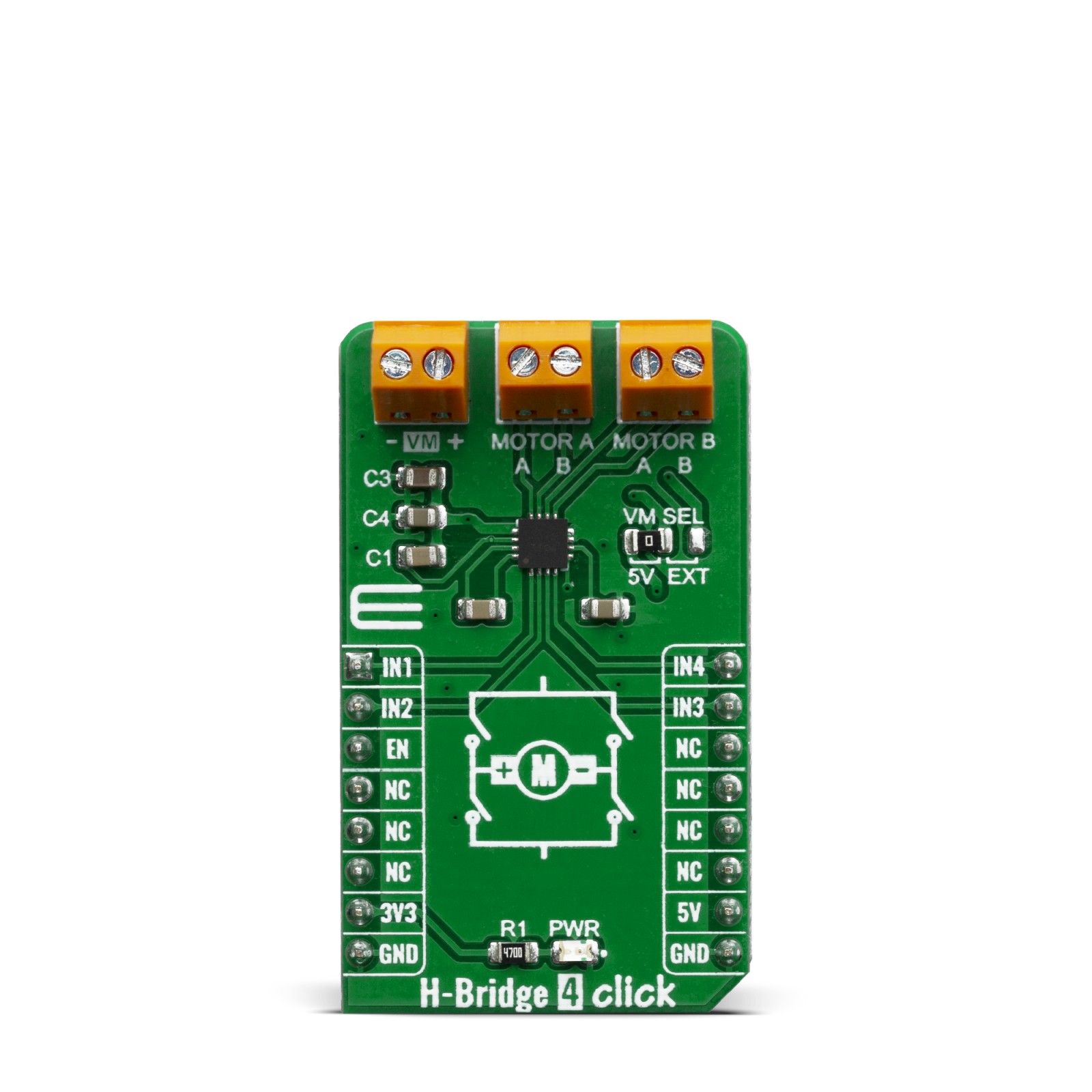

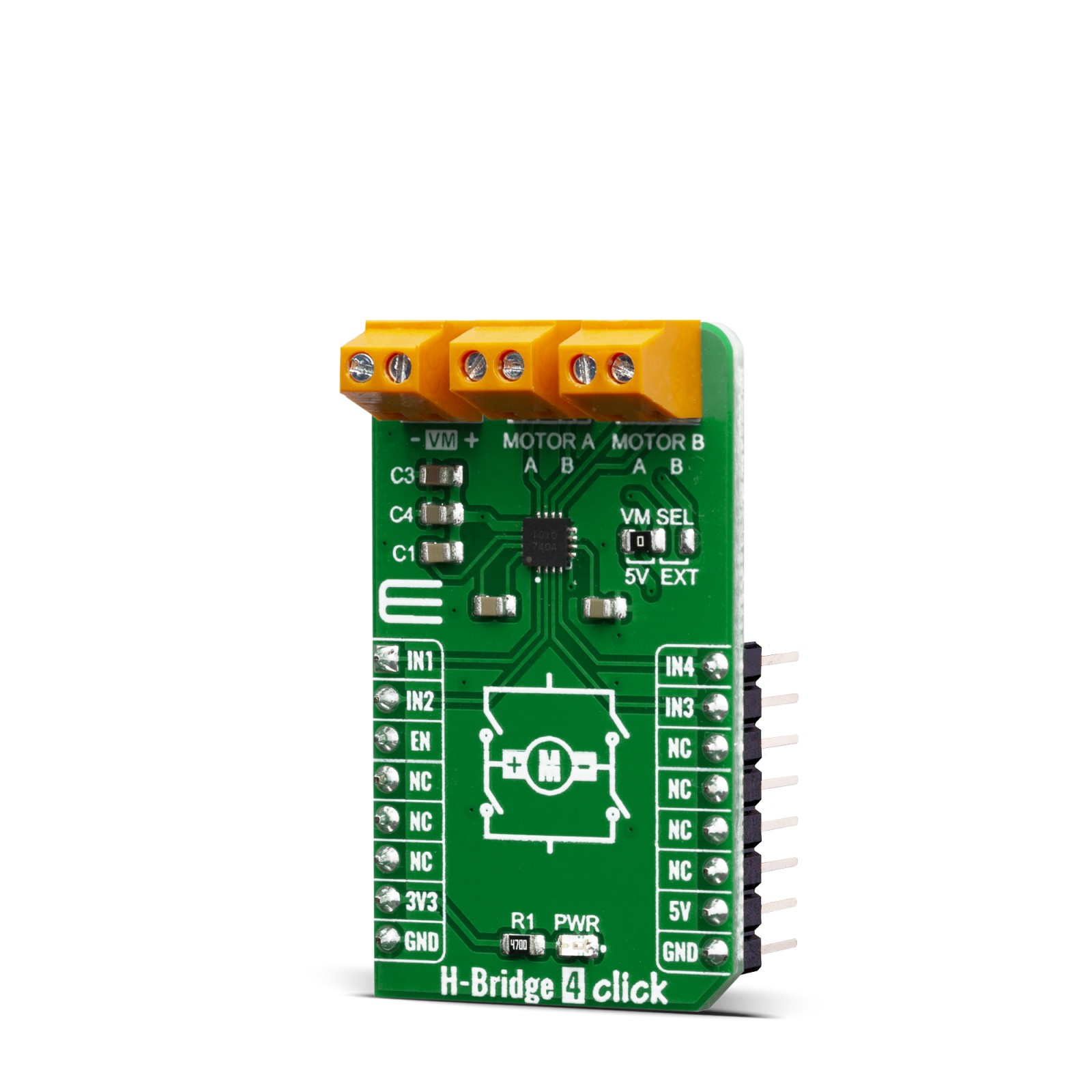

H-Bridge 4 Click

R320.00 ex. VAT

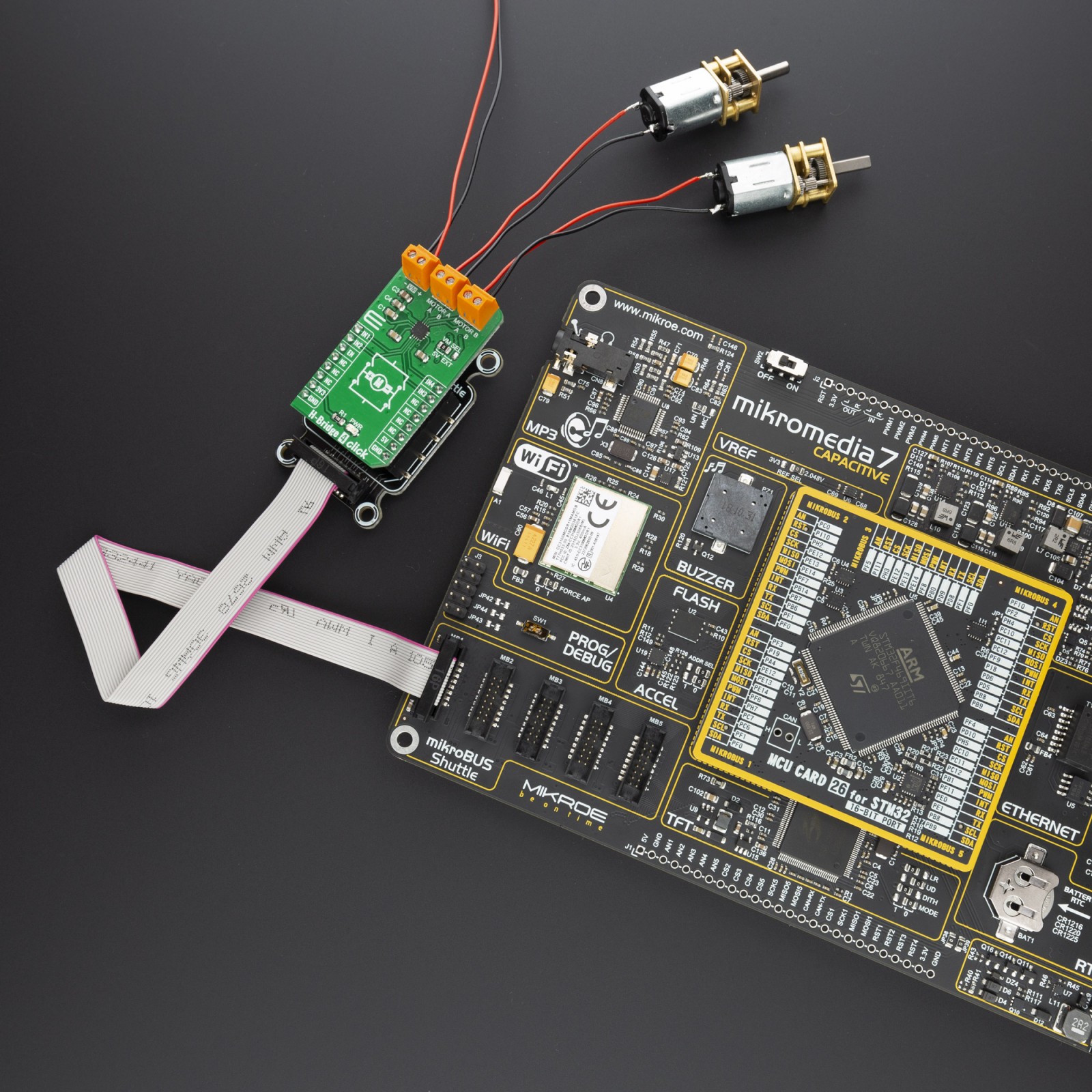

H-Bridge 4 Click is a Click board™ that contains the AP1010AEN, which is a two channel H-Bridge motor driver compatible with a motor operating voltage up to 18V and can drive two DC motors or one stepper motor. The protection circuit has under voltage lockout circuit, thermal shutdown circuit, and overcurrent protection circuit, and overcurrent protection circuit can be disabled with the DIS OCP terminal.

