LDC1000 Click

R770.00 ex. VAT

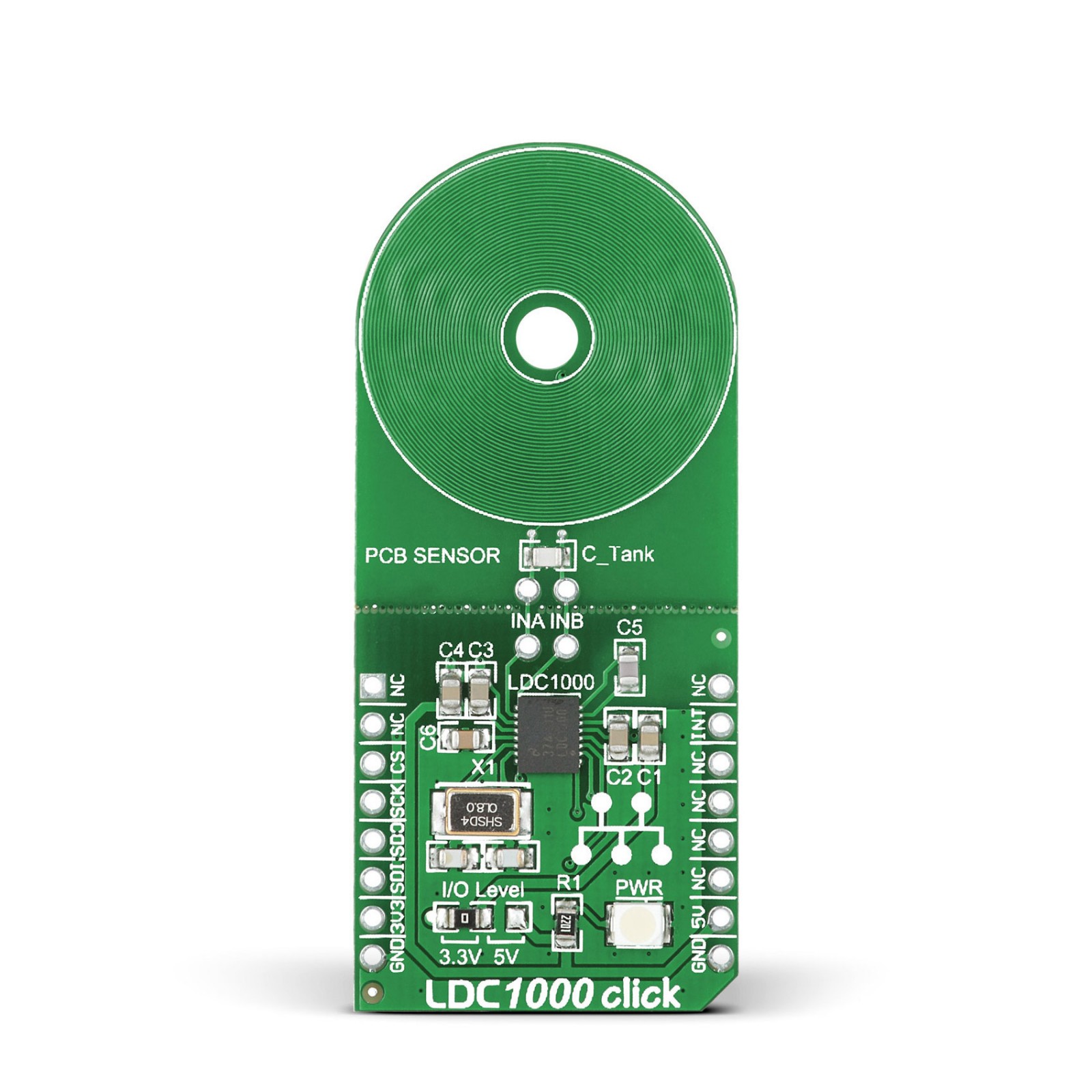

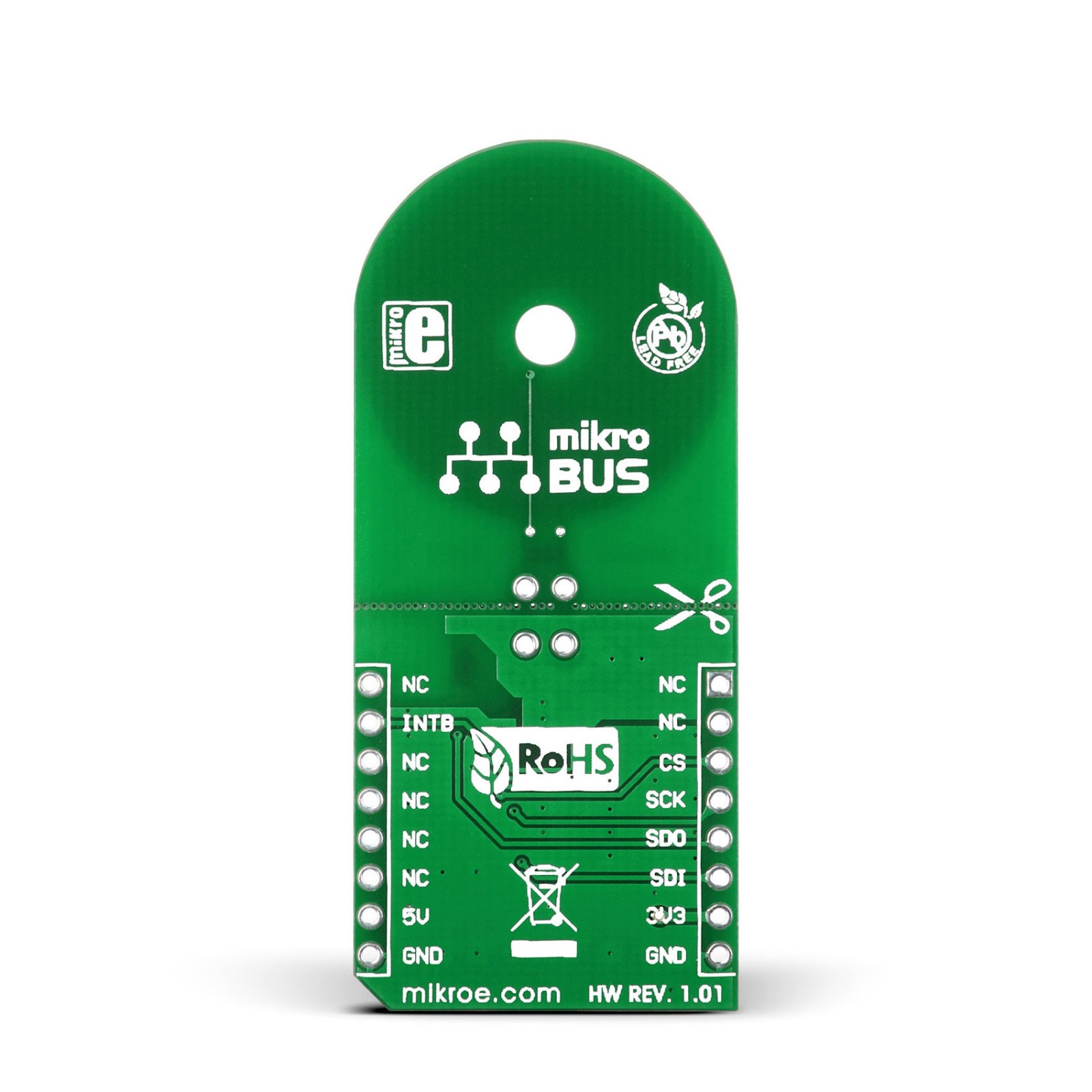

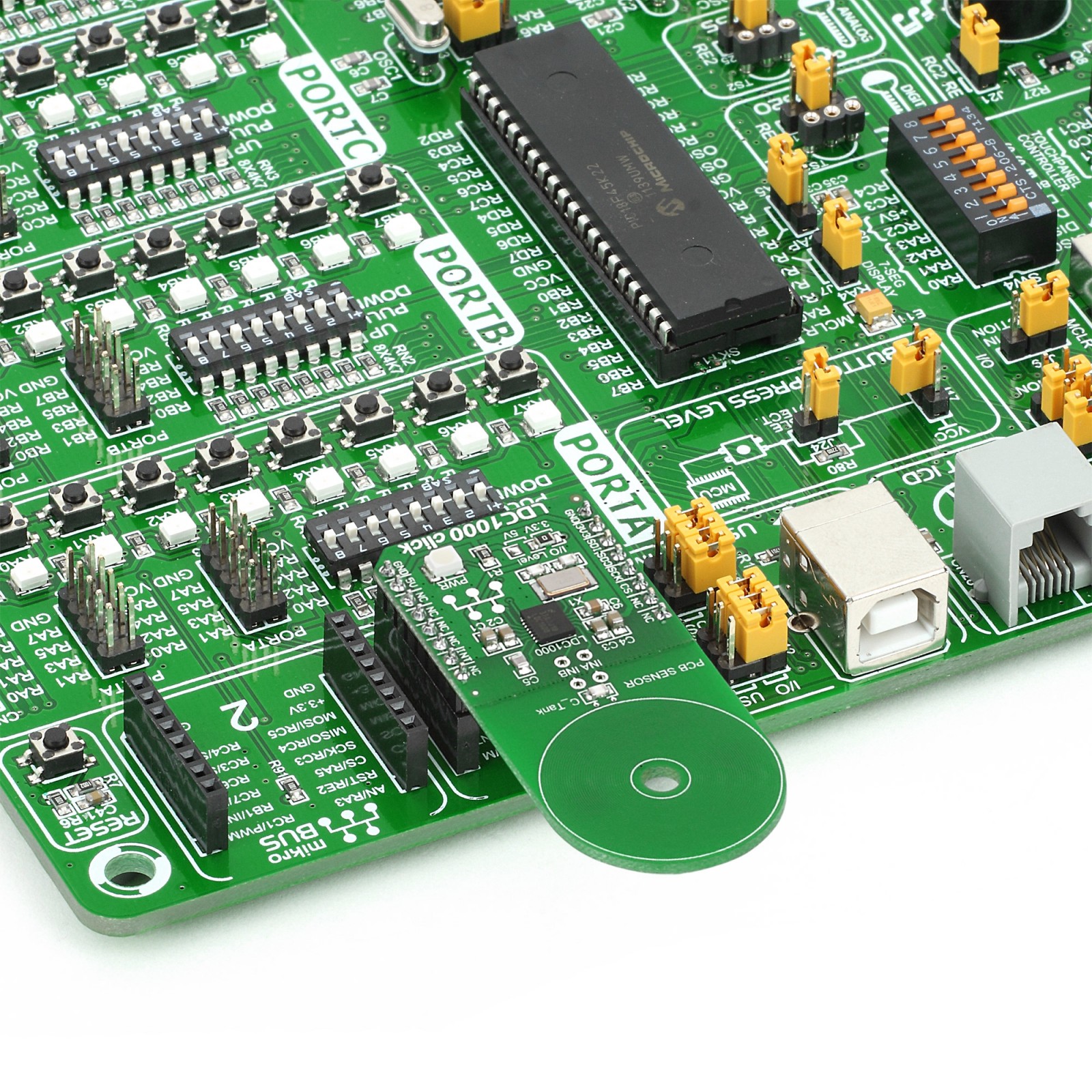

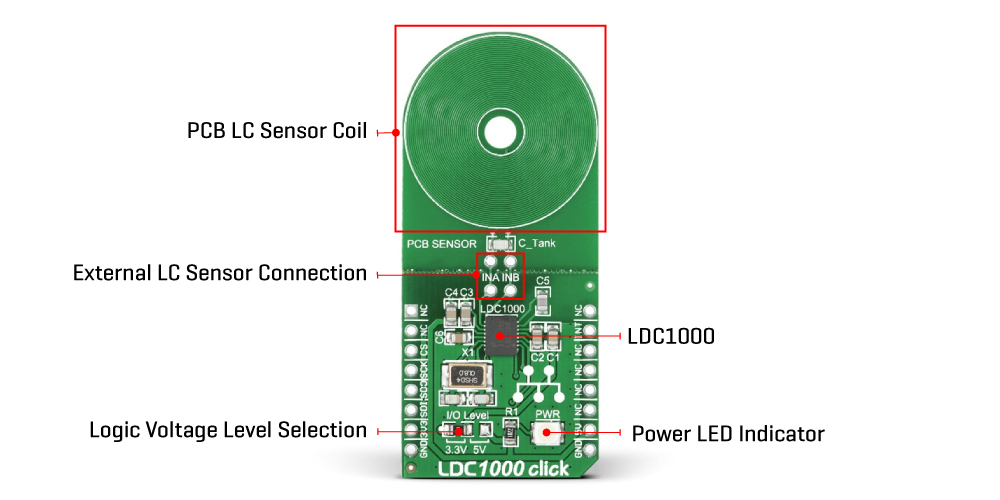

LDC1000 Click is a compact add-on board that measures the inductance change a conductive target causes when it moves into the inductor’s AC magnetic field. This board features the LDC1000, a low-power inductance-to-digital converter (LDC) for inductive sensing solutions from Texas Instruments. This SPI-configurable sensor requires only the frequency between 5kHz and 5MHz to begin sensing, demonstrating the use of inductive sensing technology to sense and measure a conductive target object’s presence, position, or composition. It comes with an example of a PCB sensor coil designed to provide the user with maximum flexibility. Also, onboard IN pins allow you to replace the offered detachable sensor and solder your own. This Click board™ is suitable for contactless, short-range sensing that enables high-resolution position sensing of conductive targets, even in harsh environments.

LDC1000 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R731.50 |

| 10+ | R693.00 |

| 15+ | R654.50 |

| 20+ | R629.86 |