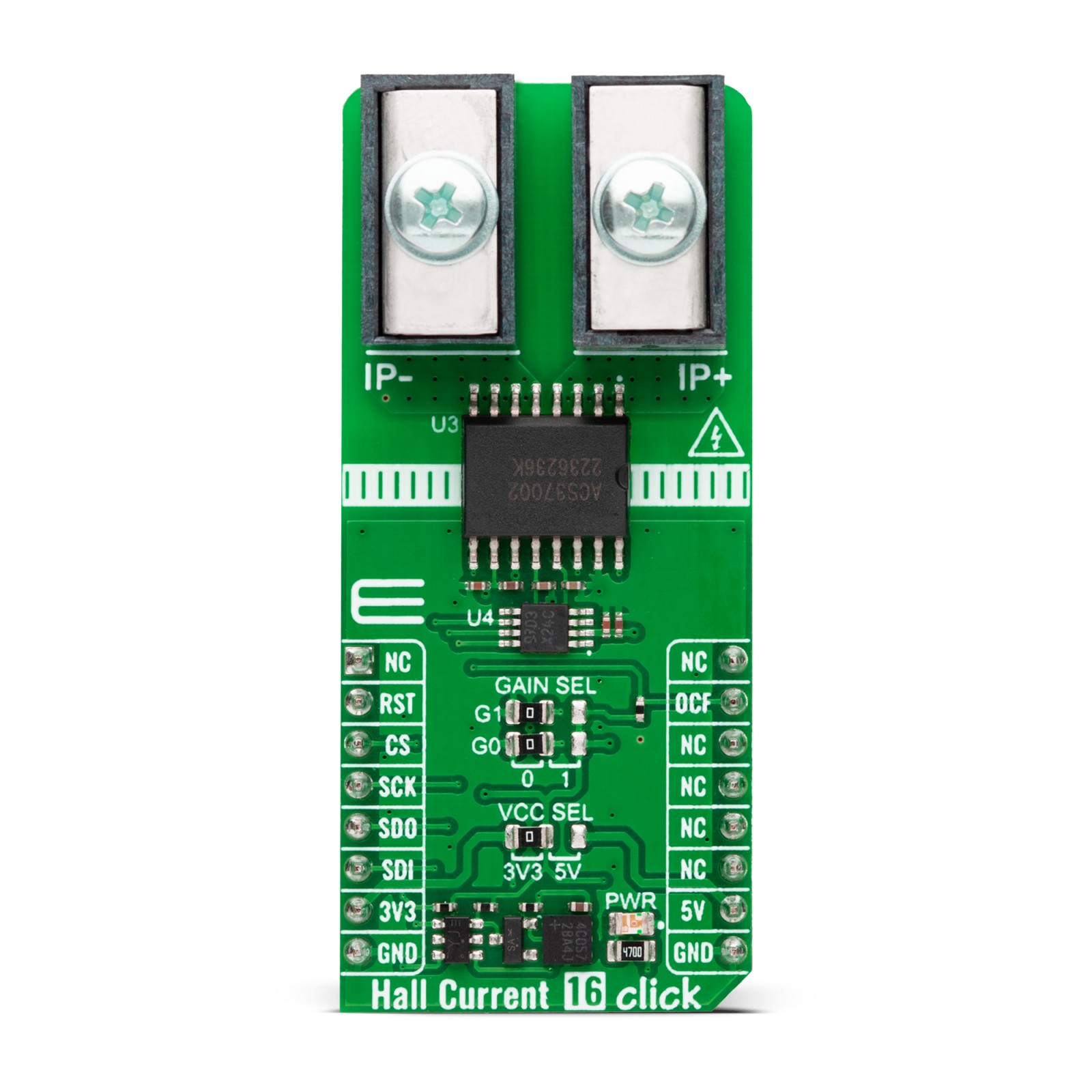

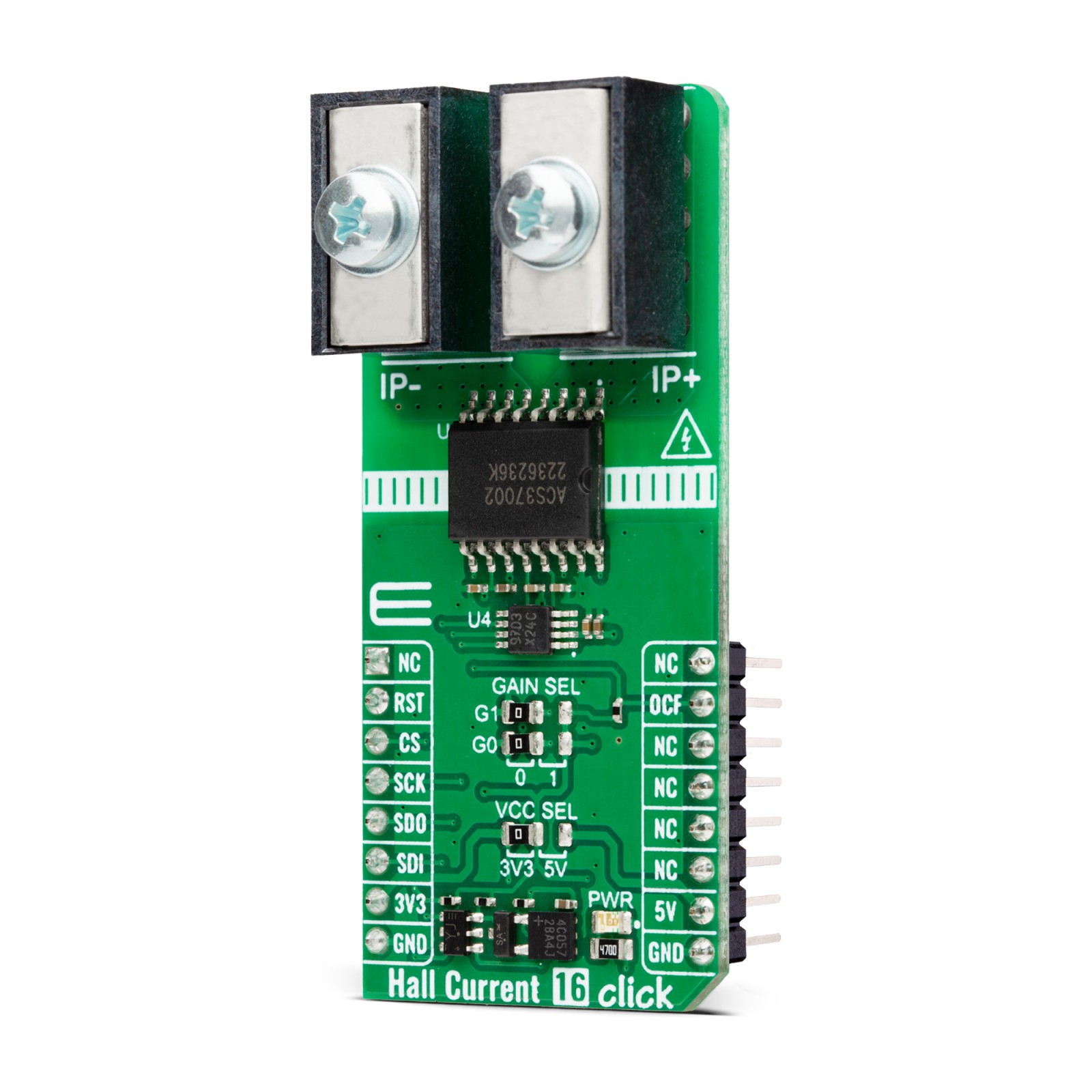

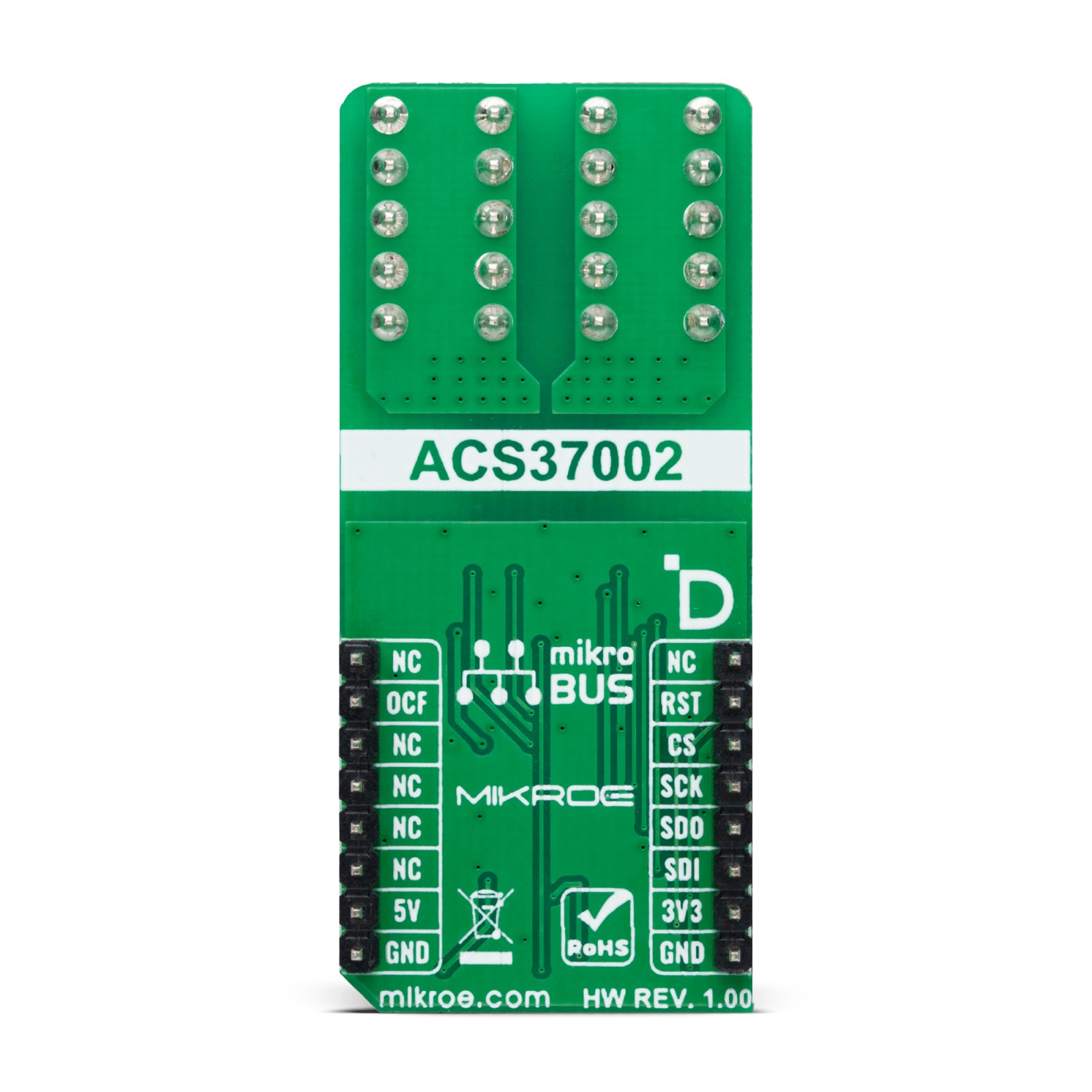

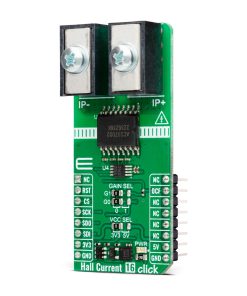

