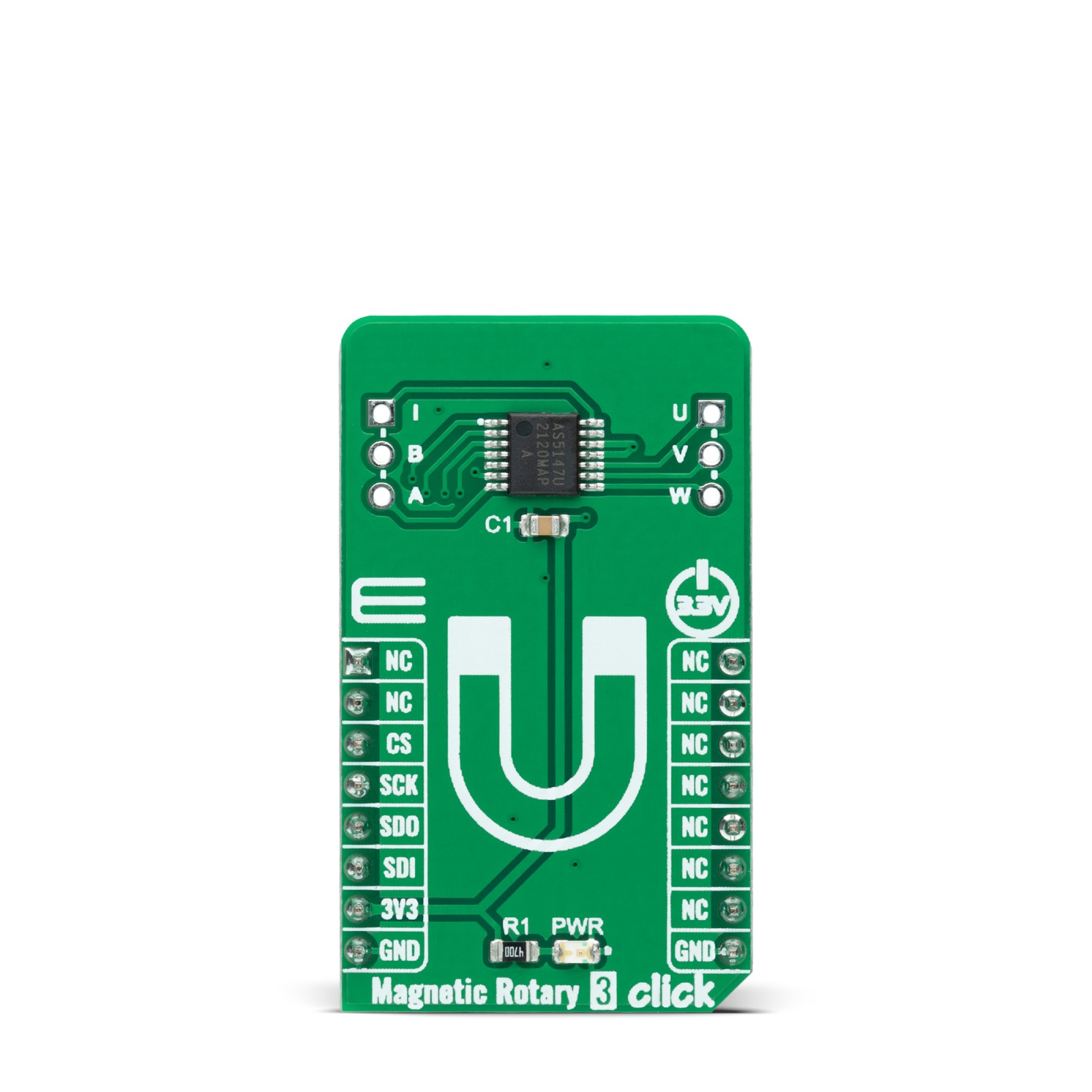

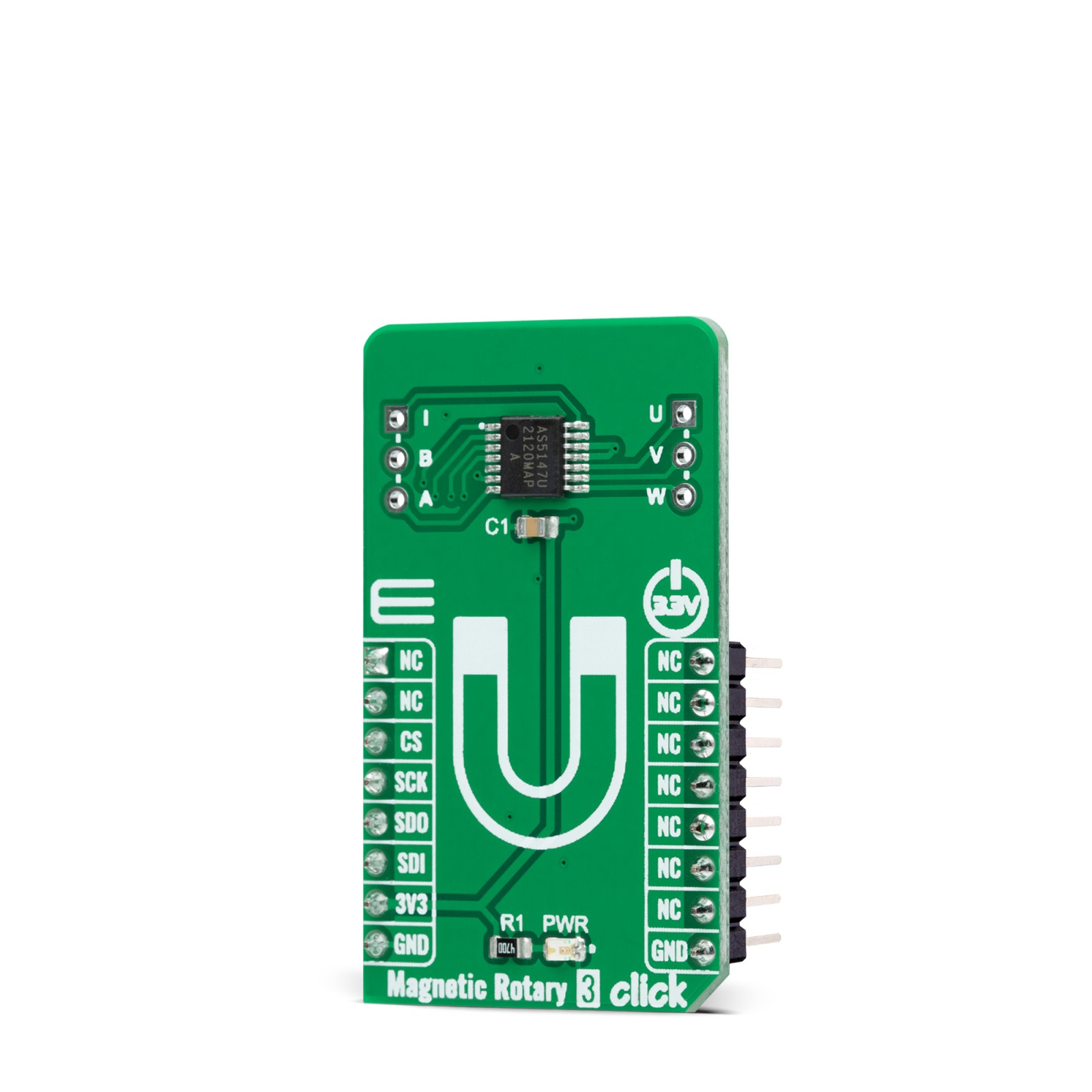

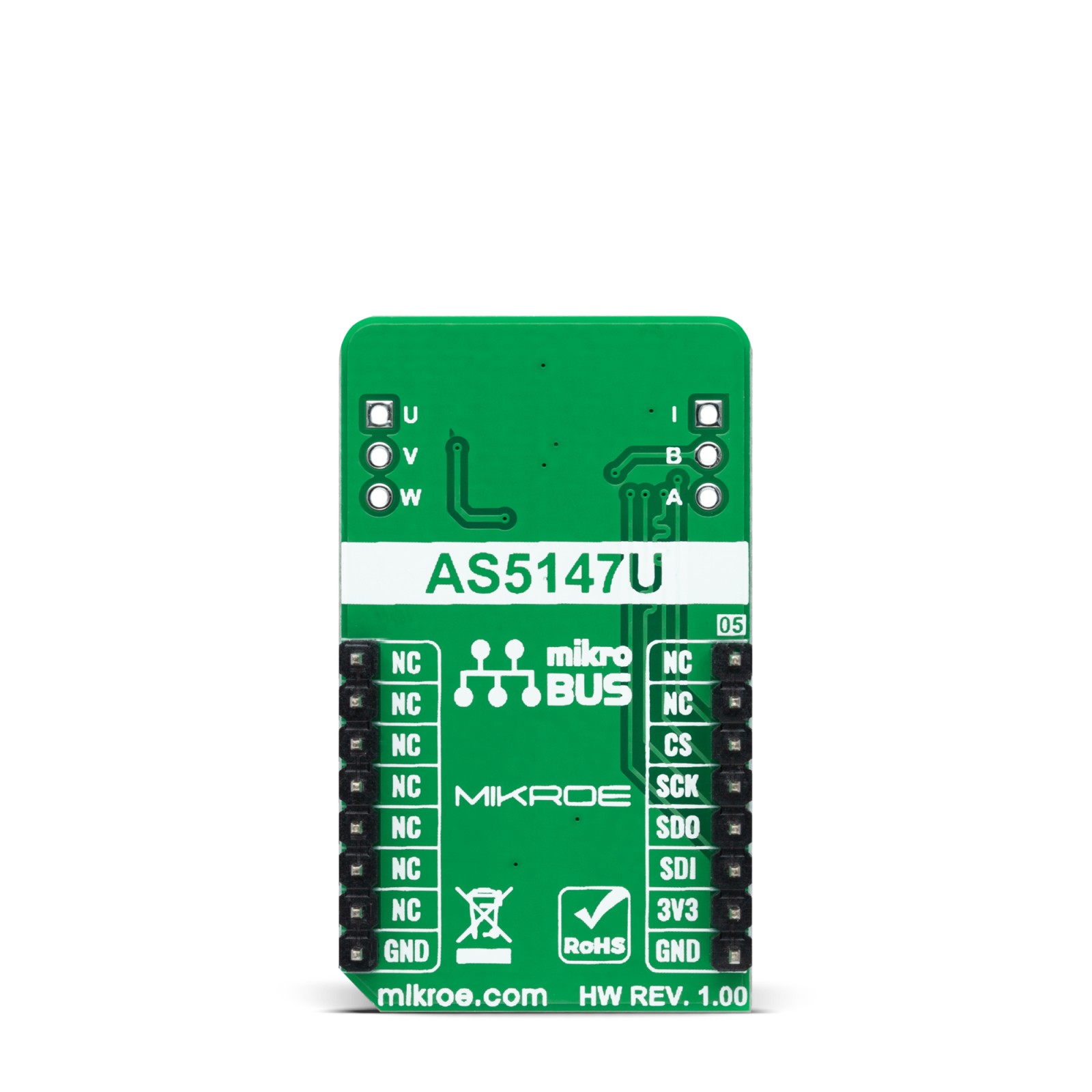

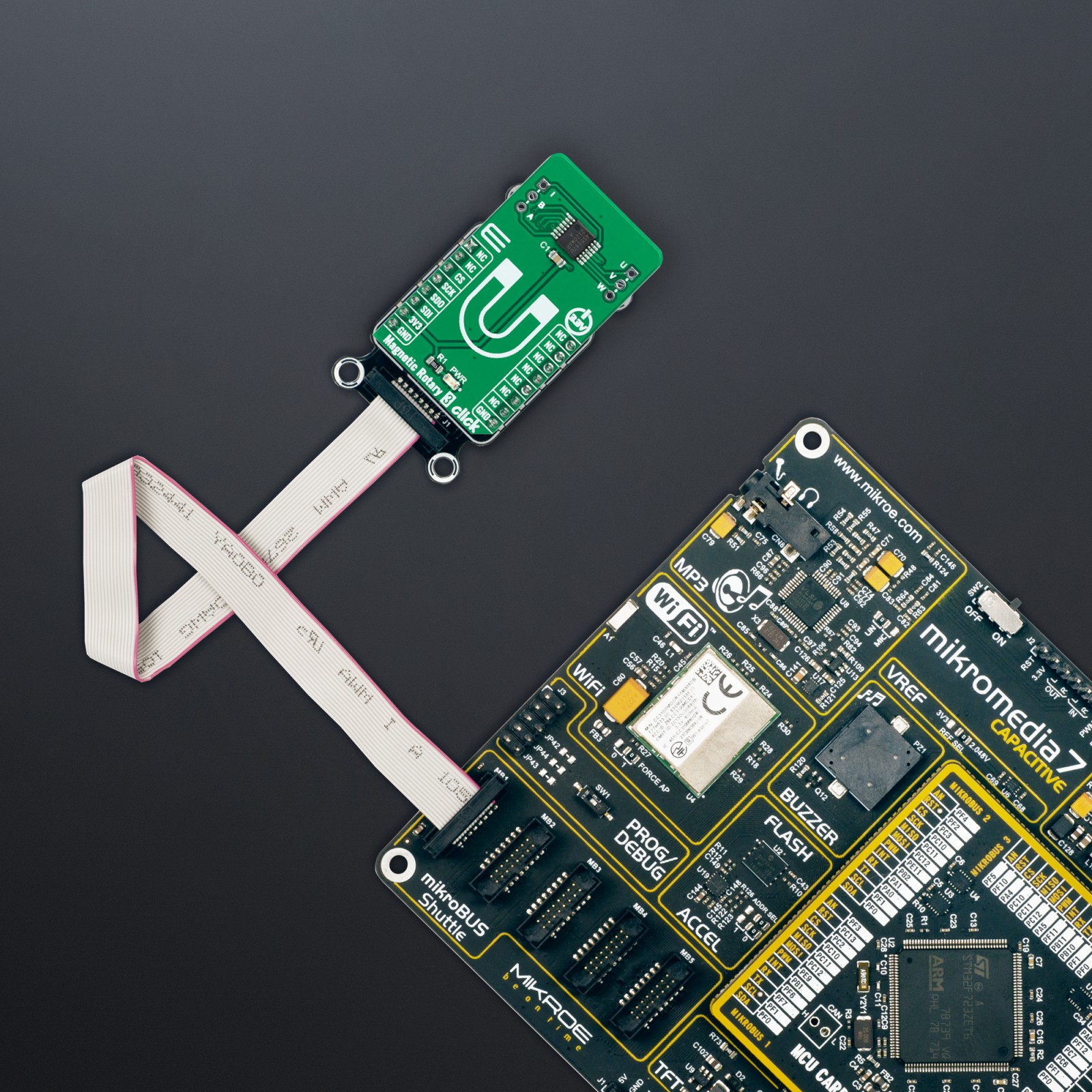

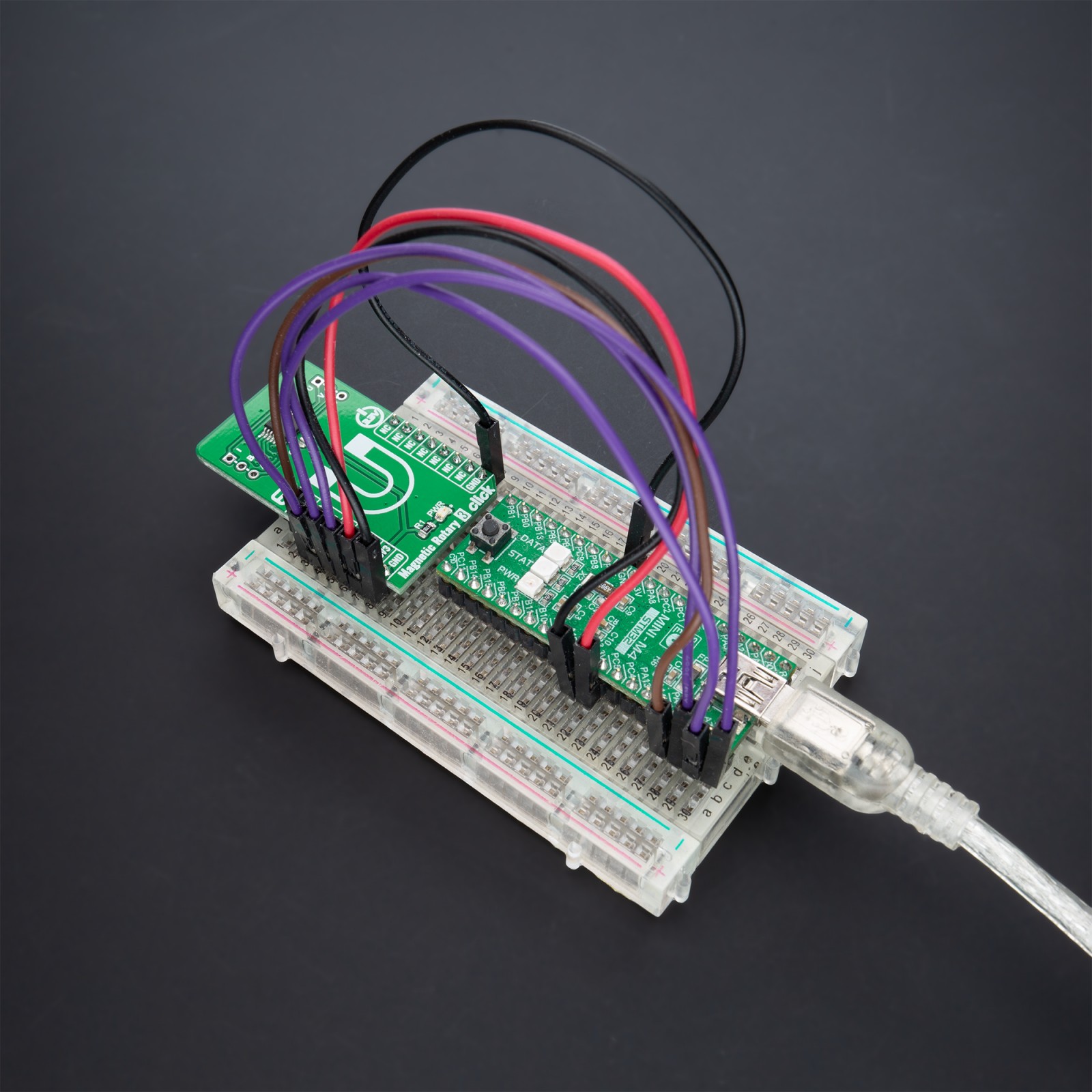

