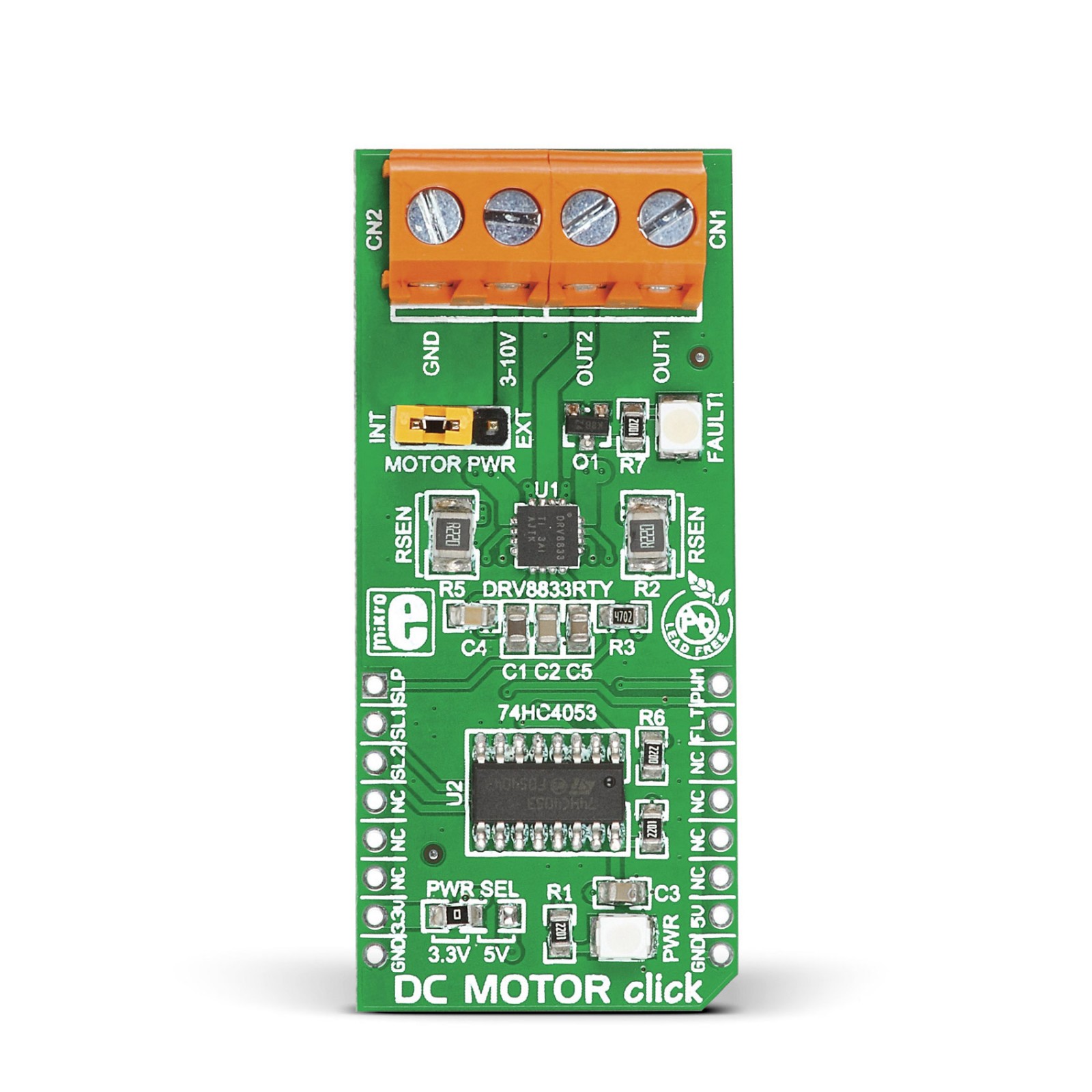

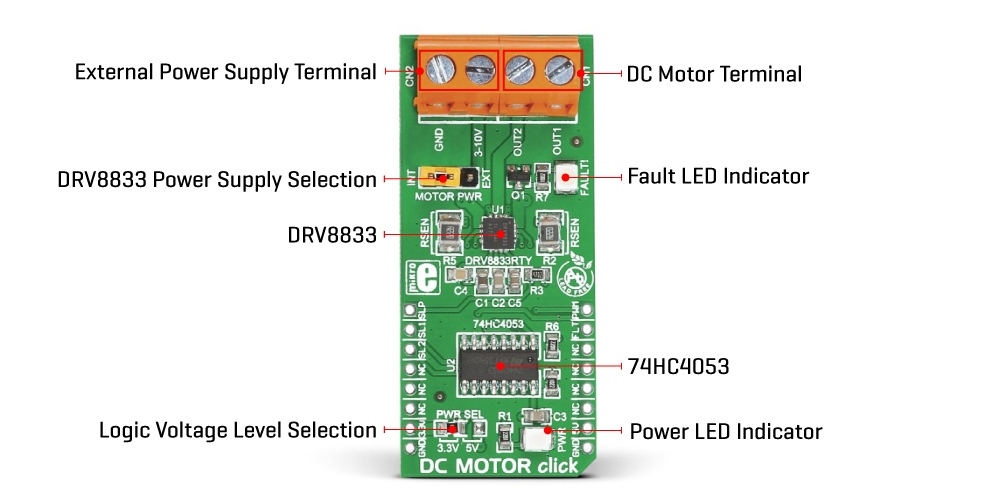

DC MOTOR Click

R390.00 ex. VAT

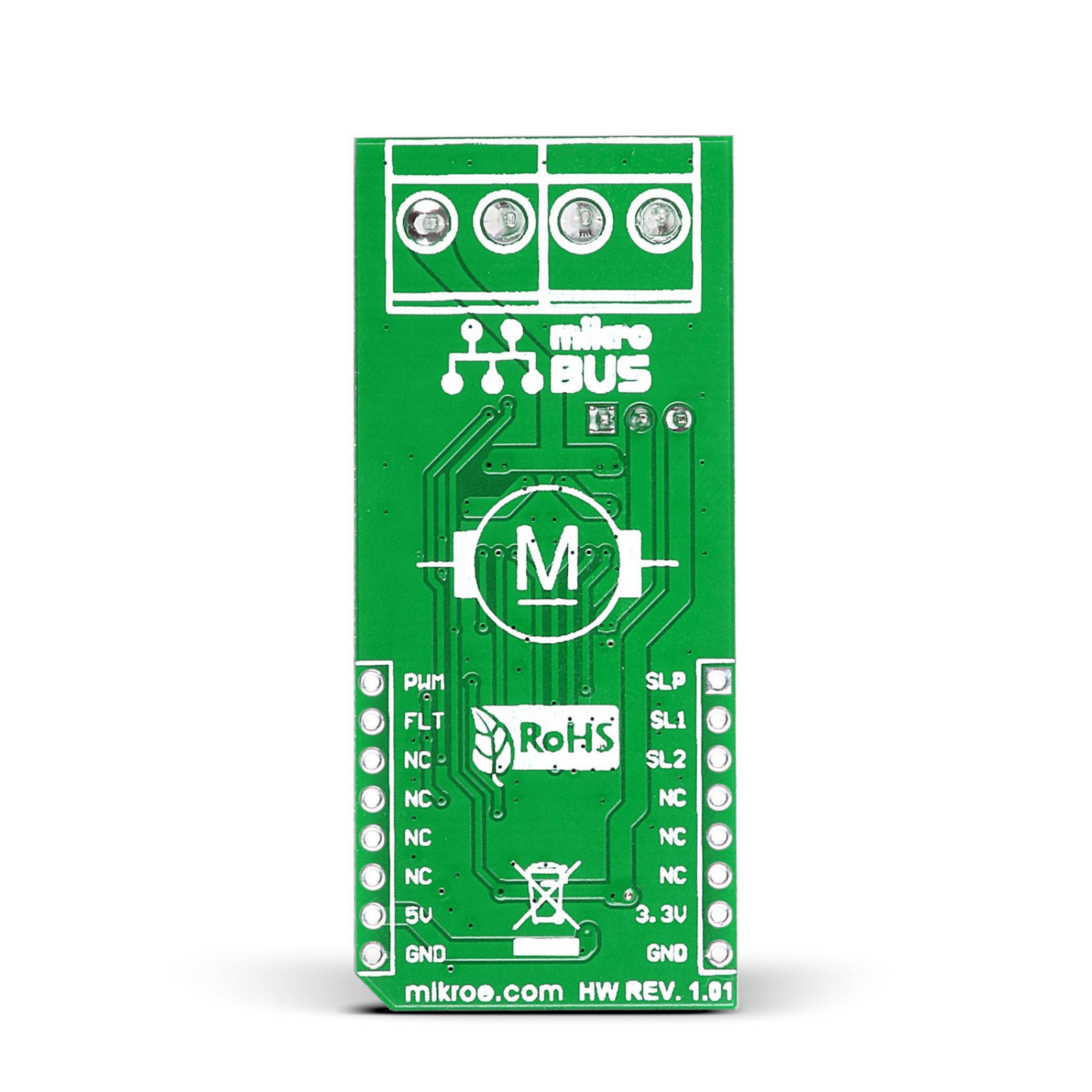

DC Motor Click is a compact add-on board with a brushed DC motor driver. This board features the DRV8833, an H-bridge motor driver with current-control PWM circuitry from Texas Instruments. The DRV8833 has two integrated H-bridges connected in parallel for double the current of a single H-bridge rated for an operating voltage range from 3V to 10V with simple PWM and GPIO control. It also has a complete set of diagnostic (fault indication) and protection capabilities that support robust and reliable operation, like over-current protection, short circuit protection, under voltage lockout, and overtemperature. This Click board™ is suitable for driving DC brushed motors for toys, printers, and other mechatronic applications.

