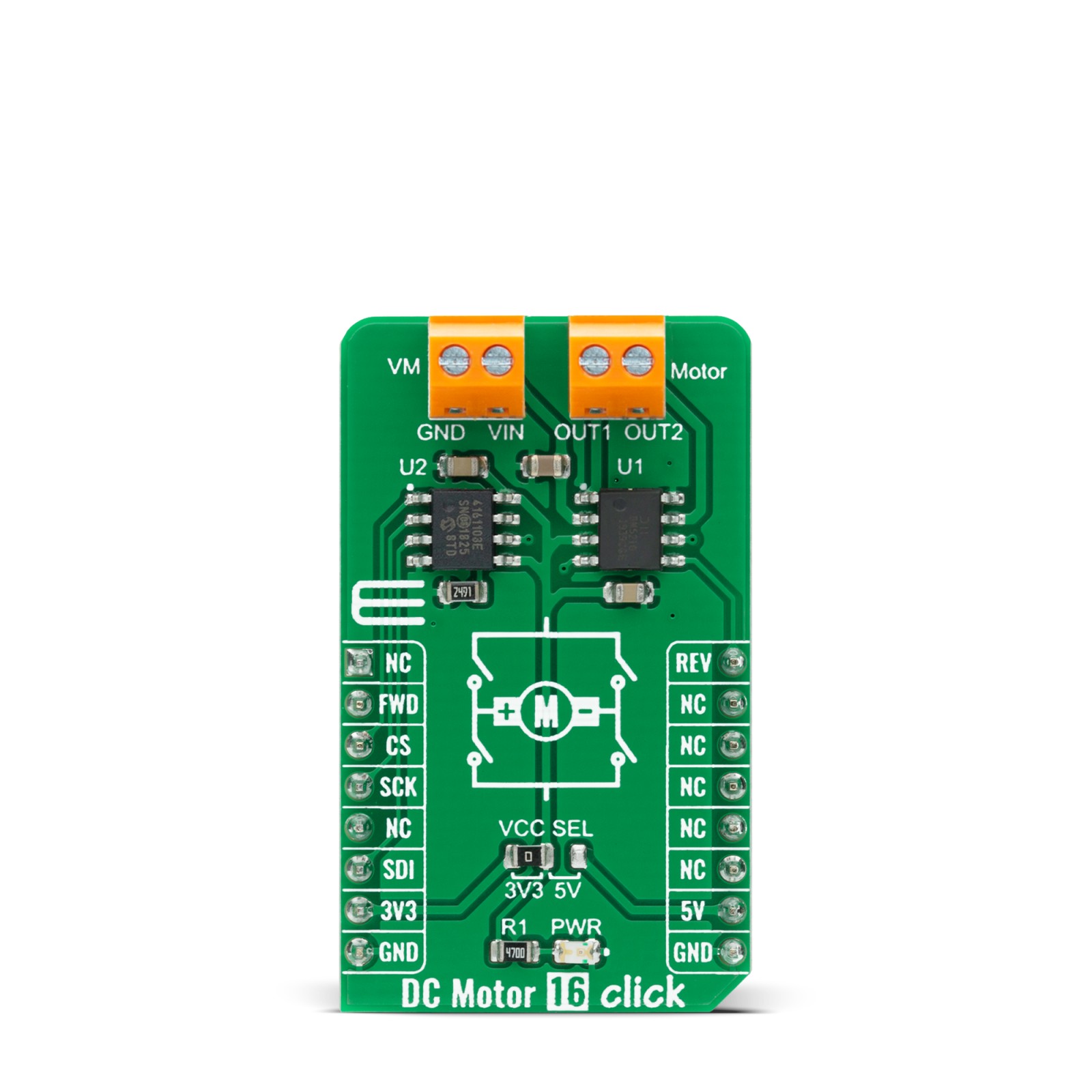

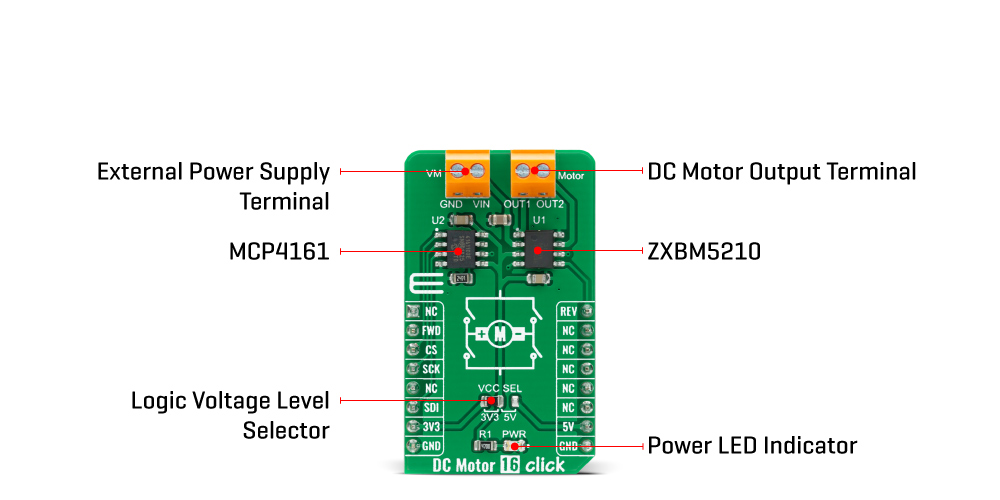

DC Motor 16 Click

R195.00 ex. VAT

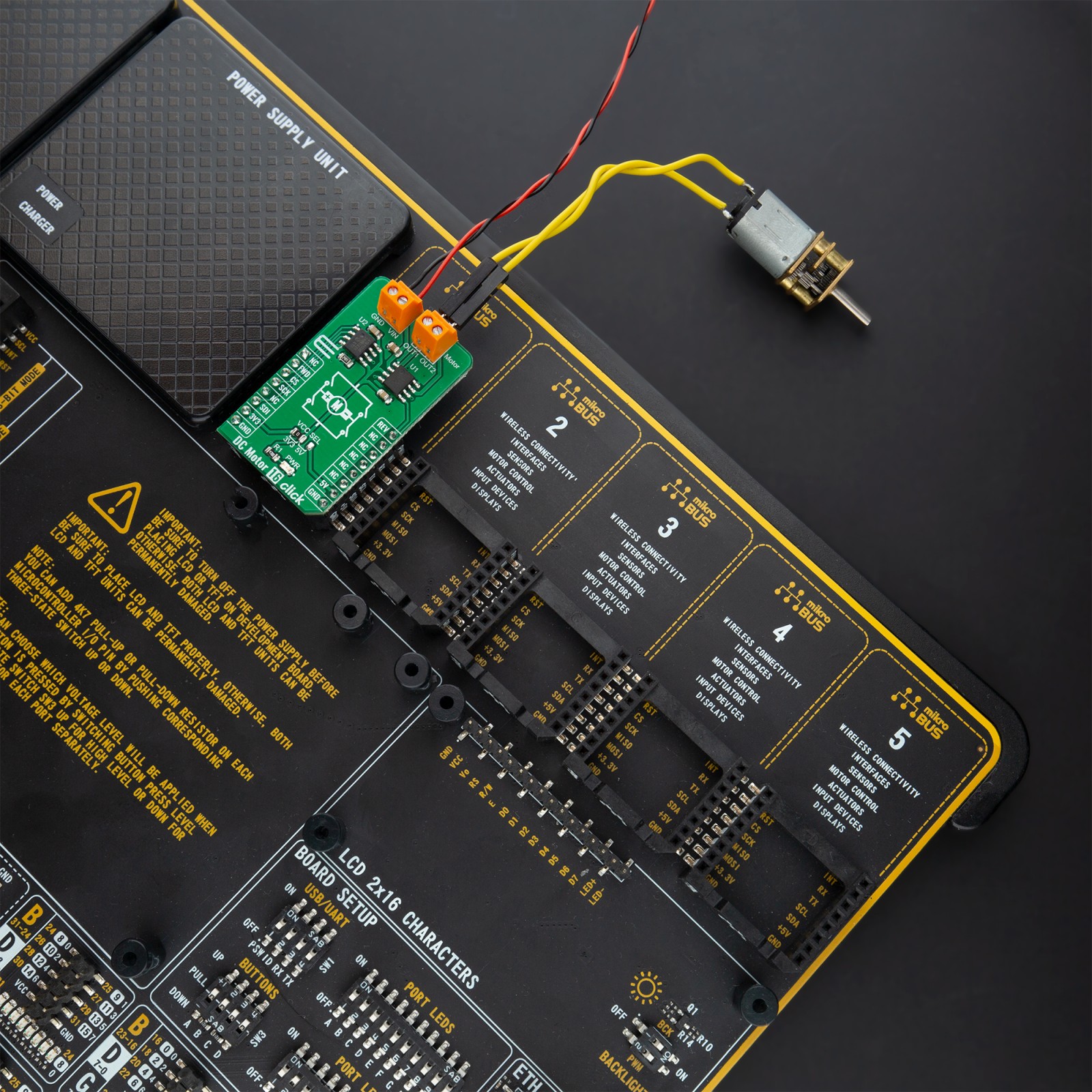

DC Motor 16 Click is a compact add-on board that contains a high-performance single phase reversible DC motor drive with speed control. This board features the ZXBM5210, a fully-featured DC motor drive solution with an average current capability of up to 1200mA from Diodes Incorporated. The ZXBM5210 has several modes of operations selected by two GPIO pins, has a wide supply voltage range from 3V to 18V, and low power consumption. It possesses three speed control modes, and provides under/over voltage protection, over current limit, and thermal shutdown capability. This Click board™ is suitable for a reversible DC motor and actuator drive, remote control motorized toy applications, home appliances, handheld power tools, and many more.

DC Motor 16 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R185.25 |

| 10+ | R175.50 |

| 15+ | R165.75 |

| 20+ | R159.51 |