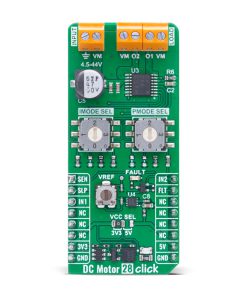

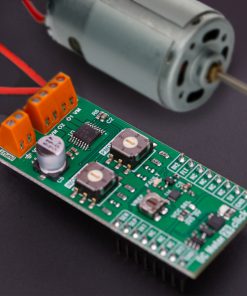

DC Motor 28 Click – FNG

R515.00 ex. VAT

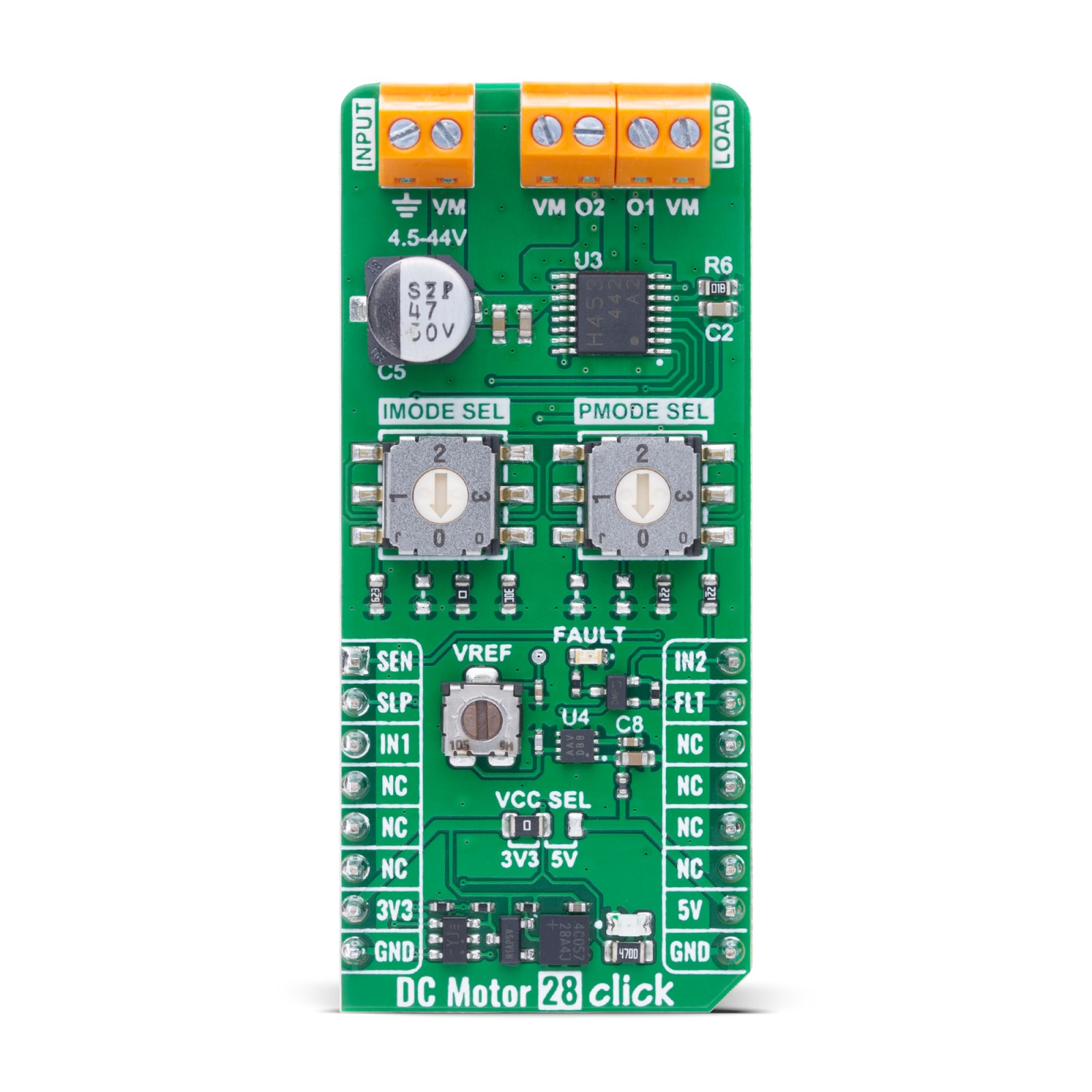

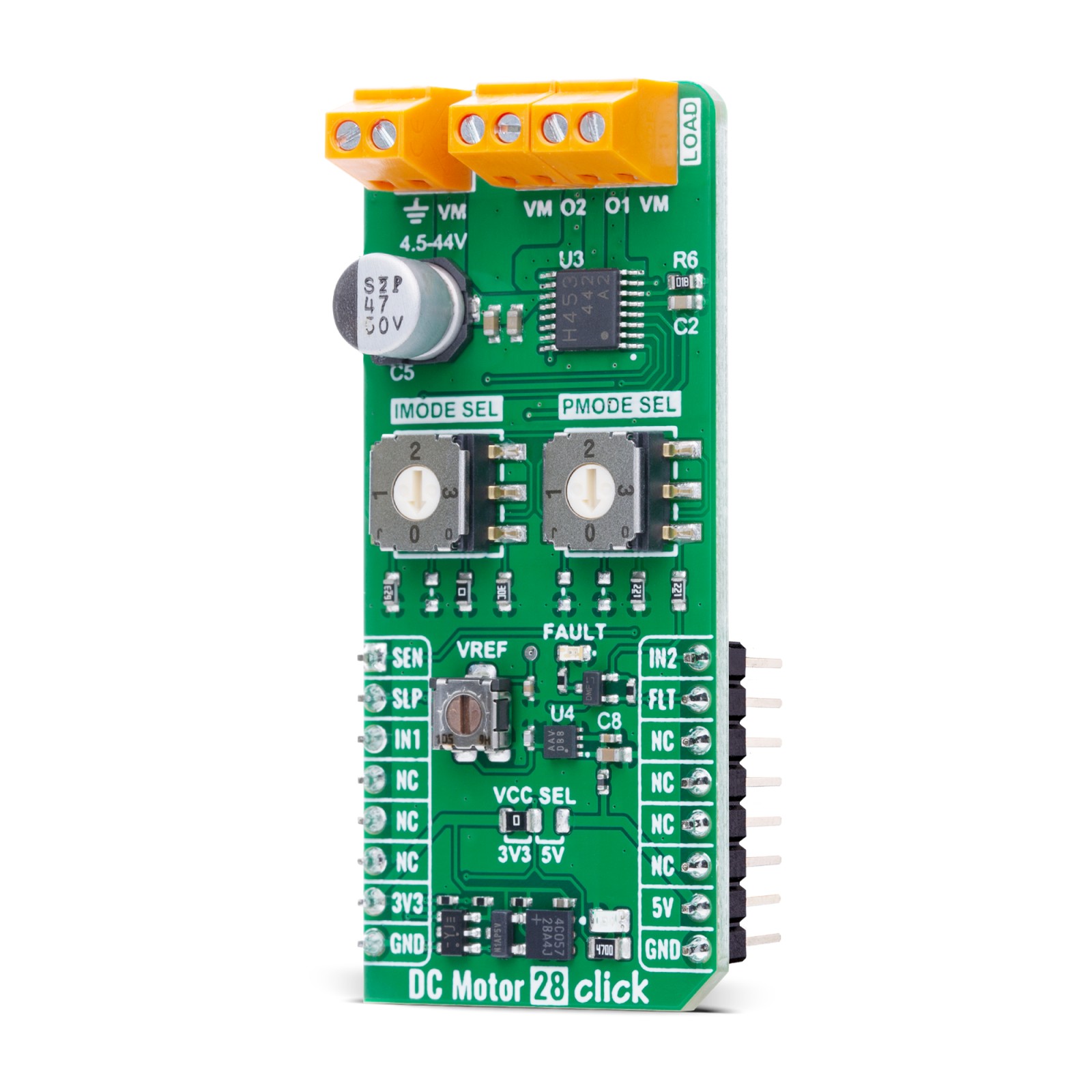

