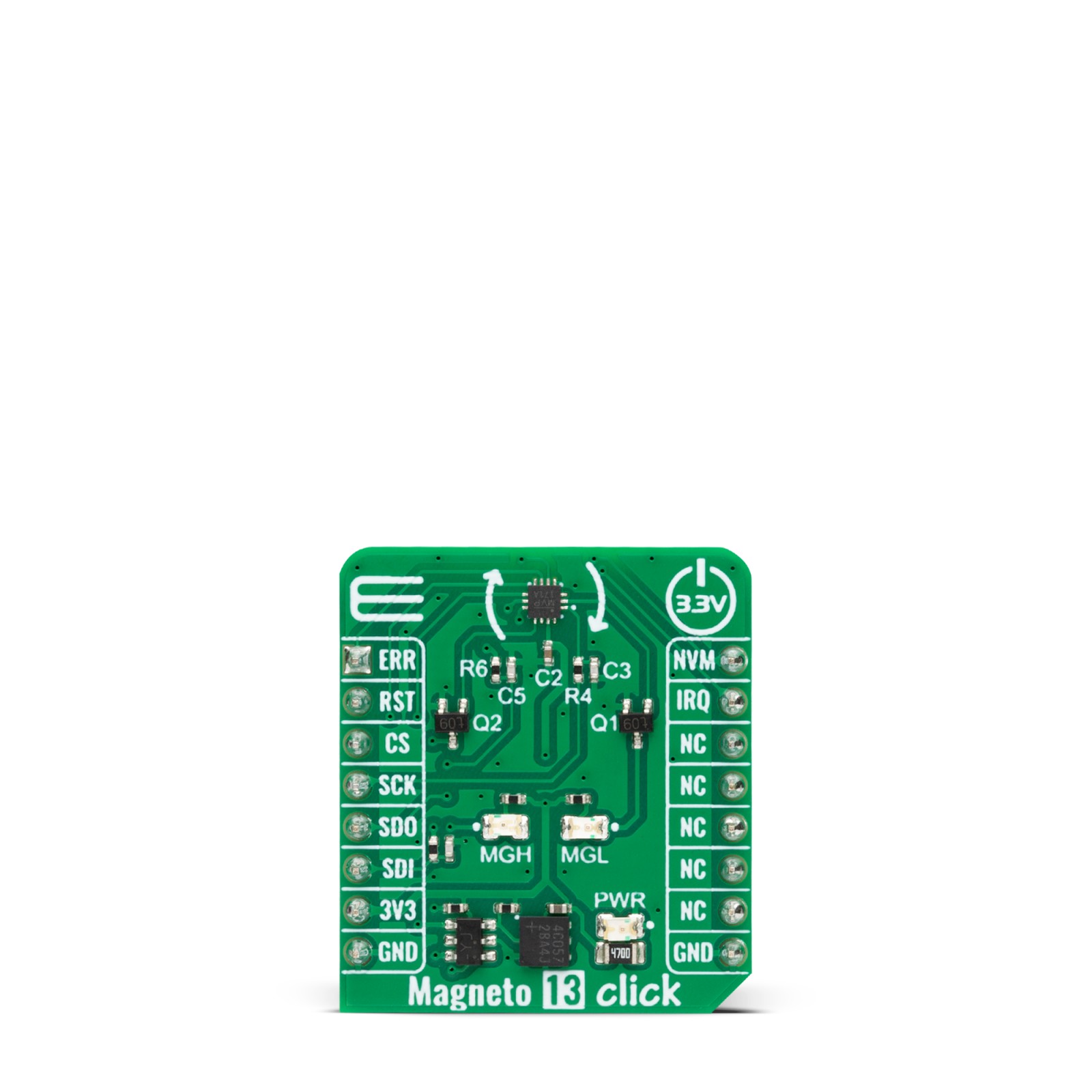

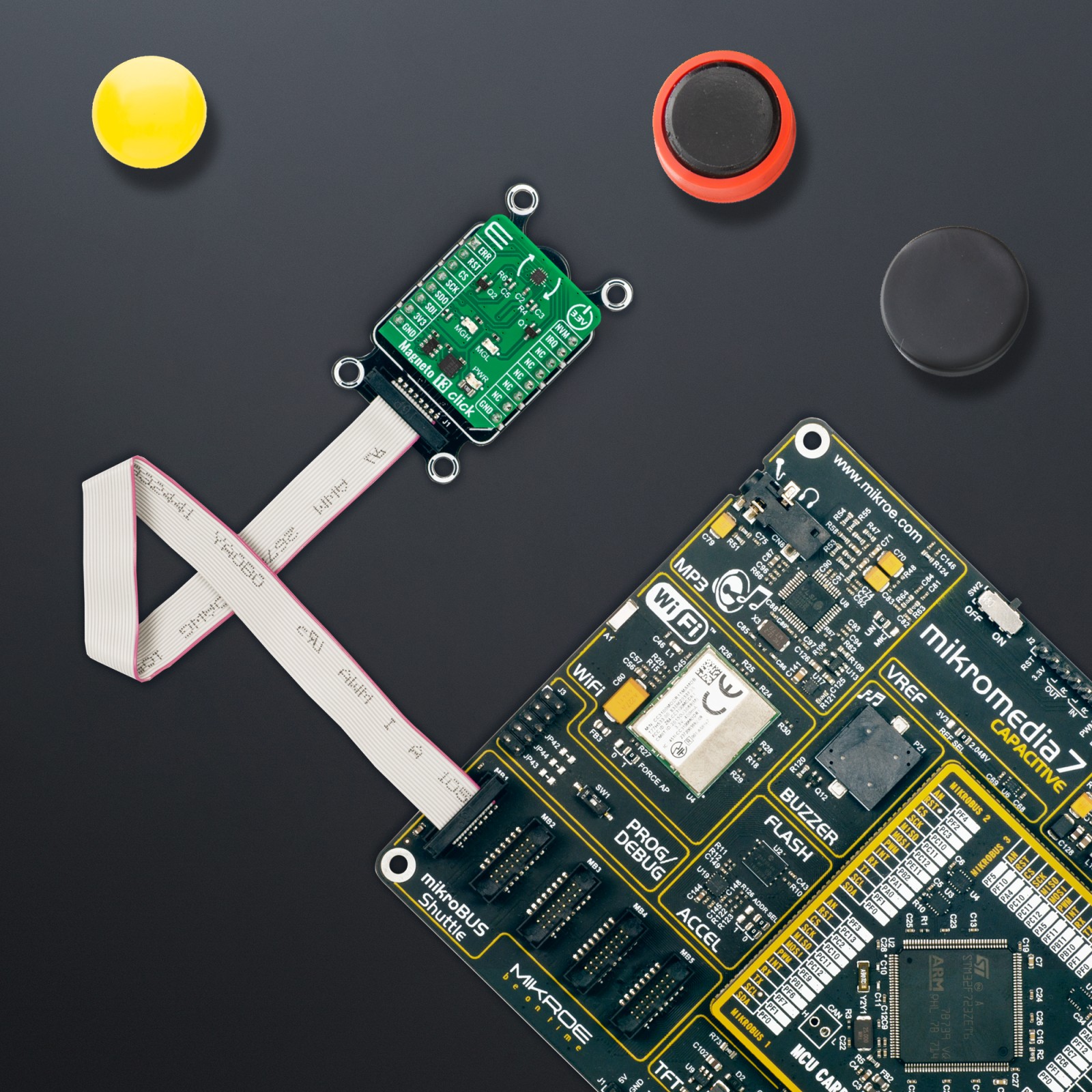

Magneto 13 Click

R350.00 ex. VAT

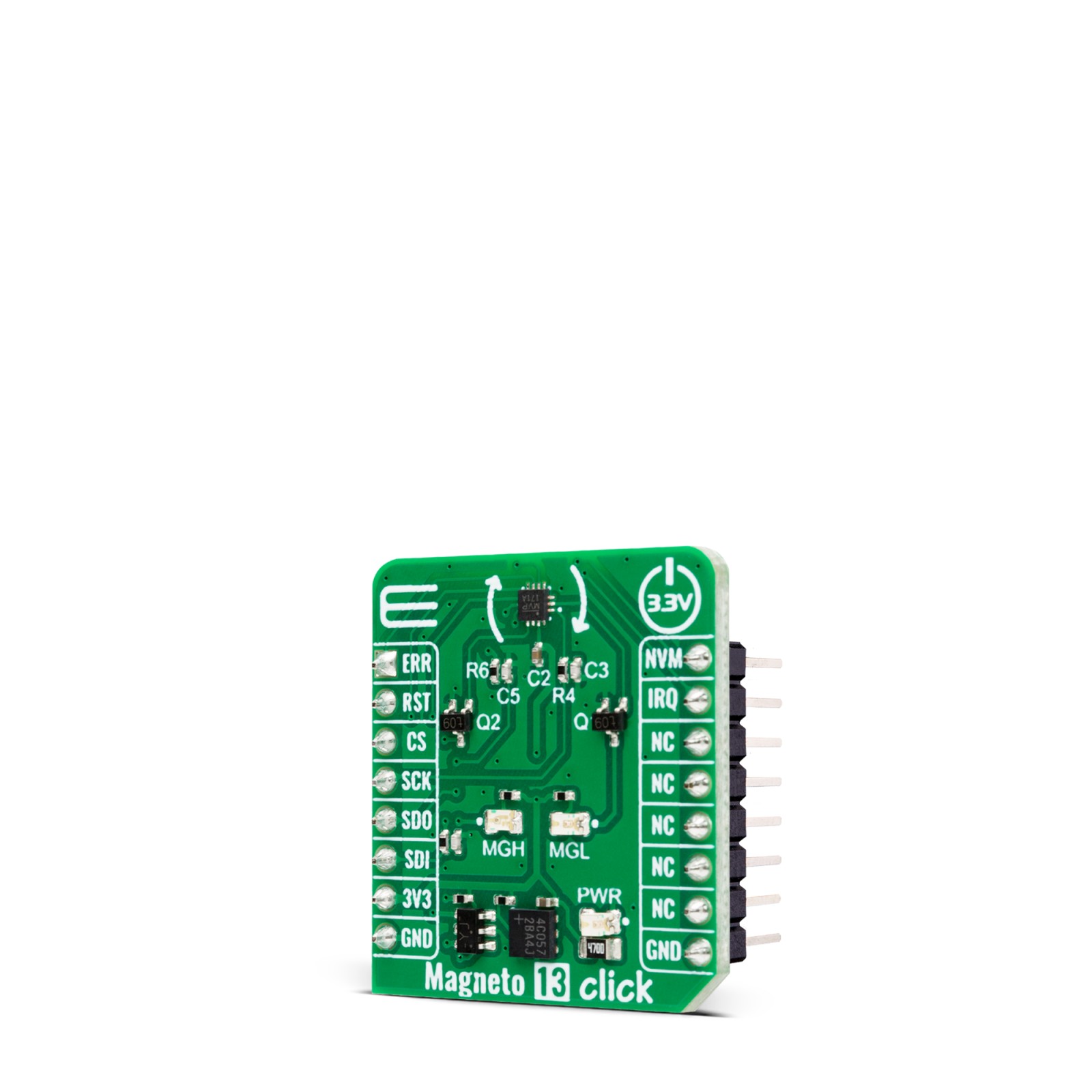

