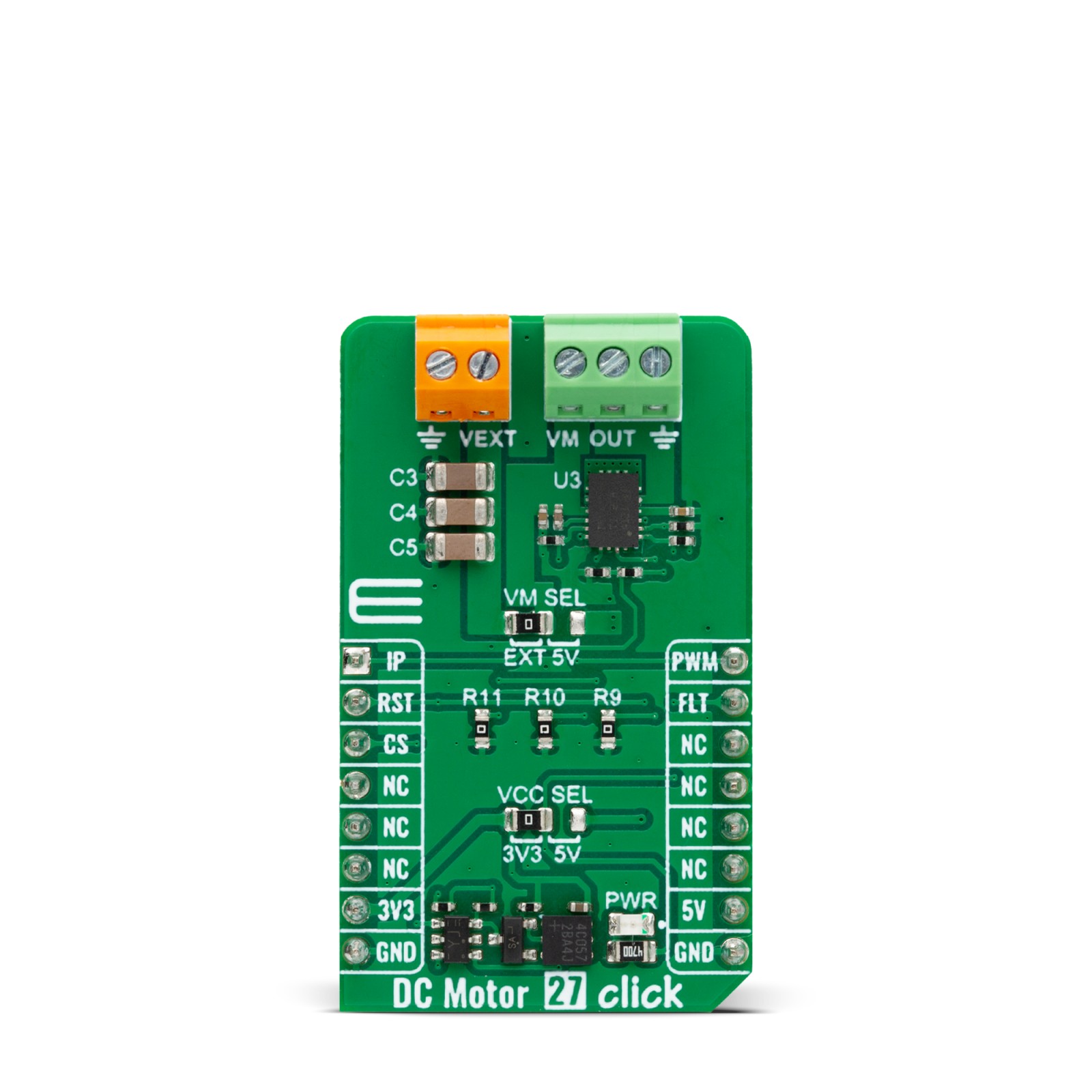

DC Motor 27 Click

R440.00 ex. VAT

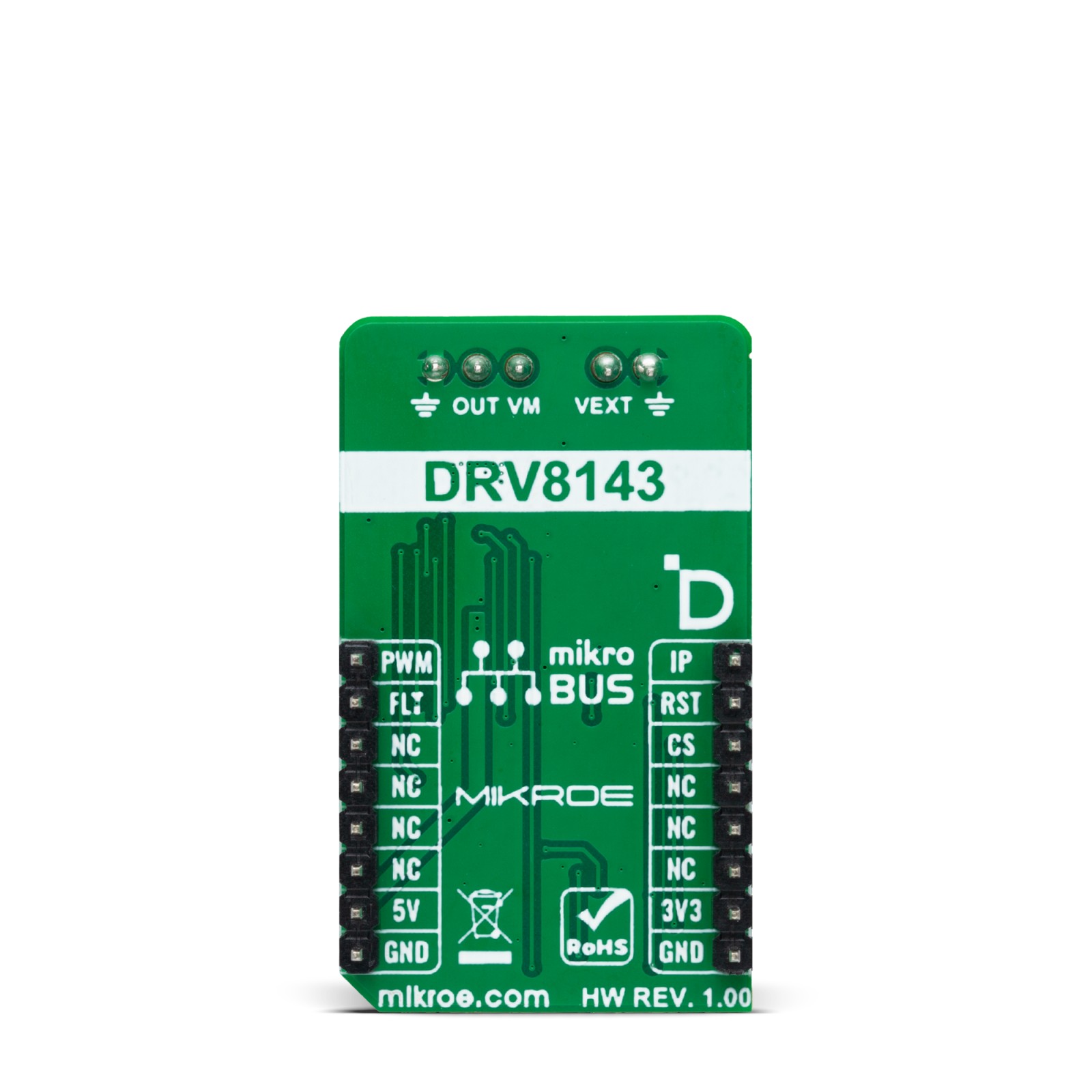

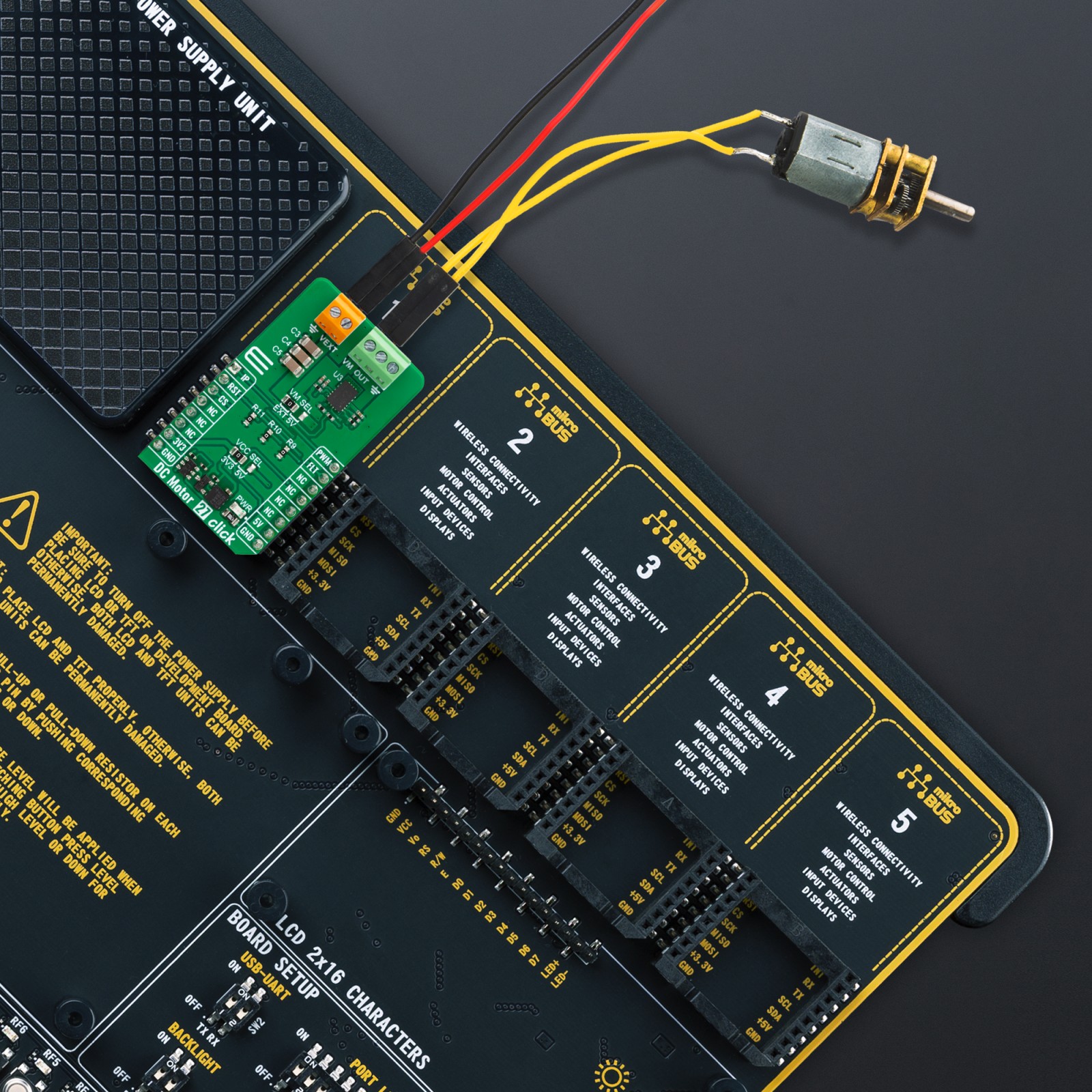

