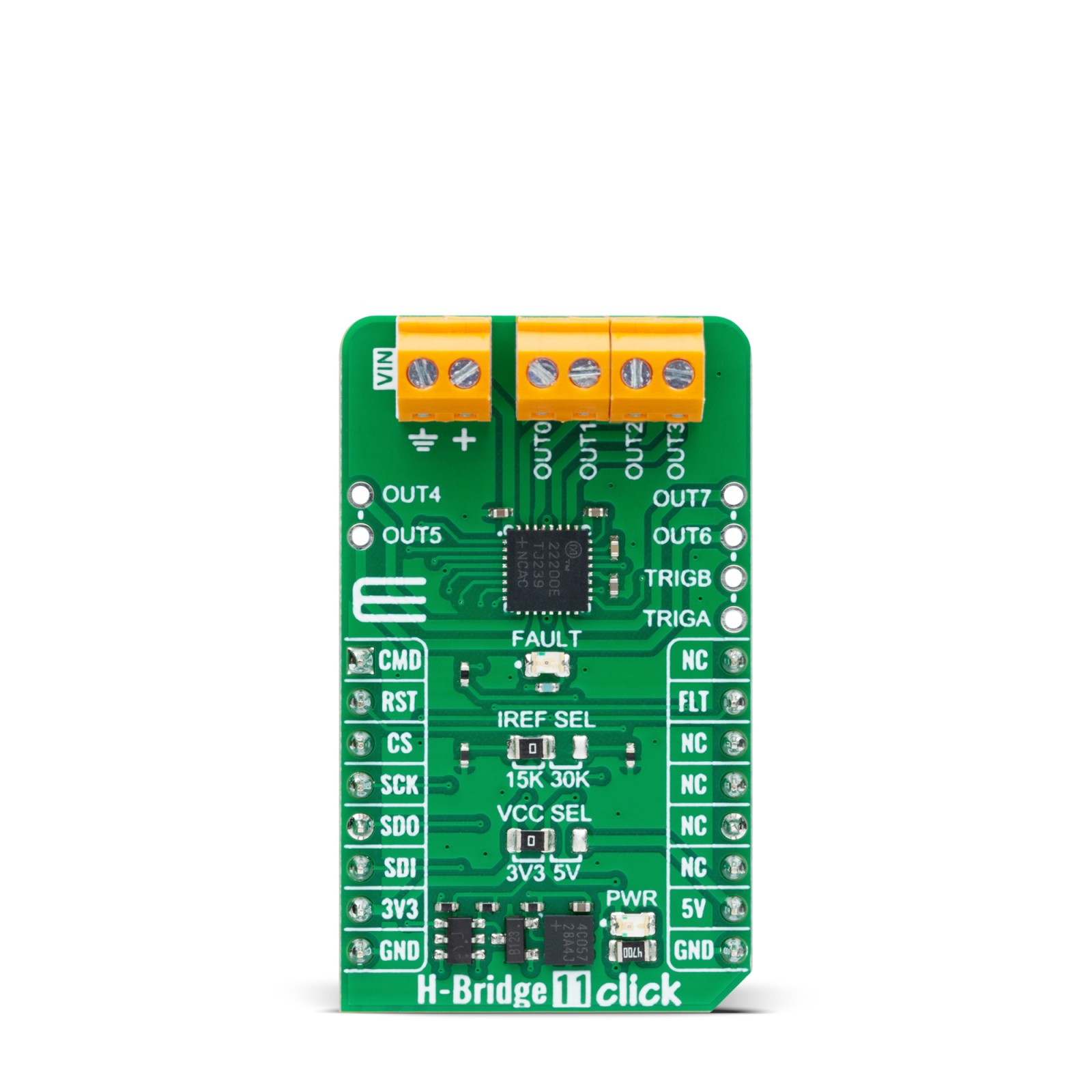

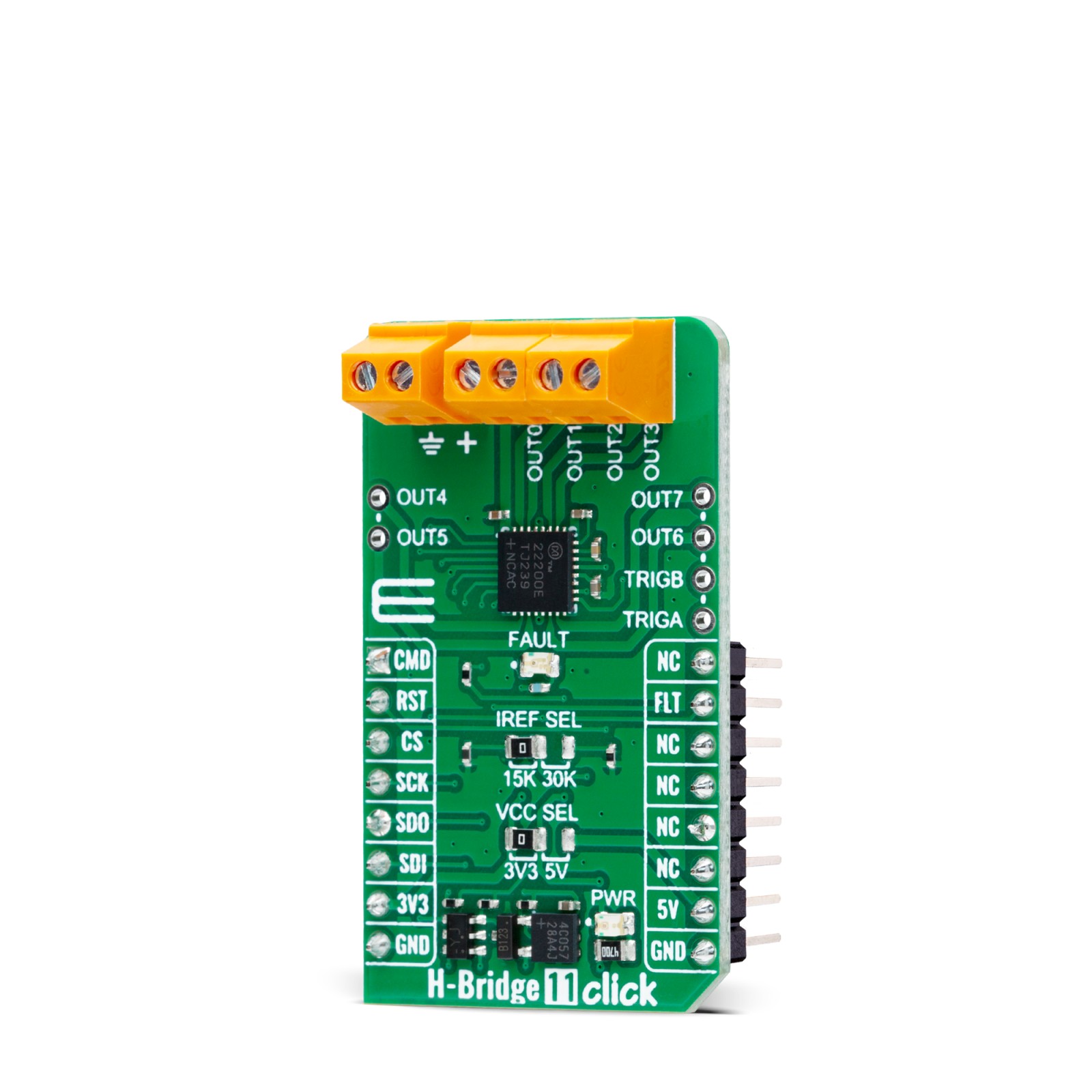

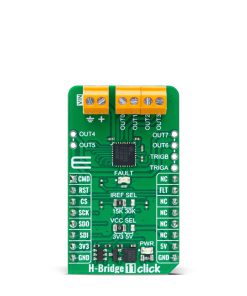

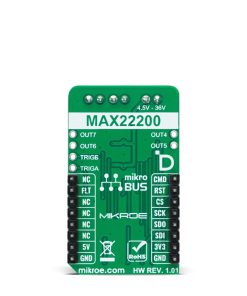

H-Bridge 11 Click

R610.00 ex. VAT

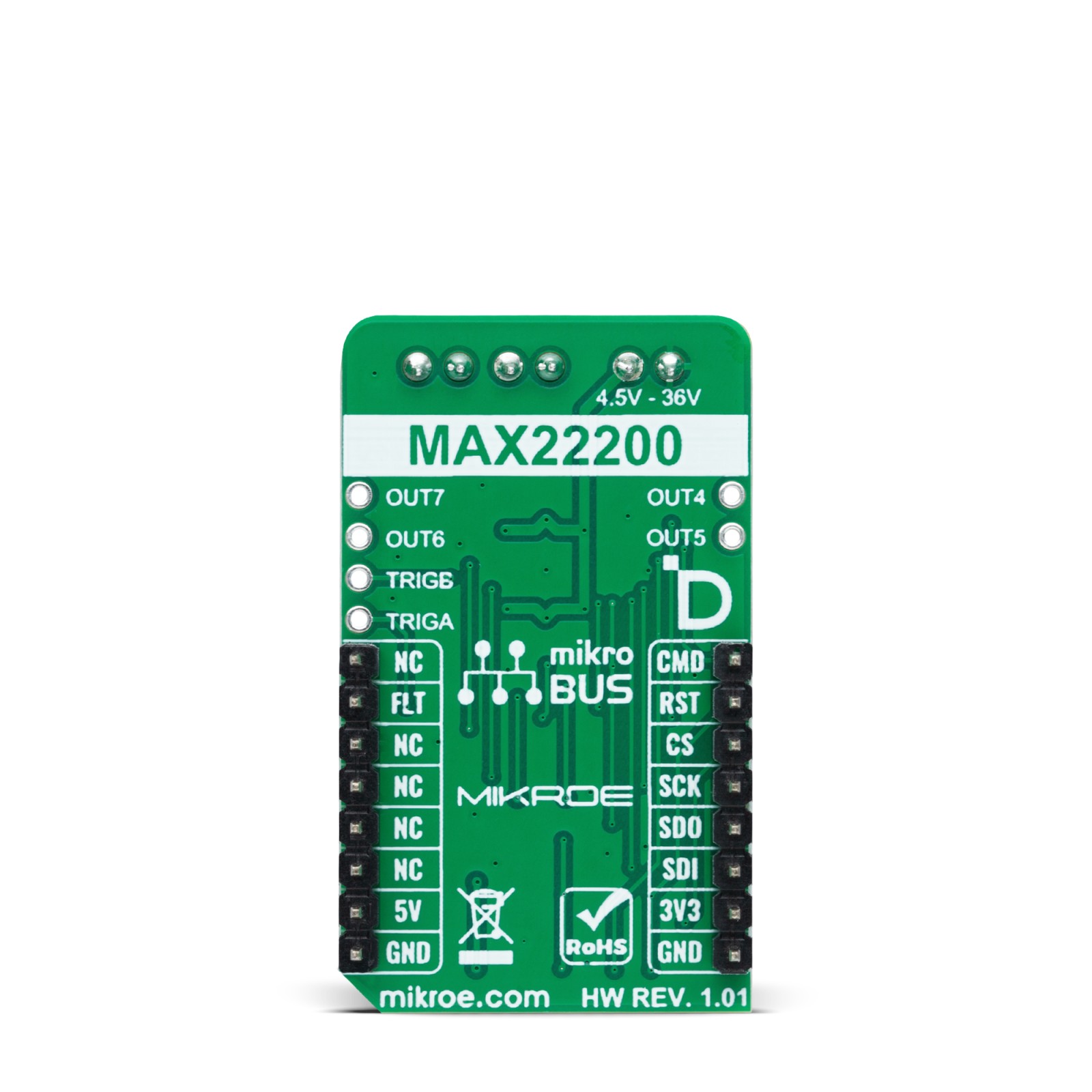

