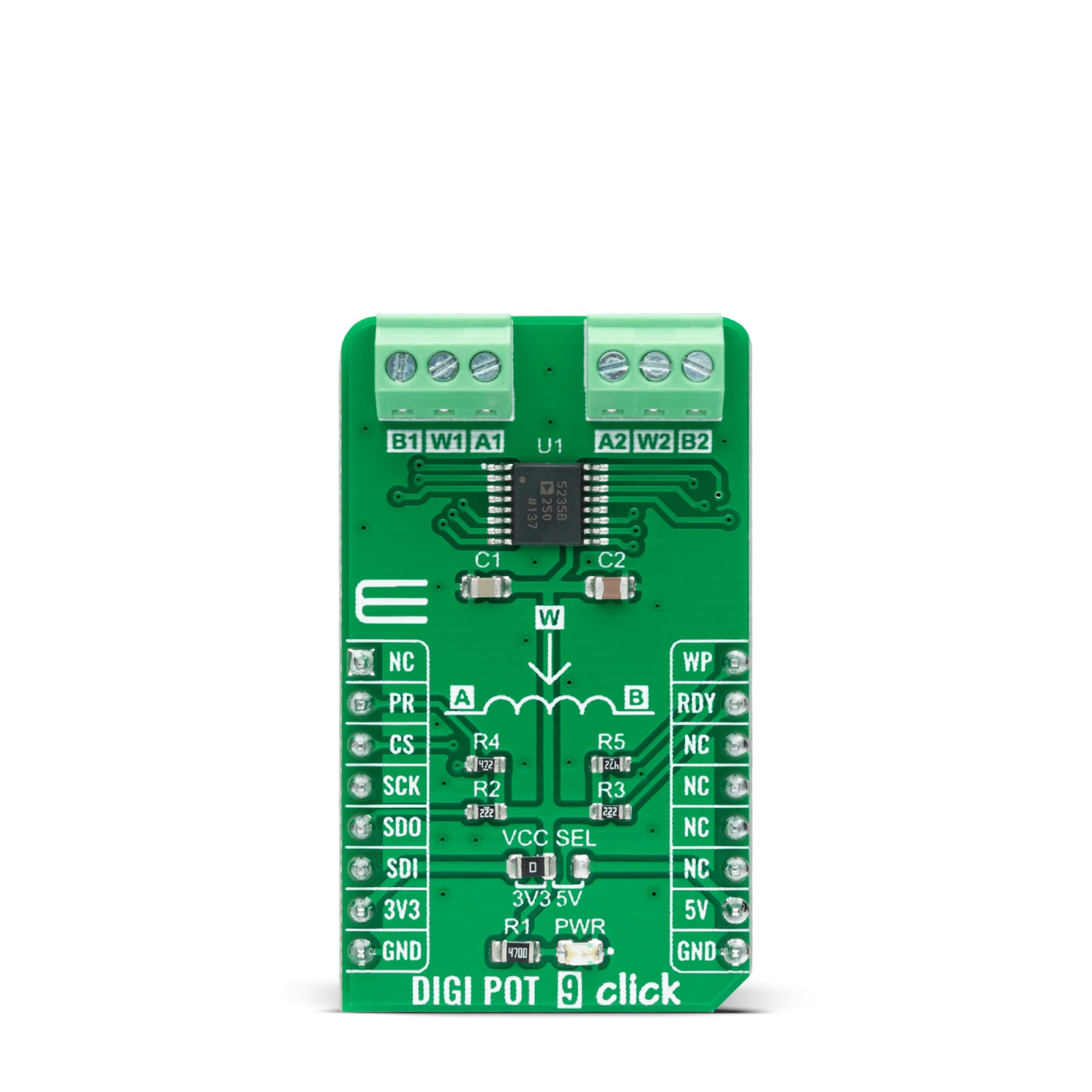

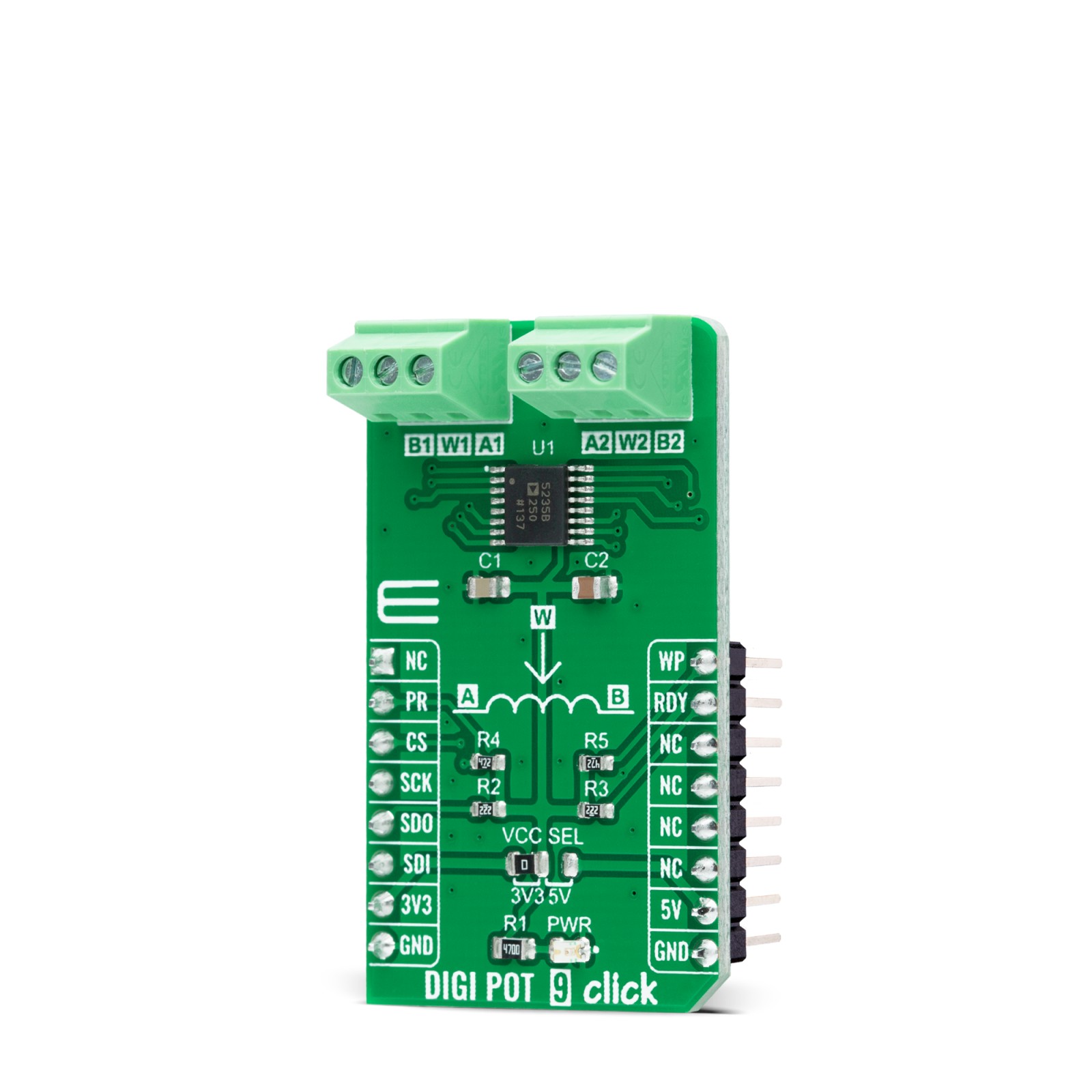

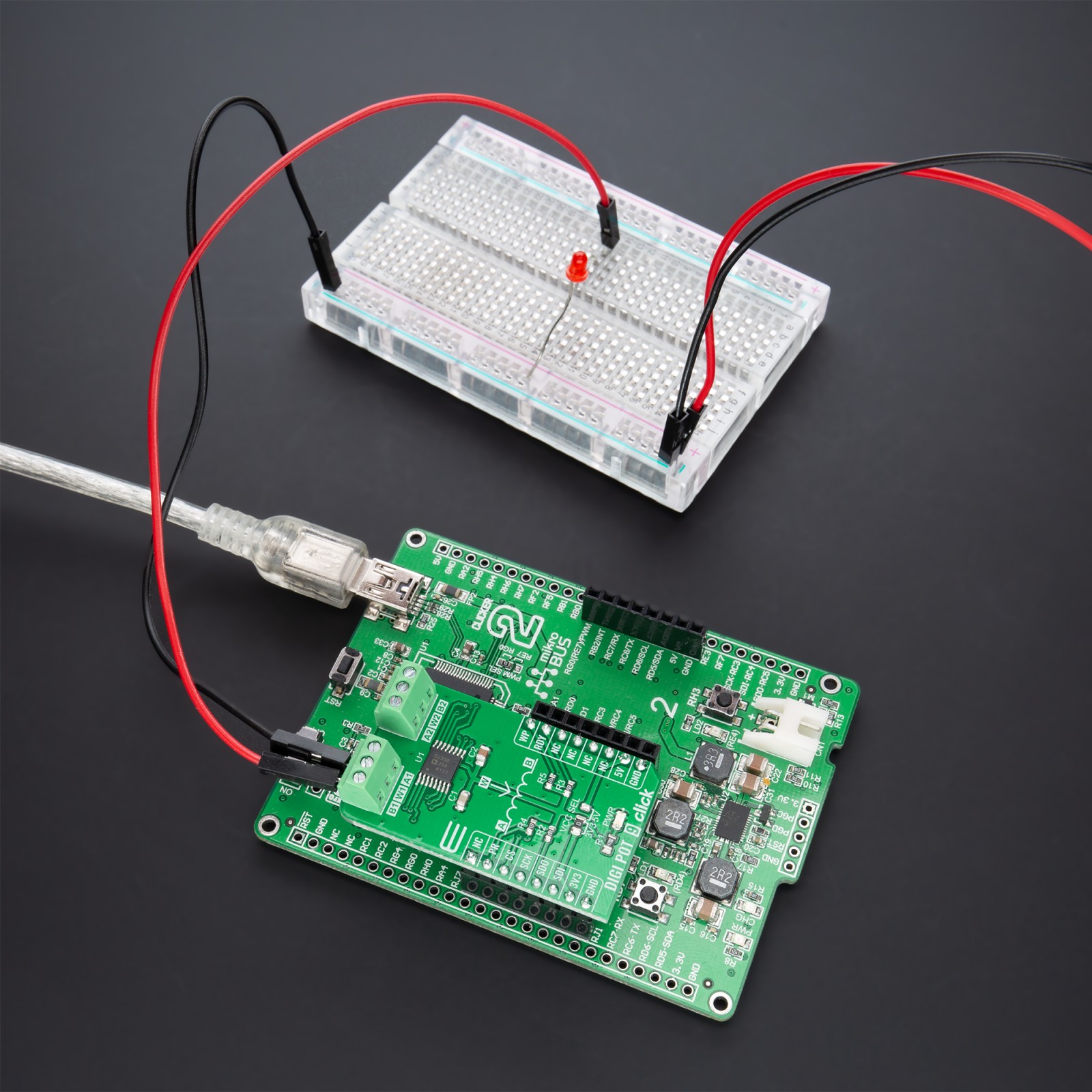

DIGI POT 9 Click

R750.00 ex. VAT

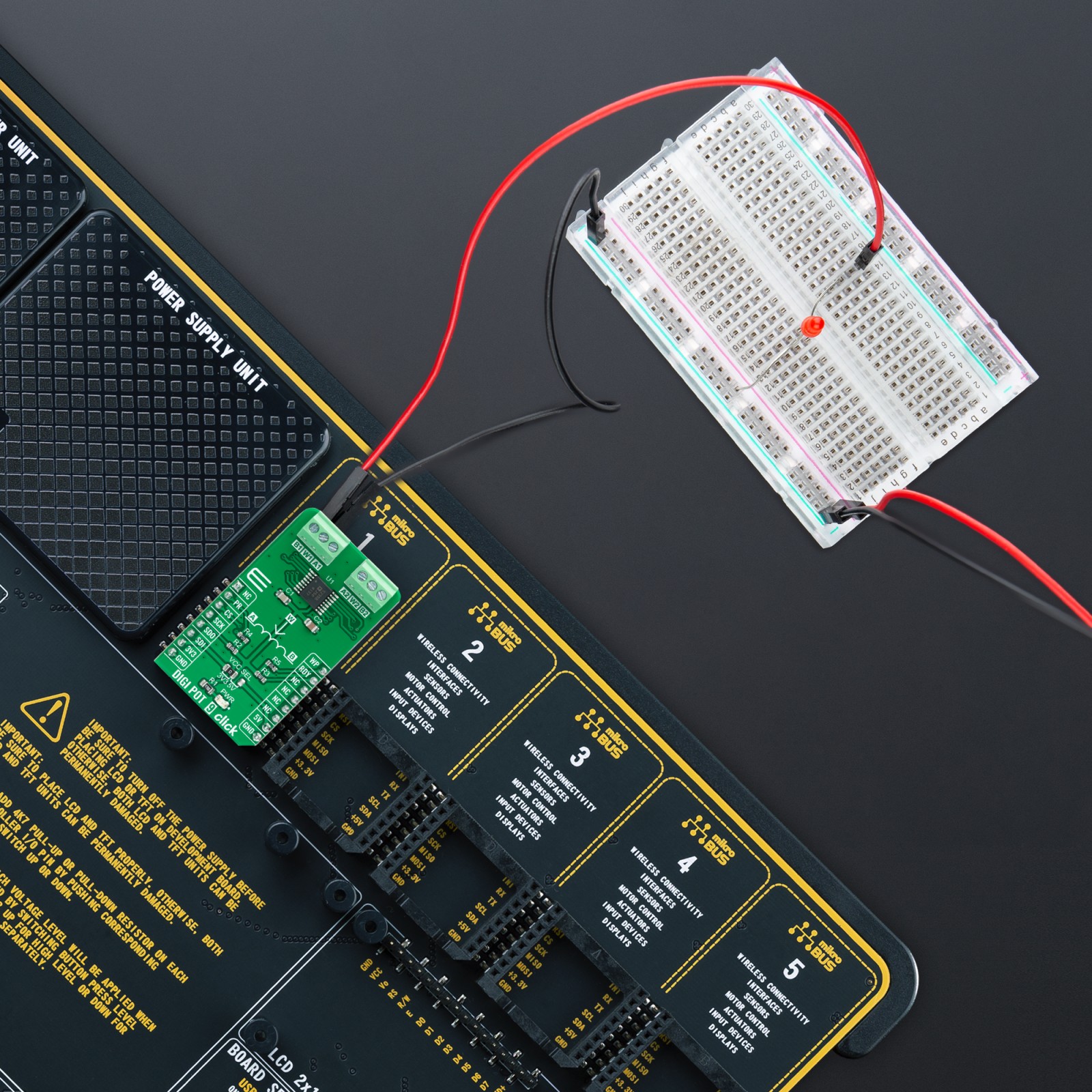

