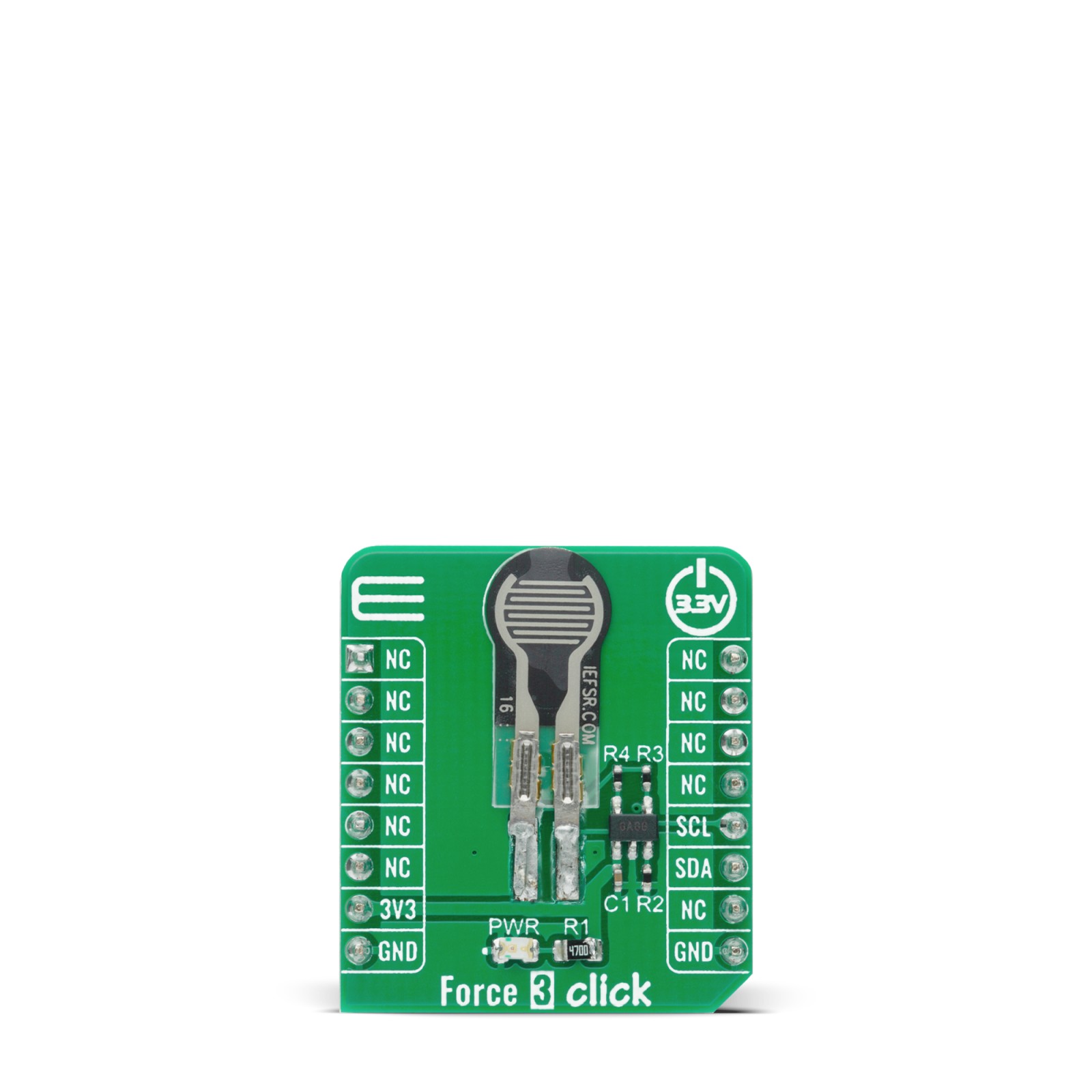

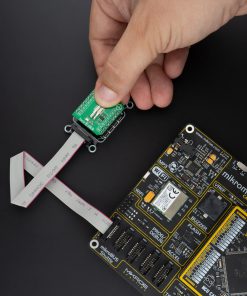

Force 3 Click

R530.00 ex. VAT

Force 3 Click is a compact add-on board with circuitry for implementing Force Sensing Resistor into your projects whose resistance changes when a force, pressure, or mechanical stress is applied. This board features FSR 400 series 34-00004 single zone Force Sensing Resistor from Interlink Electronics, a robust polymer thick film (PTF) device that exhibits a decrease in resistance with an increase in force applied to the surface of the sensor. Simple and easy to integrate, ultra-thin, and cost-effective, Force 3 Click has an actuation force as low as 0.2N and sensitivity range up to 20N. It also provides 2-Wire I2C compatible control interface using an MCP3221, low-power 12-bit resolution A/D converter. This Click board™ is optimized for use in human-machine interface devices including automotive electronics, medical systems, industrial controls and robotics.