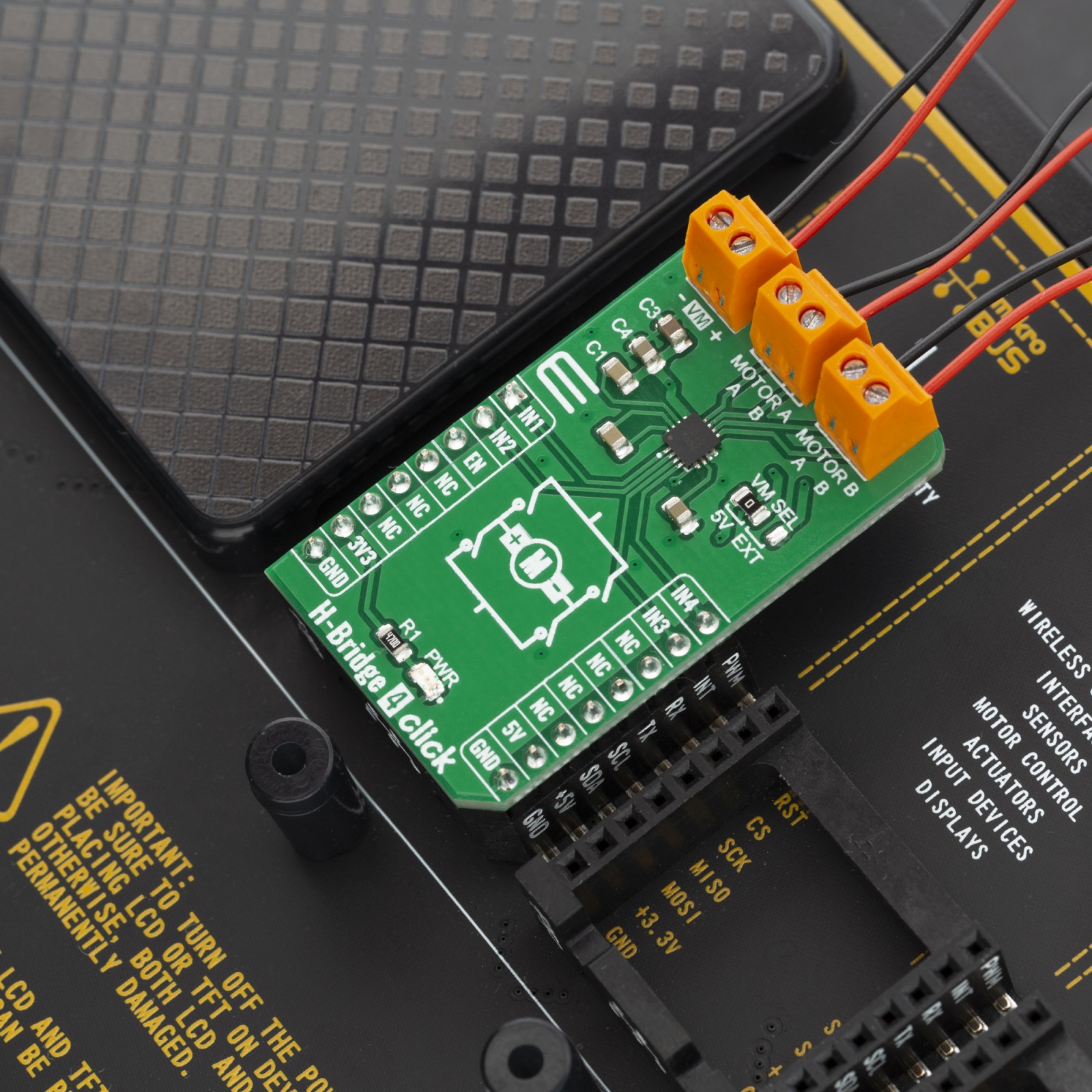

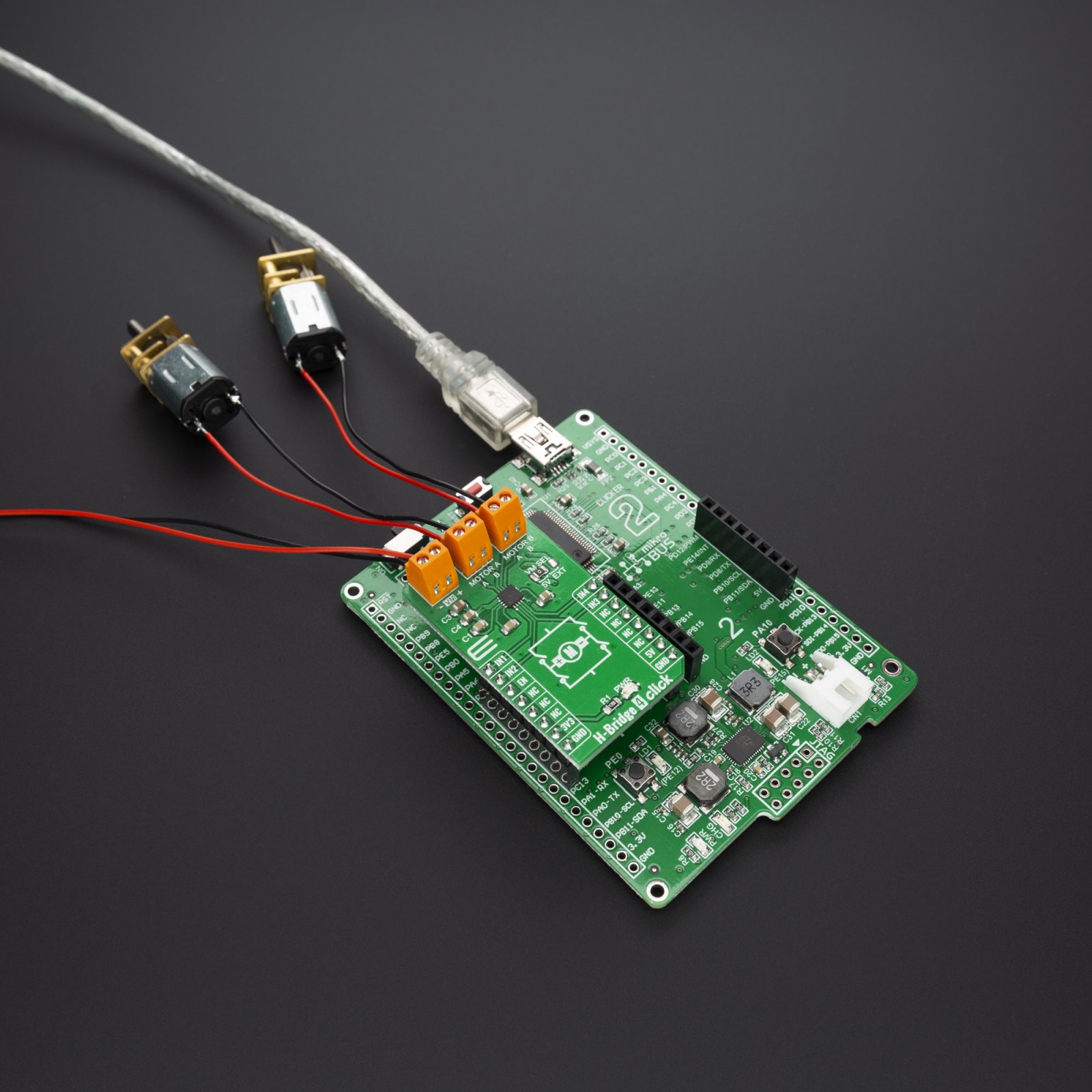

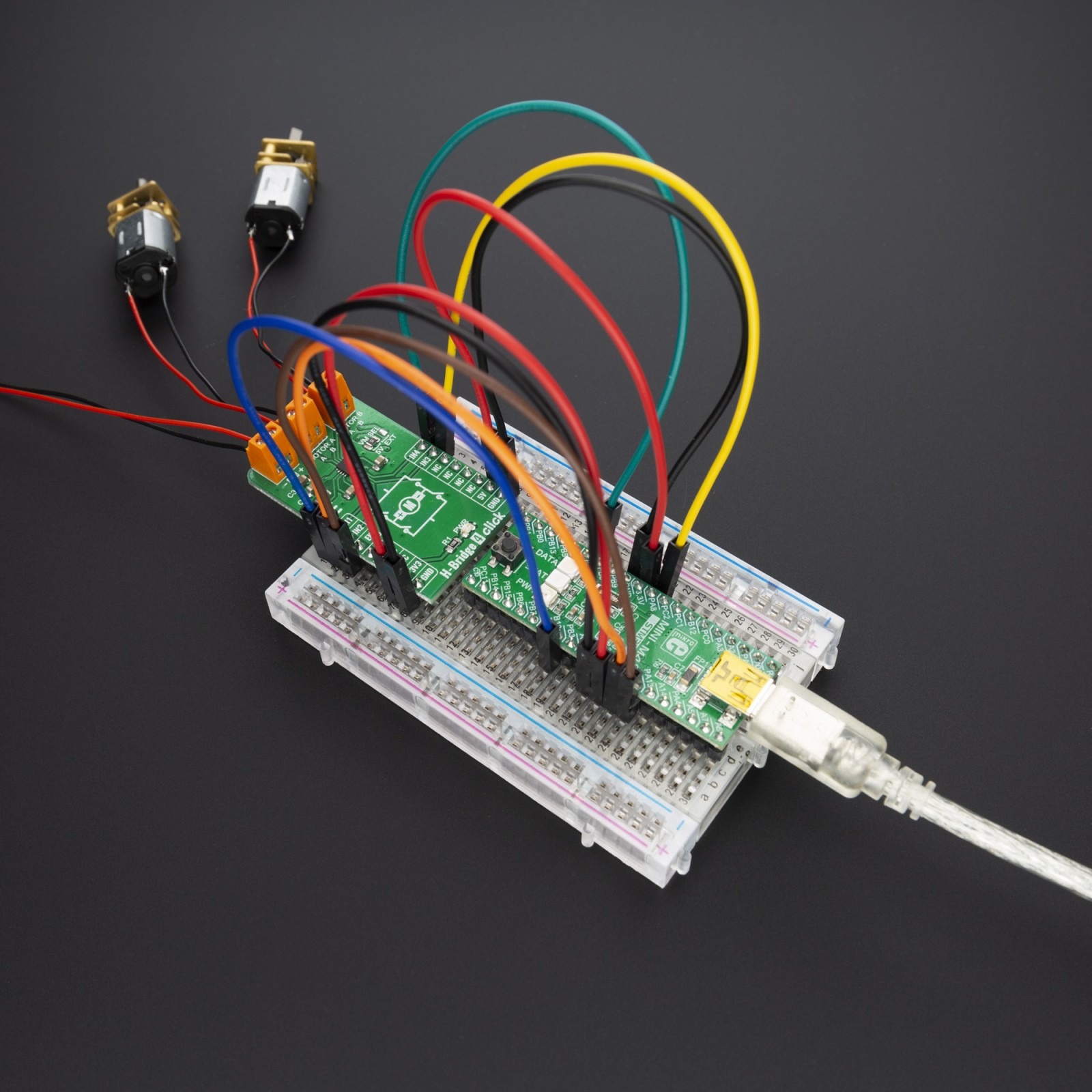

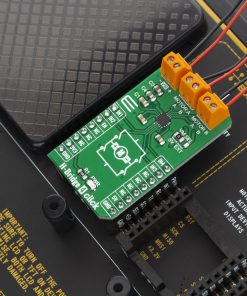

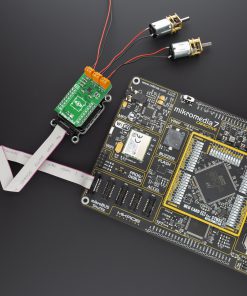

H-Bridge 4 click supports multiple connection options and can be used in different application setups which might include DC or Stepper motors.

Stock: Lead-time applicable.

| 5+ | R304.00 |

| 10+ | R288.00 |

| 15+ | R272.00 |

| 20+ | R261.76 |

How does it work?

The main component of the H-Bridge 4 click is, as mentioned, the AP1010AEN from AsahiKASEI (AKM), which is a two channel H-Bridge motor driver compatible with motor operating voltage up to. This IC is an efficient integrated H-bridge driver, with very low RDS ON output per switch. H-bridge in general, allows the current to flow in one or another direction. The output stages consist of four n-channel mosfets in H-bridge configuration. The outputs are protected against short circuits and over temperature. The bridge is controlled using the inputs IN1, IN2, IN3, and IN4, which are witer to the AN, RST, INT, and PWM pins on the mikroBUS™, respectively.

.jpg)

Its motor operating voltage range is between 6.0V~18V and control power supply is unnecessary. When it comes to its maximum output current (DC) its 0.7A @Ta=25°C and it has H-Bridge On-Resistance, which equals RON(TOP+BOT) = 1.1Ω @Ta=25°C. The Click board™ has an onboard motor voltage supply selection switch, although it is recommended to use the external power supply. The AP1010AEN also has the possibility of a parallel connection, under voltage lockout circuit and the thermal shutdown circuit. The Overcurrent protection circuit is disabled when DIS OCP terminal = “H” and the operating Temperature Range is between -30°C~85°C.