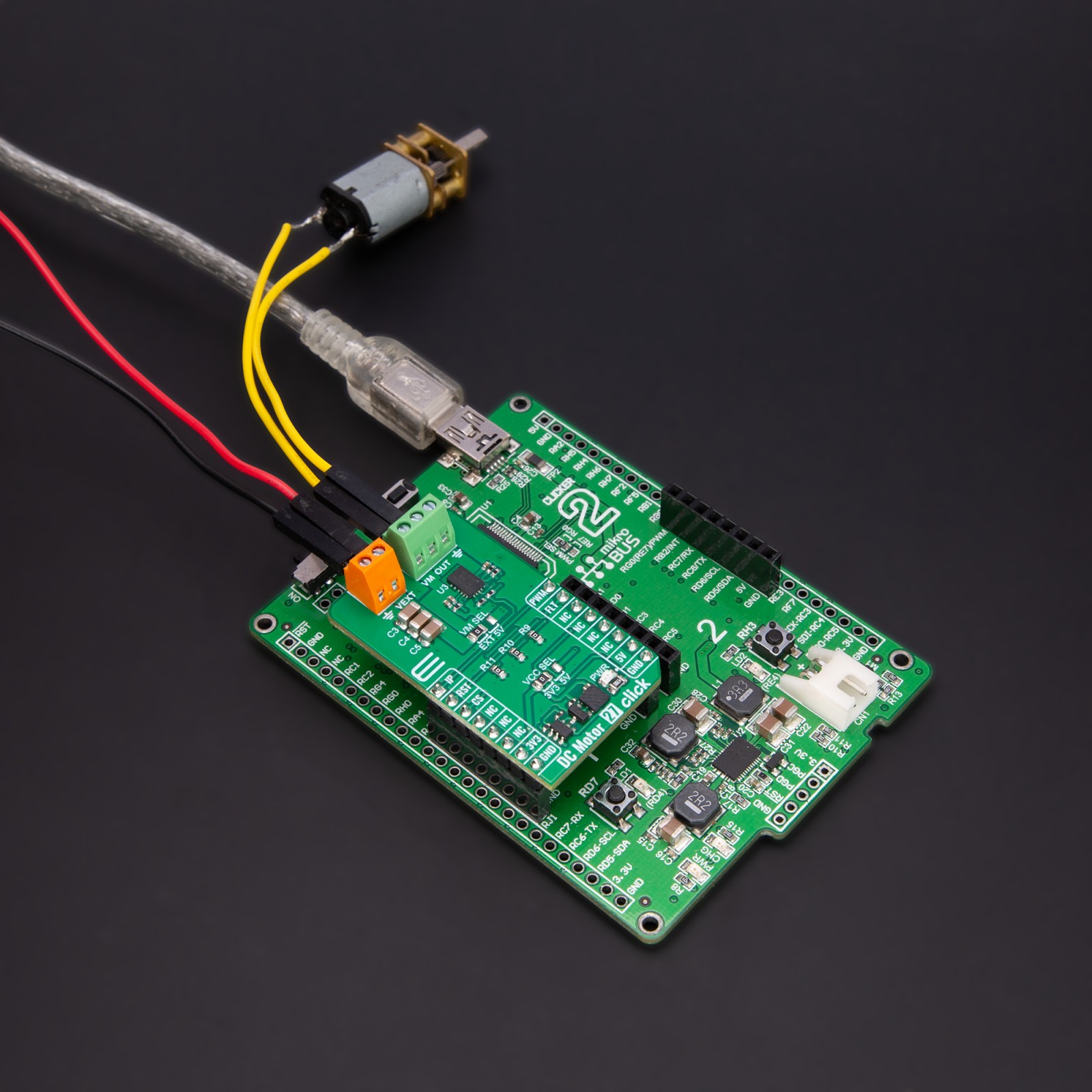

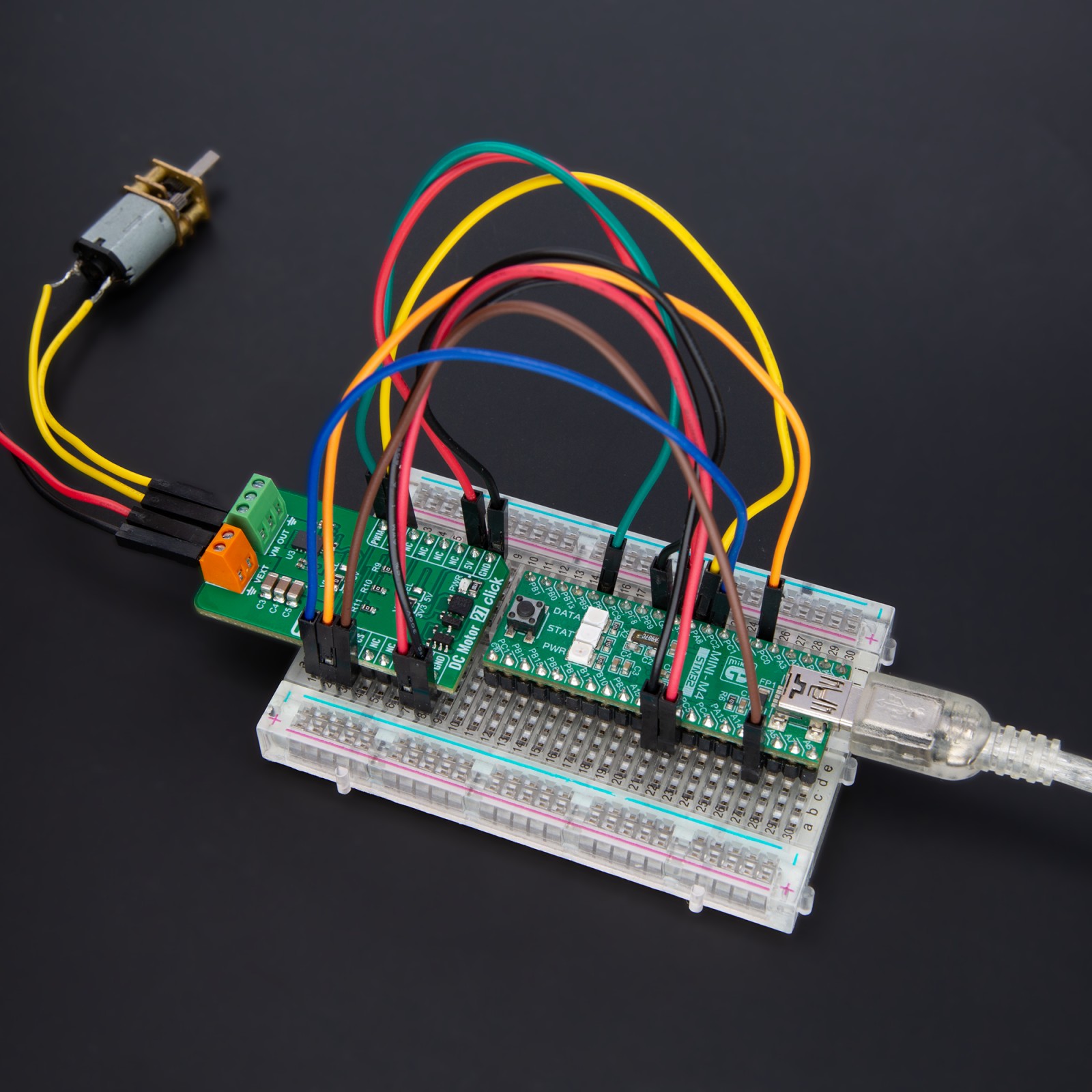

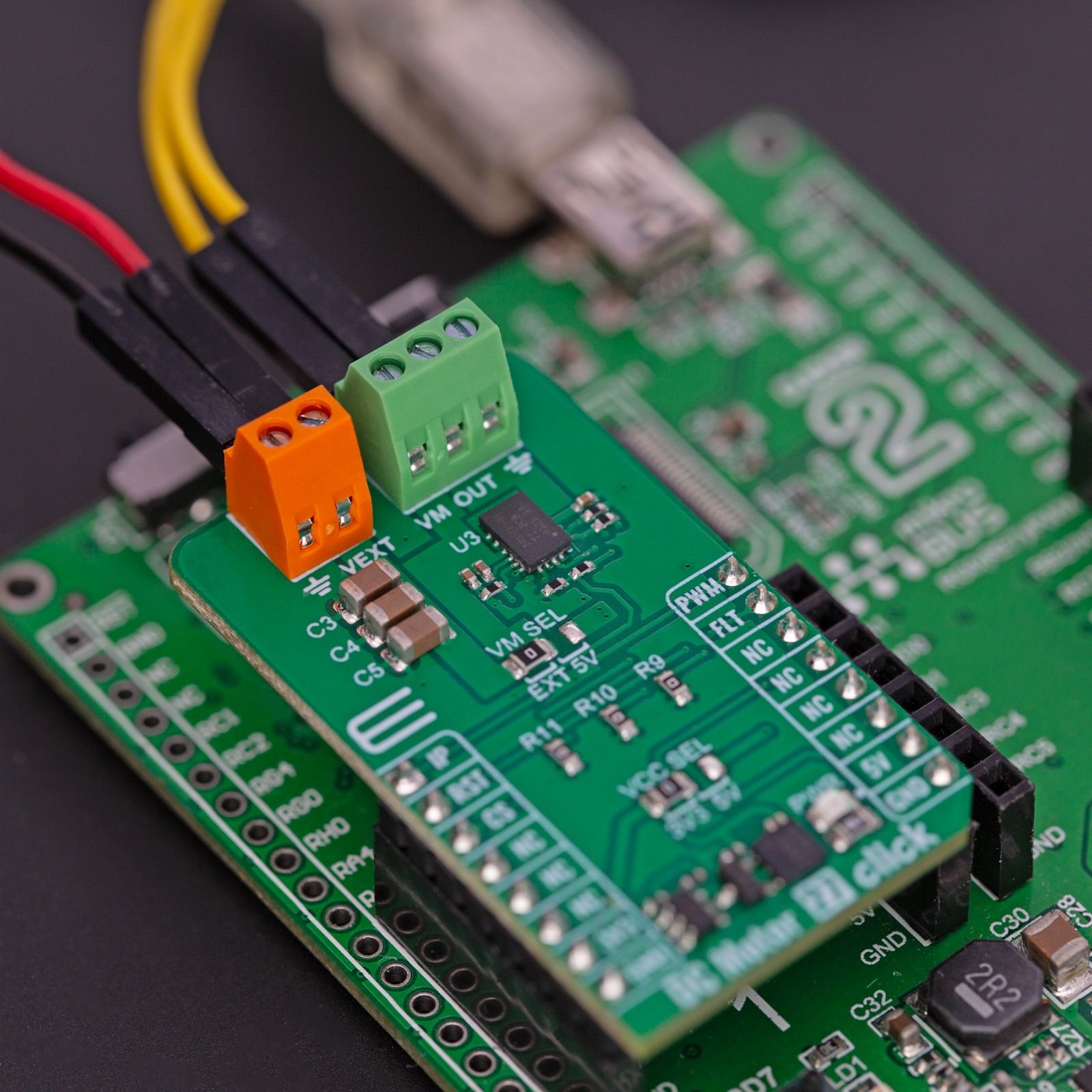

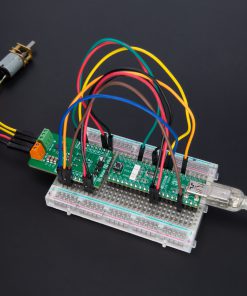

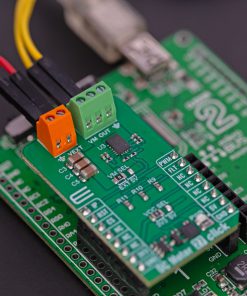

DC Motor 27 Click is a compact add-on board that contains a high-performance brushed DC motor driver. This board features the DRV8143, an automotive half-bridge driver with integrated current sense and diagnostic from Texas Instruments. It is designed in a BiCMOS high-power process technology node and has an operating range of 4.5V up to 35V. The driver features excellent power handling, thermal capability, EMI control, accurate current sense, robustness, and diagnostic capability. This Click board™ makes the perfect solution for the development of automotive brushed DC motors, solenoids, door modules, seat modules, body control modules (BCM), fuel, water, and oil pumps, onboard chargers, and more.

