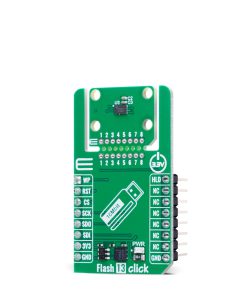

Flash 13 Click

R170.00 ex. VAT

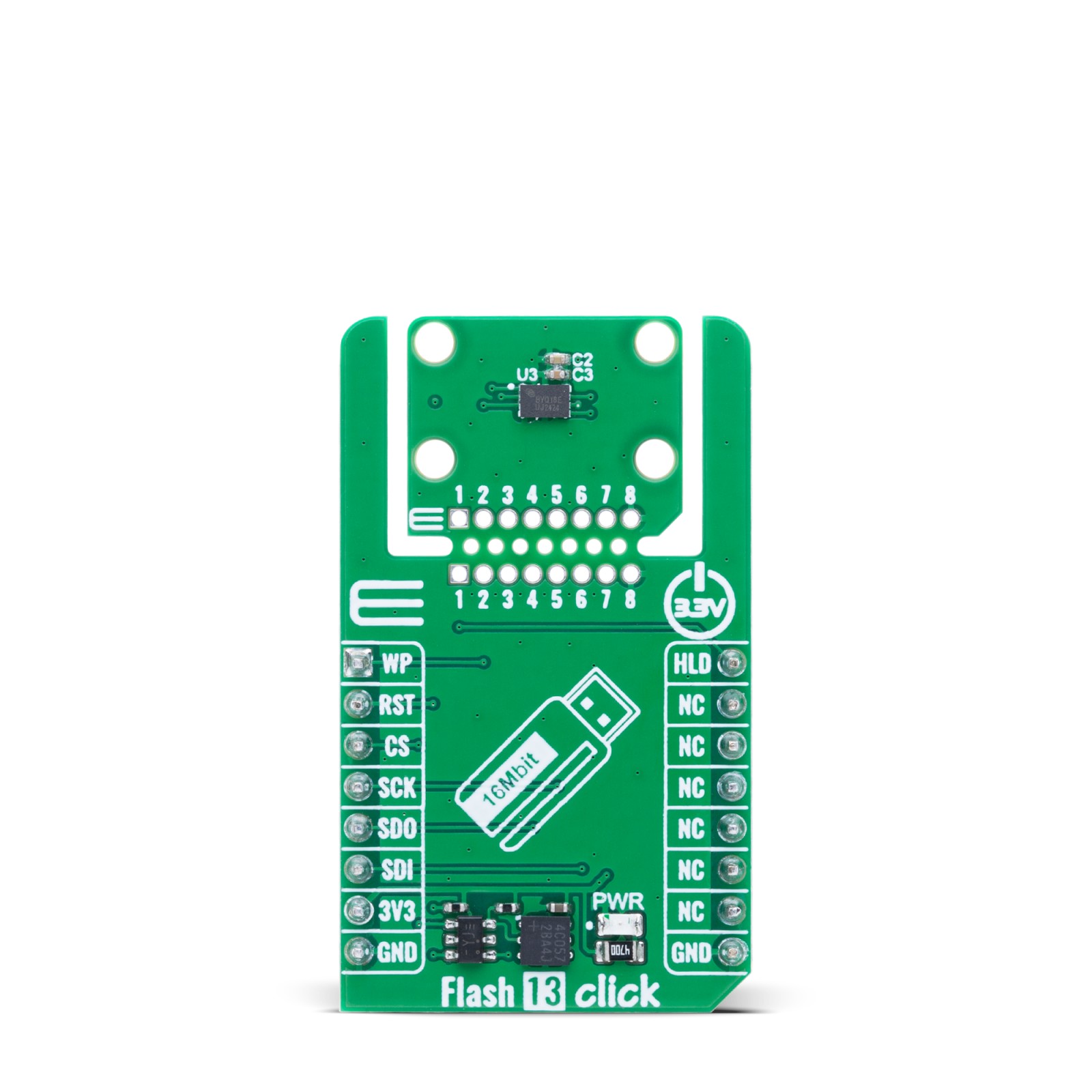

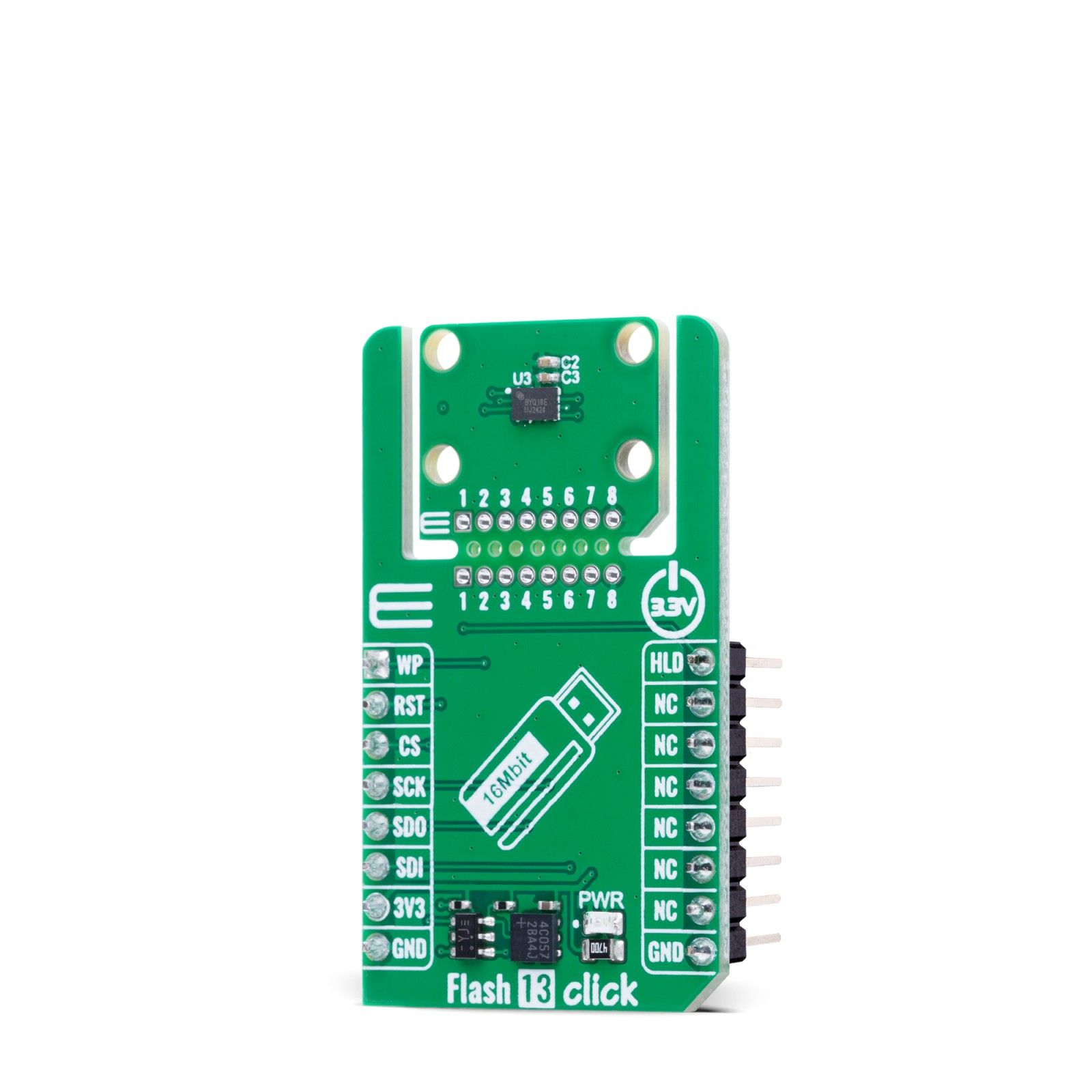

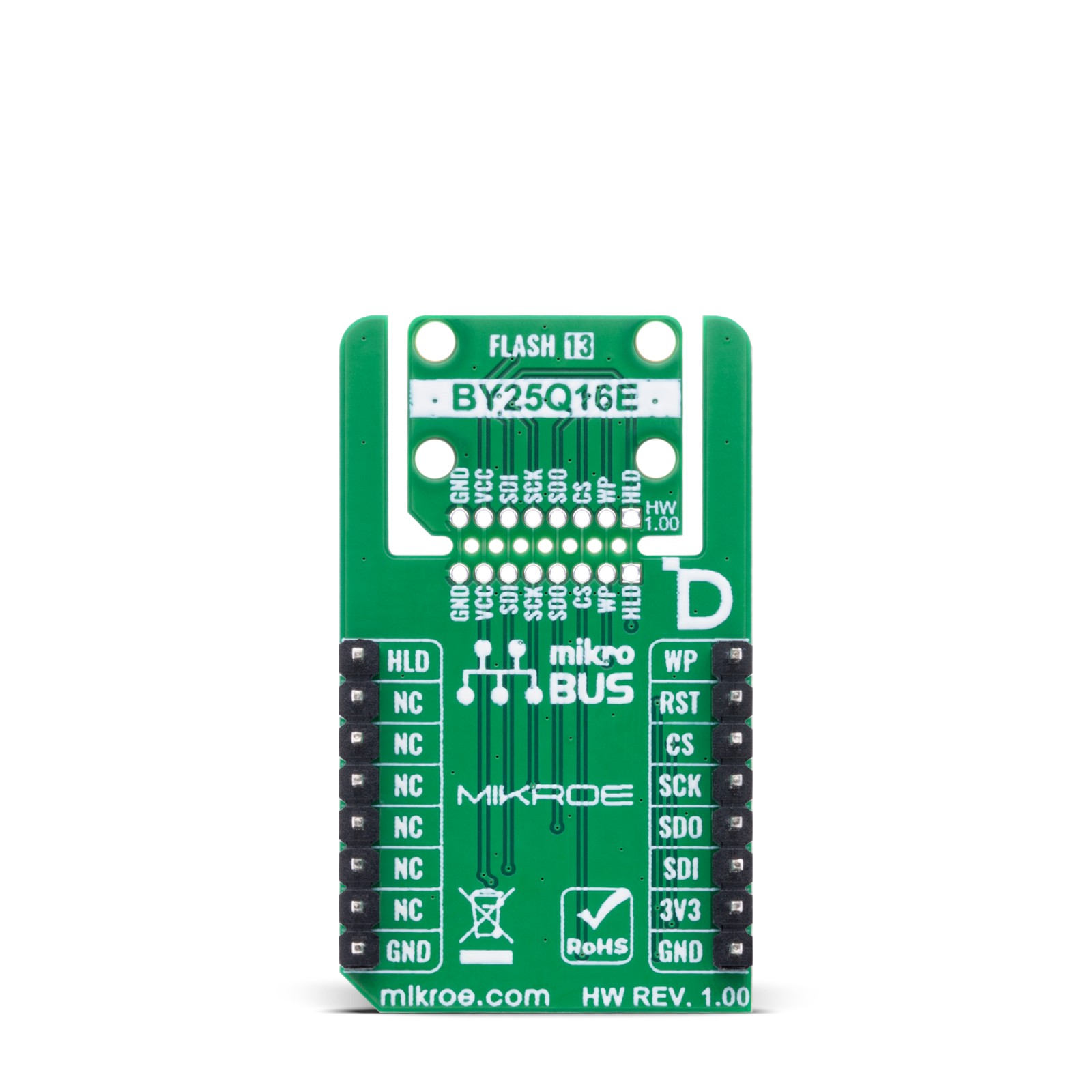

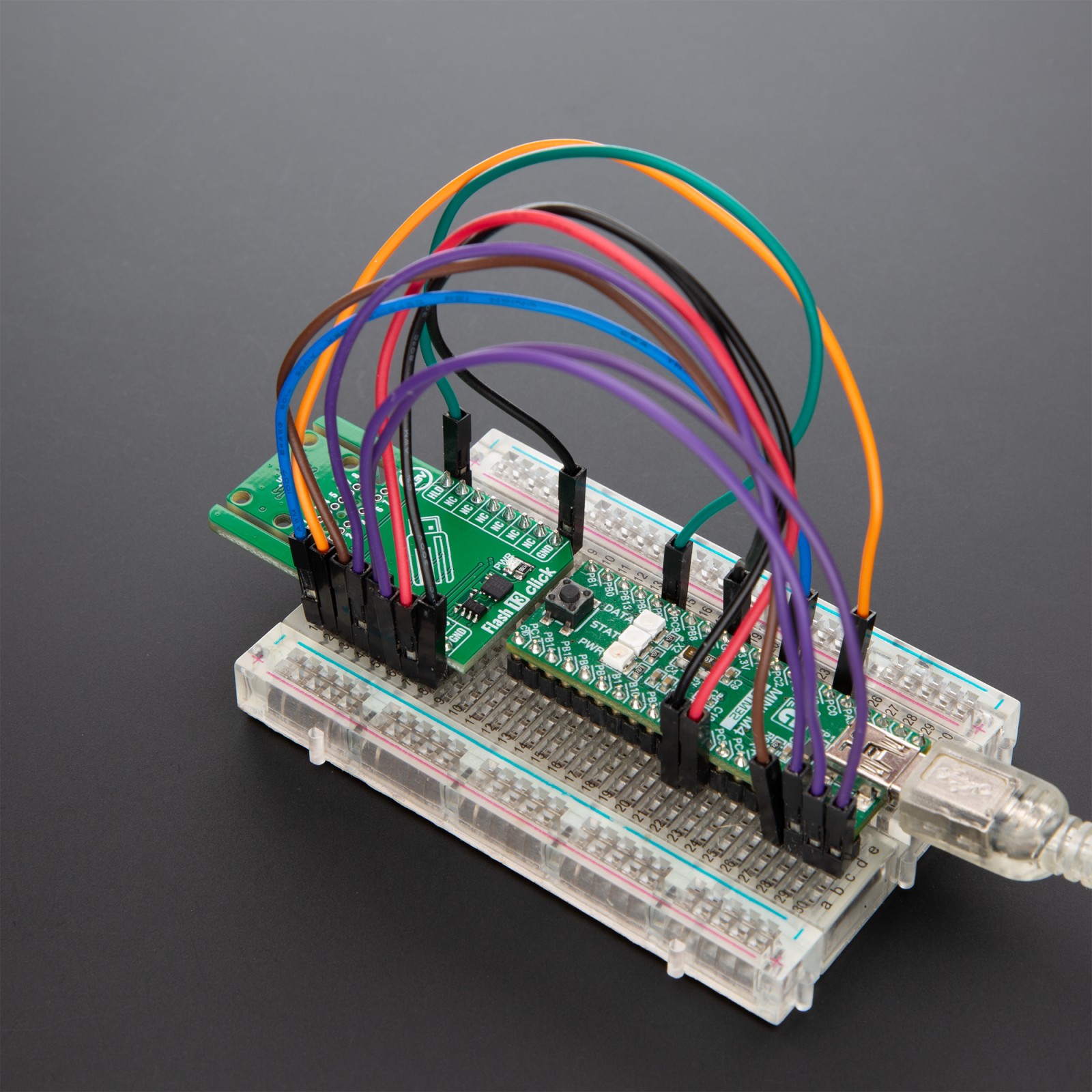

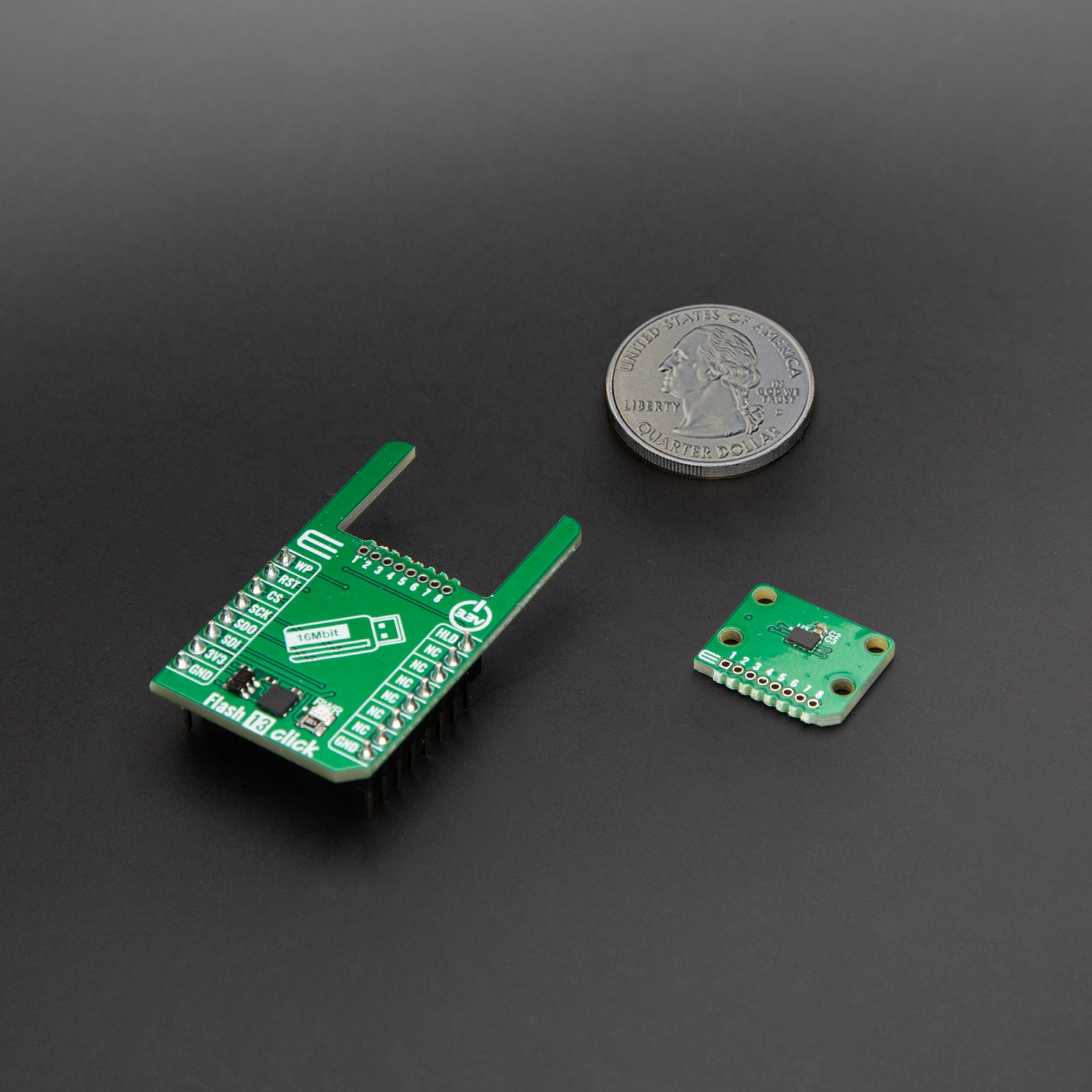