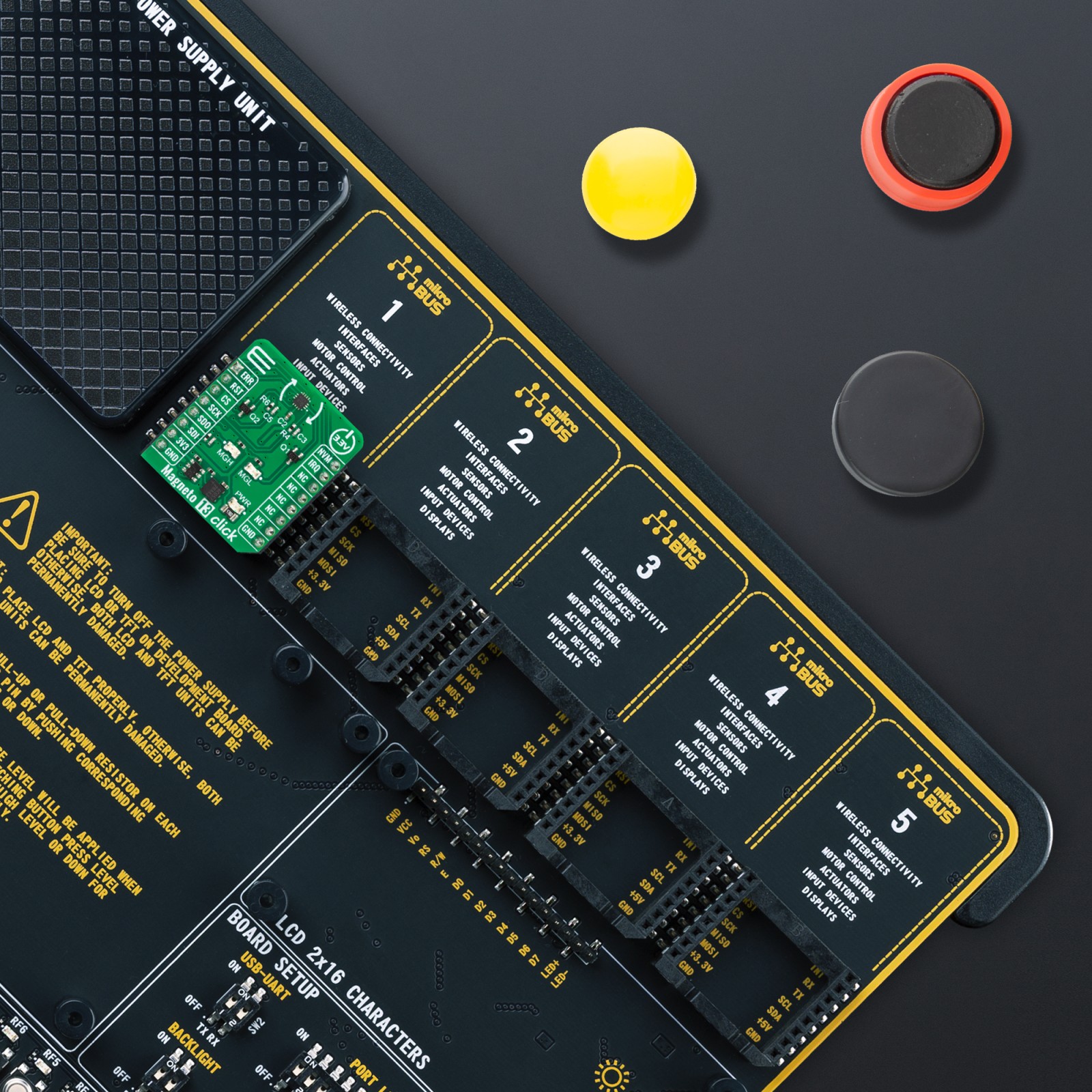

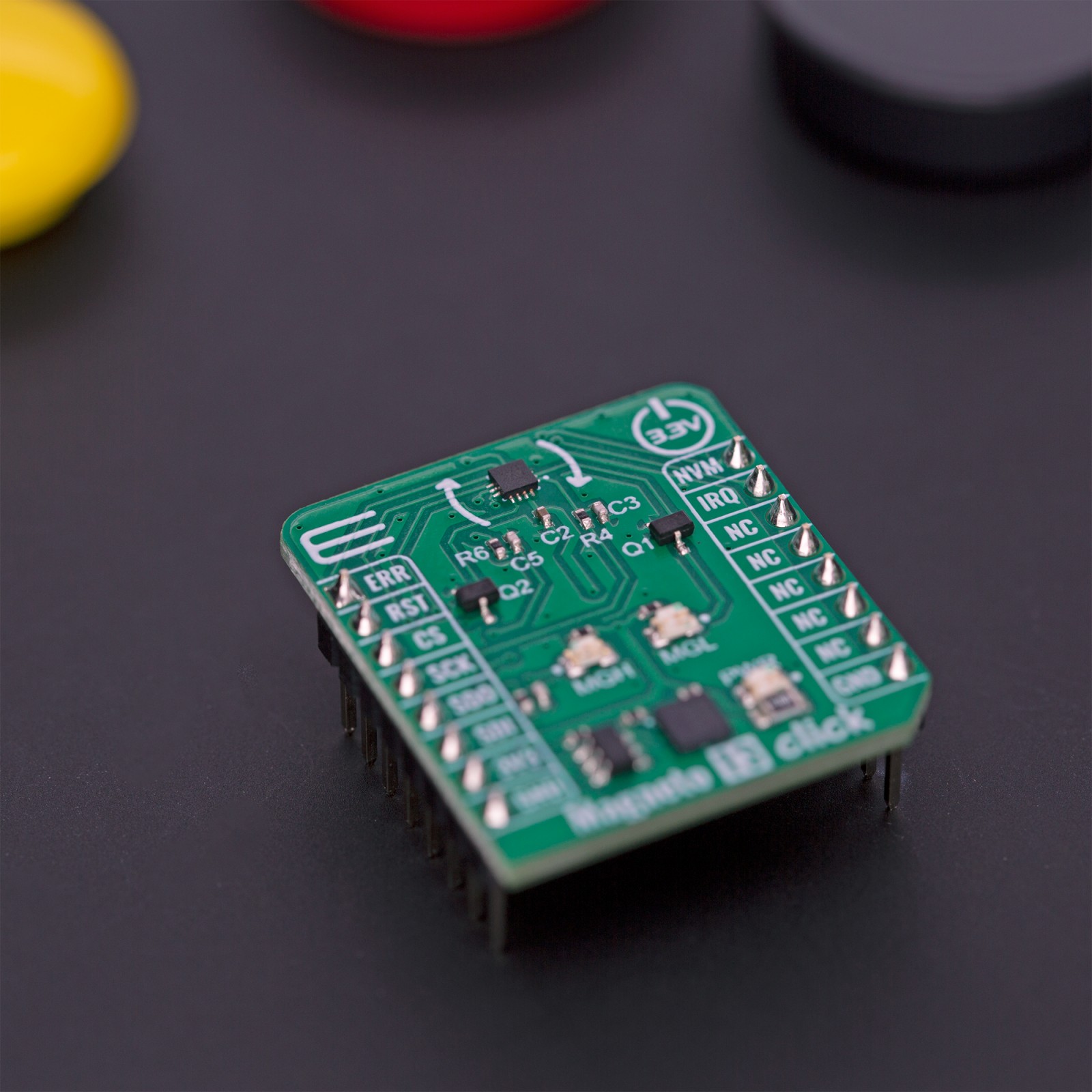

Magneto 13 Click is a compact add-on board with an accurate and reliable magnetic device. This board features the MA736, a contactless digital angle sensor from Monolithic Power Systems. It is a MagAlpha sensor that detects the absolute angular position of a permanent magnet, typically a diametrically magnetized cylinder or a rotating shaft. The MA736 sensor supports a wide range of magnetic field strengths, end-of-shaft, and side-shaft (off-axis mounting) spatial configurations. This Click board™ makes the perfect solution for general-purpose angle measurement, high-resolution angle encoders, automotive positioning sensing, robotics, and more.