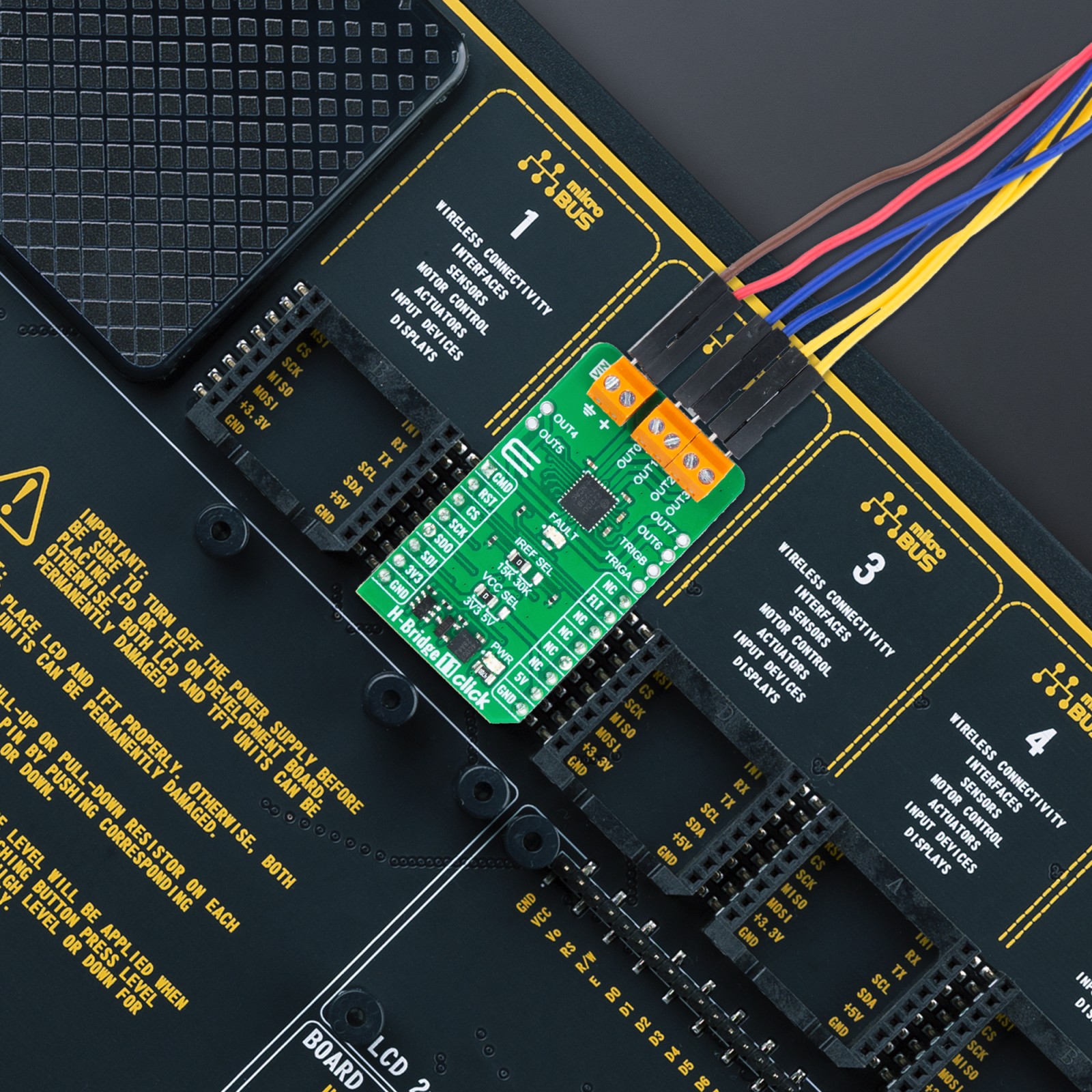

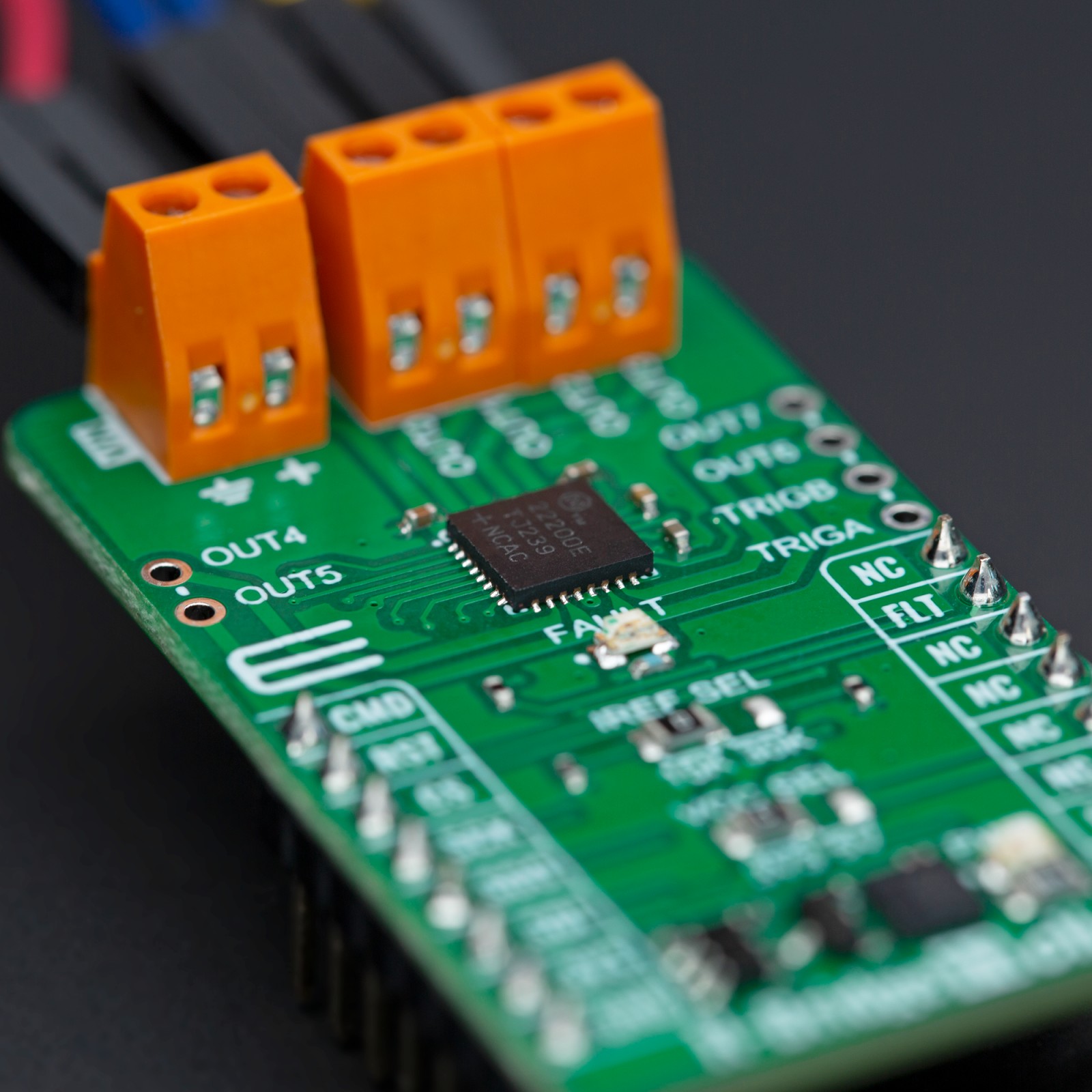

H-Bridge 11 Click is a compact add-on board that allows a voltage to be applied across a load in either direction. This board features the MAX22200, an octal serial-controlled solenoid and motor driver from Analog Devices. The MAX22200 is SPI-configurable and rated for an operating voltage range from 4.5V to 36V. Each channel features a low impedance push-pull output stage with sink-and-source driving capability up to 1A RMS driving current. Its internal half-bridges can be configured as low-side or high-side drivers, supports two control methods (voltage and current drive regulation), and features a full set of protections and diagnostic functions. This Click board™ is well-suited for solenoid driver applications (valve control, relays control) in which low power consumption and a high level of integration are required.

