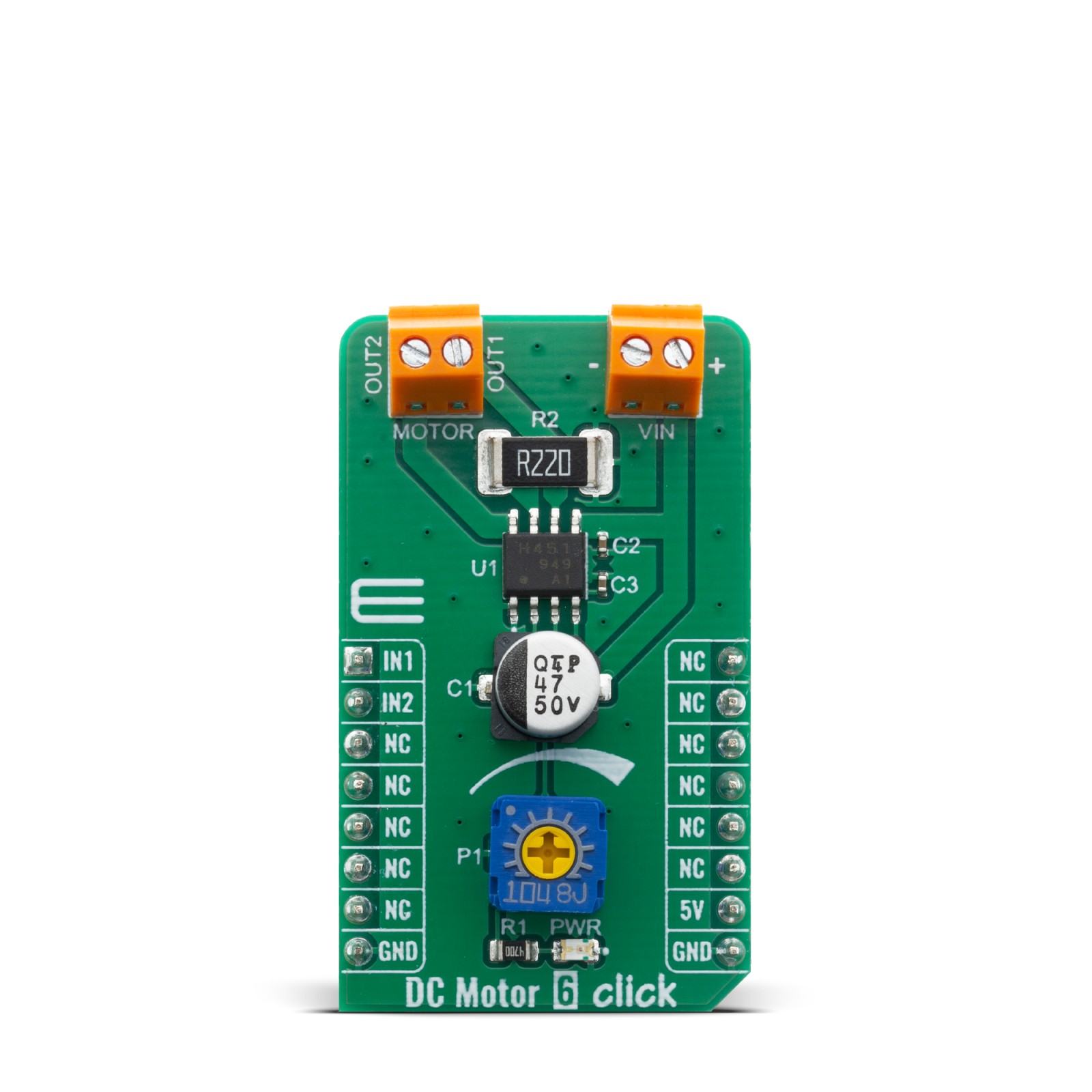

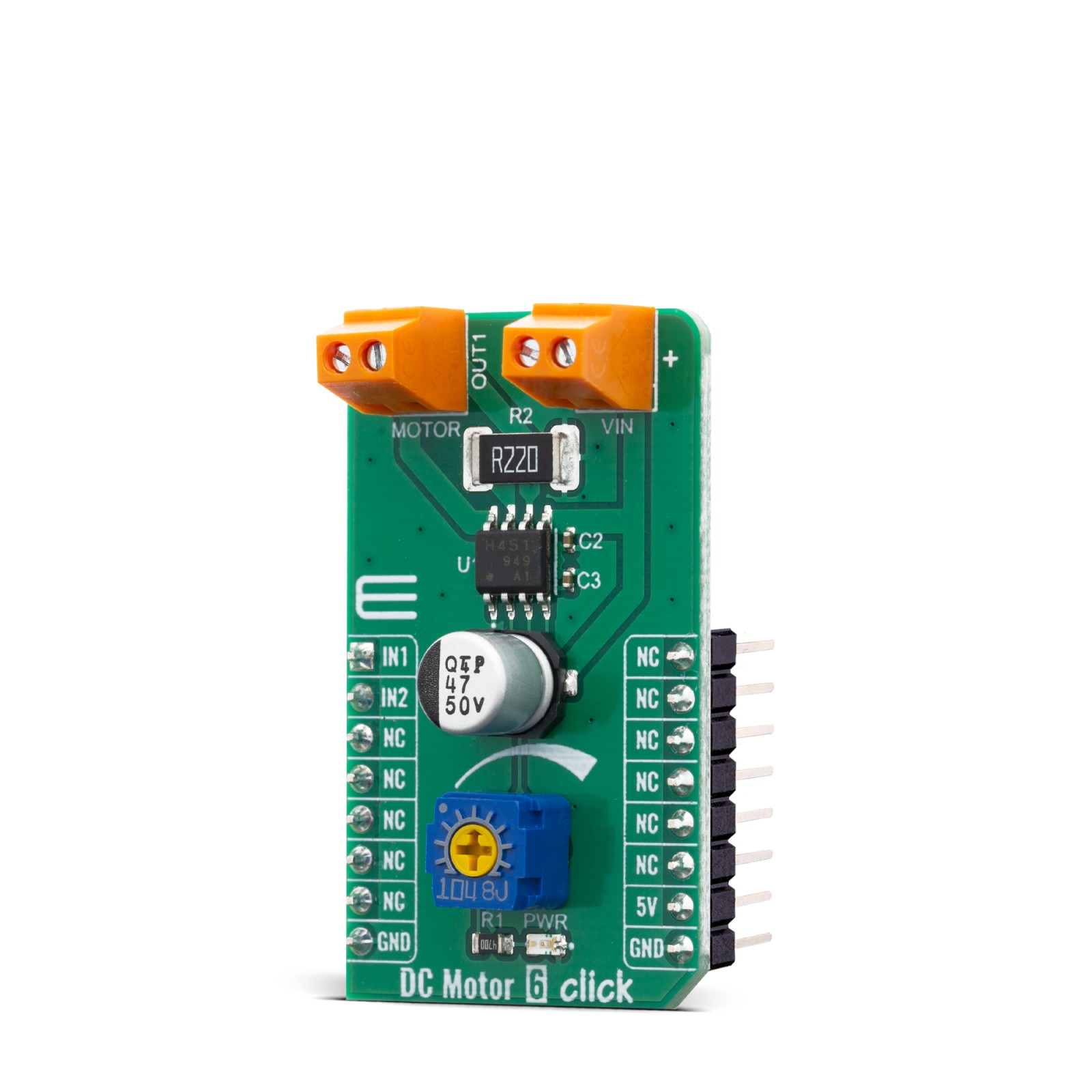

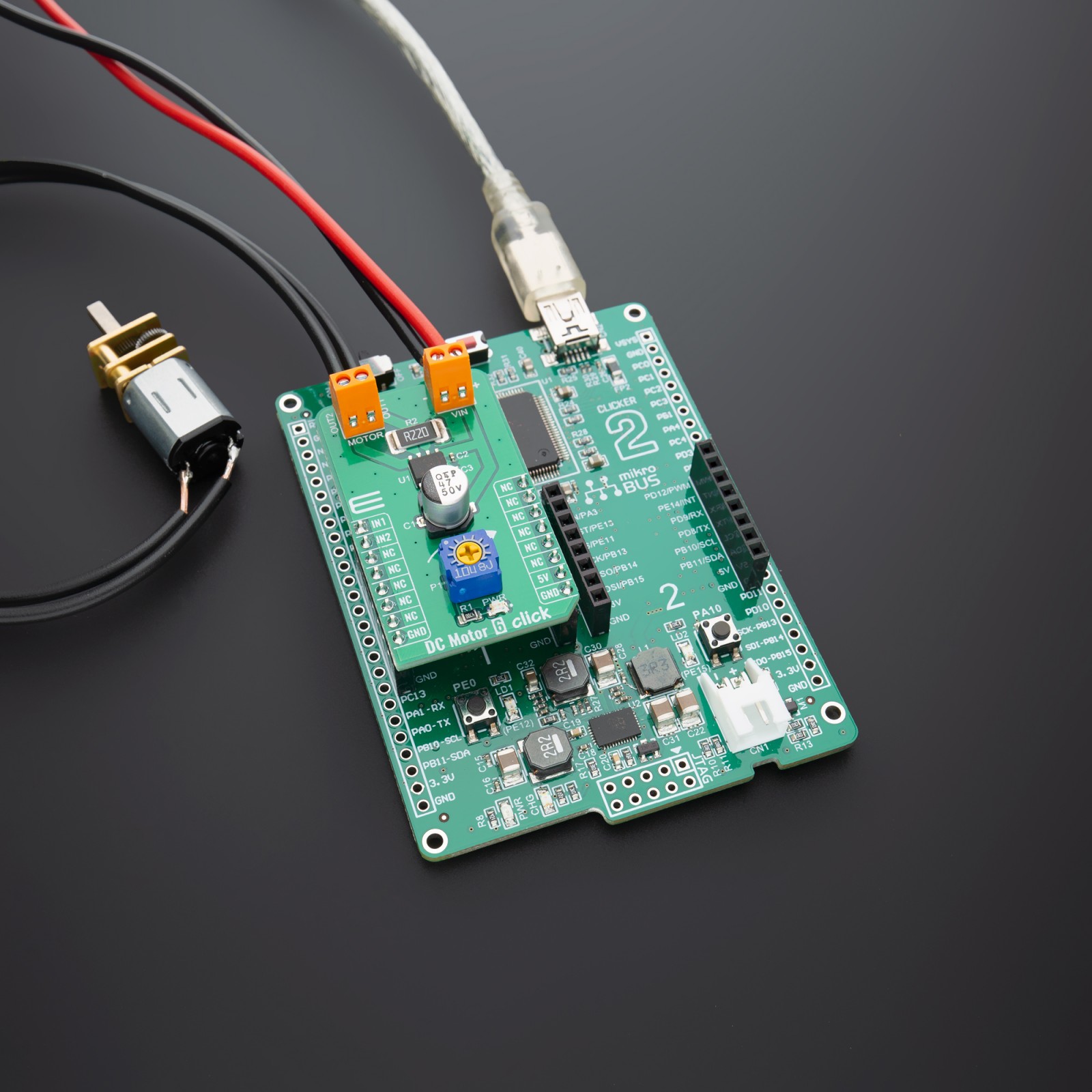

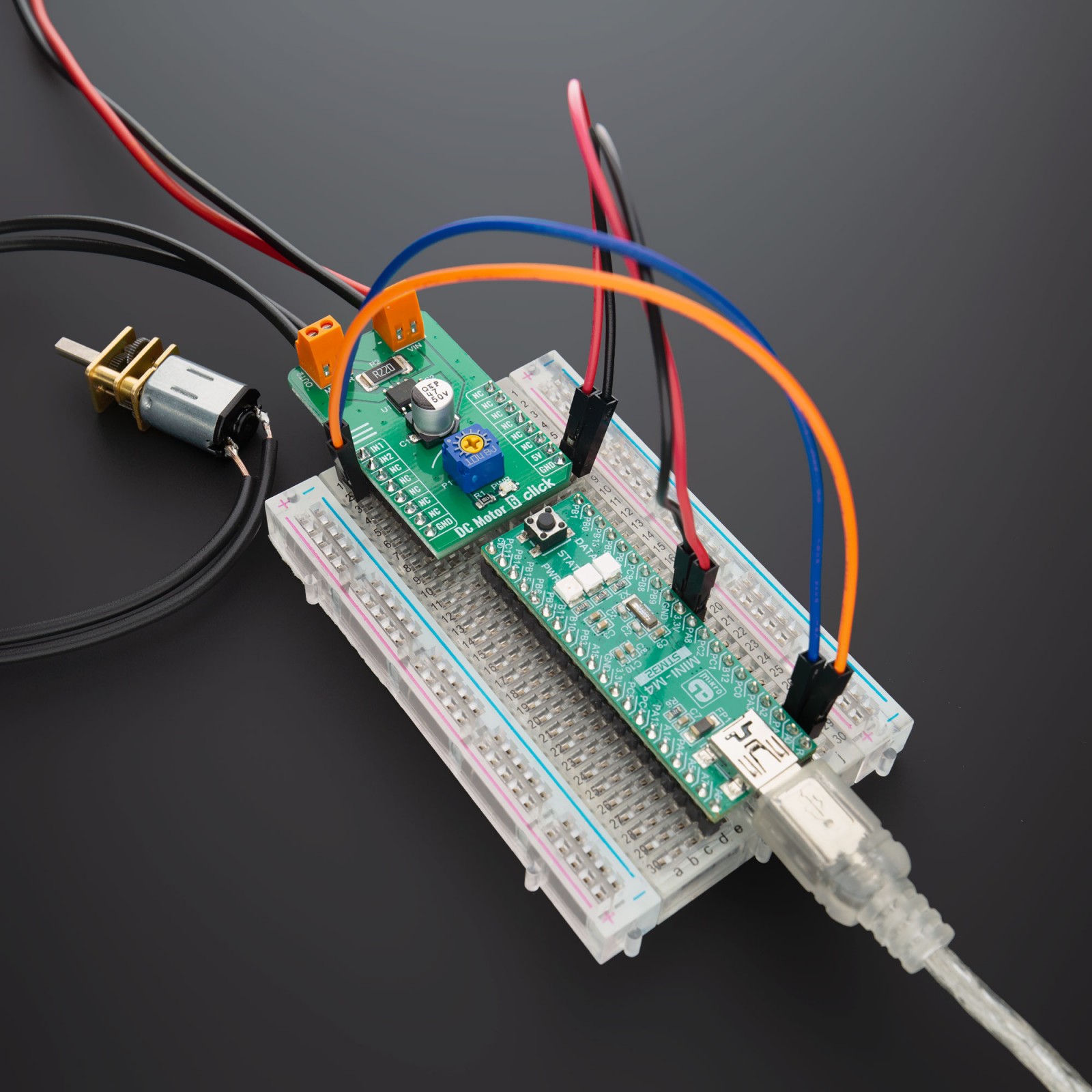

