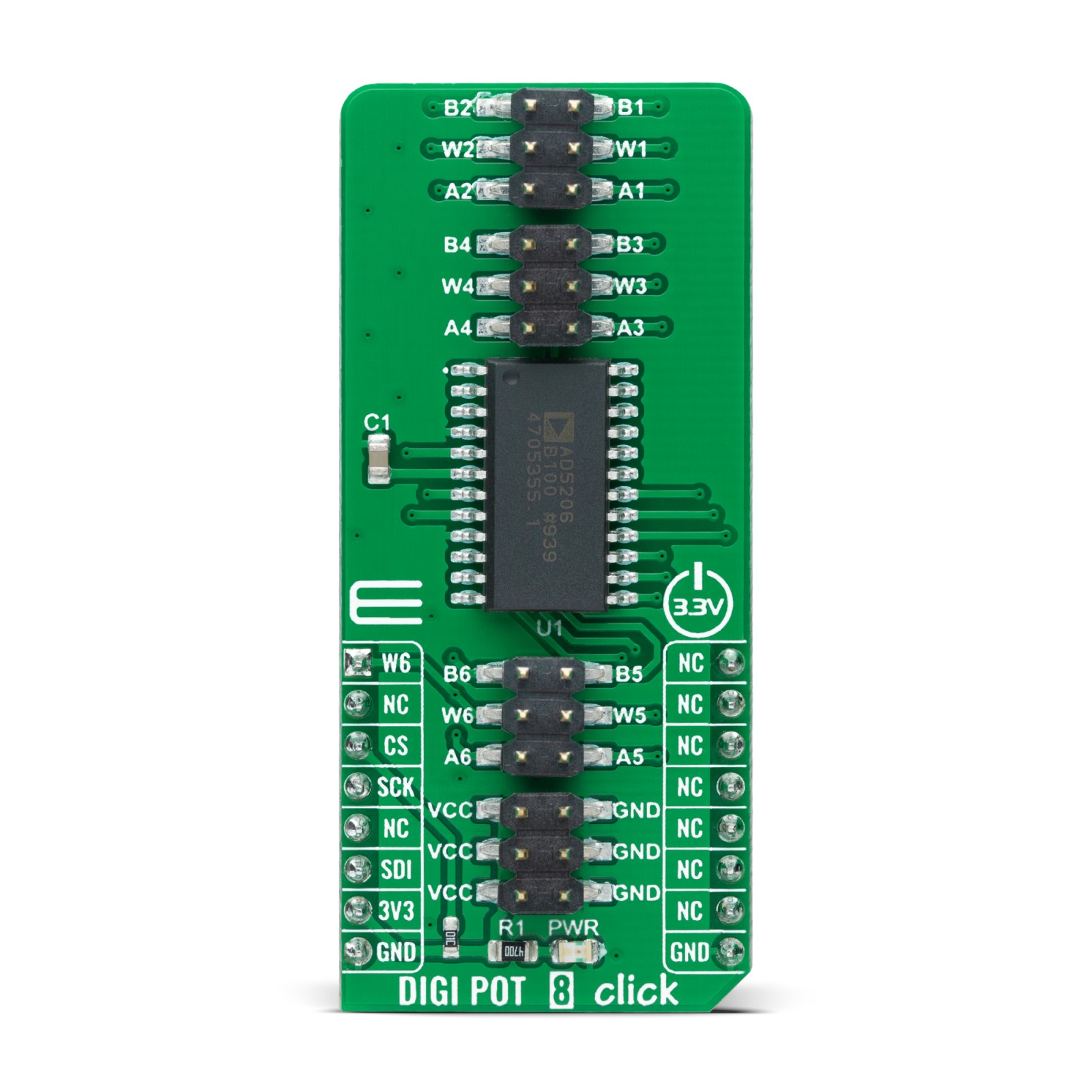

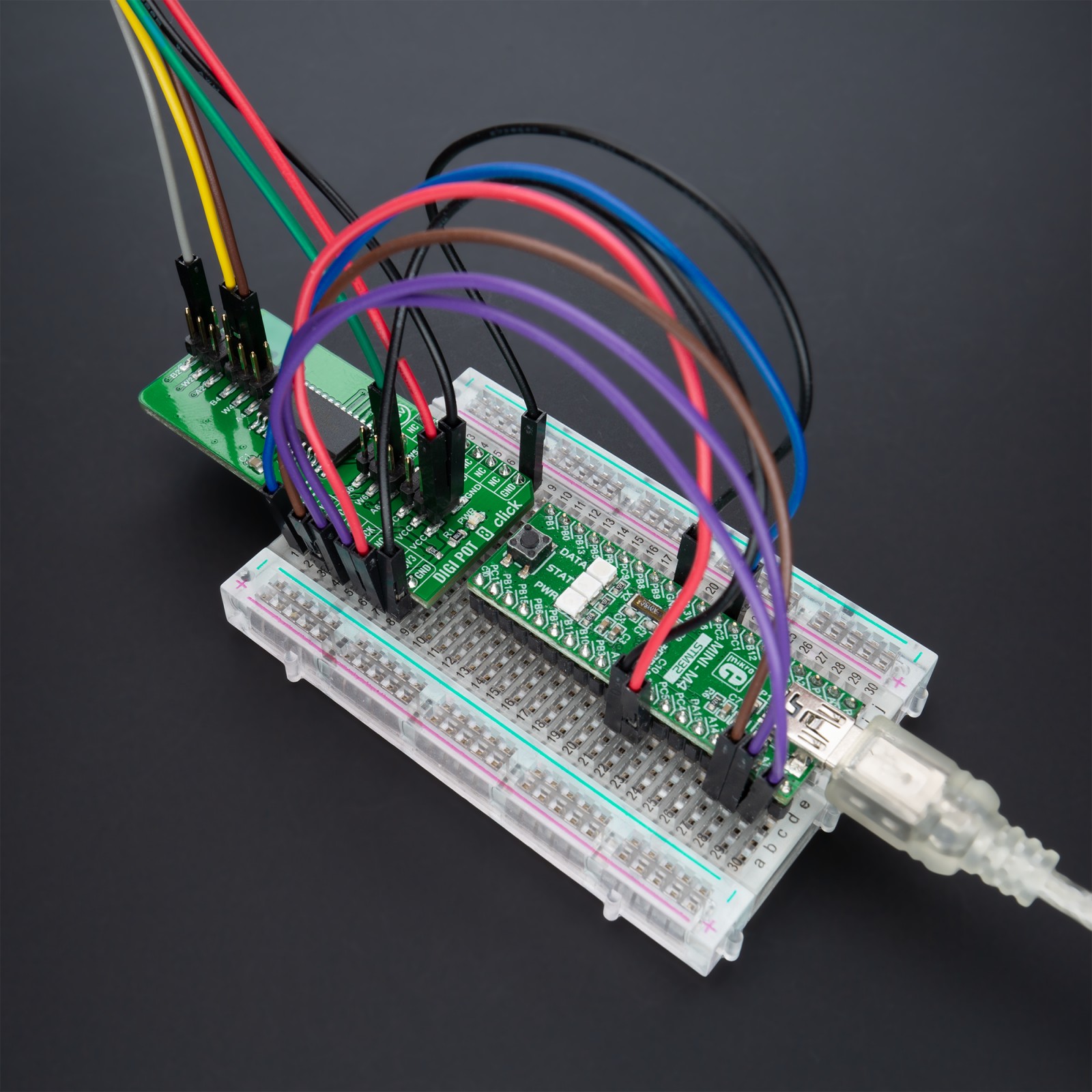

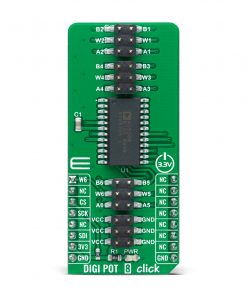

DIGI POT 8 Click

R460.00 ex. VAT

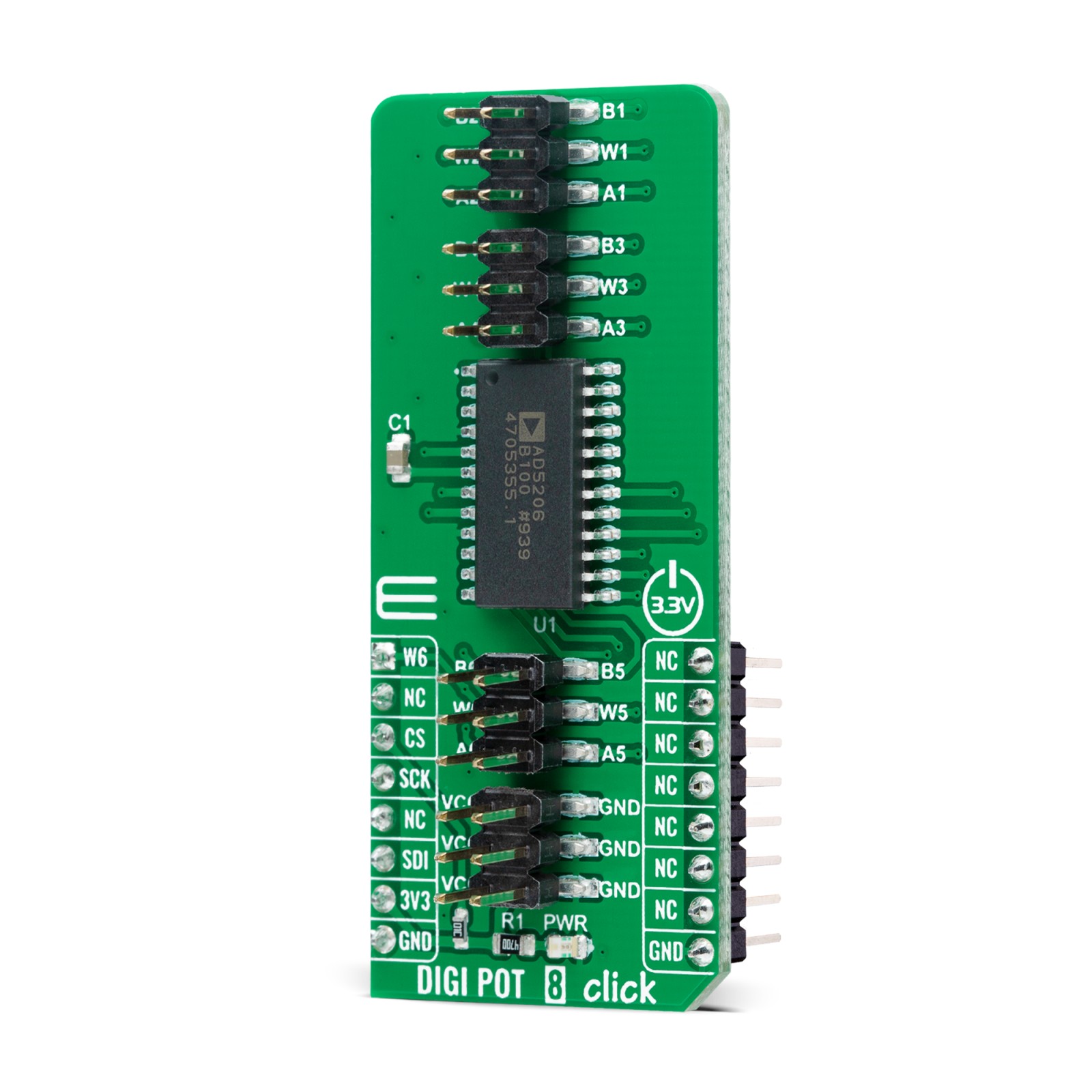

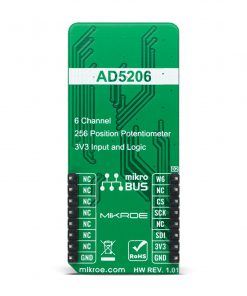

DIGI POT 8 Click is a compact add-on board used as a digitally controlled potentiometer. This board features the AD5206, 6-channel 256-position digitally controlled variable resistor device from Analog Devices. Each channel of the AD5206 contains a fixed resistor with a wiper contact that taps the fixed resistor value of 100kΩ at a point determined by a digital code loaded into the SPI-compatible serial-input register. This Click board™ can be used as mechanical potentiometer replacements, voltage-to-current conversions, gain and offset adjustment, and many other applications.