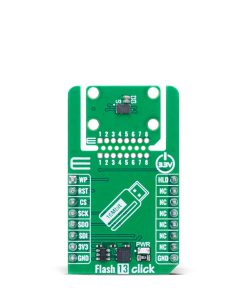

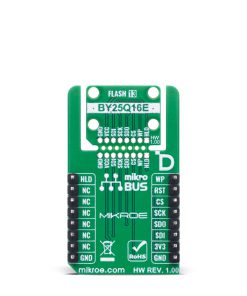

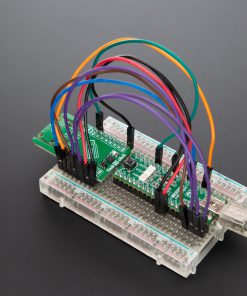

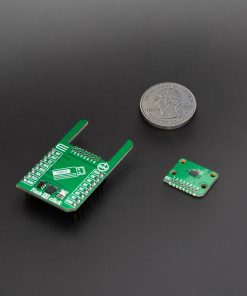

Flash 13 Click is a compact add-on board designed for fast and reliable data storage in embedded applications. This board features the BY25Q16E, a 16Mbit SPI NOR Flash memory chip from BYTe Semiconductor. It supports standard, Dual, and Quad SPI interfaces with clock speeds up to 108MHz, enabling high-speed data transfer rates up to 432MHz in Quad mode. It features Continuous Read Mode for true XIP (execute-in-place) operation, three 1024-byte security registers for secure data storage, and endurance of 100,000 program/erase cycles per sector with 20-year data retention. Communication is handled via SPI using 3.3V logic and introduces the innovative Click Snap feature for flexible chip placement with additional HOLD and Write Protect functions for advanced control. Flash 13 Click is ideal for use in both commercial and industrial environments that require high-performance, secure, and long-lasting non-volatile memory.