DC Motor 6 Click

R245.00 ex. VAT

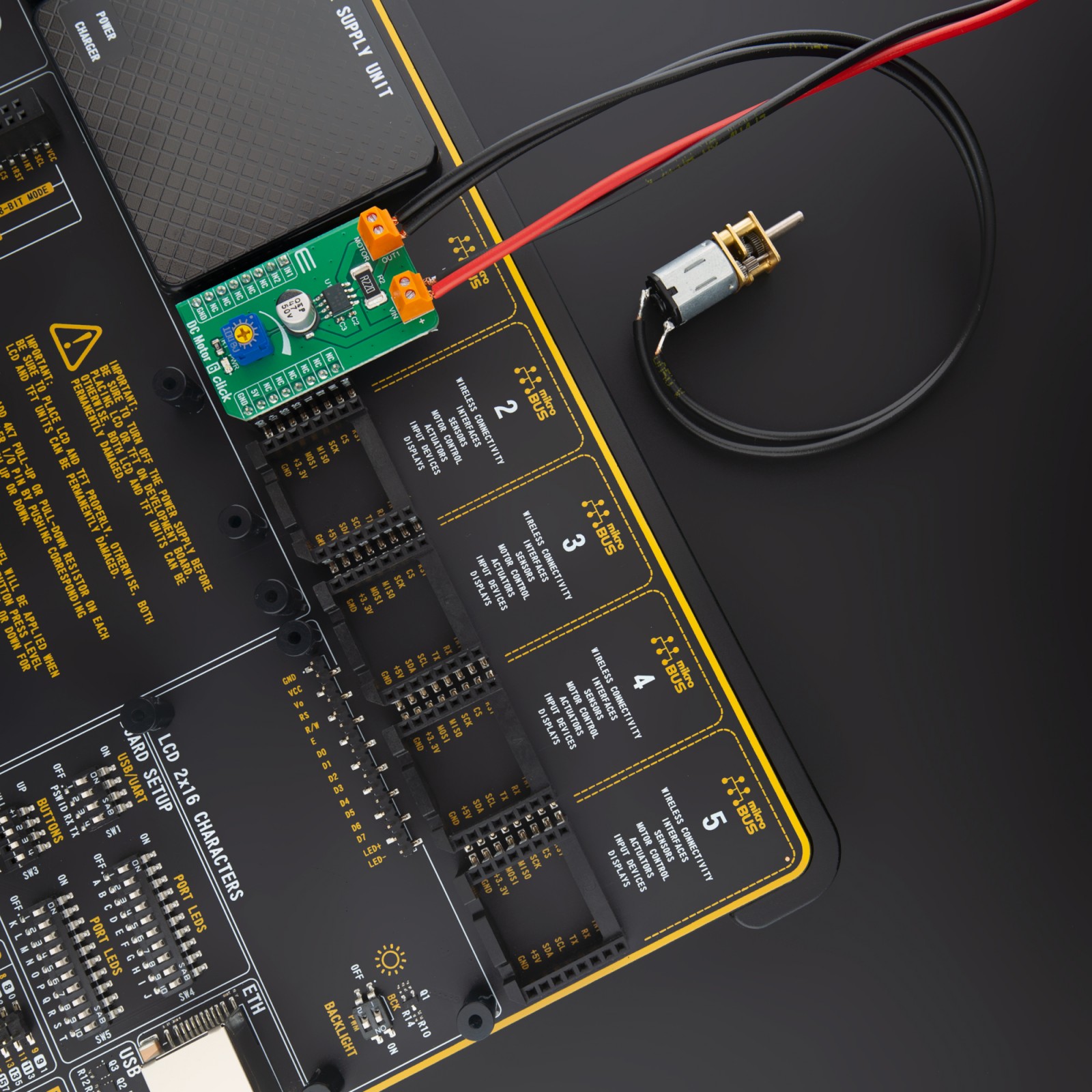

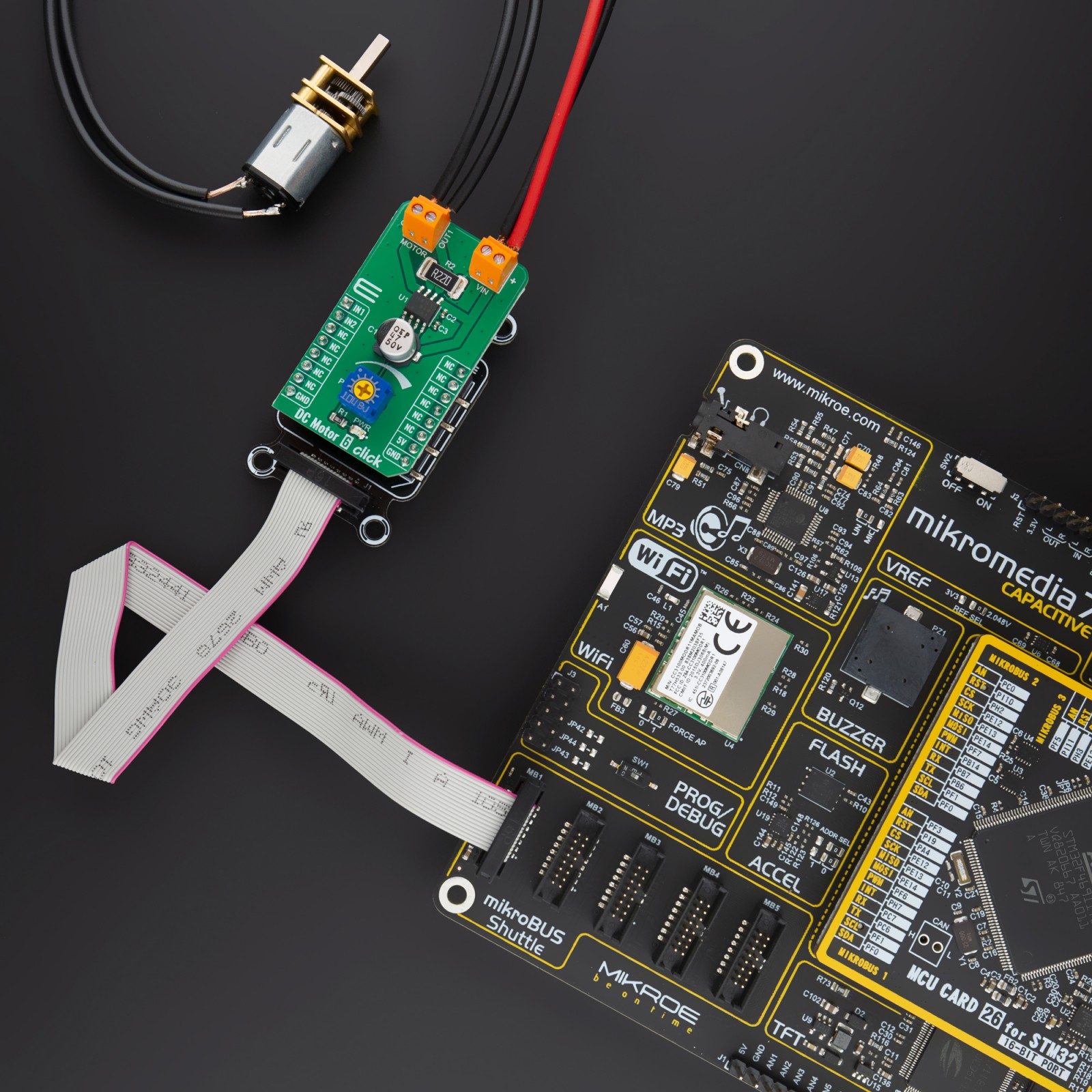

DC Motor 6 Click is a PWM chopper type brushed DC motor driver, labeled as TB67H451AFNG, produced by Toshiba. This IC includes one channel of motor output block, using a wide range of supply voltages, while delivering reasonably high current to the connected DC motors. Low ON-resistance MOSFETs and a PWM control help the TB67H451AFNG exhibit lower heat generation thus efficient motor drive. Furthermore, the TB67H451AFNG has two inputs, IN1 and IN2, which allow for selection of the four operation modes; forward (clockwise), reverse (counter-clockwise), short brake, and stop modes.

DC Motor 6 Click board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R232.75 |

| 10+ | R220.50 |

| 15+ | R208.25 |

| 20+ | R200.41 |