Force Click

R670.00 ex. VAT

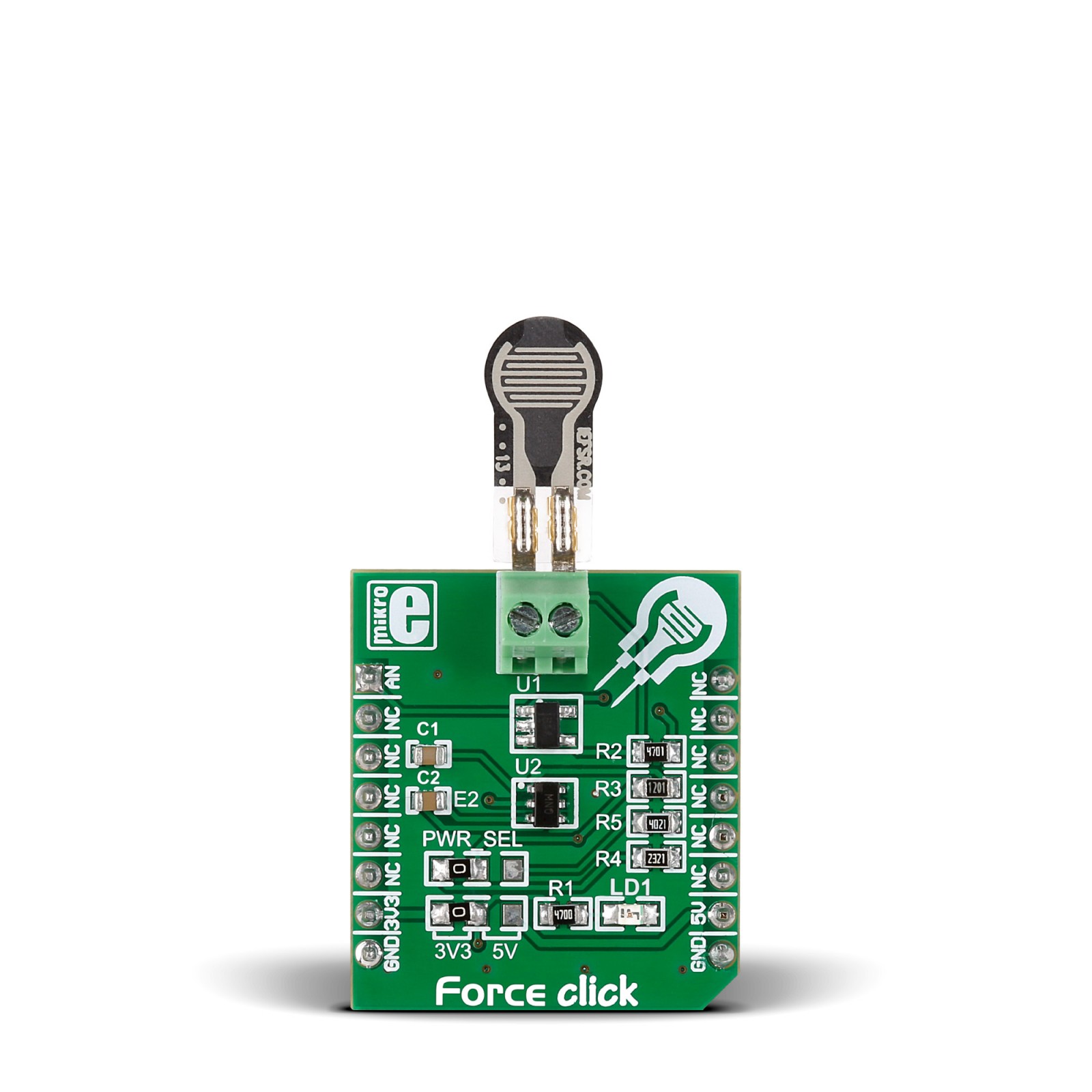

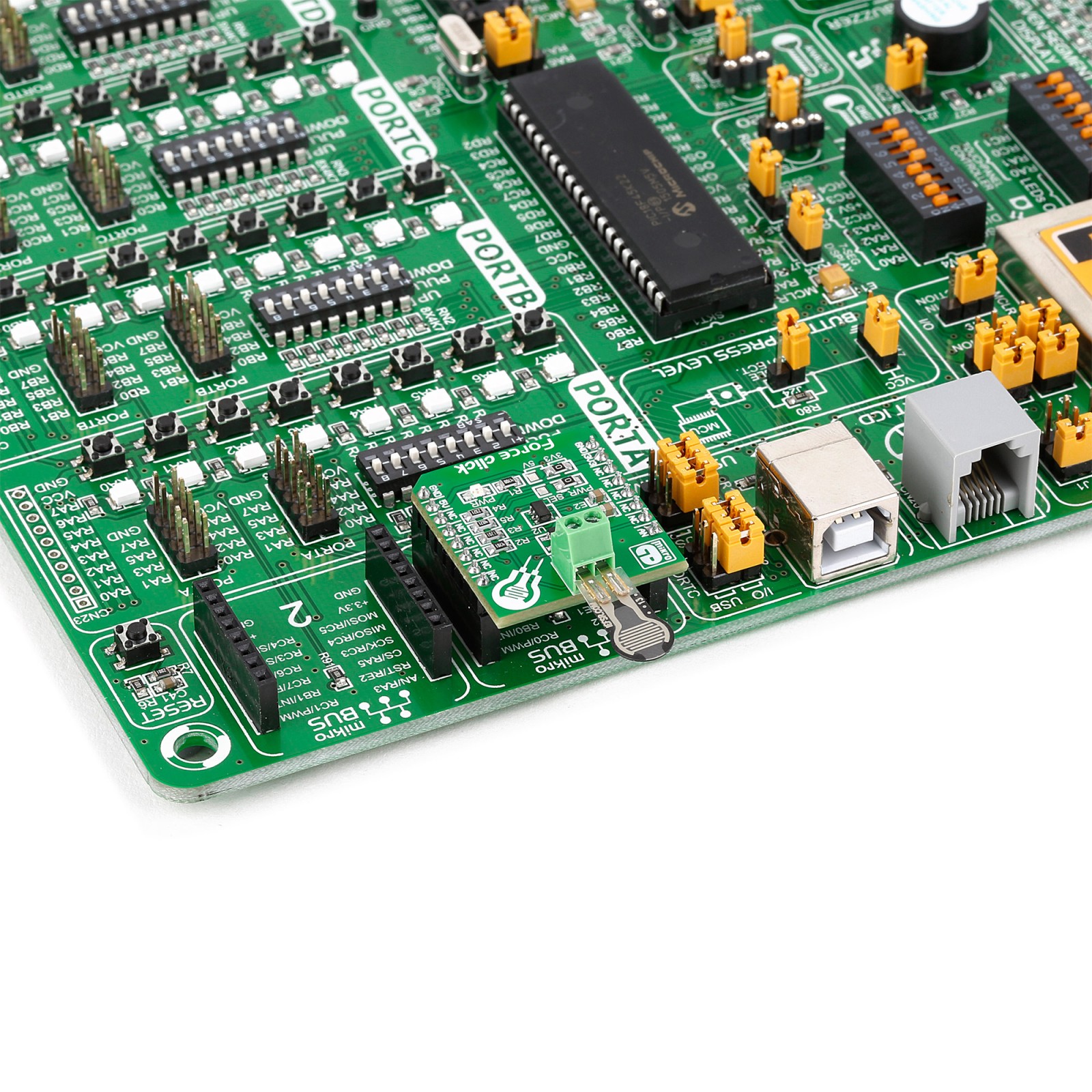

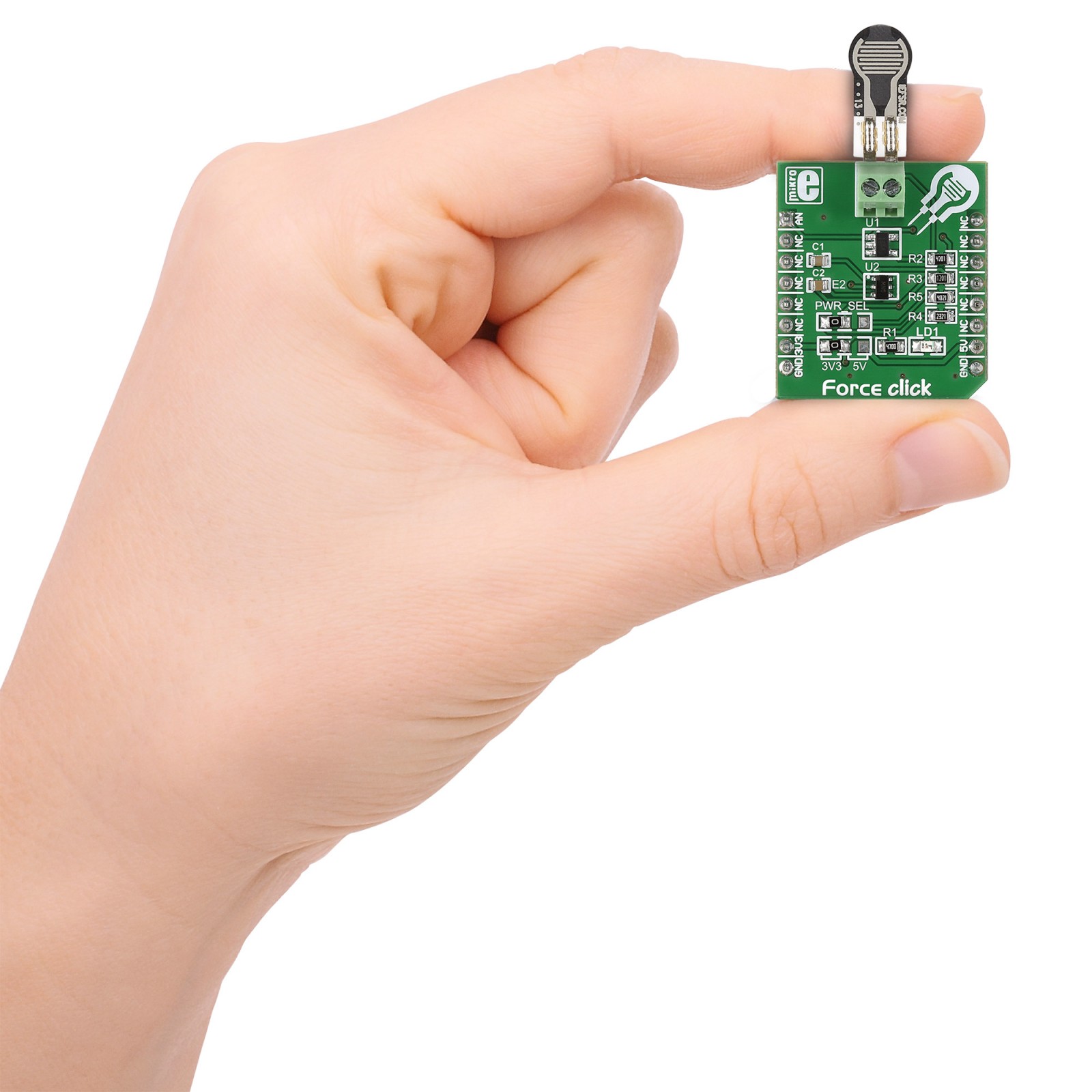

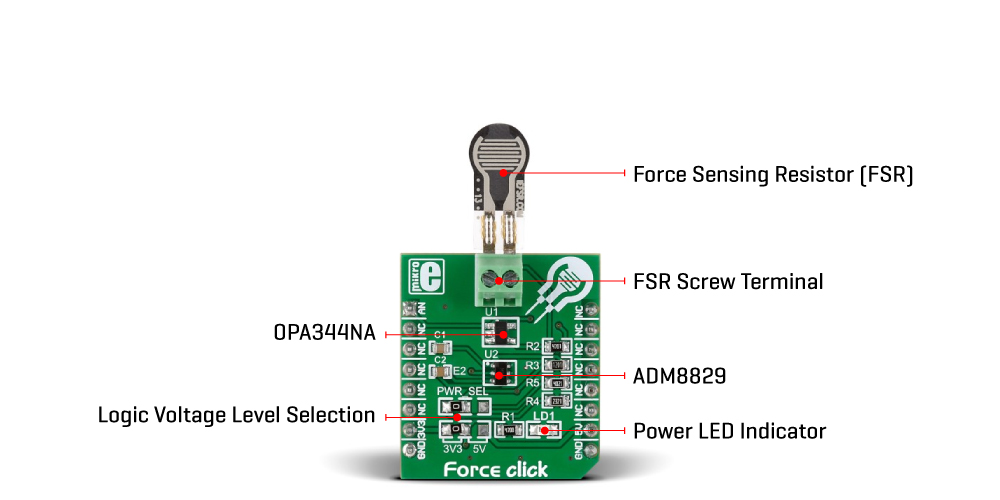

Force Click is a compact add-on board for measuring forces applied to a force-sensing resistor. This board features circuitry that allows the implementation of Force Sensing Resistors (FSR) from Interlink Electronics. The Force Click comes equipped with a screw terminal, with one single zone force sensing resistor included with the Click board™. The actuation force is low as 0.2N, and the sensitivity range from 0.2N up to 20N (although it depends on the implementation). This Click board™ makes the perfect solution for developing applications with simple-to-implement force (pressure) measurement (when squeezed) and is not recommended if high accuracy is required.

