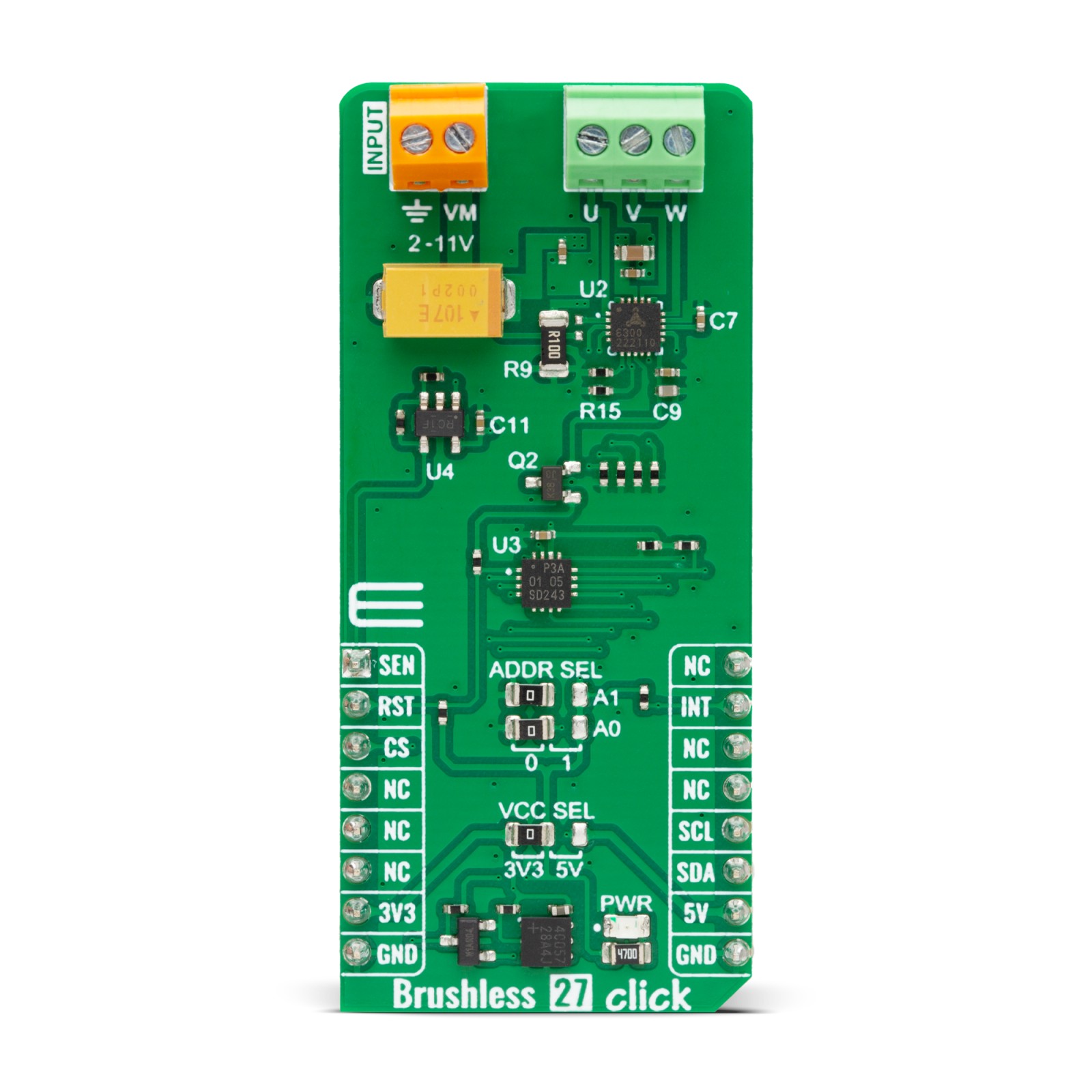

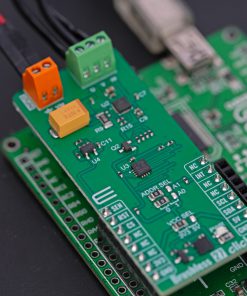

Brushless 27 Click

R405.00 ex. VAT

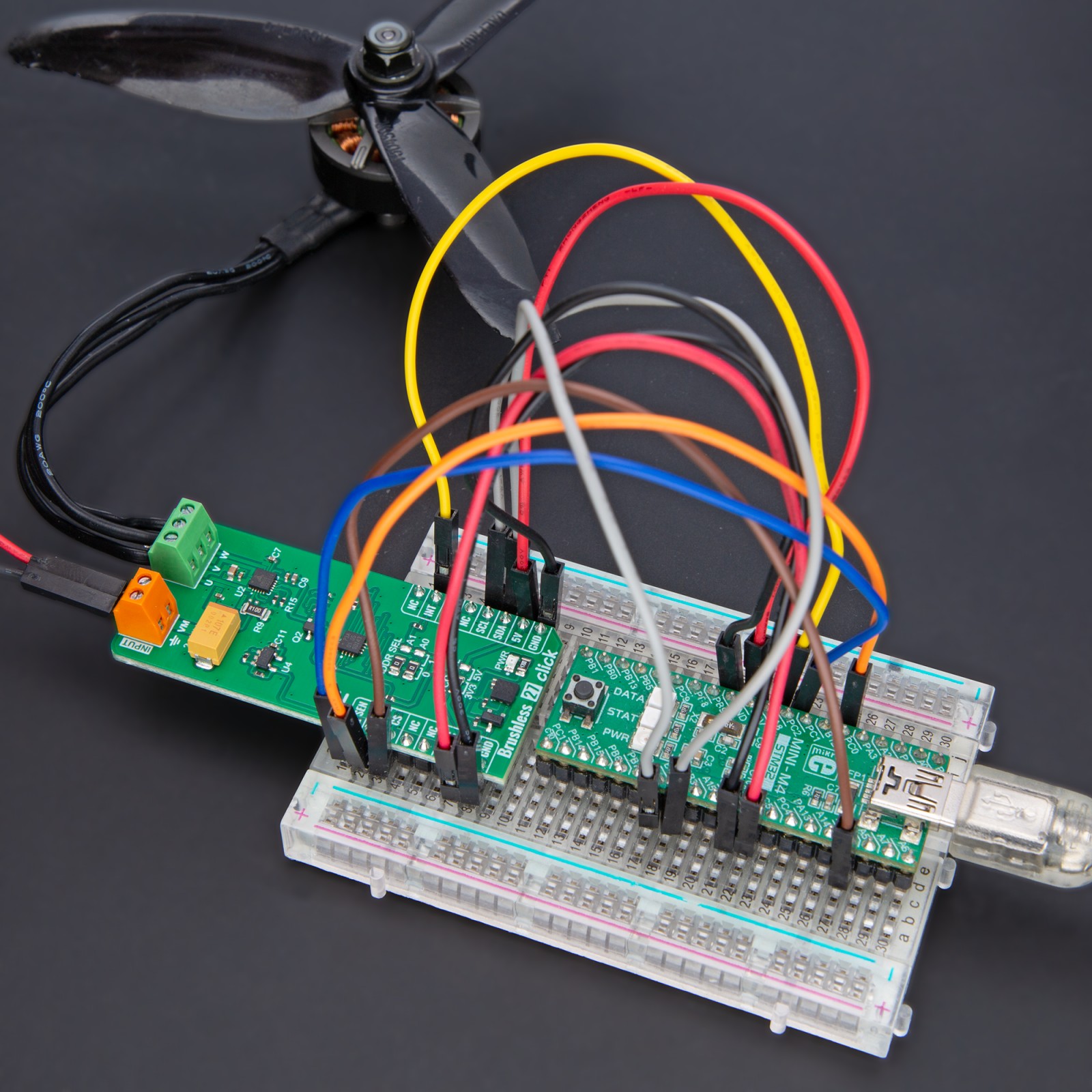

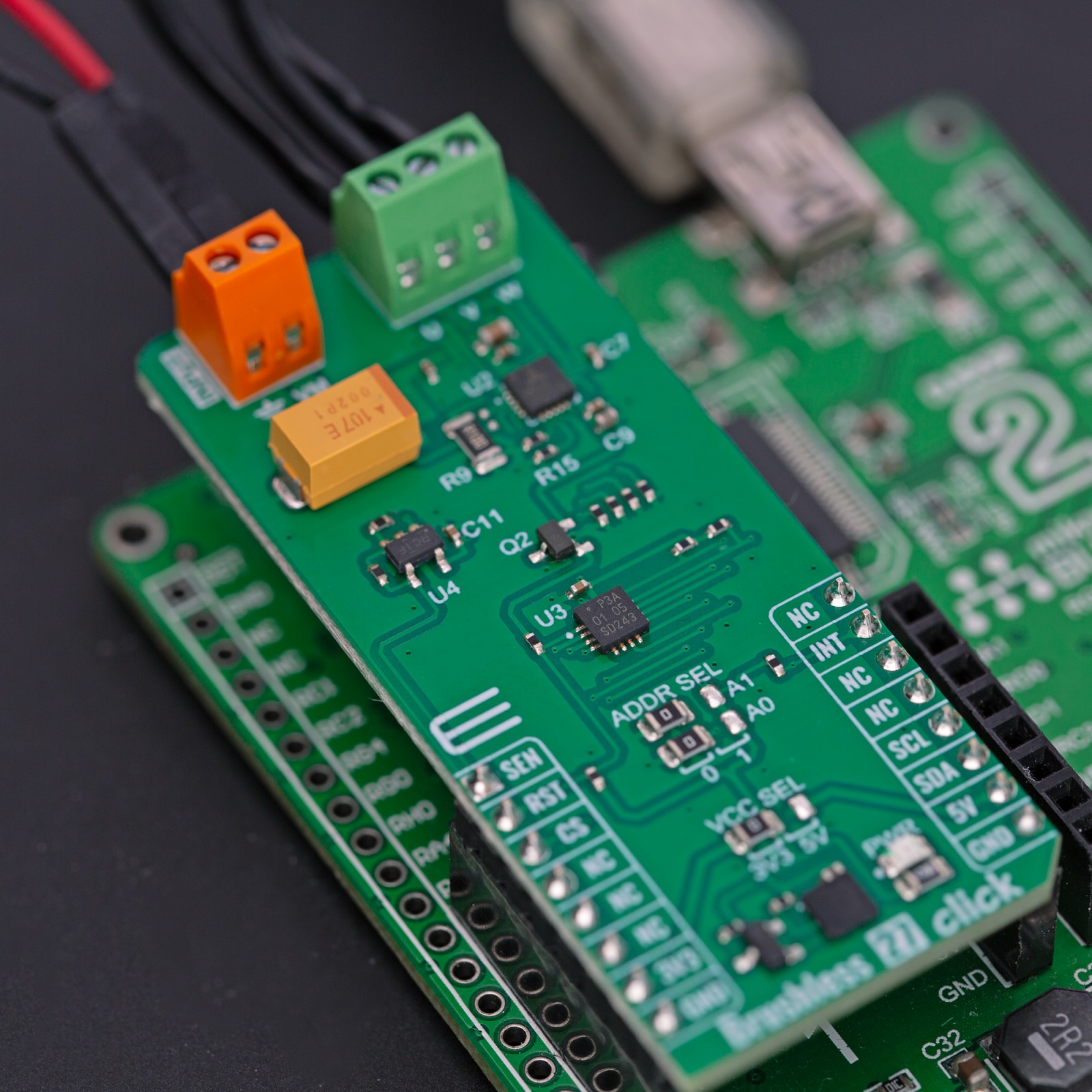

Brushless 27 Click is a compact add-on board that controls DC brushless motors with any MCU. This board features the TMC6300, a power driver for BLDC/PMSM motors from Analog Devices. It is a highly efficient low voltage, zero standby driver for 3-phase BLDC/PMSM motors with up to 2A peak current. The triple half-bridge of this driver separates the HS and LS control signals, which allow driving a PMSM or a BLDC motor. This Click board™ makes the perfect solution for the development of IoT and handheld devices, battery-operated motors, printers, POS, toys, office and home automation devices, and more.