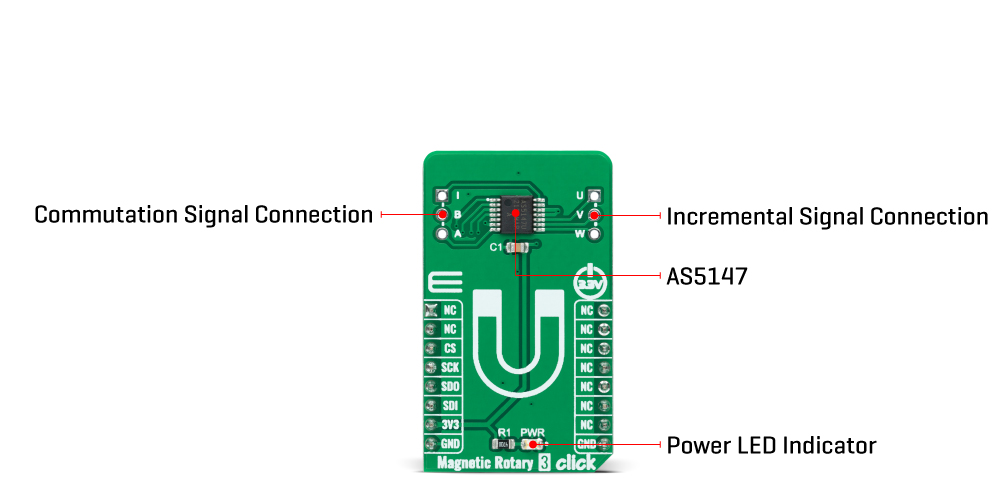

Magnetic Rotary 3 Click is a compact add-on board for accurate magnet-position sensing. This board features the AS5147U, an SPI-configurable high-resolution rotary position sensor for fast absolute angle measurement over a full 360-degree range from ams AG. The AS5147U position sensor suppresses the influence of any homogenous external stray magnetic field, equipped with a revolutionary integrated dynamic angle error compensation (DAEC™) with almost zero latency. It also comes with onboard headers reserved for incremental and commutation signals of their respective A/B/I and U/V/W signals alongside embedded self-diagnostics, including magnetic field strength too high, magnetic field strength too low or lost magnet, and other related diagnostic features. This Click board™ has been designed to support BLDC motor commutation for the most challenging automotive applications.

