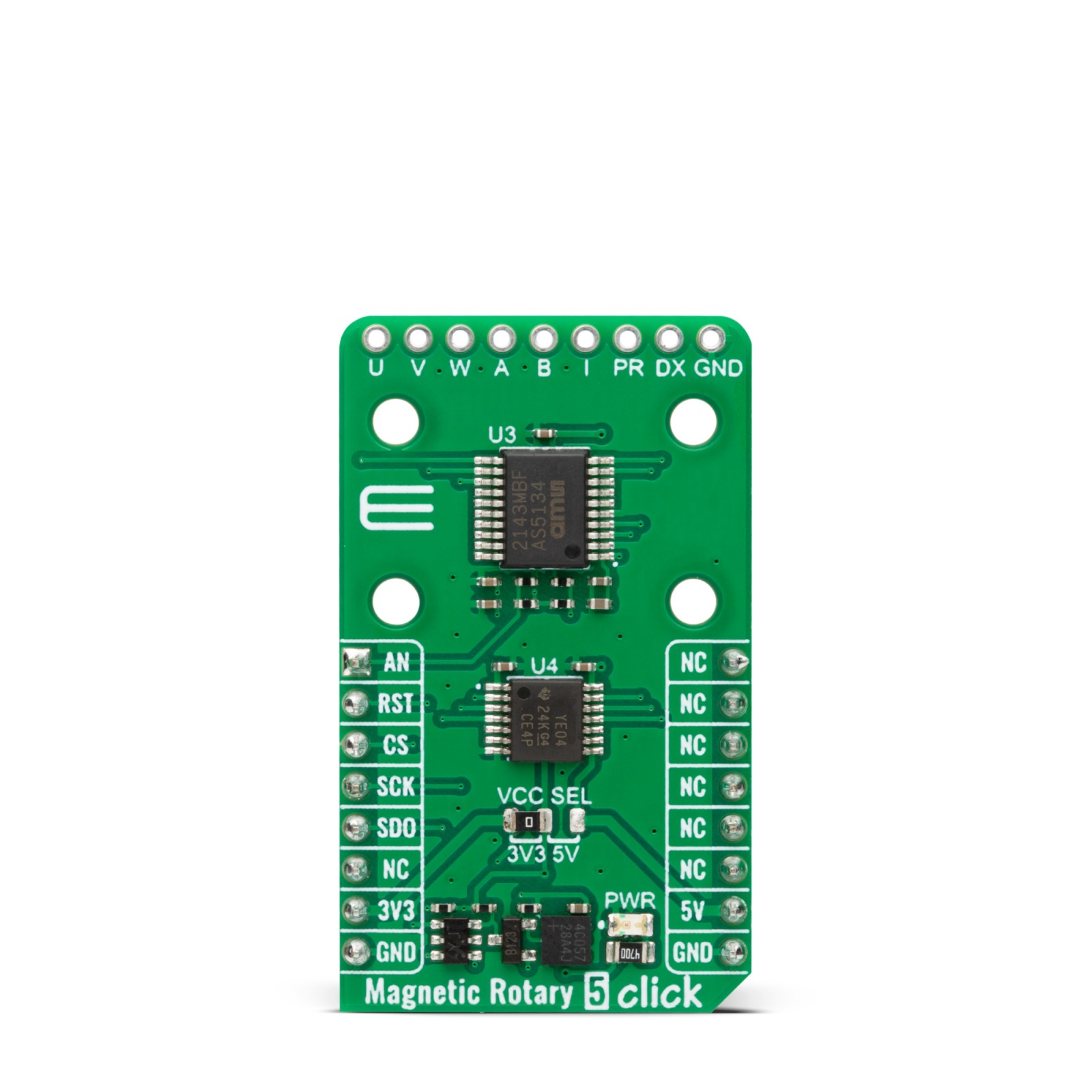

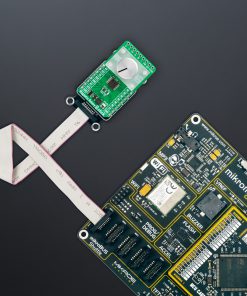

Magnetic Rotary 5 Click

R530.00 ex. VAT

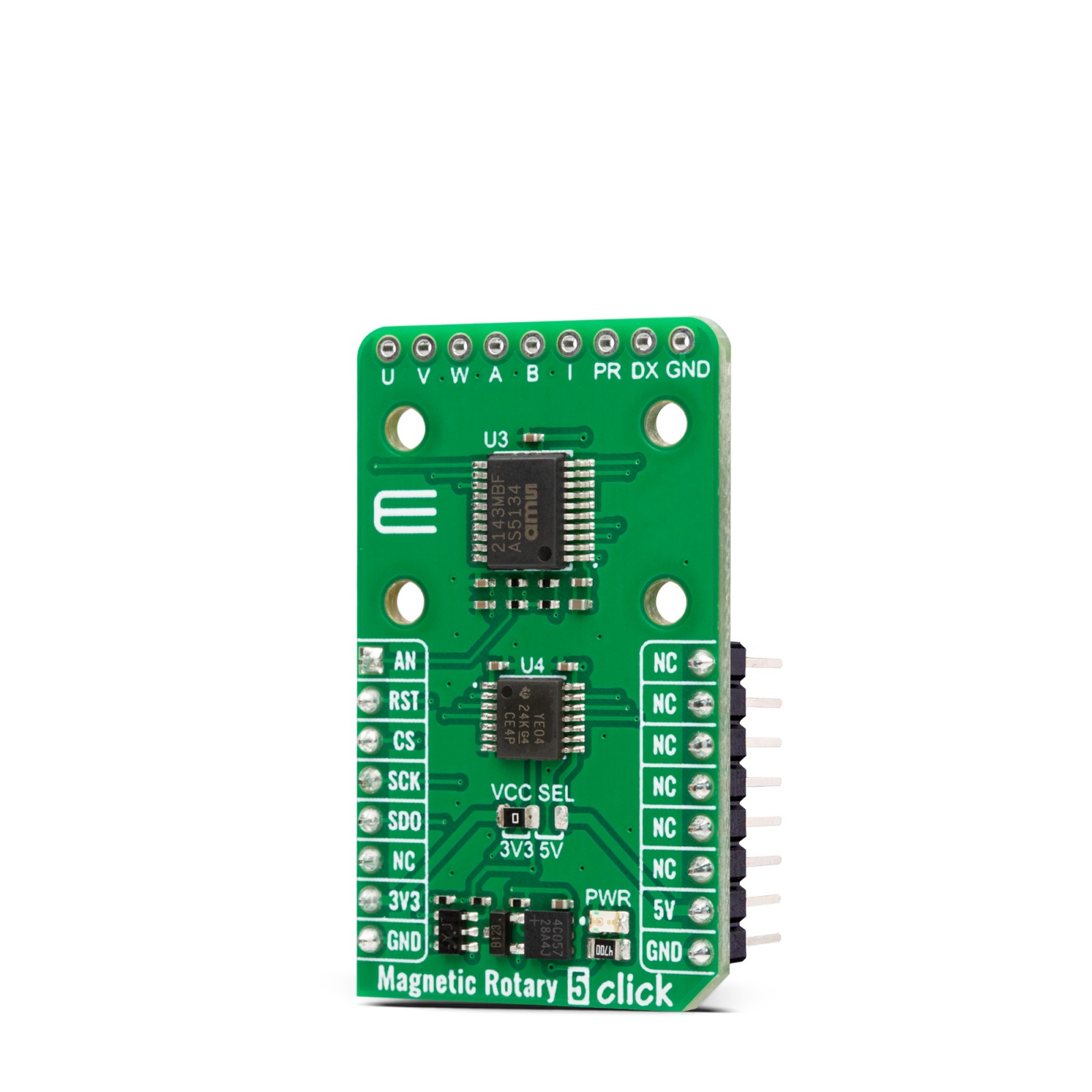

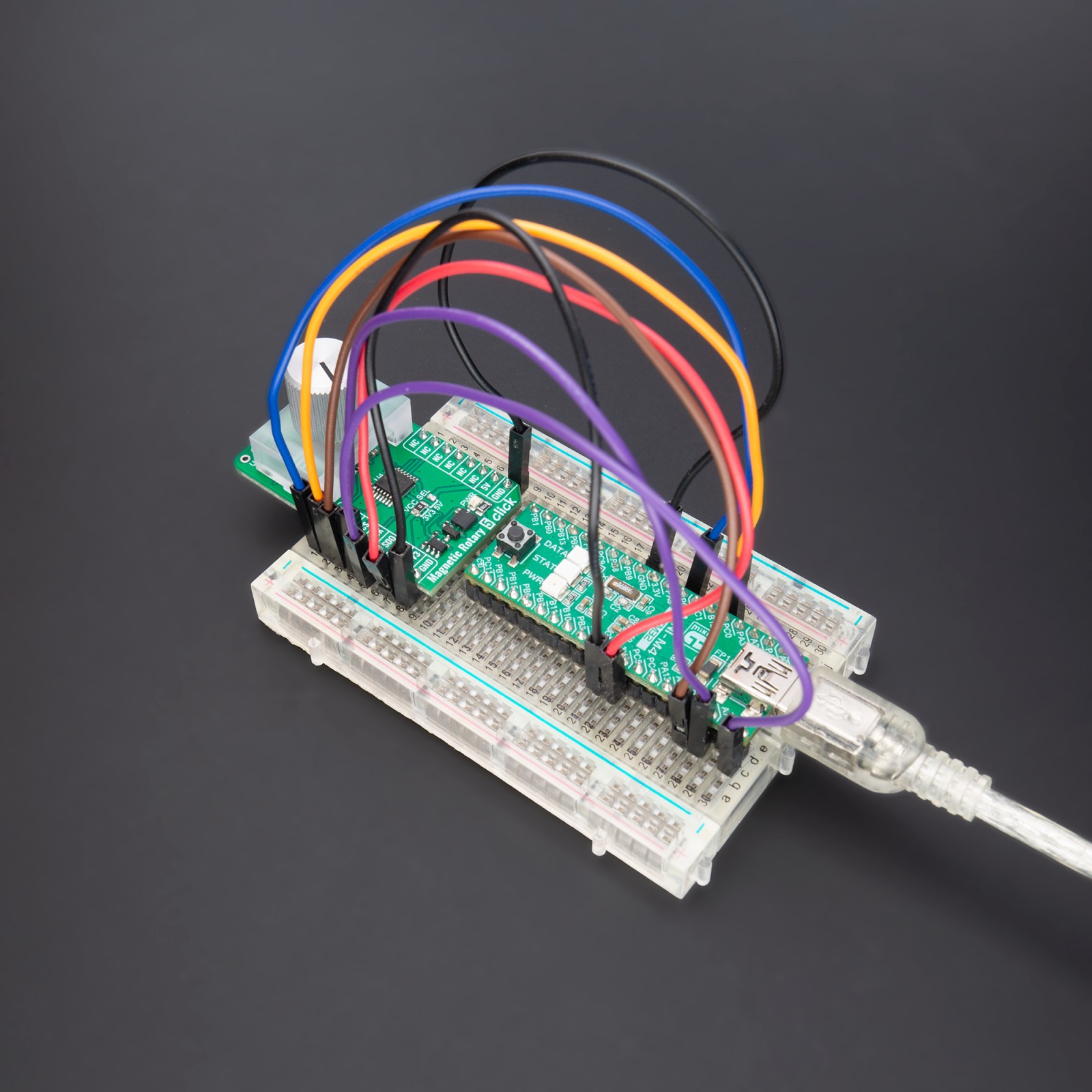

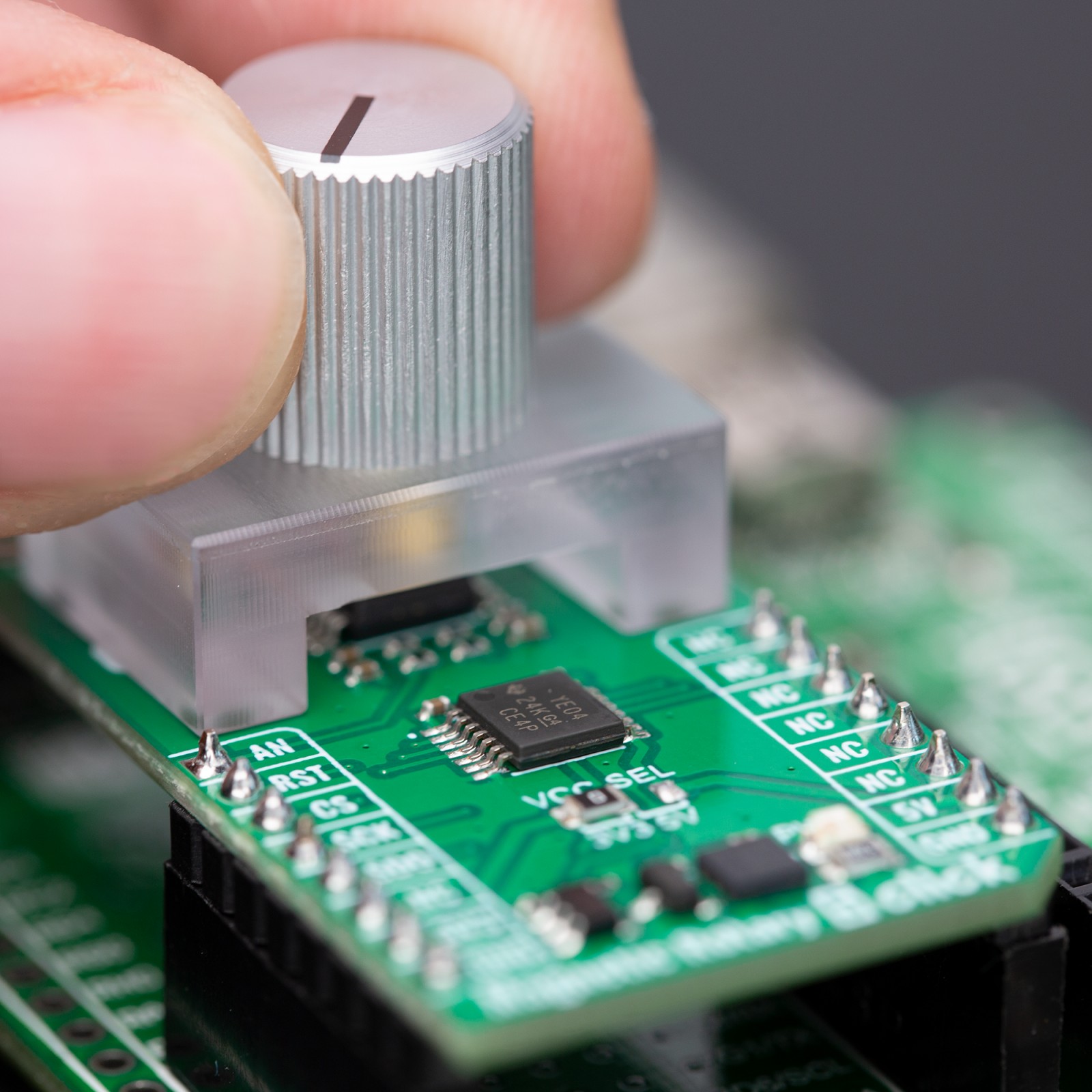

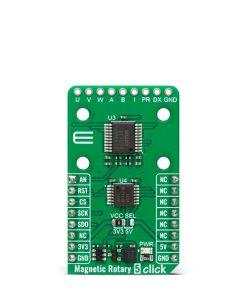

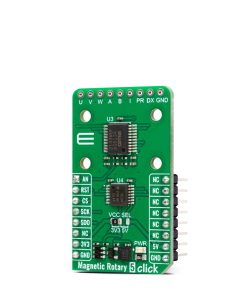

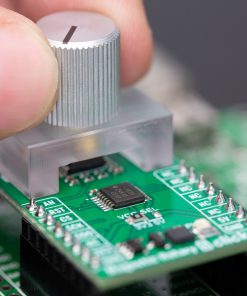

Magnetic Rotary 5 Click is a compact add-on board for accurate magnet-position sensing. This board features the AS5134, a contactless magnetic rotary encoder from ams for accurate angular measurement over a full turn of 360º. It is designed to provide accurate angle measurements with a simple two-pole magnet rotating over the center of the chip, featuring an integrated Hall element, analog front end, and digital signal processing. Offering a high resolution of 8.5 bits, which equates to 360 positions per revolution, it is also capable of high-speed performance, with a maximum RPM of 76875. It can accommodate a wide range of magnetic fields, from 20 to 80mT. It also has an onboard header for incremental and commutation signals of their respective A/B/I and U/V/W signals and pins for Daisy Chain Mode and OTP programming. This Click board™ is suitable for contactless rotary position sensing, rotary switches (human-machine interface), AC/DC motor position control, and brushless DC motor position control.

