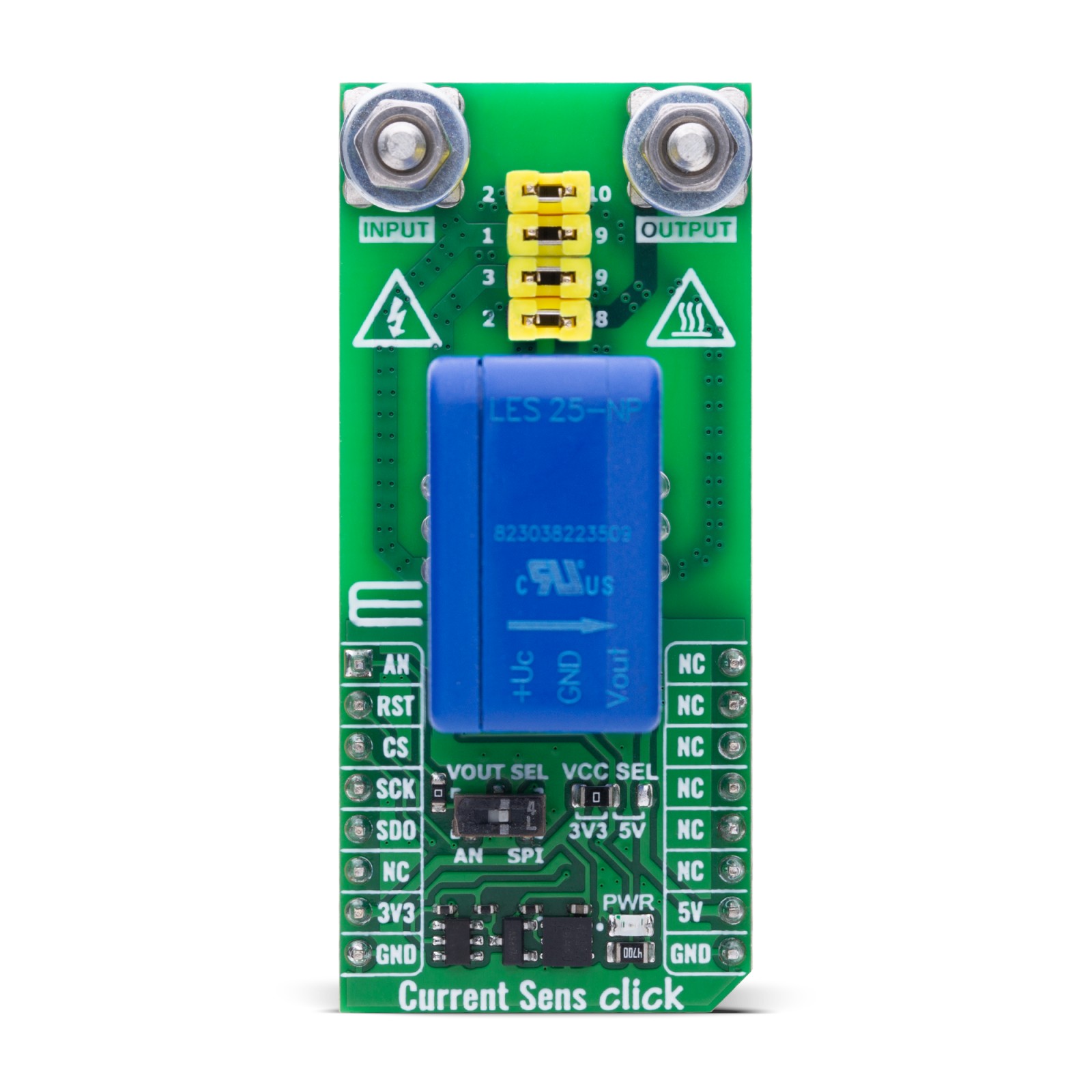

Current Sens Click

R1,250.00 ex. VAT

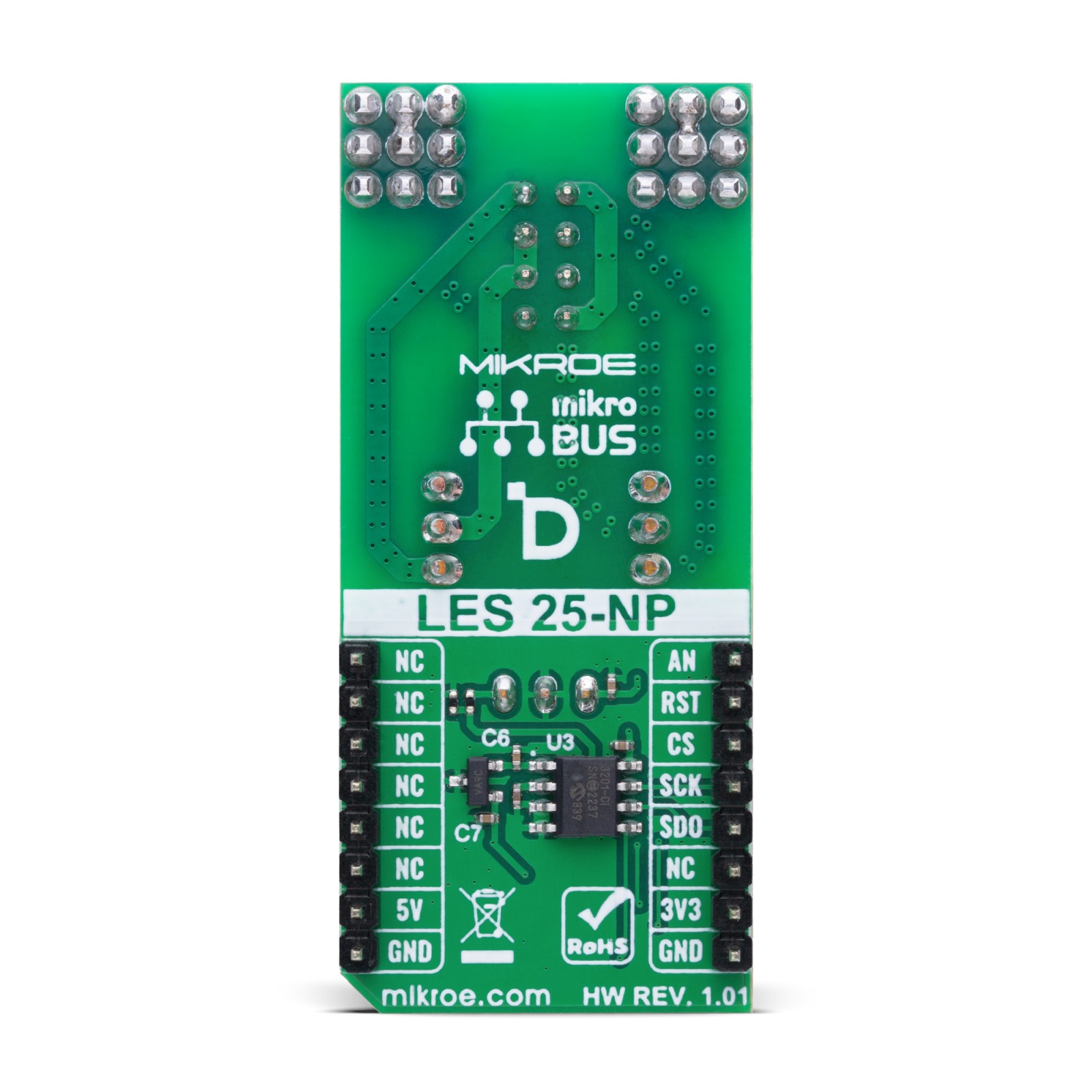

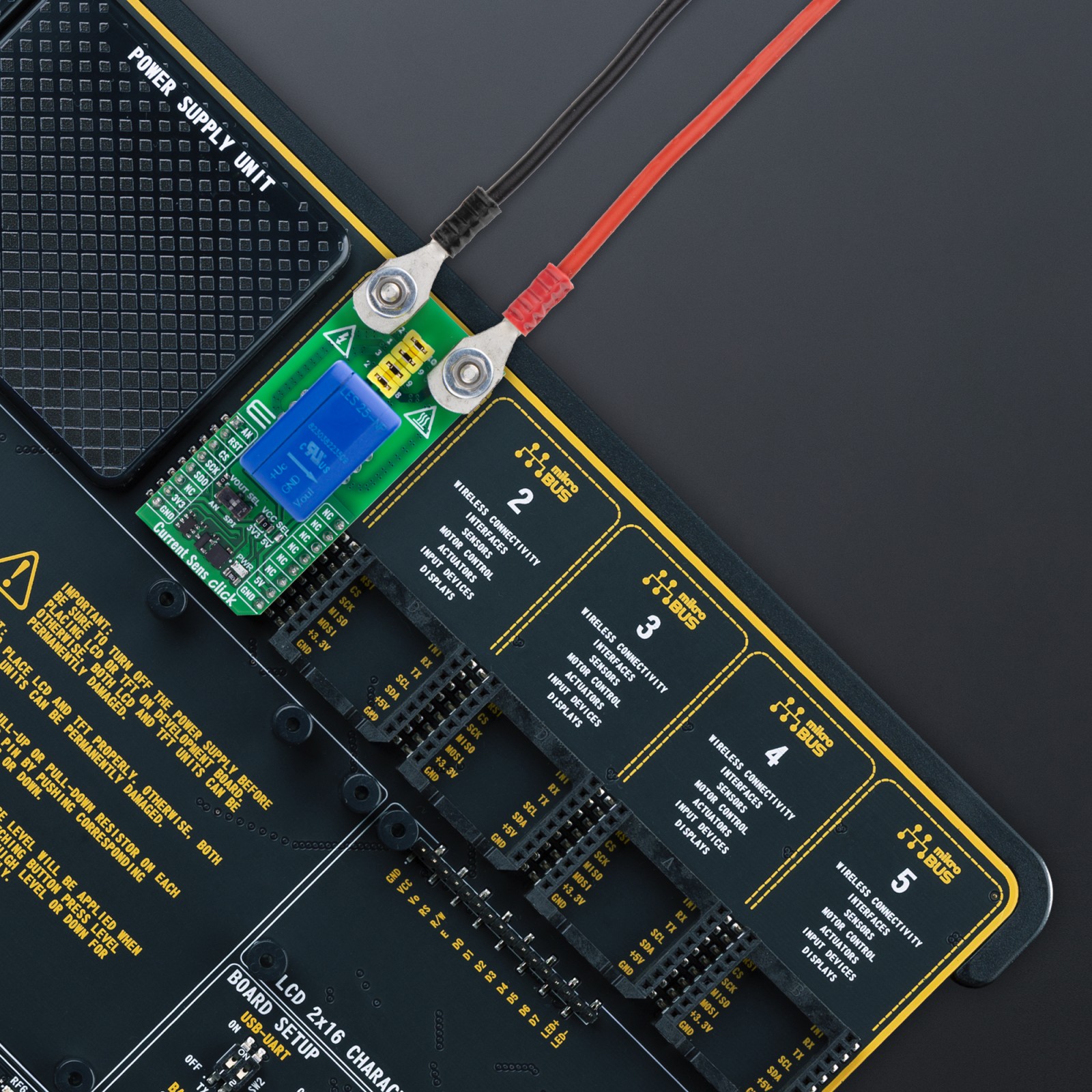

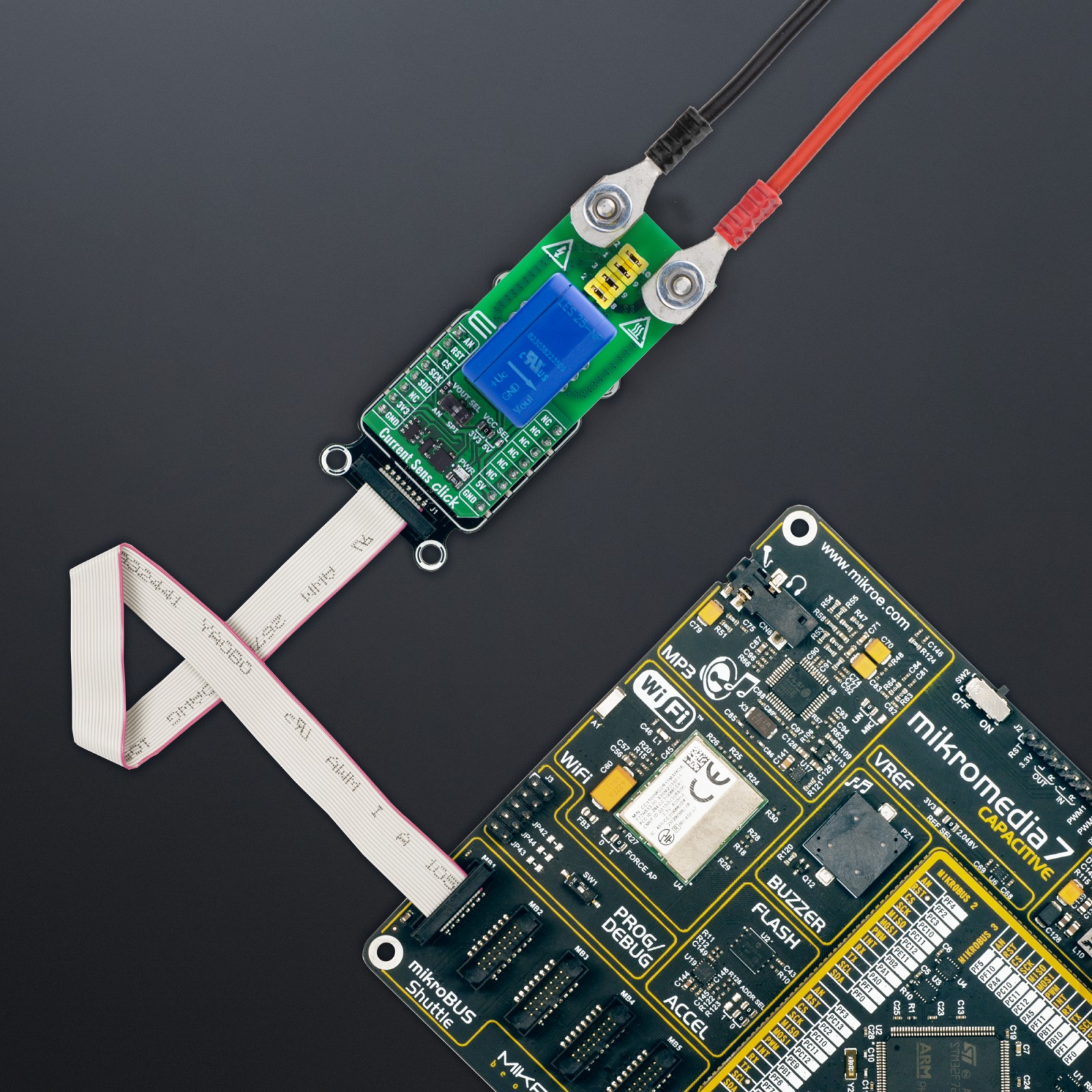