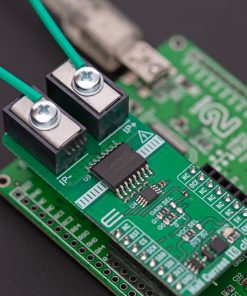

Hall Current 16 Click

R855.00 ex. VAT

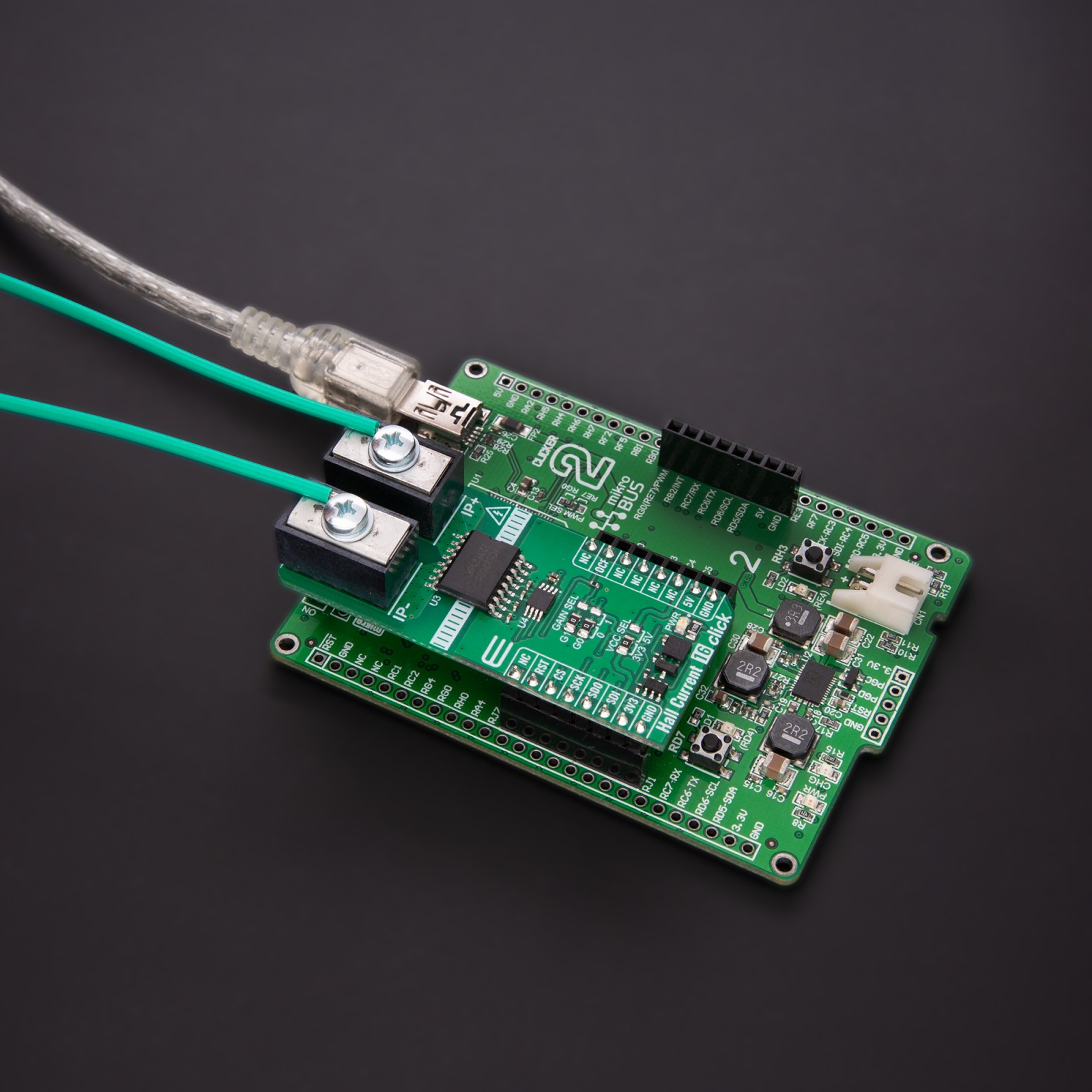

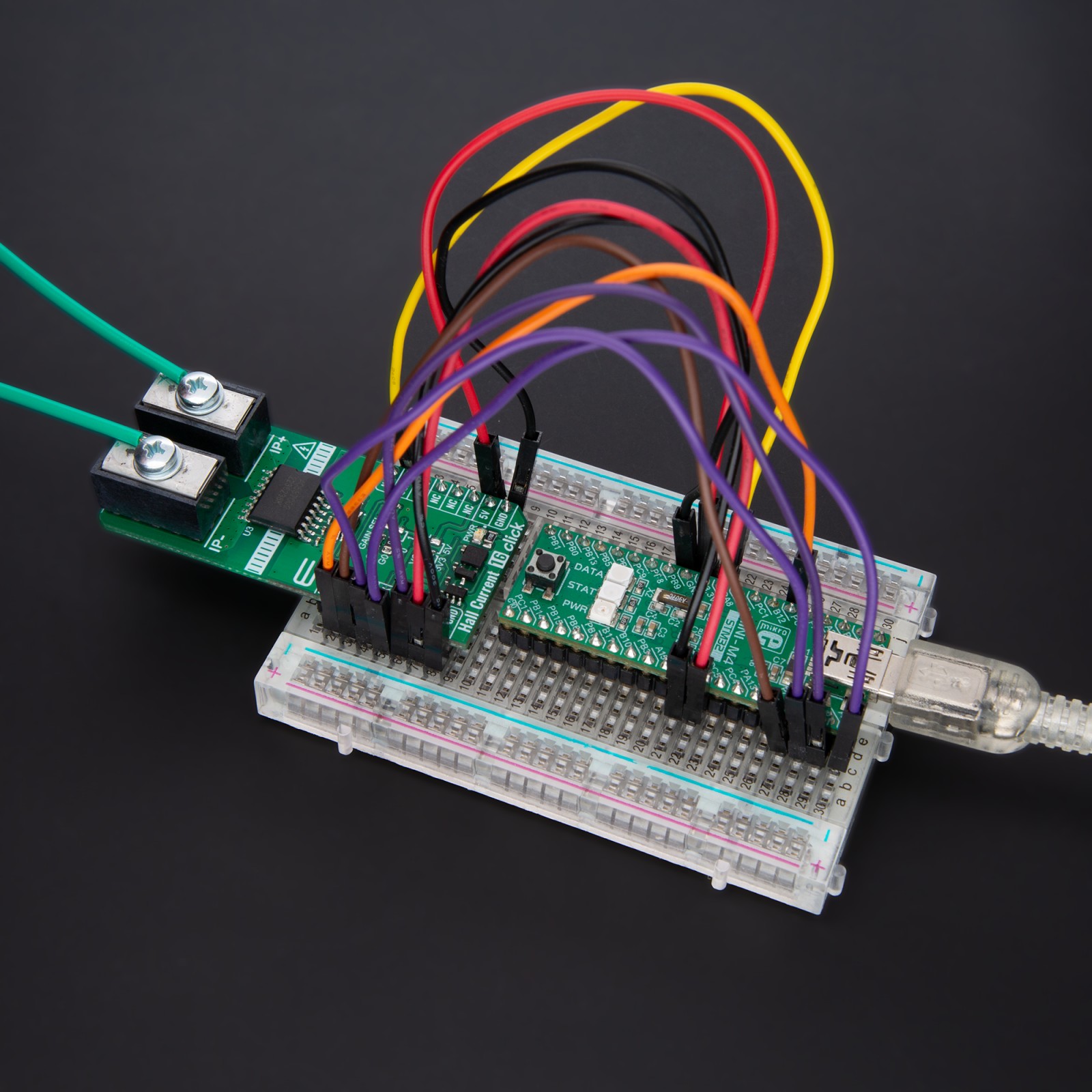

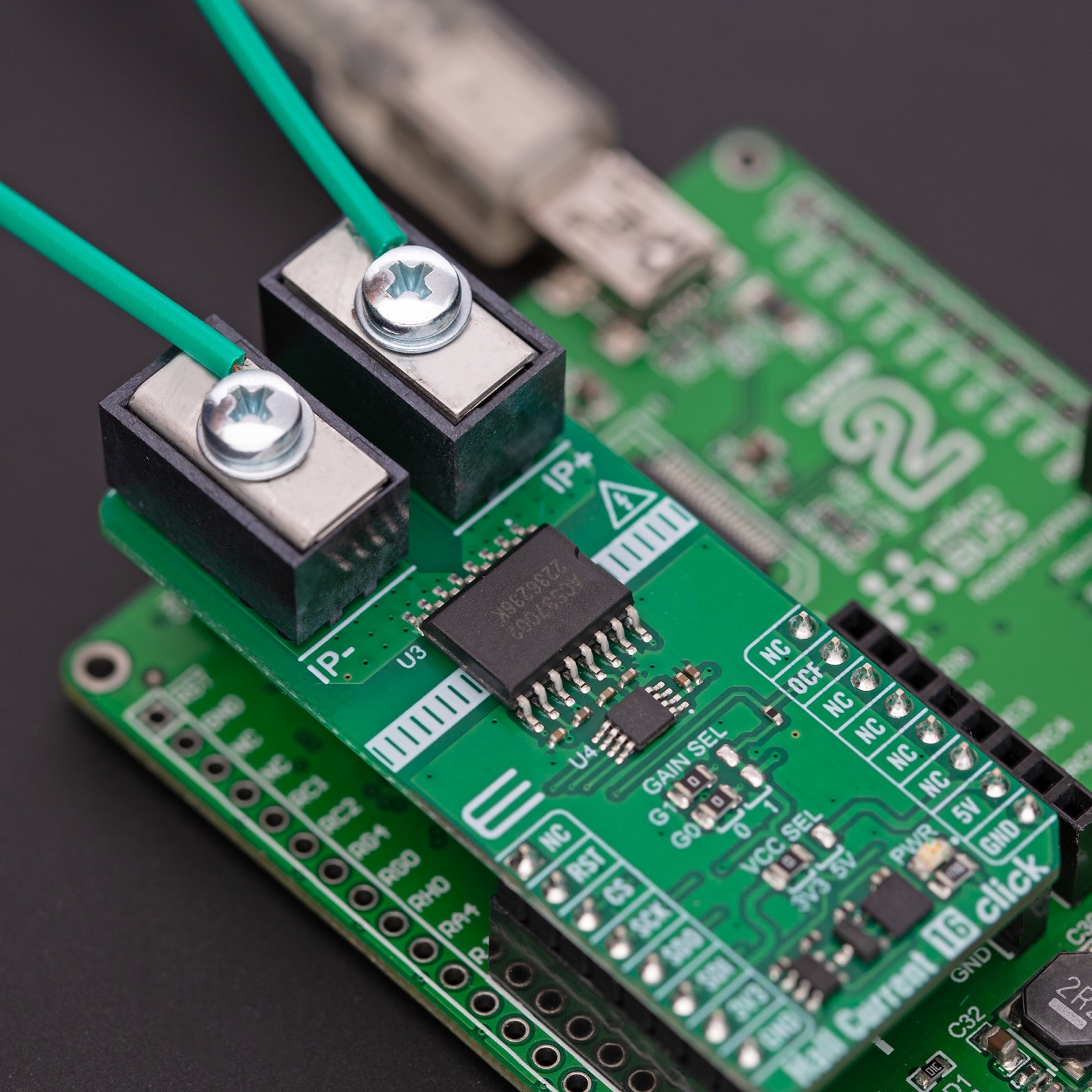

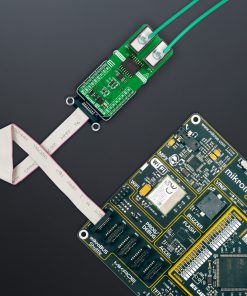

Hall Current 16 Click is a compact add-on board that contains a precise solution for AC/DC current sensing. This board features the ACS37002, a 400kHz high-accuracy current sensor from Allegro Microsystems. This sensor features pin-selectable gains that can be used to configure the device to one of the four defined sensitivities and corresponding current ranges, increasing design flexibility. In addition, an adjustable overcurrent fast fault provides short-circuit detection. This Click board™ makes the perfect solution for the development of applications requiring a combination of high-current monitoring and high isolation voltage between the primary high-current and low-voltage sides.