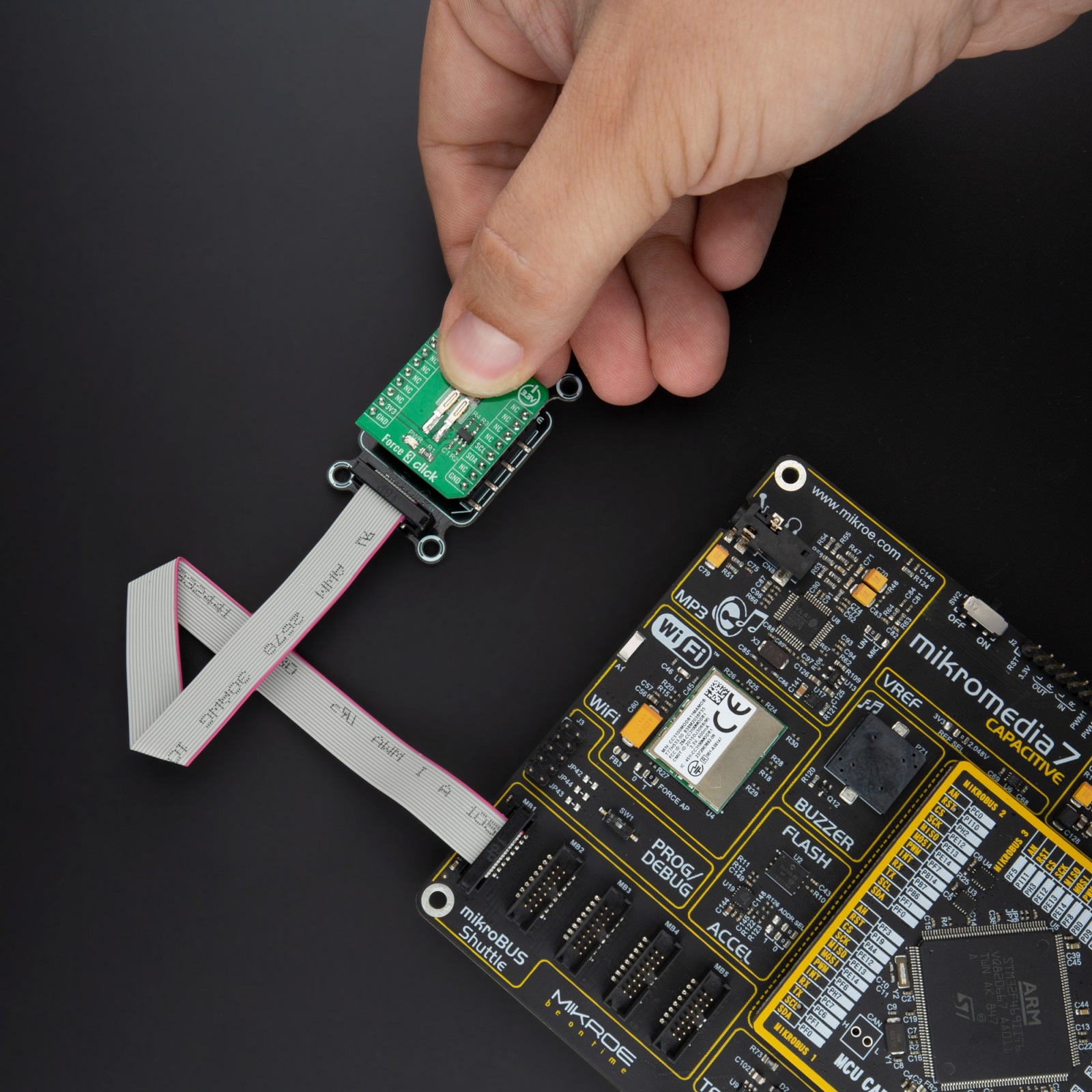

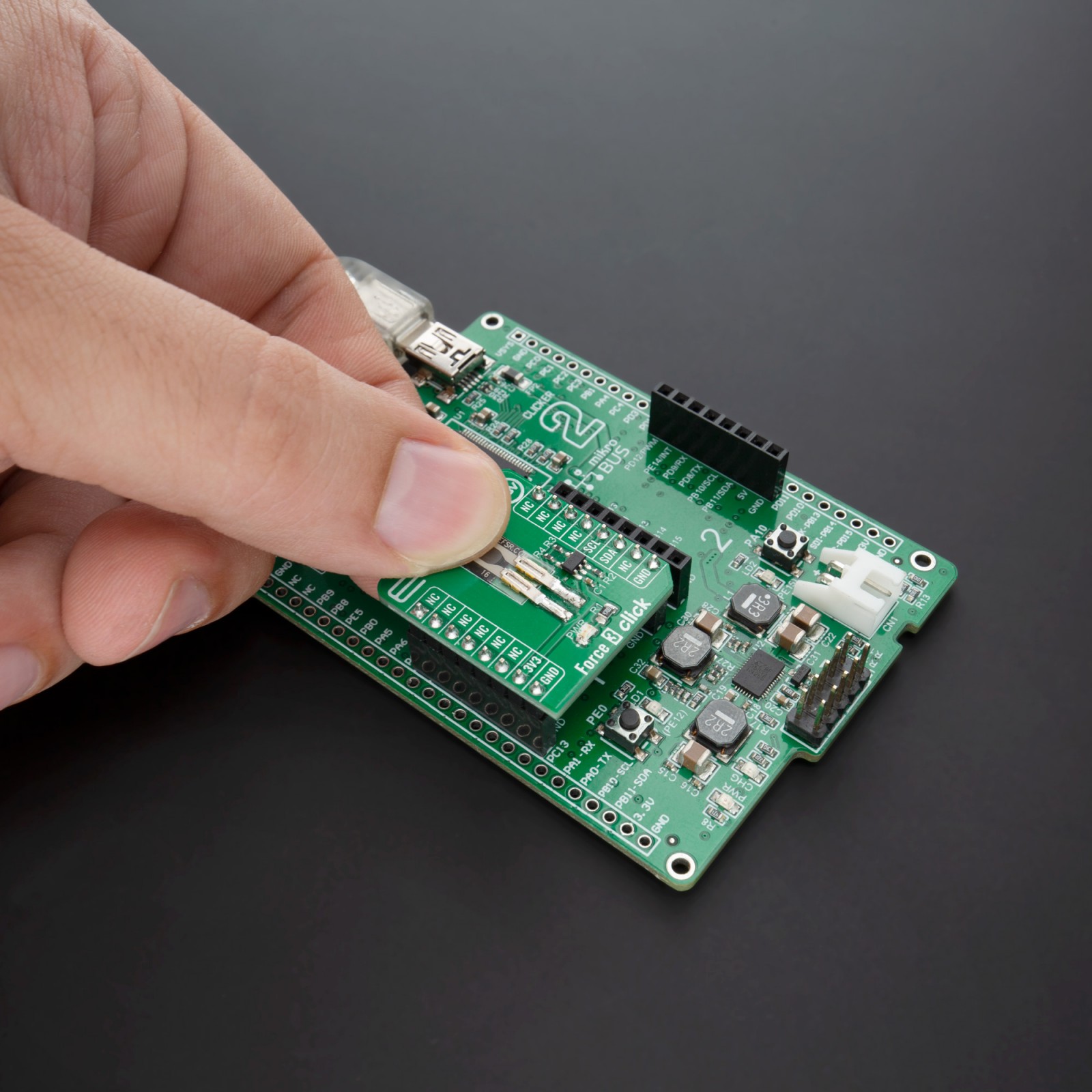

Force 3 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R503.50 |

| 10+ | R477.00 |

| 15+ | R450.50 |

| 20+ | R433.54 |