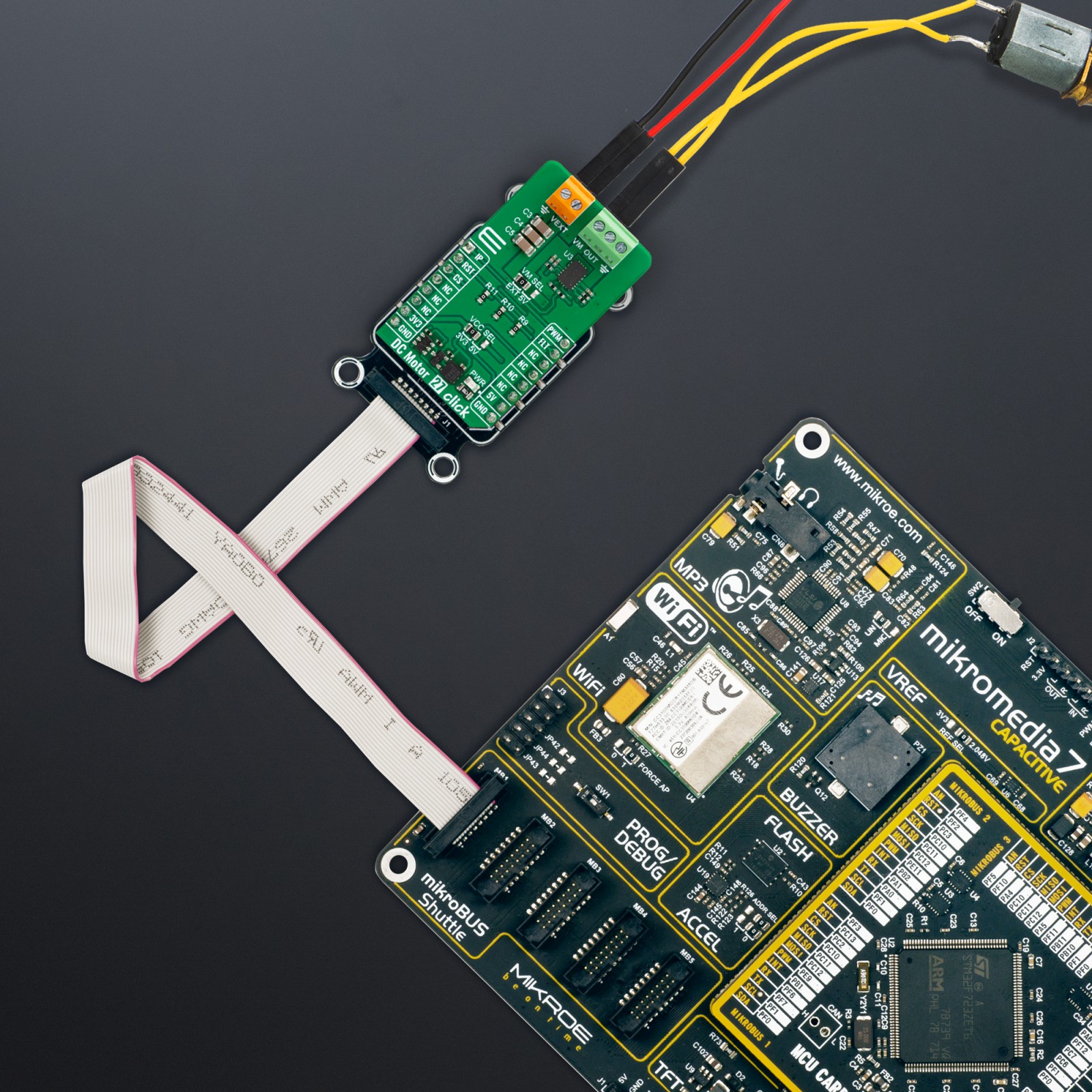

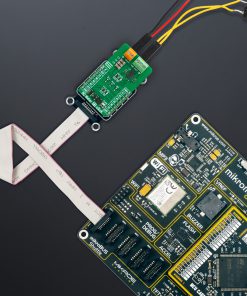

DC Motor 27 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R418.00 |

| 10+ | R396.00 |

| 15+ | R374.00 |

| 20+ | R359.92 |

.jpg)