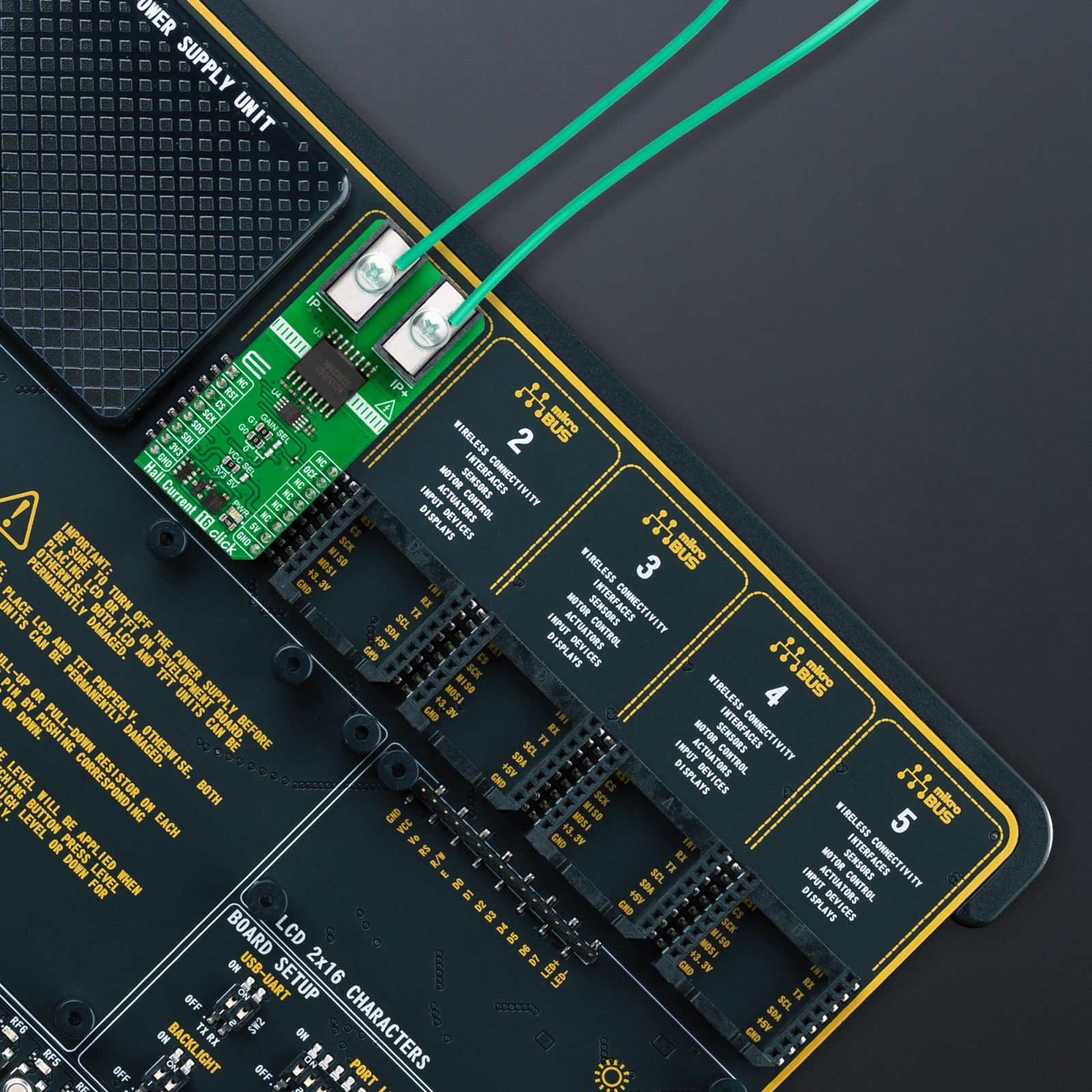

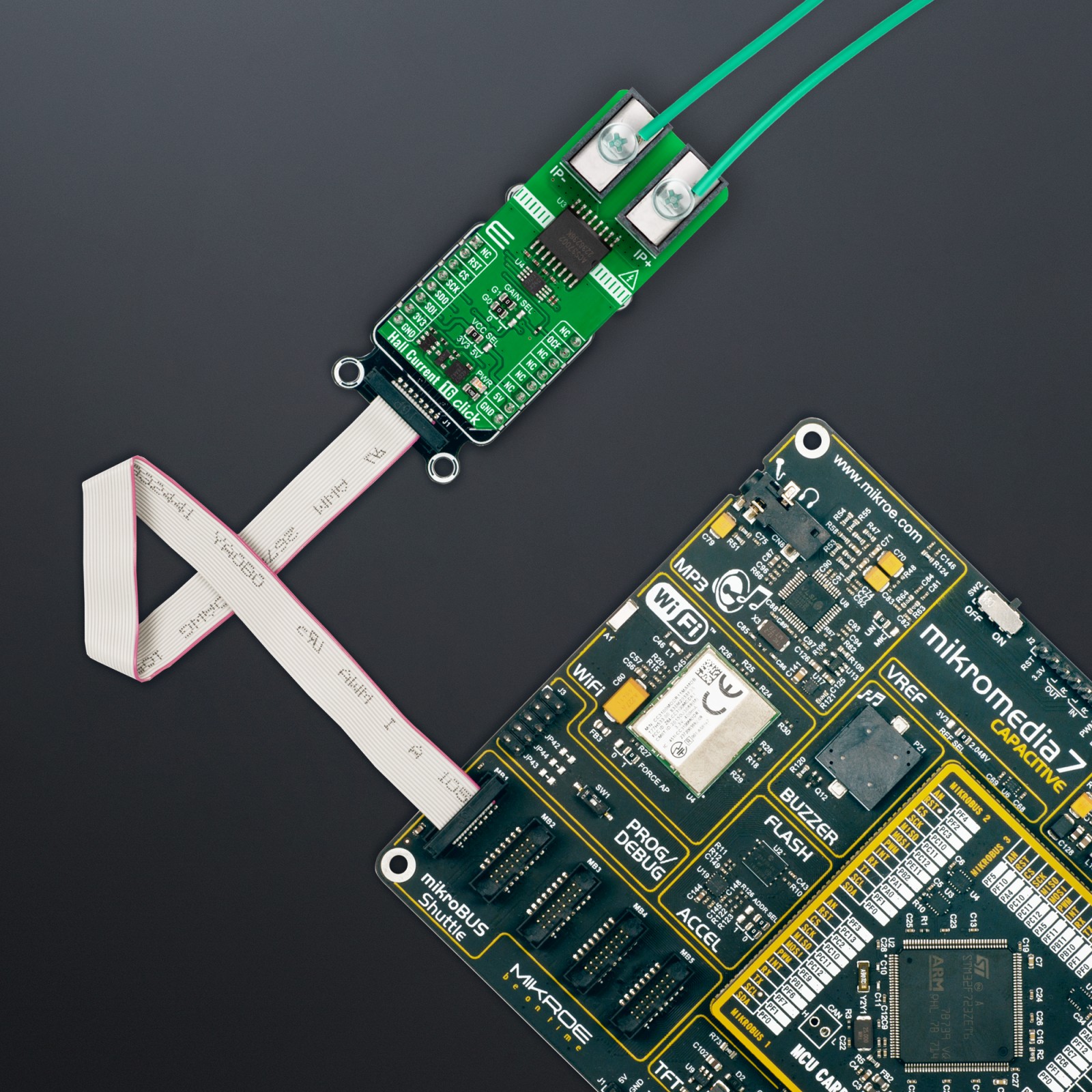

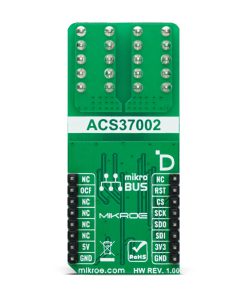

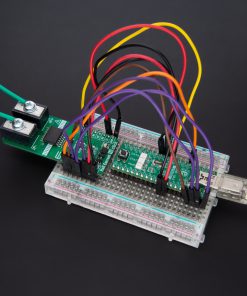

Hall Current 16 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R812.25 |

| 10+ | R769.50 |

| 15+ | R726.75 |

| 20+ | R699.39 |

DO NOT TOUCH THE BOARD WHILE THE LOAD IS CONNECTED!

DO NOT TOUCH THE BOARD WHILE THE LOAD IS CONNECTED!.jpg)