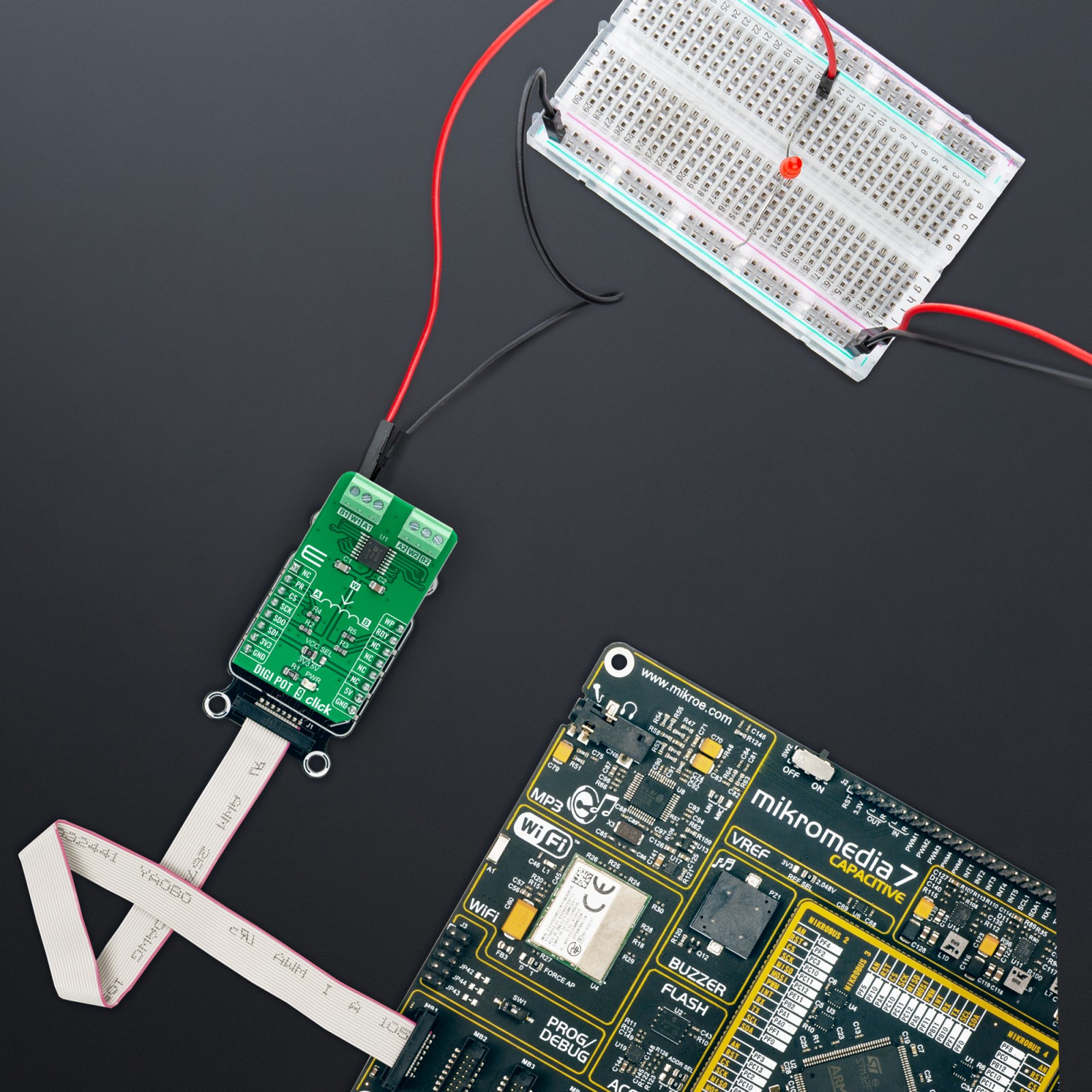

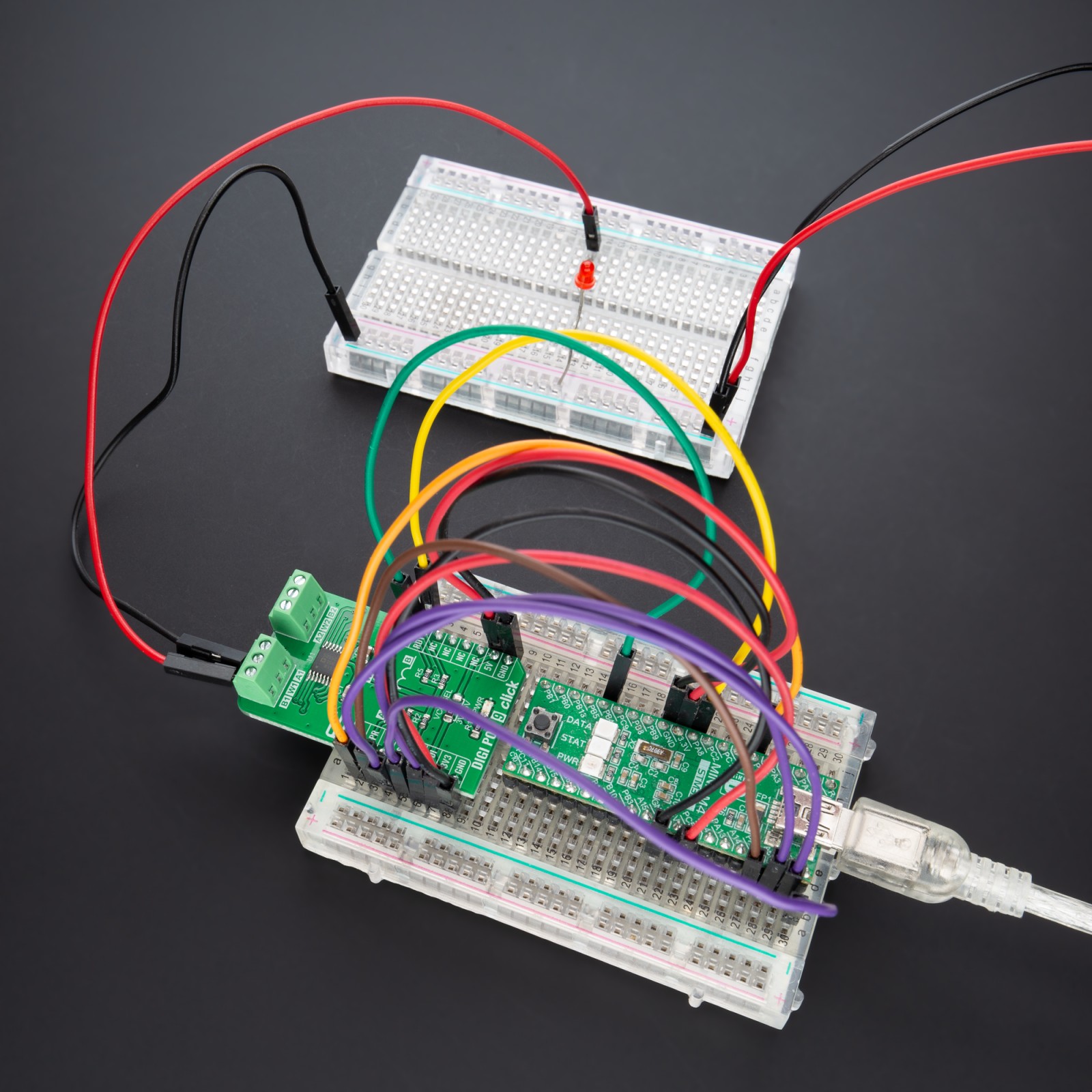

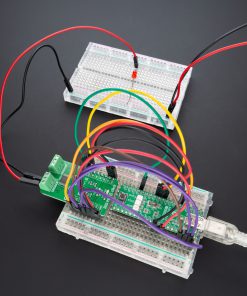

DIGI POT 9 Click is a compact add-on board used as a digitally controlled potentiometer. This board features the AD5235, a dual-channel, nonvolatile memory, digitally controlled potentiometer from Analog Devices. The AD5235’s versatile programming via an SPI-compatible serial interface allows multiple modes of operation and adjustment. The resistor wiper position is determined by the RDAC register contents, which act as a scratchpad register, allowing unlimited changes of resistance settings. The nominal resistance of the RDAC between terminal A and terminal B (RAB) is 250 kΩ with 1024 positions (10-bit resolution). This Click board™ can be used as mechanical potentiometer replacements, voltage-to-current conversions, gain and offset adjustment, and many other applications.

DIGI POT 9 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R712.50 |

| 10+ | R675.00 |

| 15+ | R637.50 |

| 20+ | R613.50 |