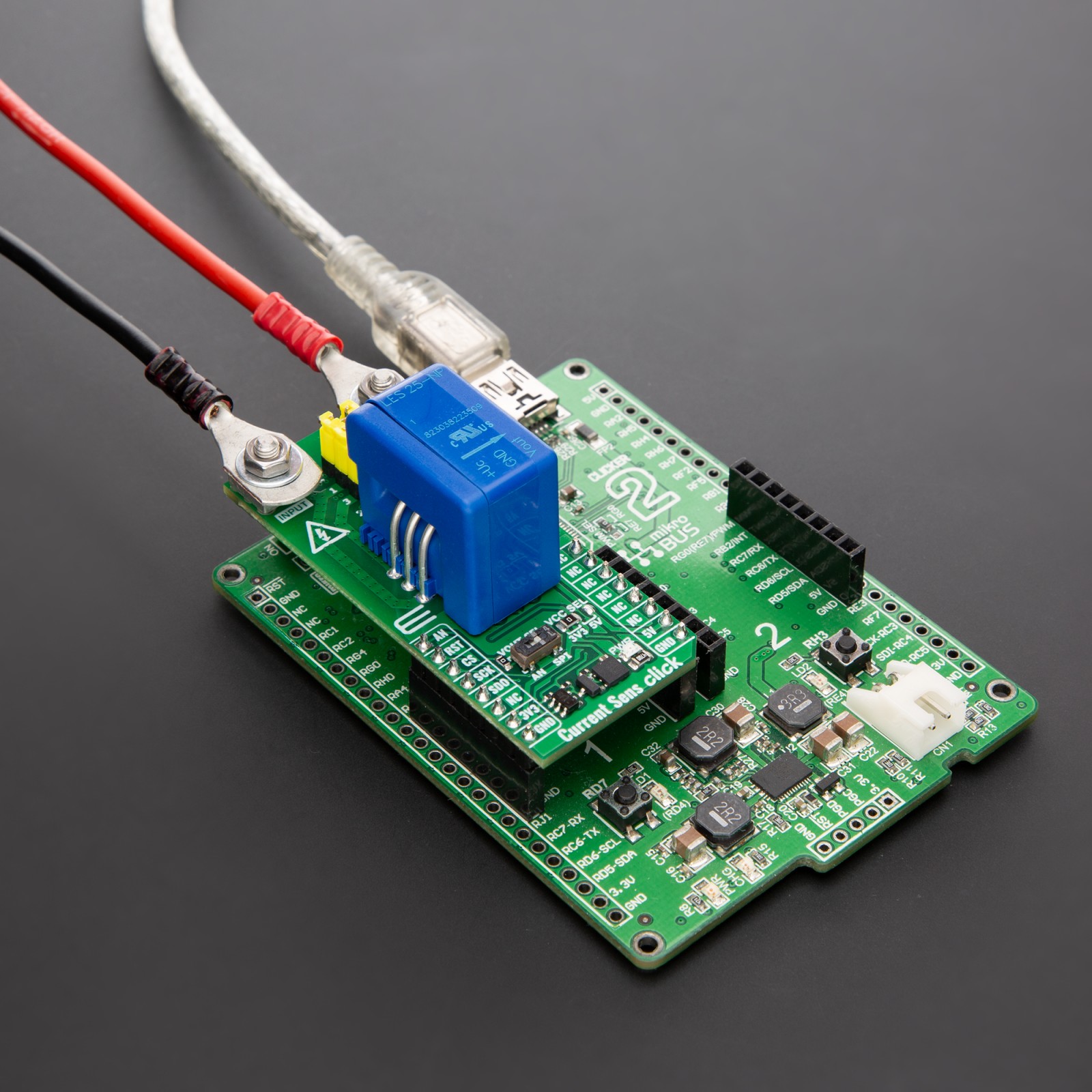

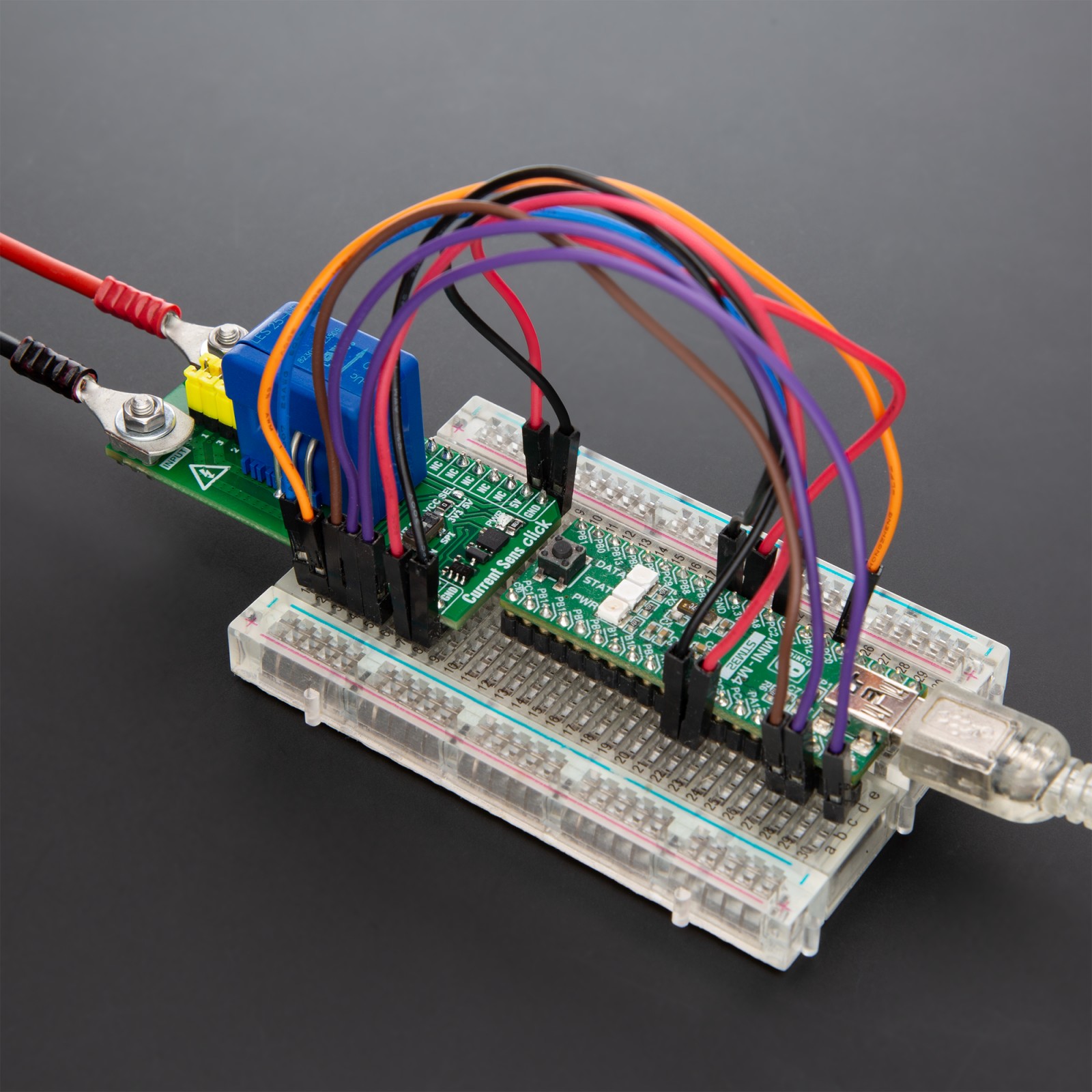

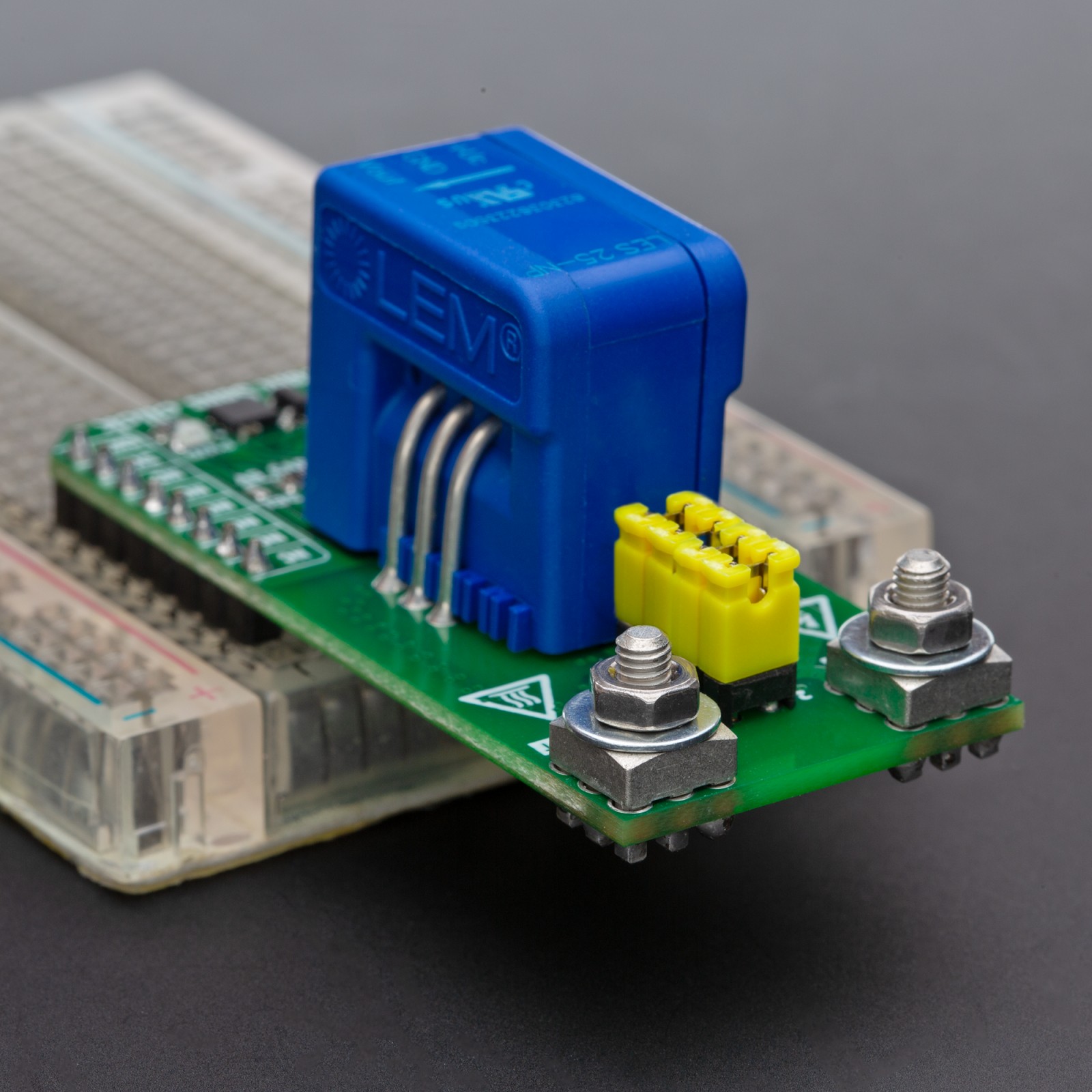

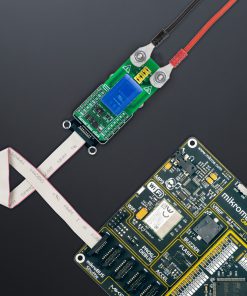

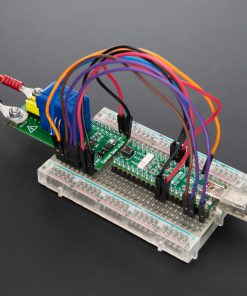

Current Sens Click is a compact add-on board for precise AC, DC, and pulsed current measurement with galvanic isolation. This board features the LES 25-NP current transducer from LEM USA, a closed-loop, multi-range sensor designed for accurate current detection up to 25A. The board offers selectable analog or digital output via SPI using the MCP3201 12-bit ADC, with a stable 2.5V reference provided by the MCP1525. A jumper-configurable section allows adjustment of the nominal primary current with support for three connection configurations to enhance resolution. It supports both 3.3V and 5V logic levels and includes an onboard switch for easy output selection. Ideal for industrial applications, it fits seamlessly into systems such as motor drives, UPS units, SMPS, battery-powered devices, welding equipment, and solar inverters.

Current Sens Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R1,187.50 |

| 10+ | R1,125.00 |

| 15+ | R1,062.50 |

| 20+ | R1,022.50 |

DO NOT TOUCH THE BOARD WHILE THE EXTERNAL POWER SUPPLY IS ON!

DO NOT TOUCH THE BOARD WHILE THE EXTERNAL POWER SUPPLY IS ON!