When the internal temperature of the IC reaches the specified temperature (TTSD=155°C), and the H-Bridge driver outputs Hi-Z. When the internal temperature after the detection is lowered about 30°C (TTSDHYS), the driver resumes operation. Restart Temperature = TTSD – TTSDHYS

When the current of 2.6 A or more continues to flow to the H – Bridge driver for 10 μs, all H – Bridge driver outputs are set to Hi – Z, and automatically return after 200 ms. Over current protection circuit can be used by setting the DIS OCP terminal to L level. When not using the overcurrent protection circuit, connect the DIS OCP terminal to the VDC terminal.

Specifications

Type

Brushed,Stepper

Applications

Can be used for a wide range of different applications which require two DC motors or one stepping motor.

On-board modules

AP1010AEN, which is a 2ch H-Bridge motor driver compatible with a motor operating voltage 18V

Key Features

The protection circuit has under voltage lockout circuit, thermal shutdown circuit, and overcurrent protection circuit, and overcurrent protection circuit can be disabled with the DIS OCP terminal

Interface

GPIO

Feature

No ClickID

Compatibility

mikroBUS™

Click board size

M (42.9 x 25.4 mm)

Input Voltage

3.3V,5V

Pinout diagram

This table shows how the pinout on H-Bridge 4 click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | – | Power LED Indicator |

| JP1 | VM SEL | – | Select motor voltage |

Software Support

We provide a library for the H-Bridge 4 click on our LibStock page, as well as a demo application (example), developed using MikroElektronika compilers. The demo can run on all the main MikroElektronika development boards.

Library Description

The library covers all the necessary functions to control H-Bridge 4 click board. The H-Bridge 4 click communicates with the target board through the AN, INT, PWM, RST and CS lines on MikroBUS. This library offers functions for setting or clearing of any and every of the five pins used for communication, also user can use functions that enable or disable clockwise or counter-clockwise motion, as well as standby mode and brake for both channels.

Key functions:

void hbridge4_motorAStandby()– Function is used to put motor A into standby.void hbridge4_motorACW()– Function is used to put motor A into clockwise motion.void hbridge4_motorABrake()– Function is used to brake motor A to a halt.

Examples description

The application is composed of three sections :

- System Initialization – Initializes GPIO and LOG structures, sets AN, INT, PWM, RST and CS pins as output.

- Application Initialization – Initialization driver enables GPIO and also starts write log.

- Application Task – (code snippet) This example demonstrates the use of H-Bridge 4 click board by putting A motor in standby mode, then spining it in clockwise direction and applying brake function, and then spining it in counter-clockwise direction and applying brake function again.

void applicationTask()

{

mikrobus_logWrite( "The motor A is in standby mode", _LOG_LINE );

hbridge4_motorAStandby();

Delay_ms( 100 );

mikrobus_logWrite( "The motor A turns clockwise", _LOG_LINE );

hbridge4_motorACW();

Delay_ms( 2000 );

mikrobus_logWrite( "The motor A applies brake", _LOG_LINE );

hbridge4_motorABrake();

Delay_ms( 1000 );

mikrobus_logWrite( "The motor A turns counter-clockwise", _LOG_LINE );

hbridge4_motorACCW();

Delay_ms( 2000 );

mikrobus_logWrite( "The motor A applies brake", _LOG_LINE );

hbridge4_motorABrake();

Delay_ms( 1000 );

}

The full application code, and ready to use projects can be found on our LibStock page.

Other mikroE Libraries used in the example:

- UART

Additional notes and informations

Depending on the development board you are using, you may need USB UART click, USB UART 2 click or RS232 click to connect to your PC, for development systems with no UART to USB interface available on the board. The terminal available in all MikroElektronika compilers, or any other terminal application of your choice, can be used to read the message.

mikroSDK

This Click board™ is supported with mikroSDK – MikroElektronika Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

Resources

Downloads

| Weight | 19 g |

|---|---|

| Brand | MikroElektronika |