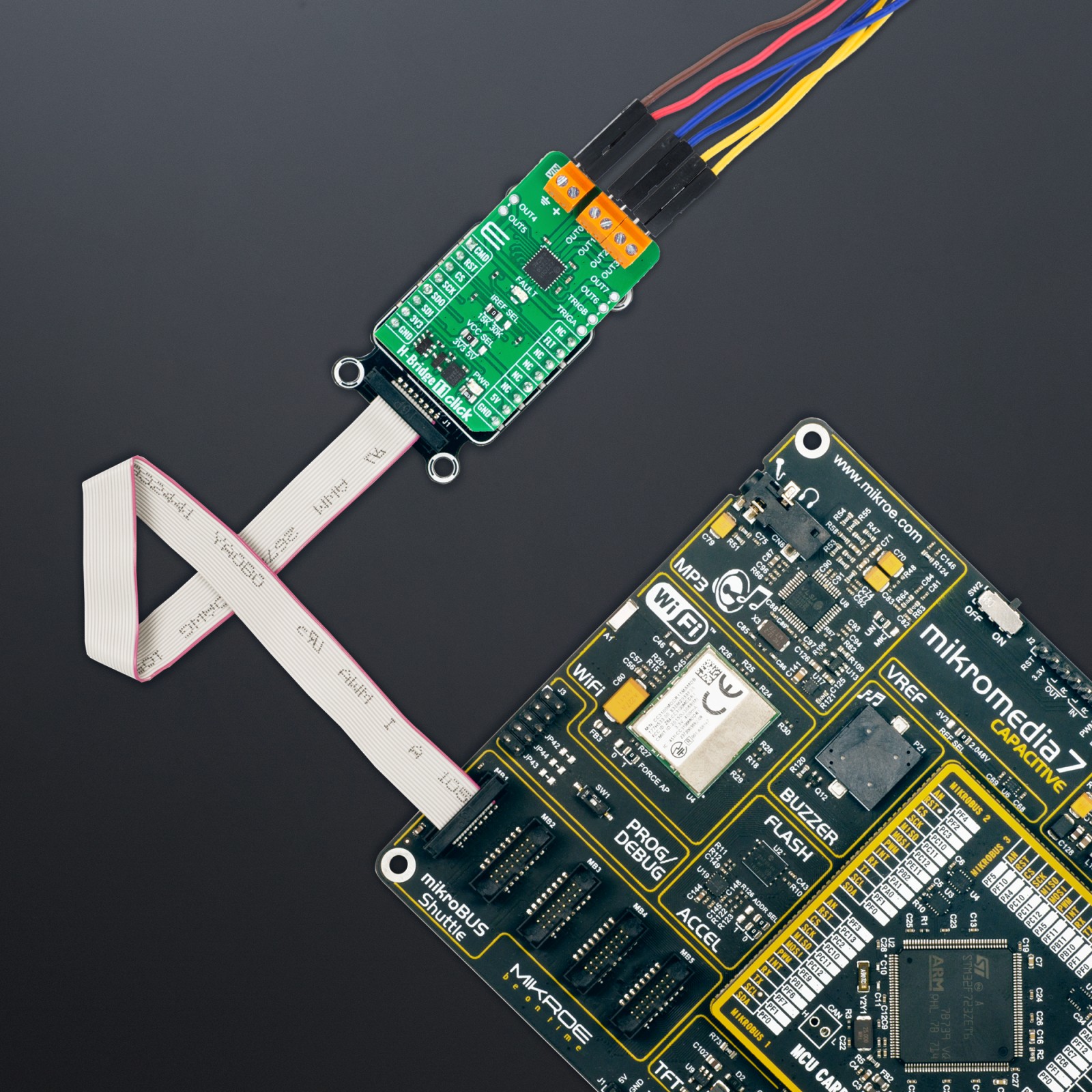

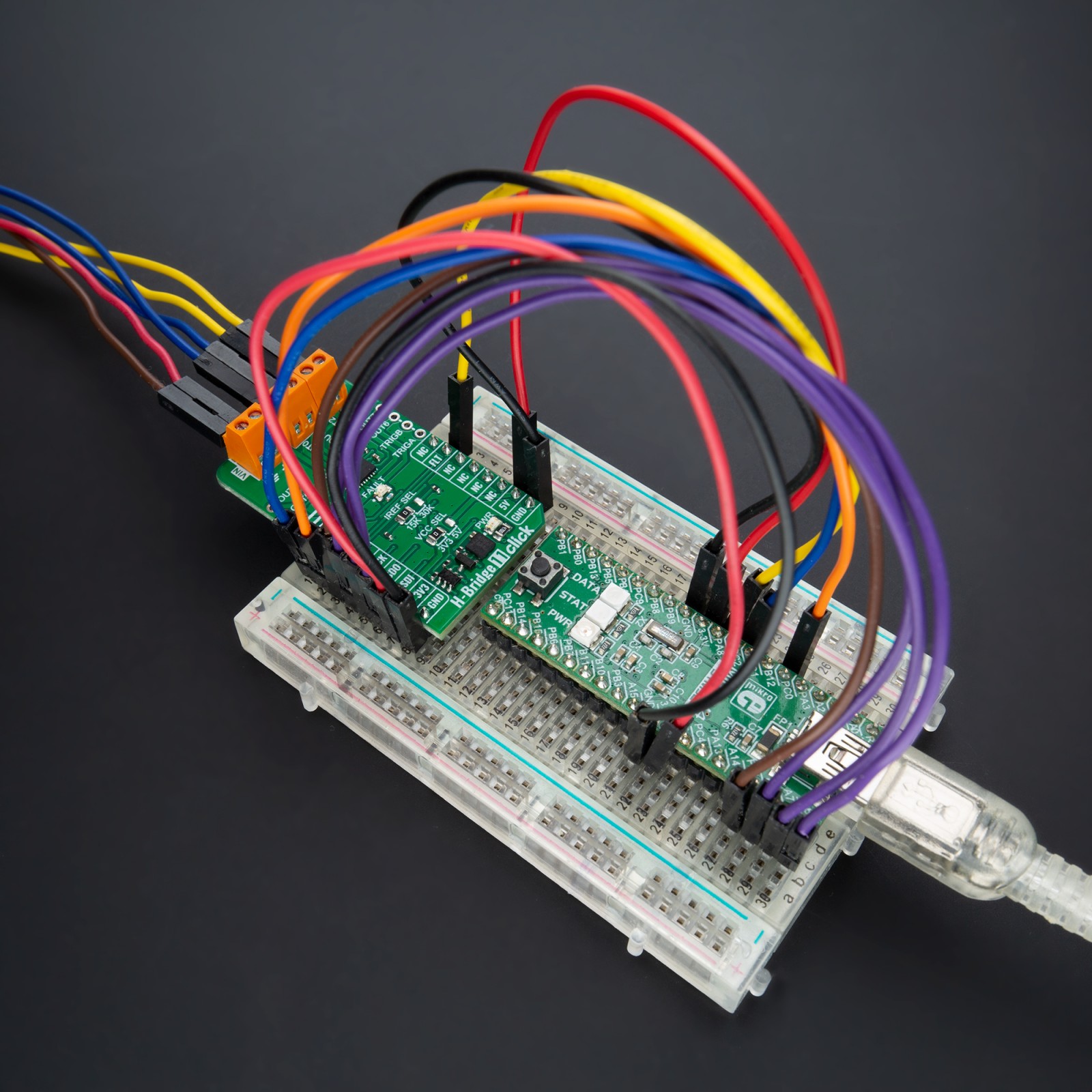

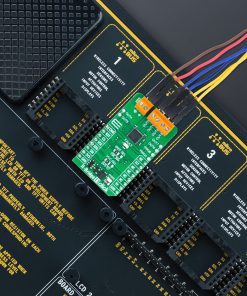

H-Bridge 11 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R579.50 |

| 10+ | R549.00 |

| 15+ | R518.50 |

| 20+ | R498.98 |