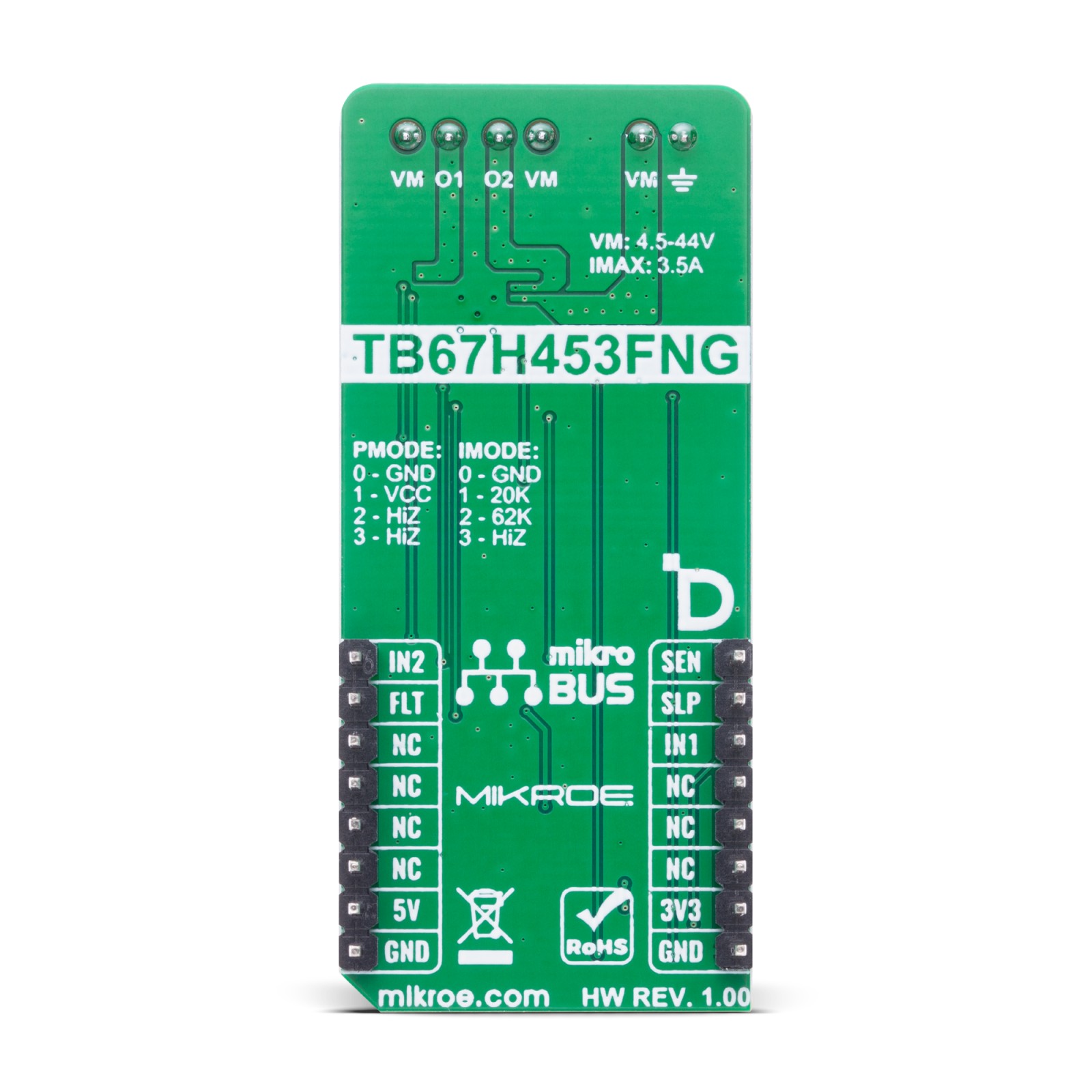

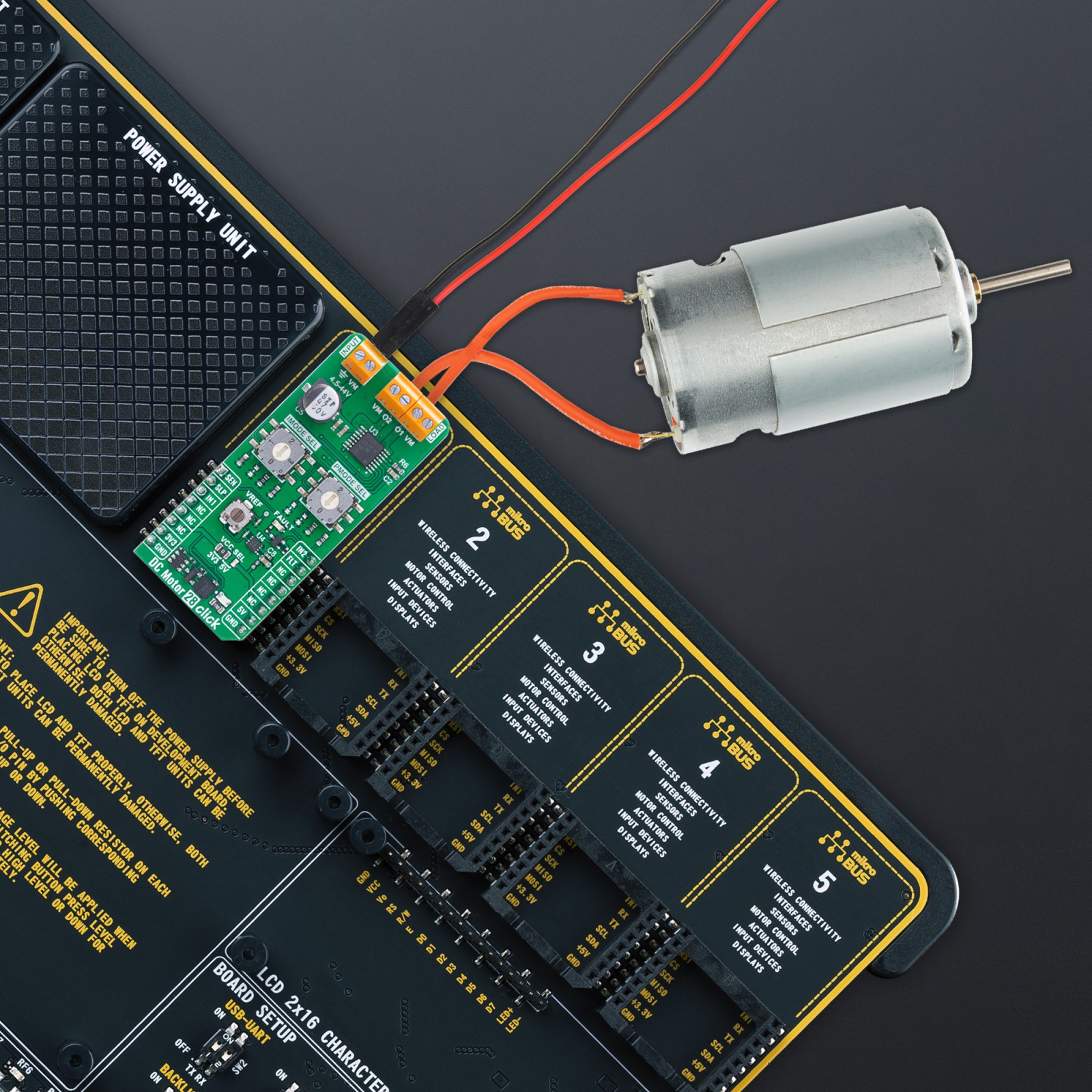

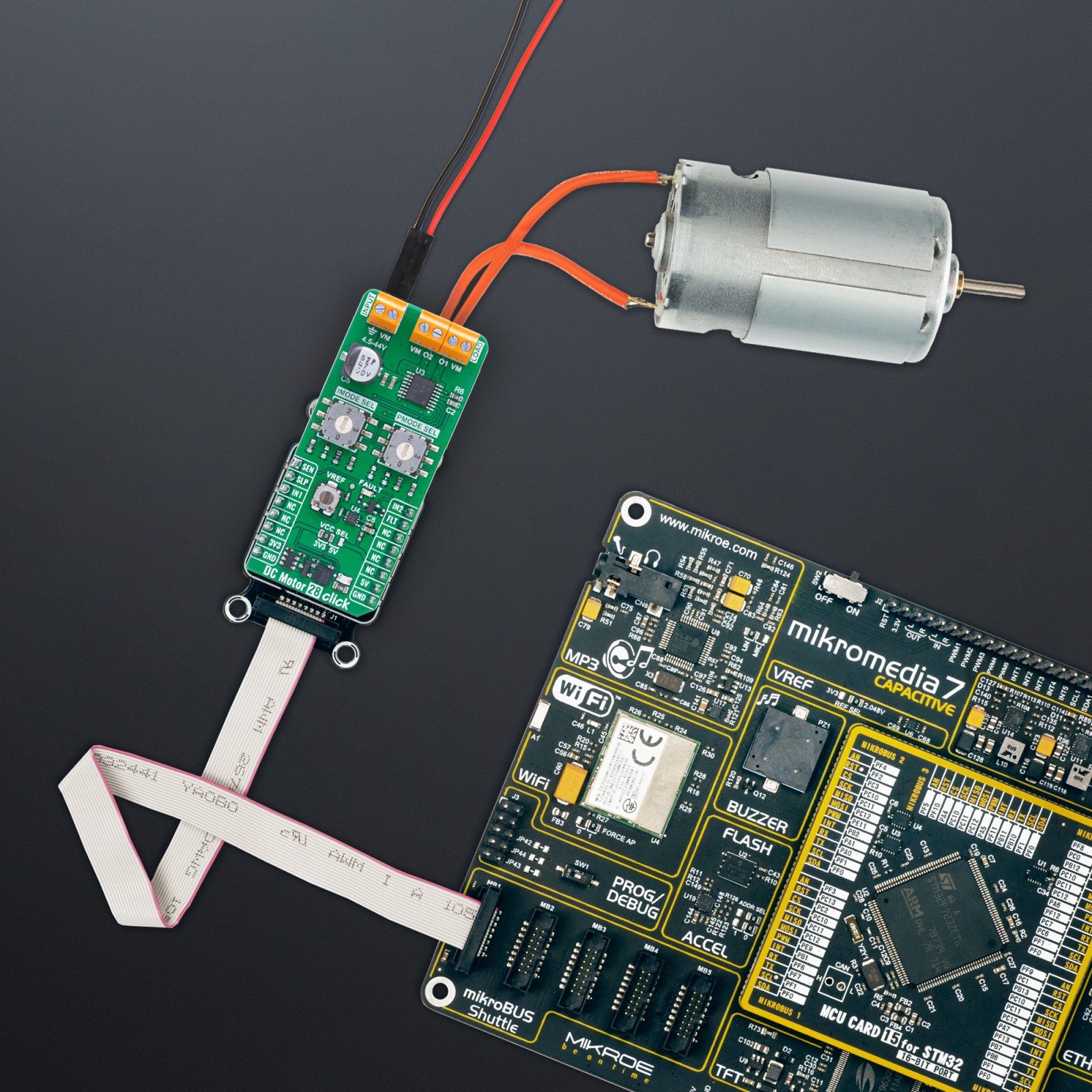

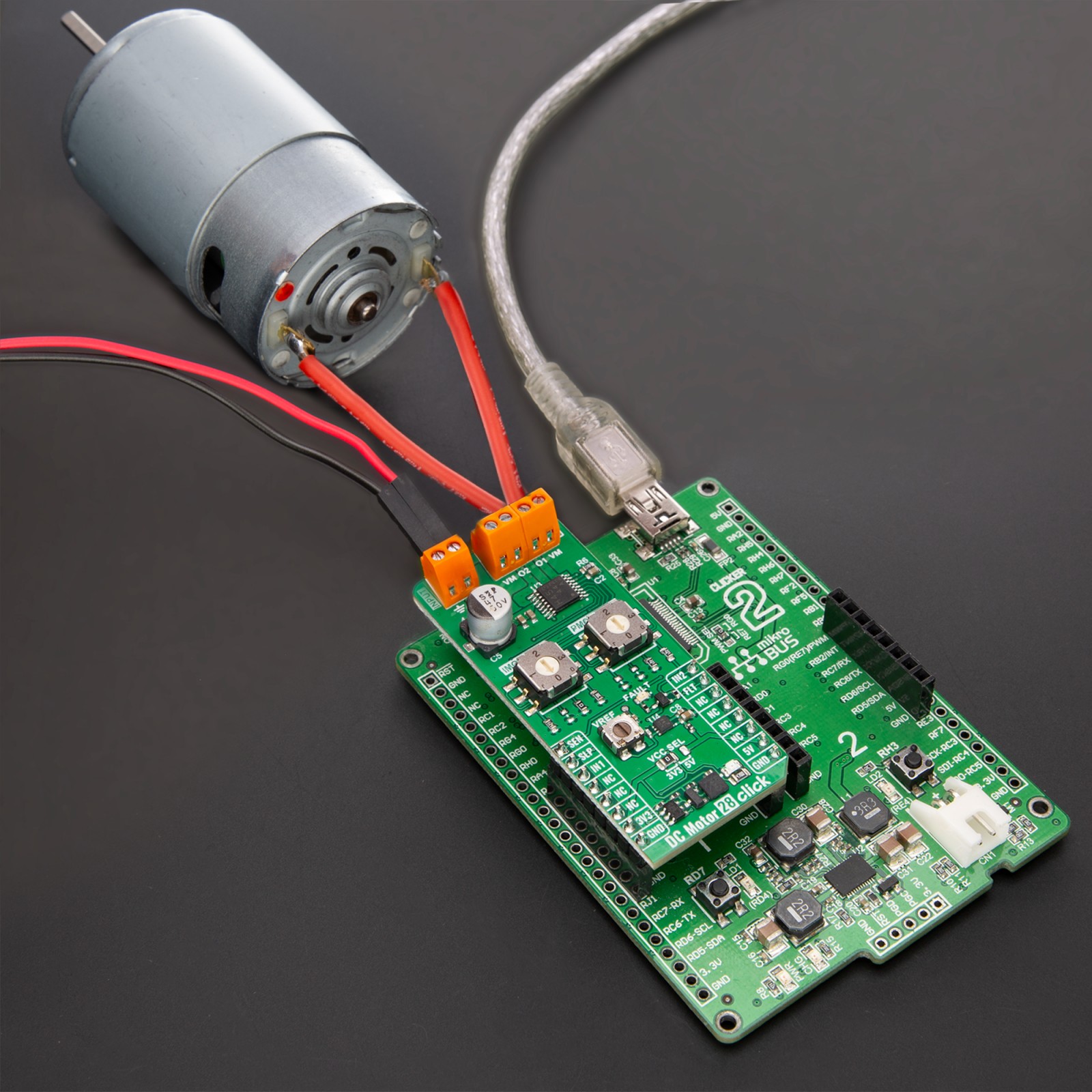