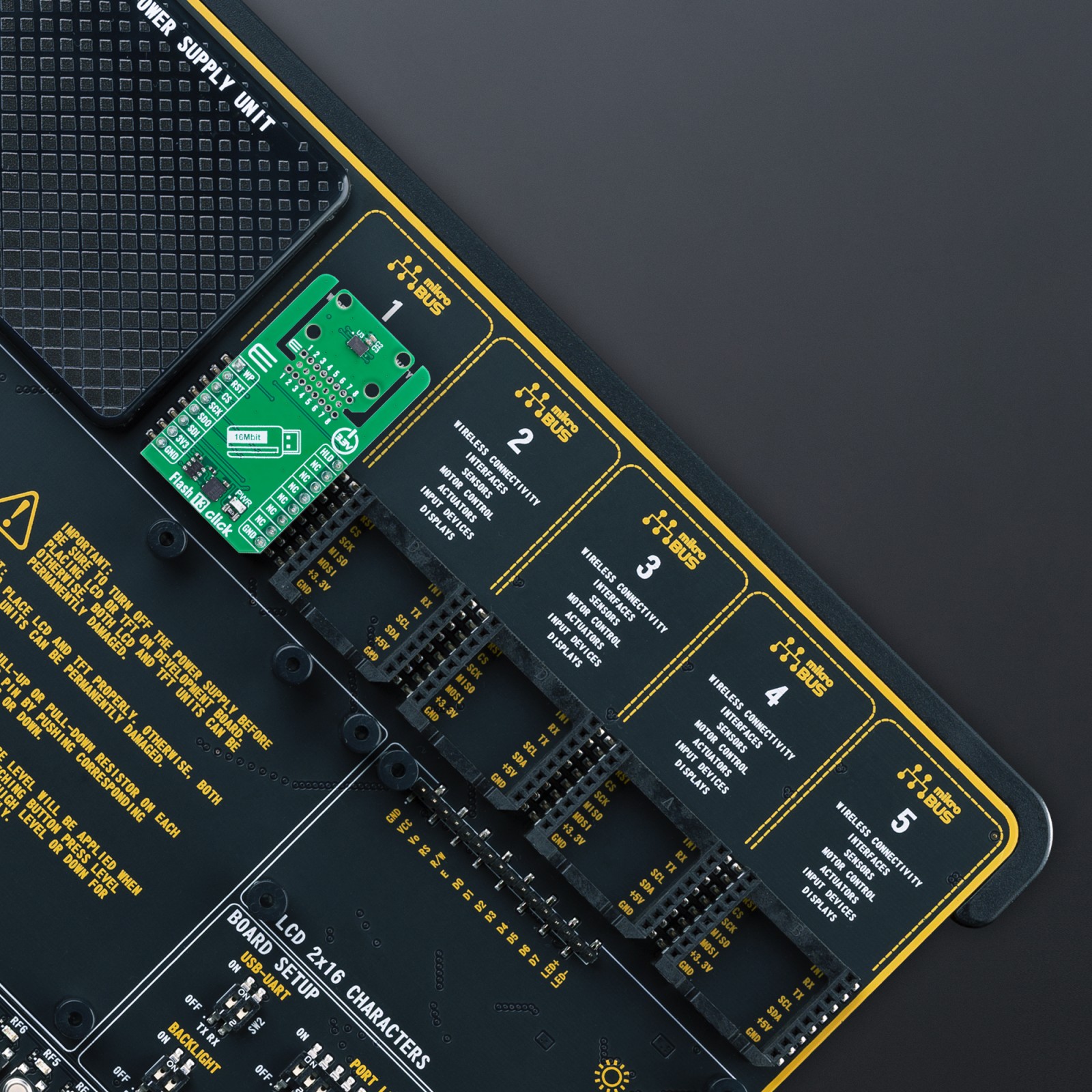

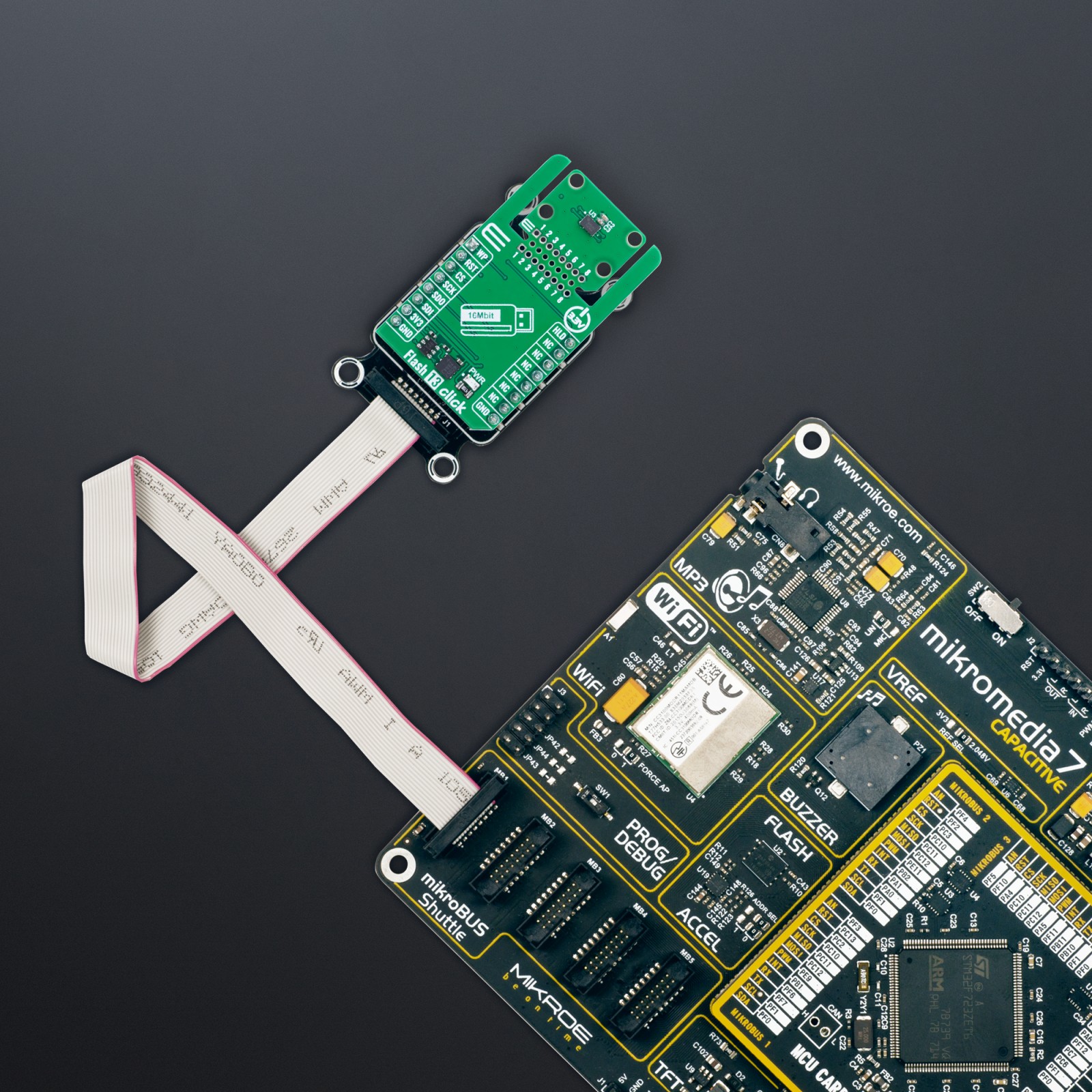

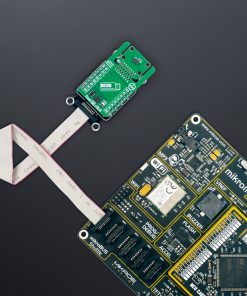

Flash 13 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board, alongside a Click Snap feature introducing a new level of flexibility and ease of use.

Stock: Lead-time applicable.

| 5+ | R161.50 |

| 10+ | R153.00 |

| 15+ | R144.50 |

| 20+ | R139.06 |