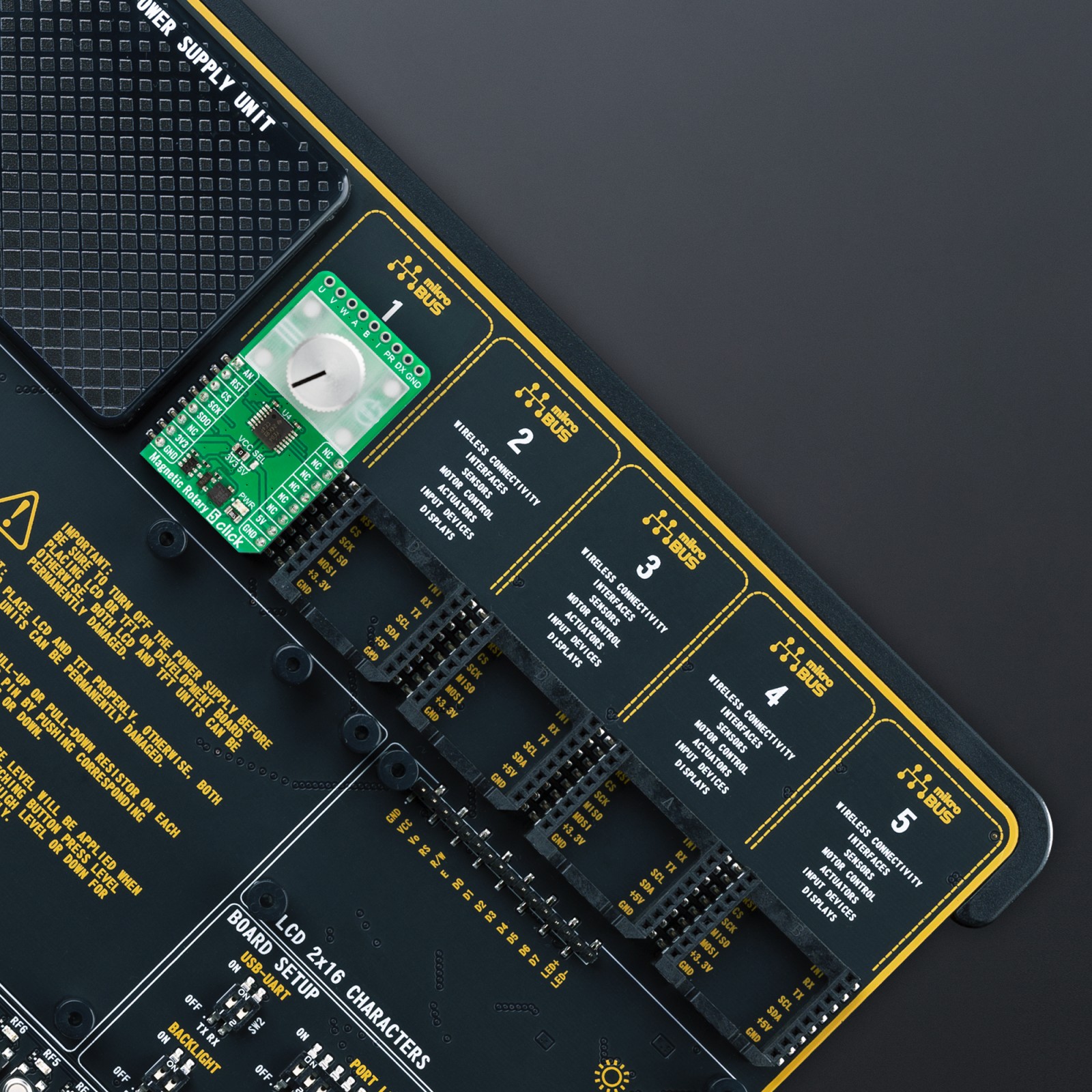

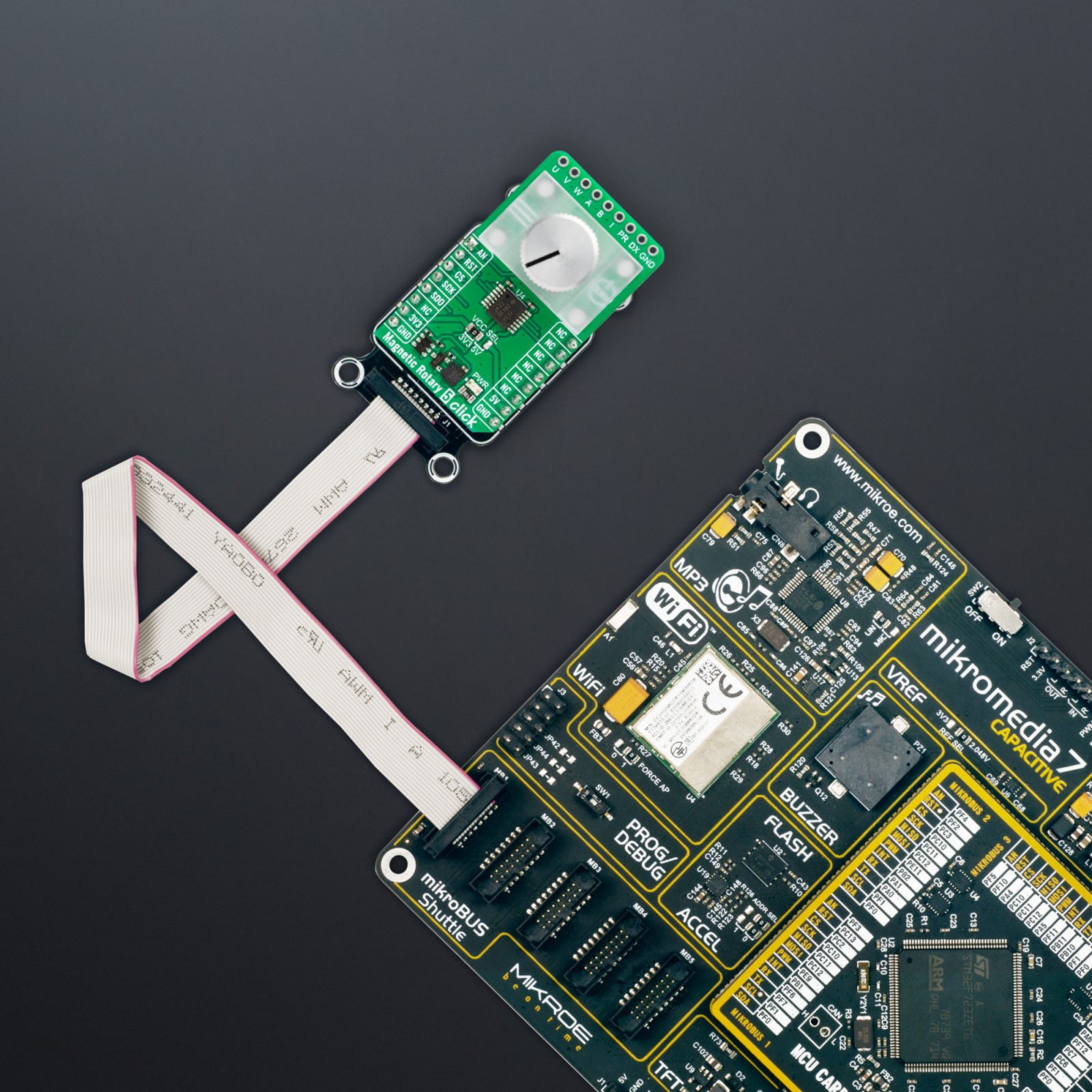

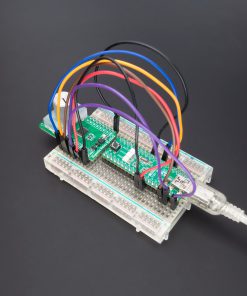

Magnetic Rotary 5 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R503.50 |

| 10+ | R477.00 |

| 15+ | R450.50 |

| 20+ | R433.54 |

.jpg)