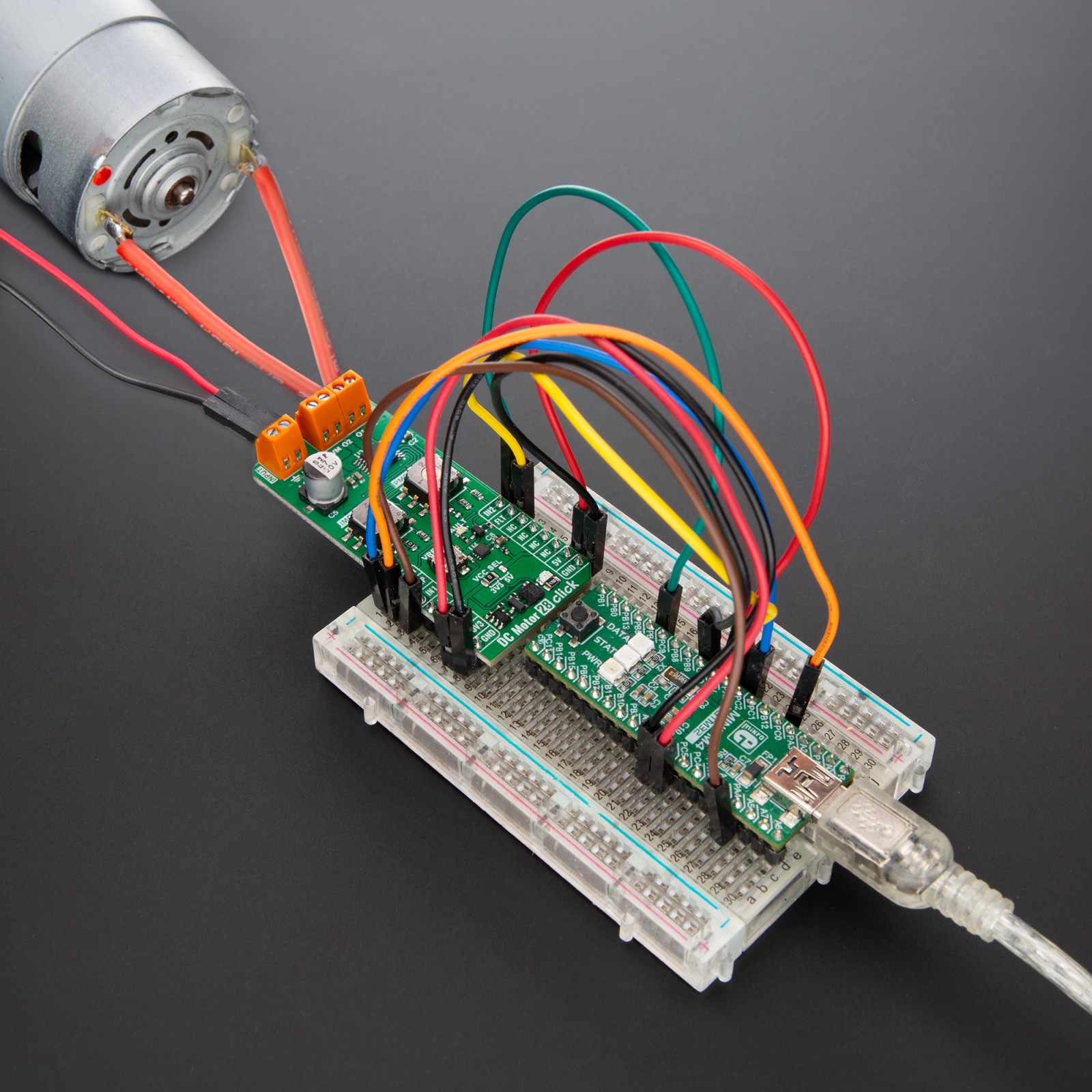

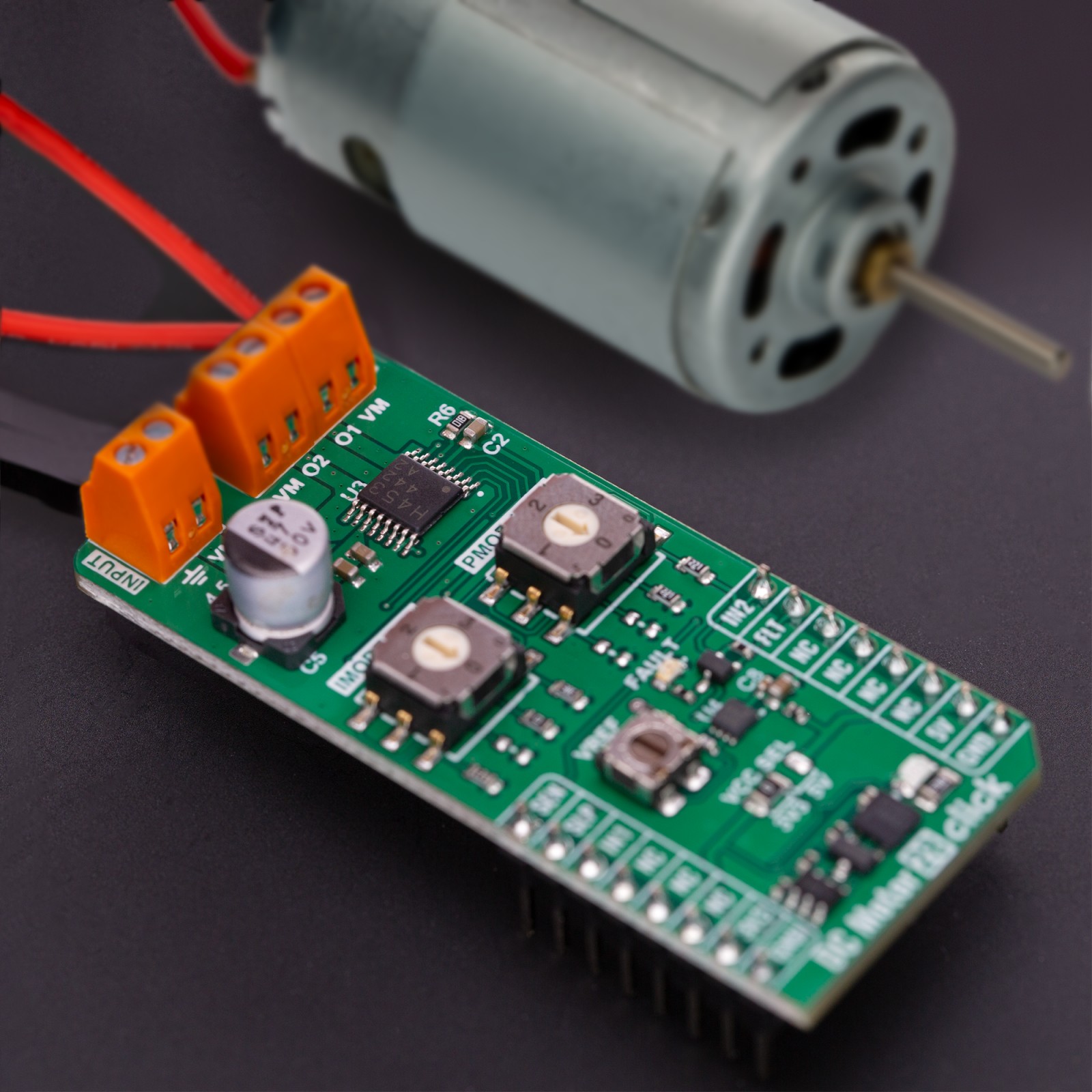

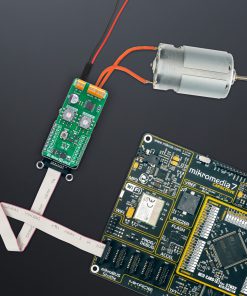

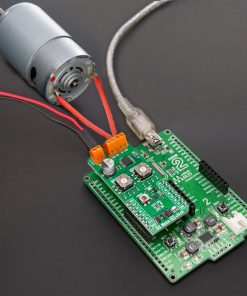

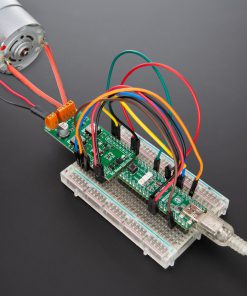

DC Motor 28 Click – FNG is a compact add-on board designed for driving brushed DC motors. This board features the TB67H453FNG, a single-channel H-Bridge driver from Toshiba Semiconductor. With an operating voltage range of 4.5V to 44V and a maximum output current of 3.5A, it features integrated current monitoring, a trimmer for output current adjustment, multiple protection mechanisms, and flexible control options. Ideal for applications in industrial automation, robotics, and other motor-driven systems, this Click board™ provides a powerful and adaptable solution for various motion control needs.

DC Motor 28 Click – FNG is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

NOTE: The DC Motor 28 Click – FNG is also available in the FTG version. For more details and specifications, please visit the DC Motor 28 Click – FTG product page.

Stock: Lead-time applicable.

| 5+ | R489.25 |

| 10+ | R463.50 |

| 15+ | R437.75 |

| 20+ | R421.27 |