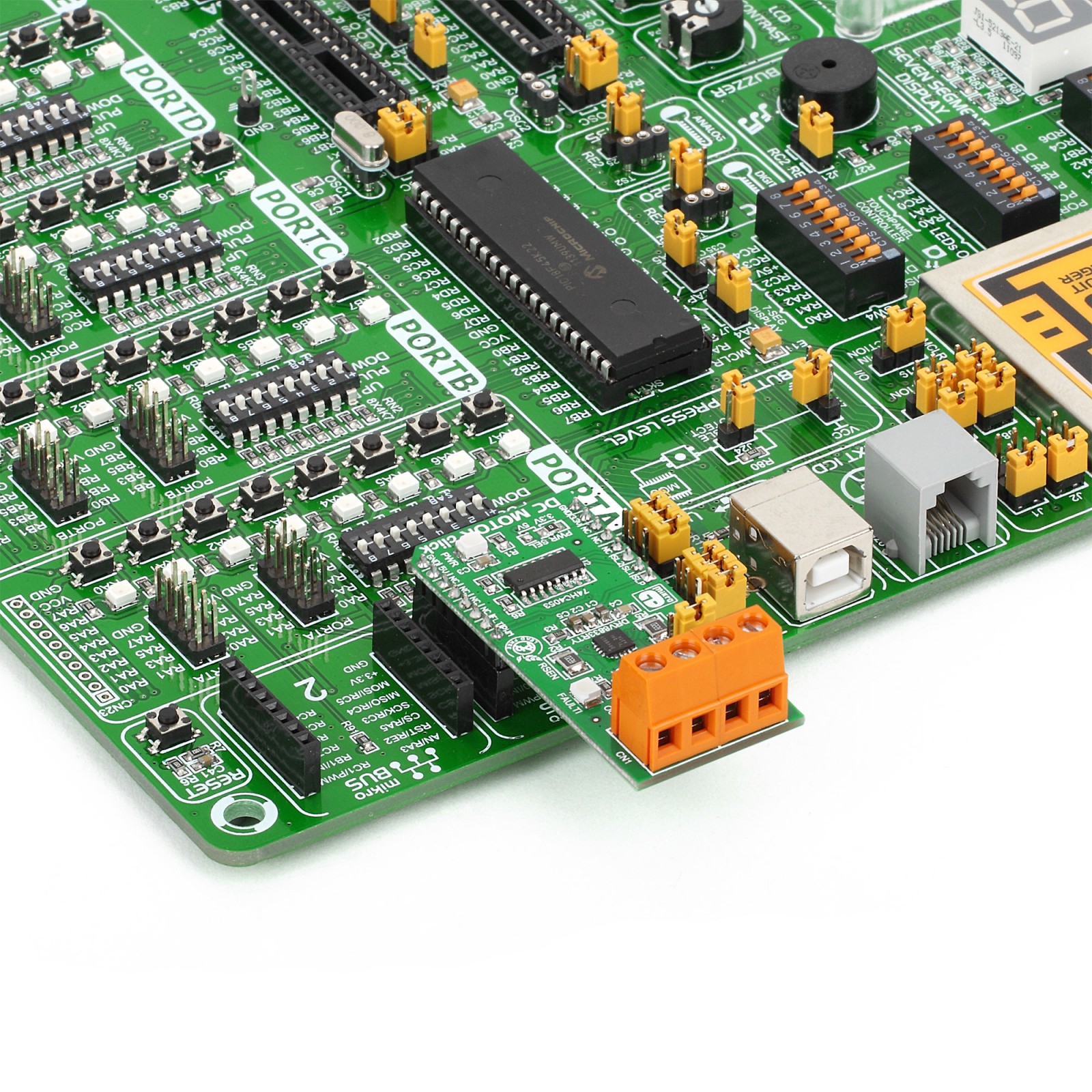

DC Motor Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R370.50 |

| 10+ | R351.00 |

| 15+ | R331.50 |

| 20+ | R319.02 |