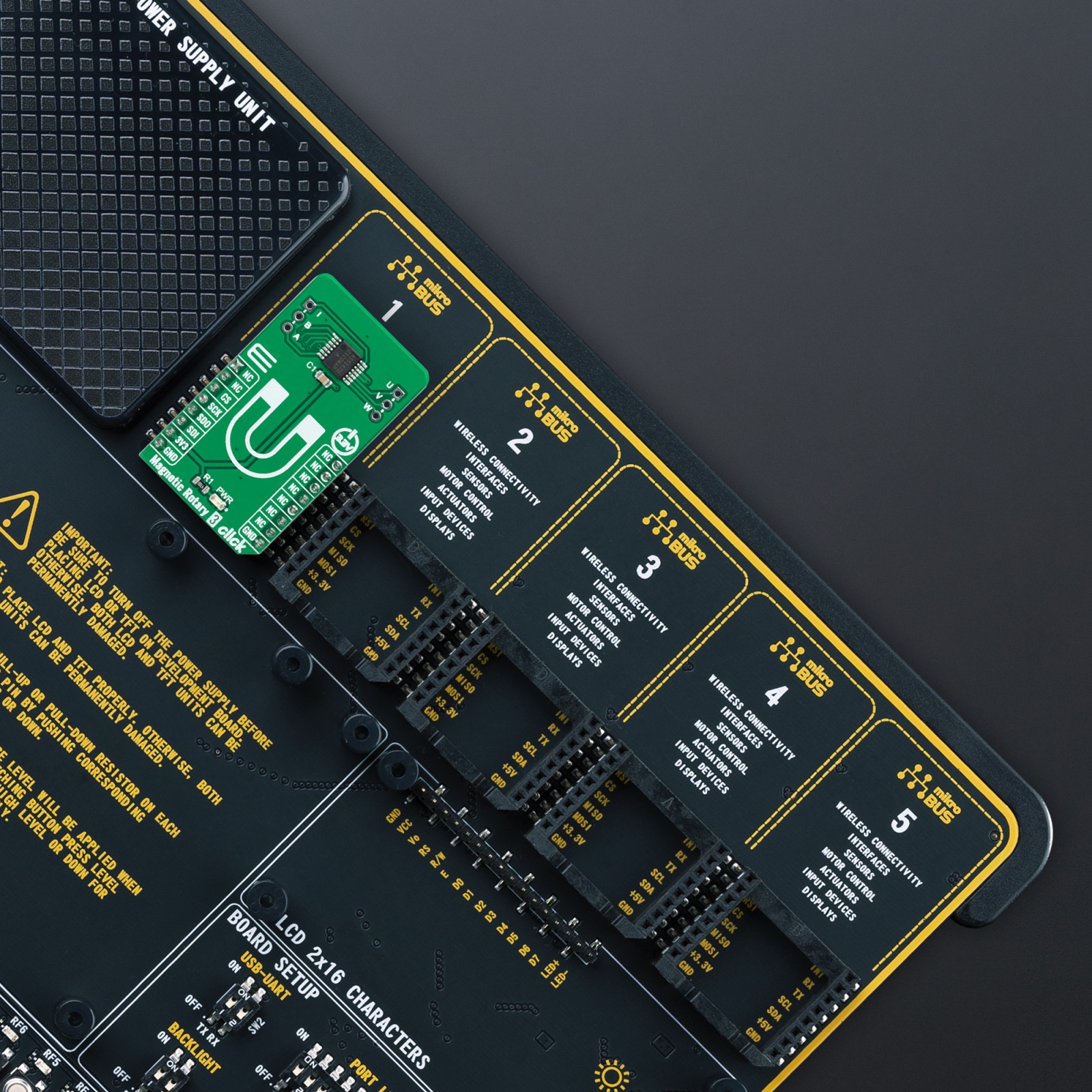

Magnetic Rotary 3 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

DAC Click

1 × R385.00

DAC Click

1 × R385.00  GPS Click

1 × R1,000.00

GPS Click

1 × R1,000.00  RN4678 Click

1 × R800.00

RN4678 Click

1 × R800.00  Alcohol Click

1 × R315.00

Alcohol Click

1 × R315.00