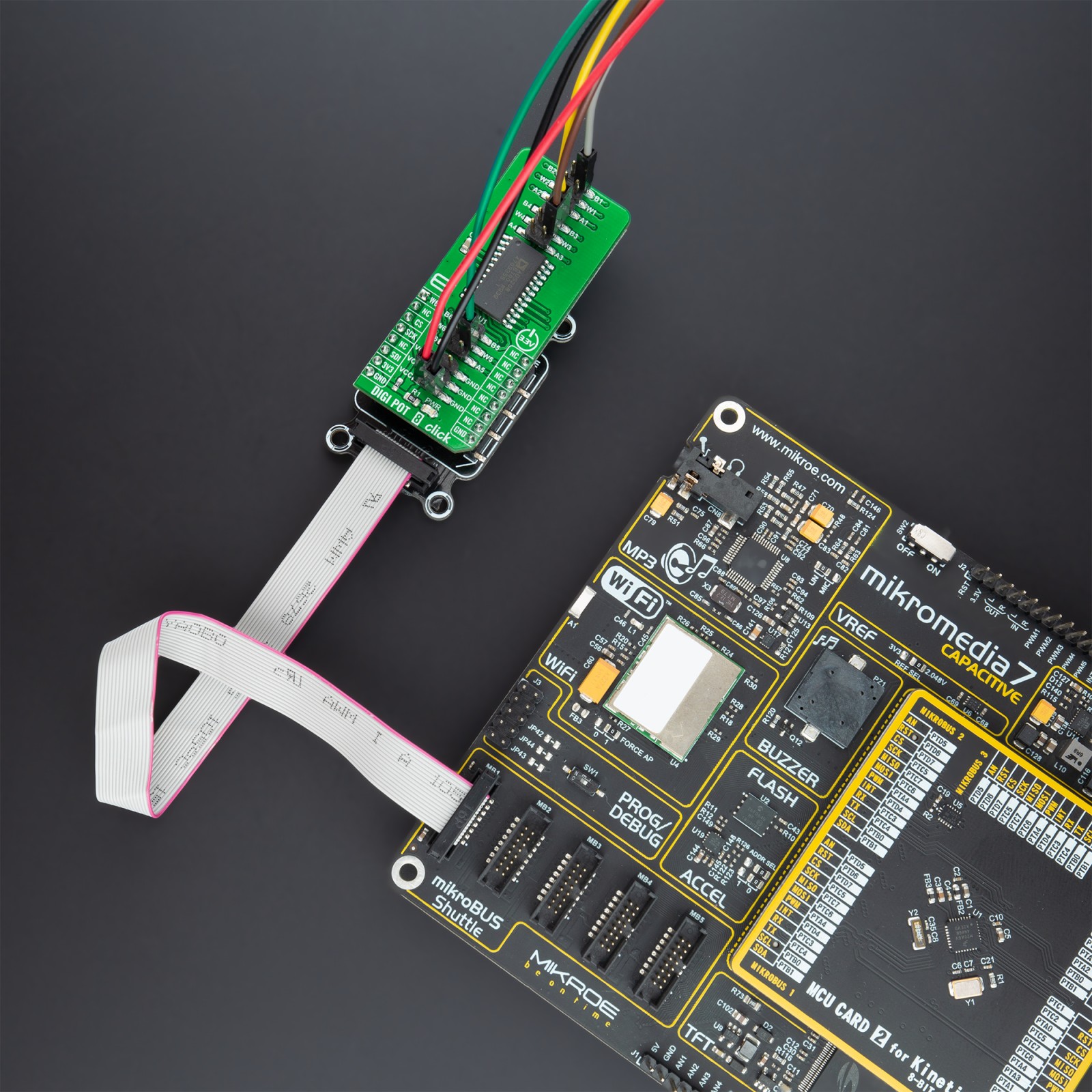

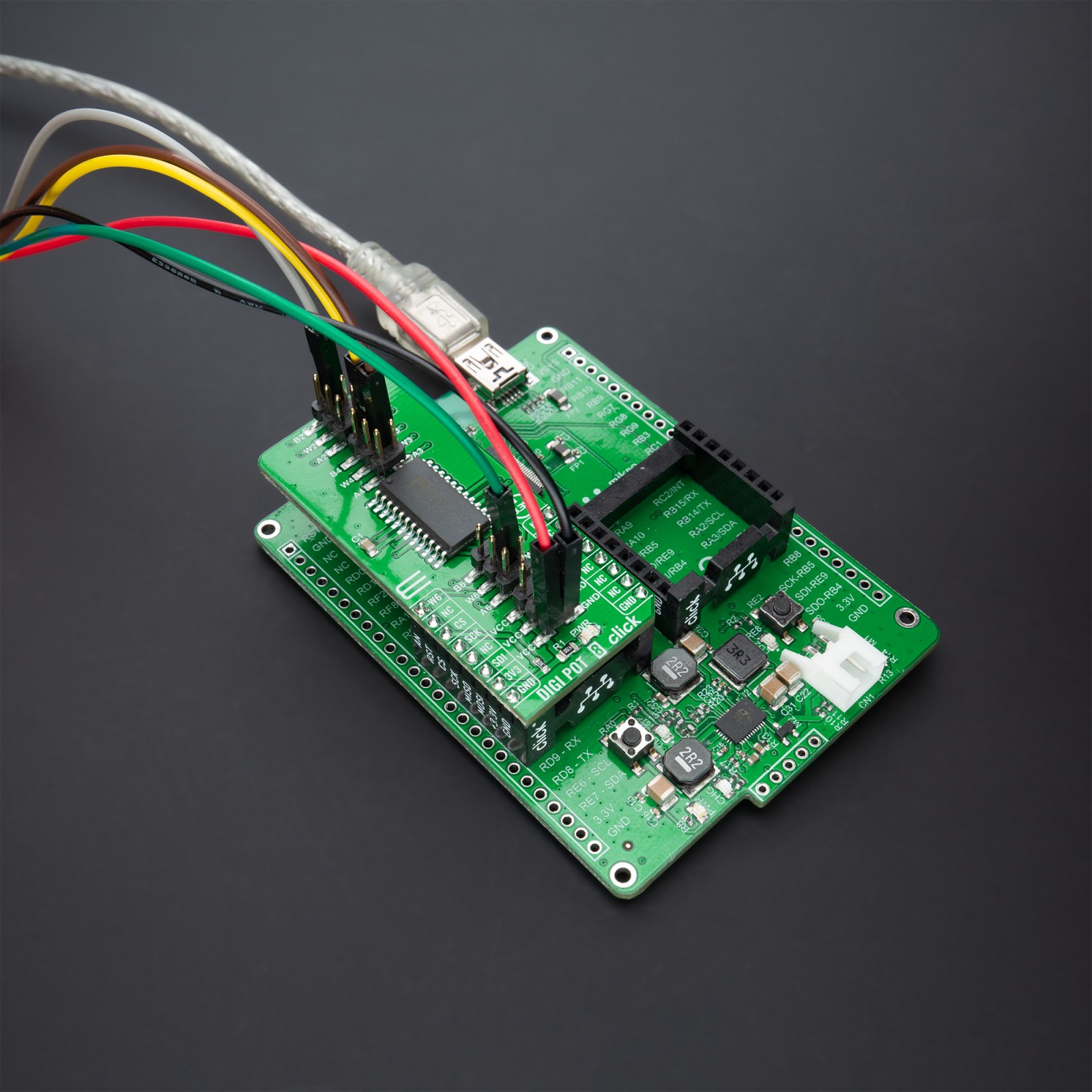

DIGI POT 8 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R437.00 |

| 10+ | R414.00 |

| 15+ | R391.00 |

| 20+ | R376.28 |