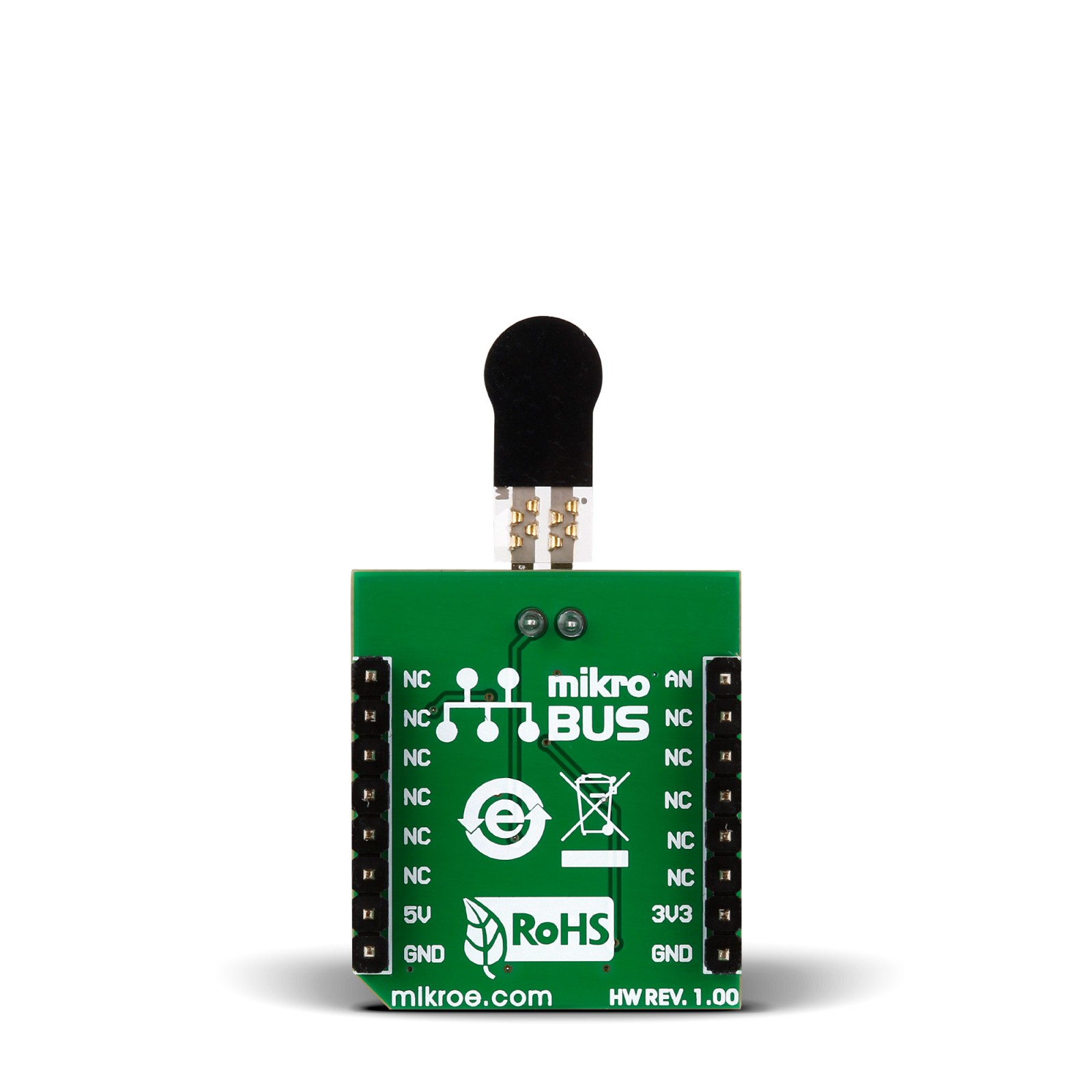

Force Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R636.50 |

| 10+ | R603.00 |

| 15+ | R569.50 |

| 20+ | R548.06 |