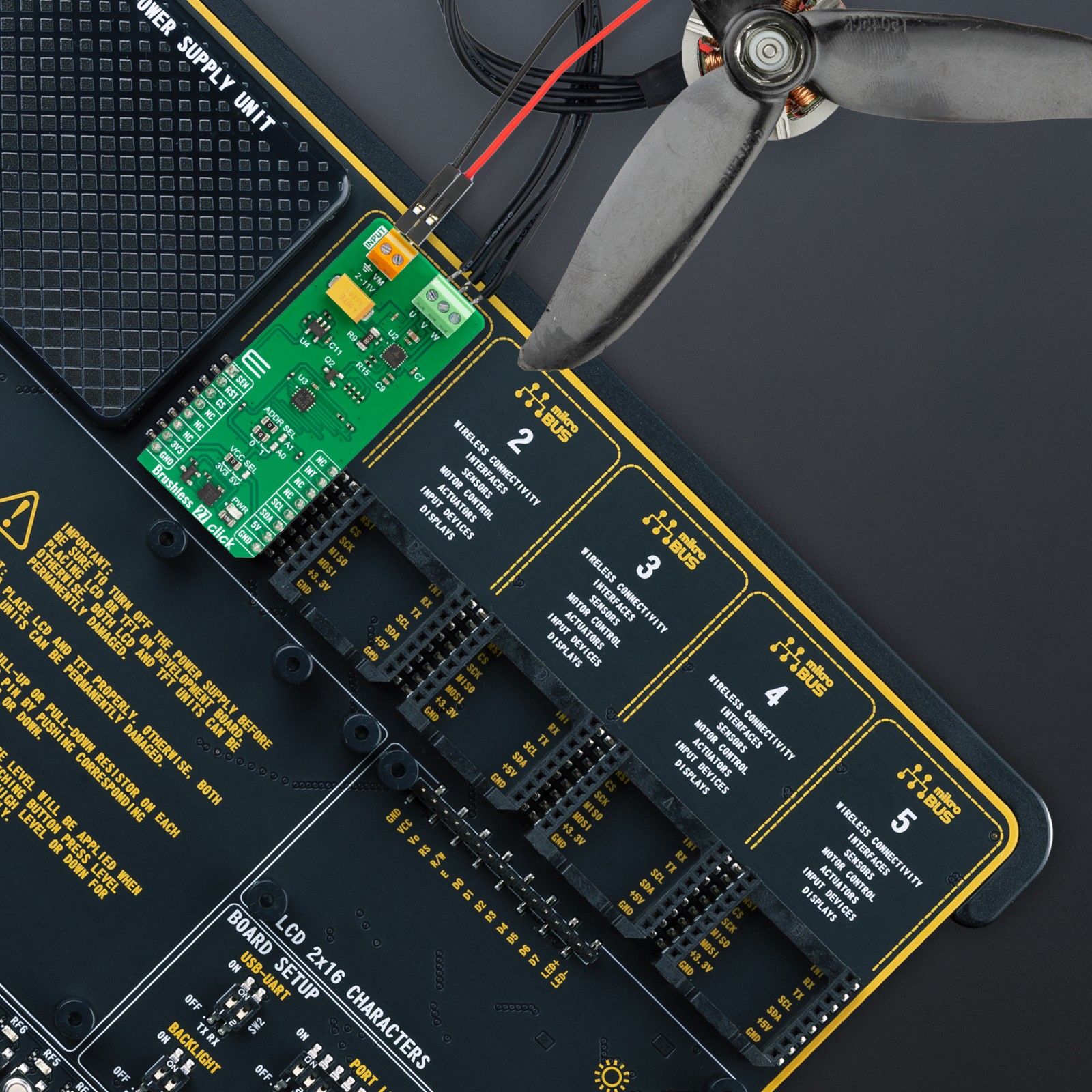

Brushless 27 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R384.75 |

| 10+ | R364.50 |

| 15+ | R344.25 |

| 20+ | R331.29 |