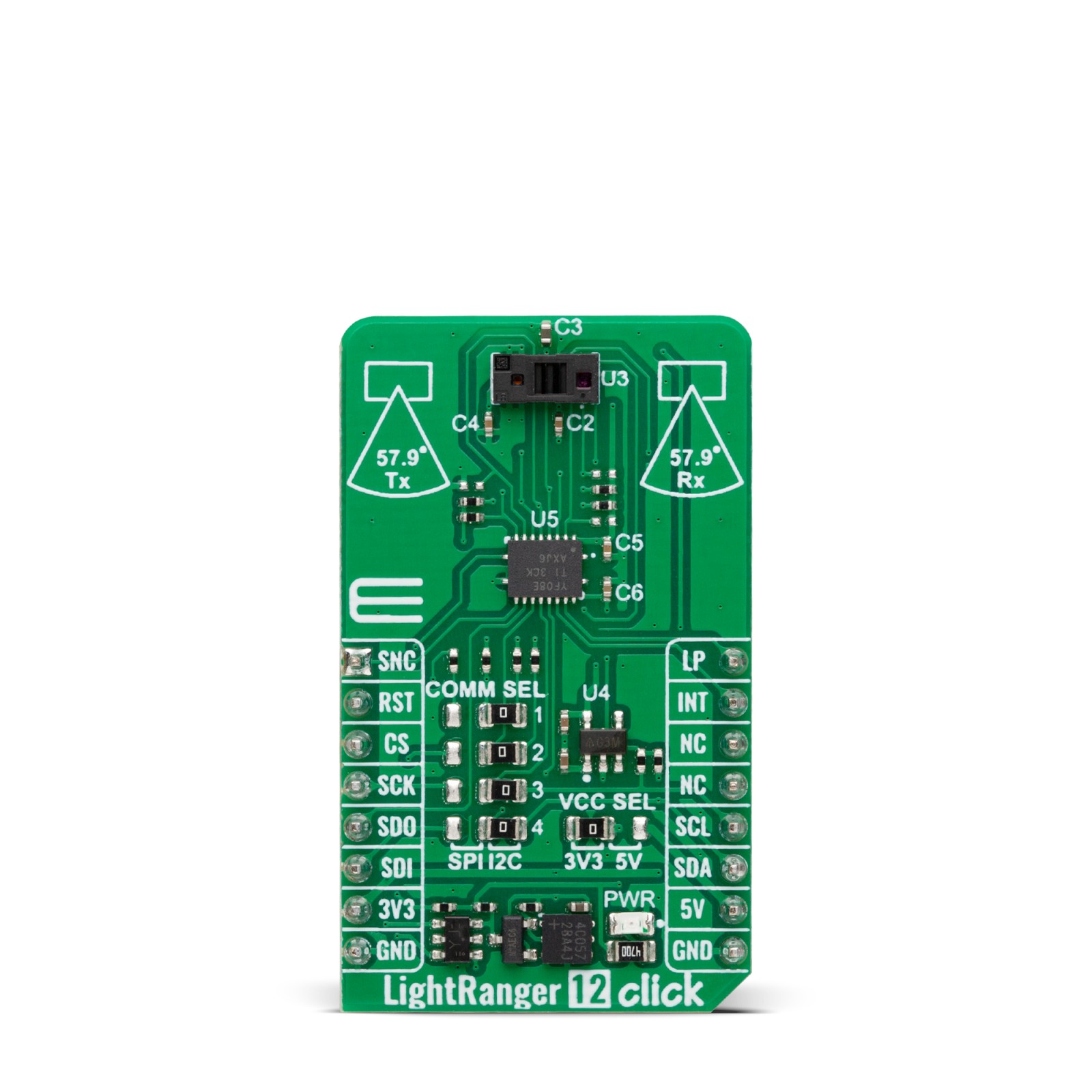

LightRanger 12 Click

R620.00 ex. VAT

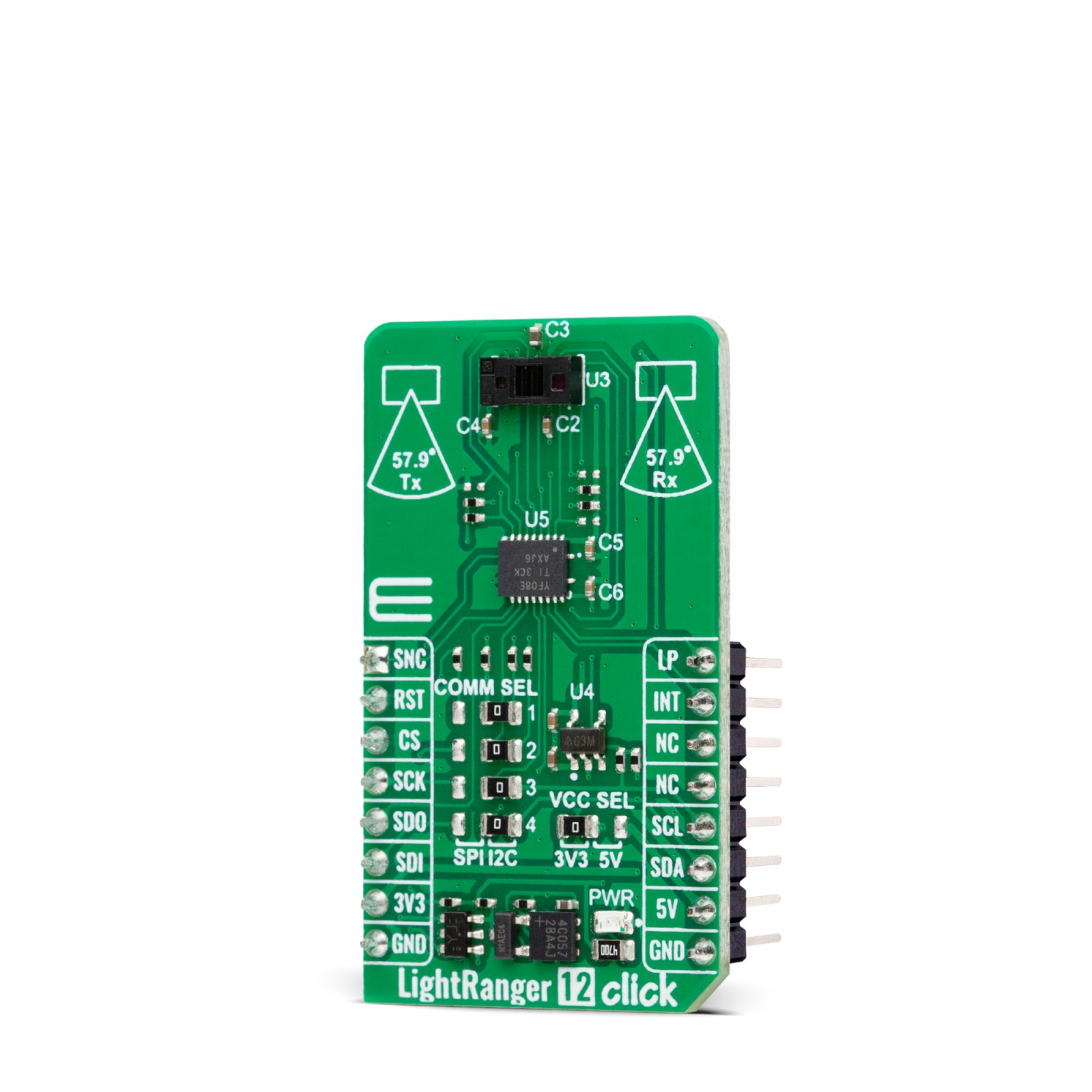

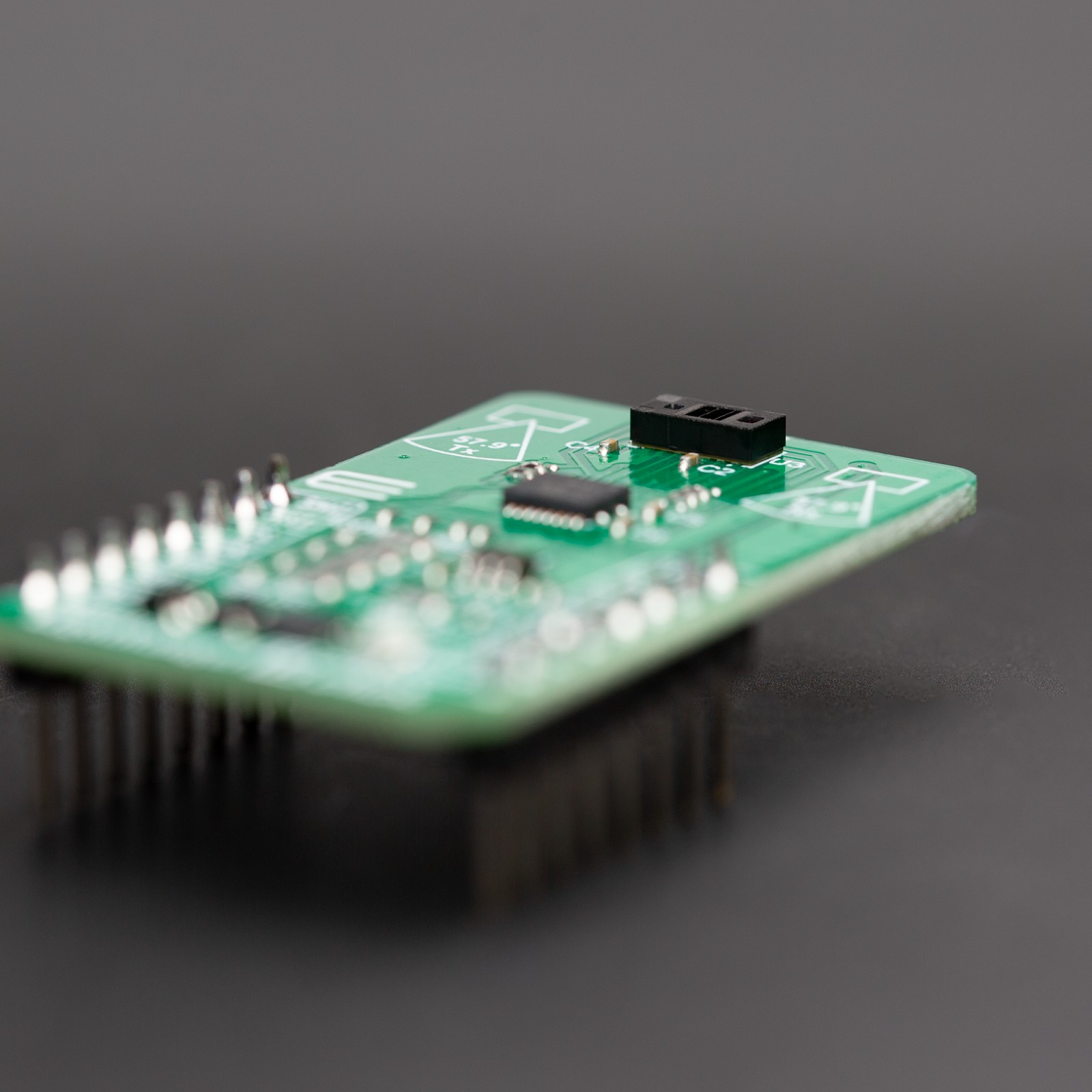

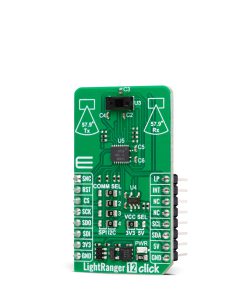

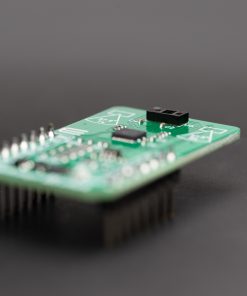

LightRanger 12 Click is a compact add-on board for precise distance measurement and spatial mapping applications. This board features the VL53L8CH, an 8×8 multizone Time-of-Flight (ToF) sensor from STMicroelectronics, made for AI-driven solutions. The board features a wide 65° diagonal field of view, supports up to 64 configurable zones, and transmits raw histogram data alongside standard ToF outputs like distance and reflectance, offering flexibility and high performance. Additionally, it integrates a Class 1 certified 940 nm VCSEL and advanced metasurface lenses, ensuring safety and optimal optical capabilities. This Click board™ is ideal for AI applications, including robotics, coffee machines, smart homes, and advanced recognition systems.