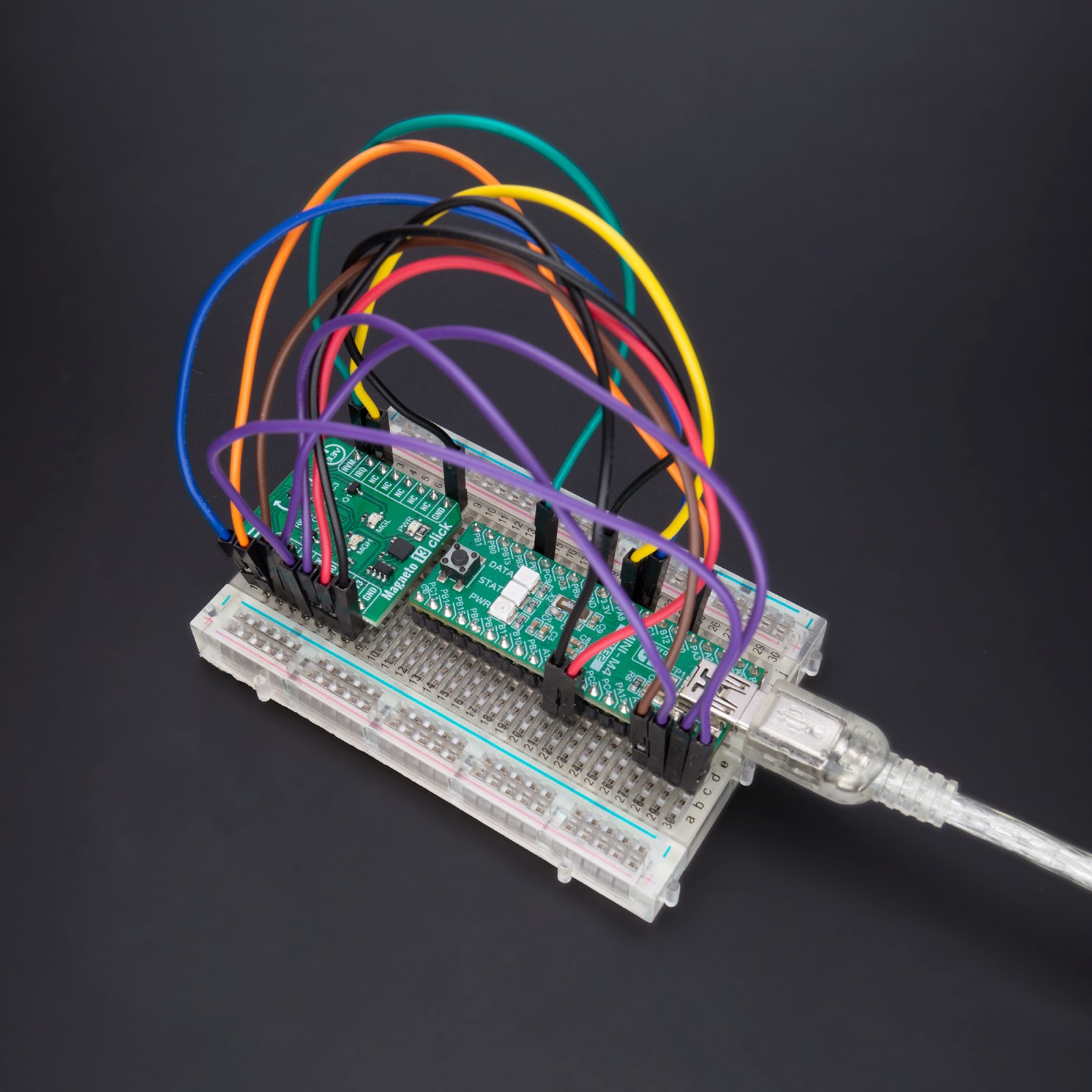

Magneto 13 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R332.50 |

| 10+ | R315.00 |

| 15+ | R297.50 |

| 20+ | R286.30 |