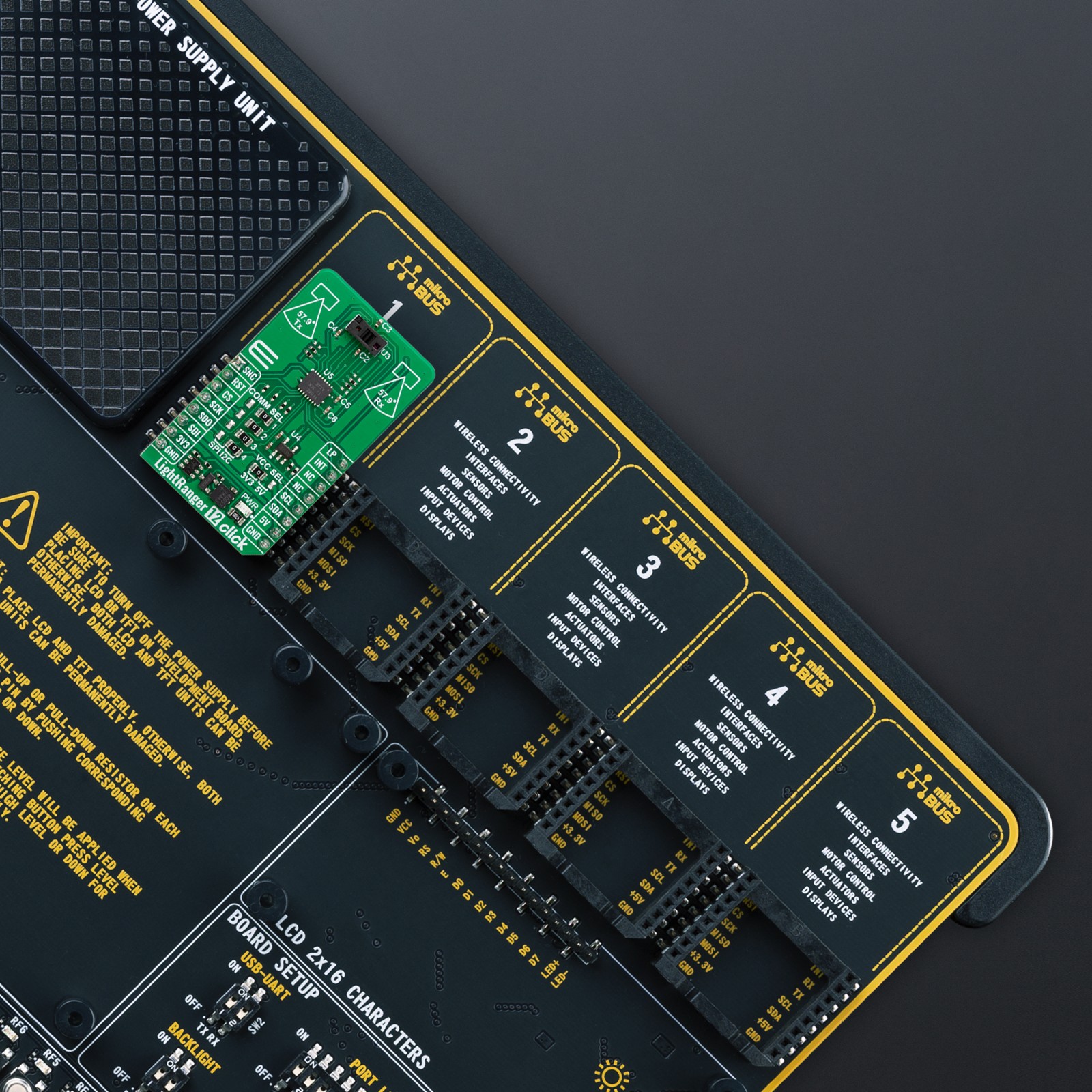

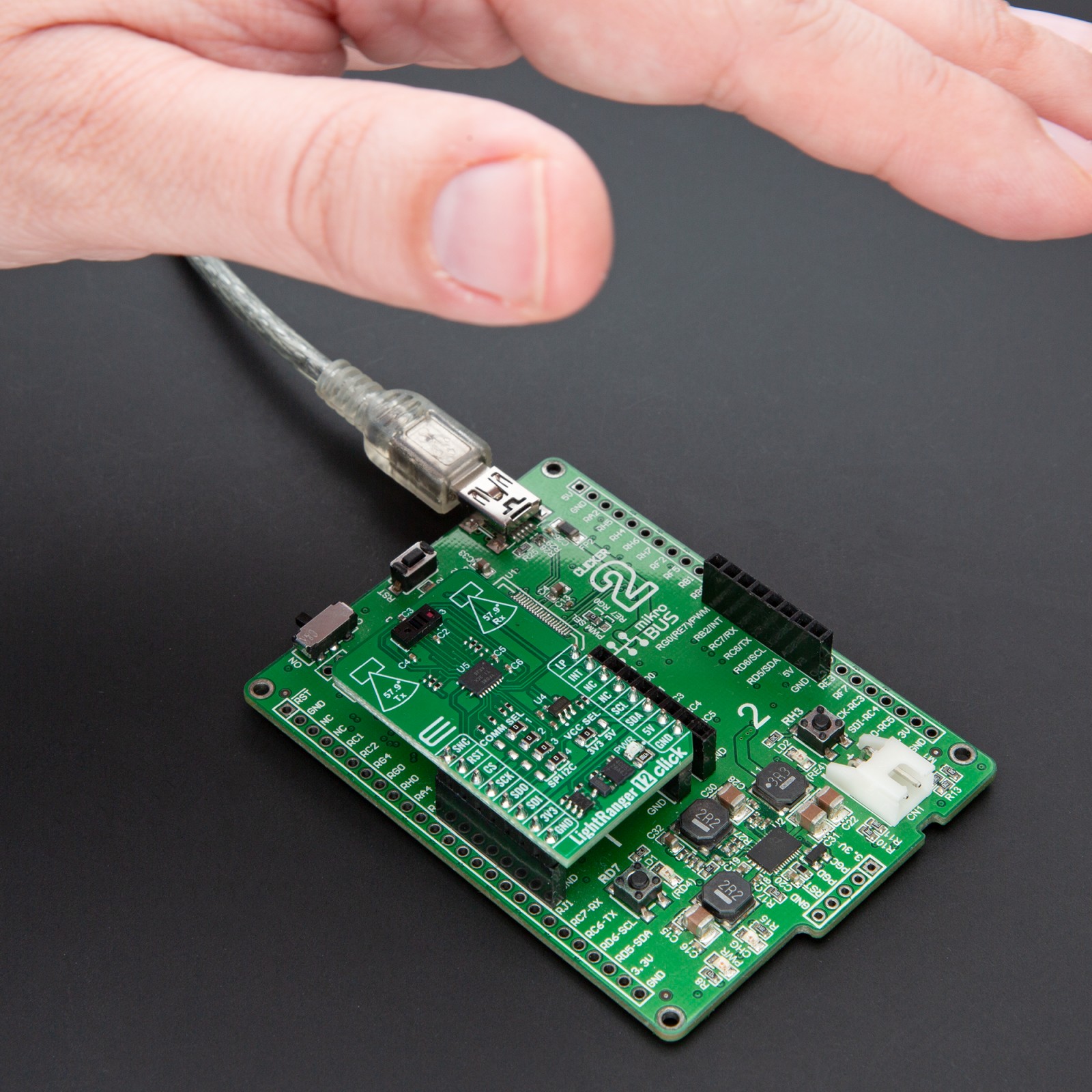

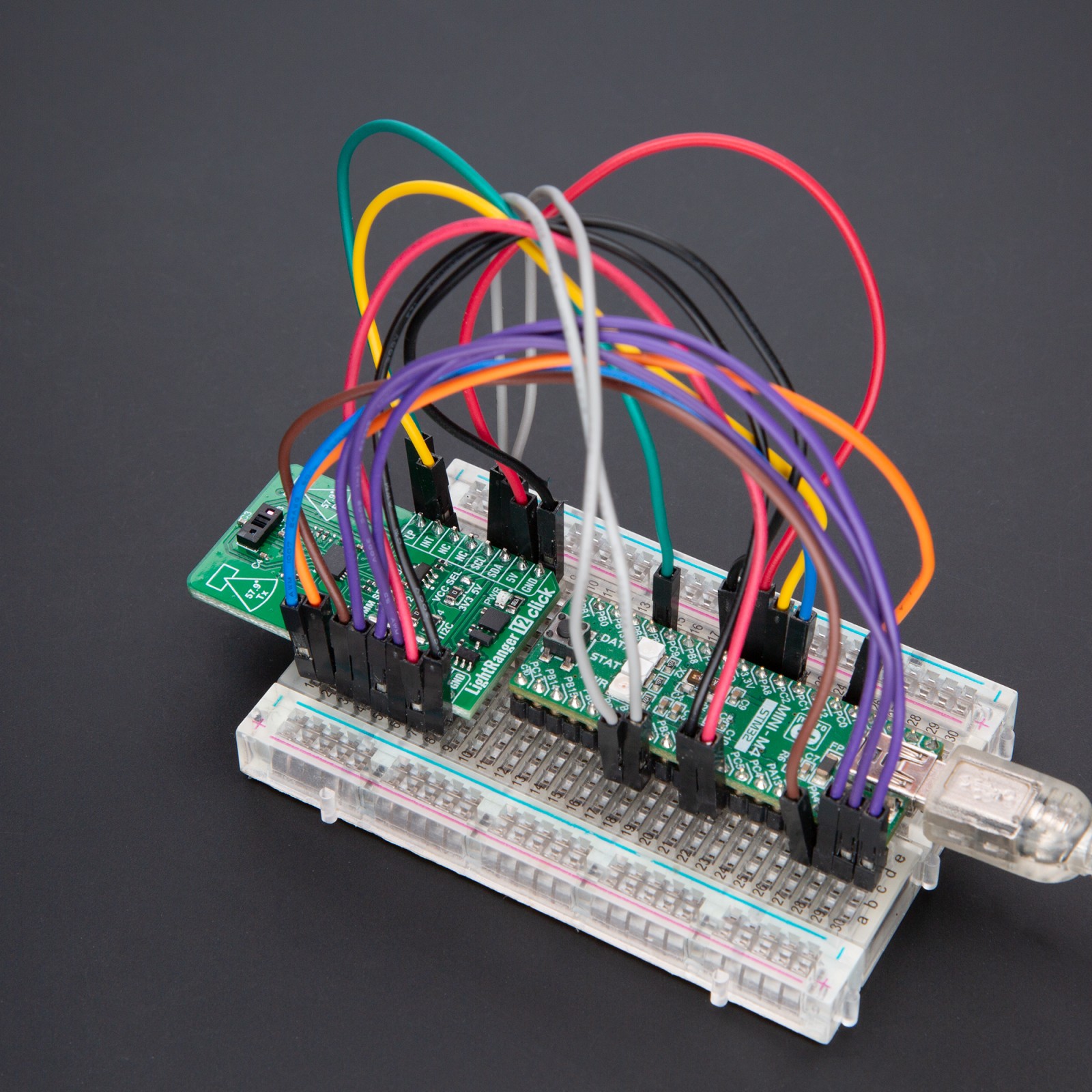

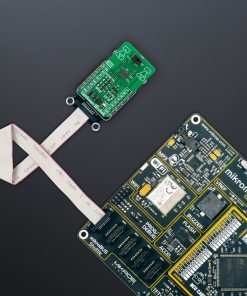

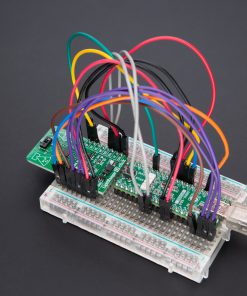

LightRanger 12 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R589.00 |

| 10+ | R558.00 |

| 15+ | R527.00 |

| 20+ | R507.16 |