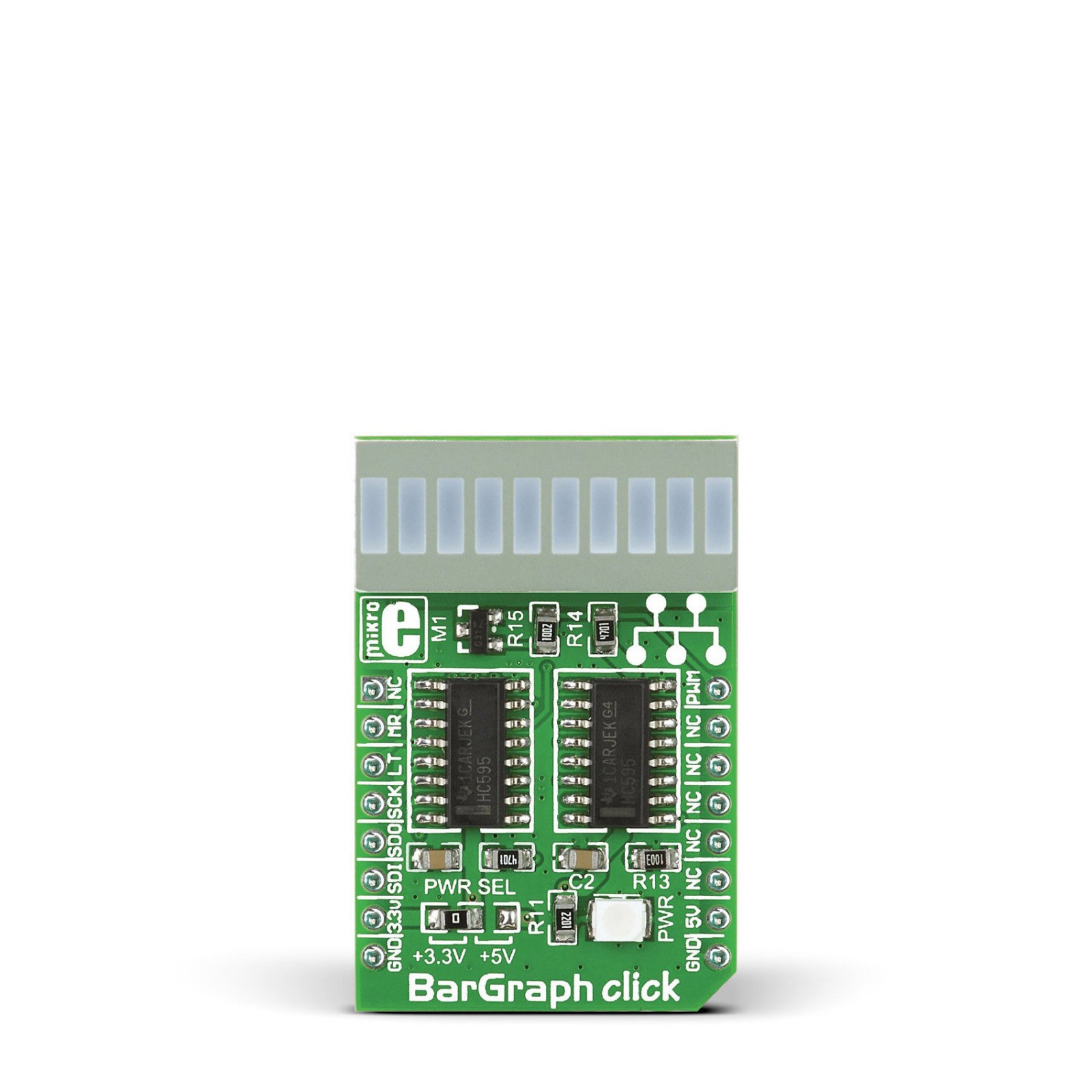

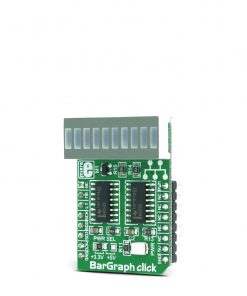

BarGraph Click

R245.00 ex. VAT

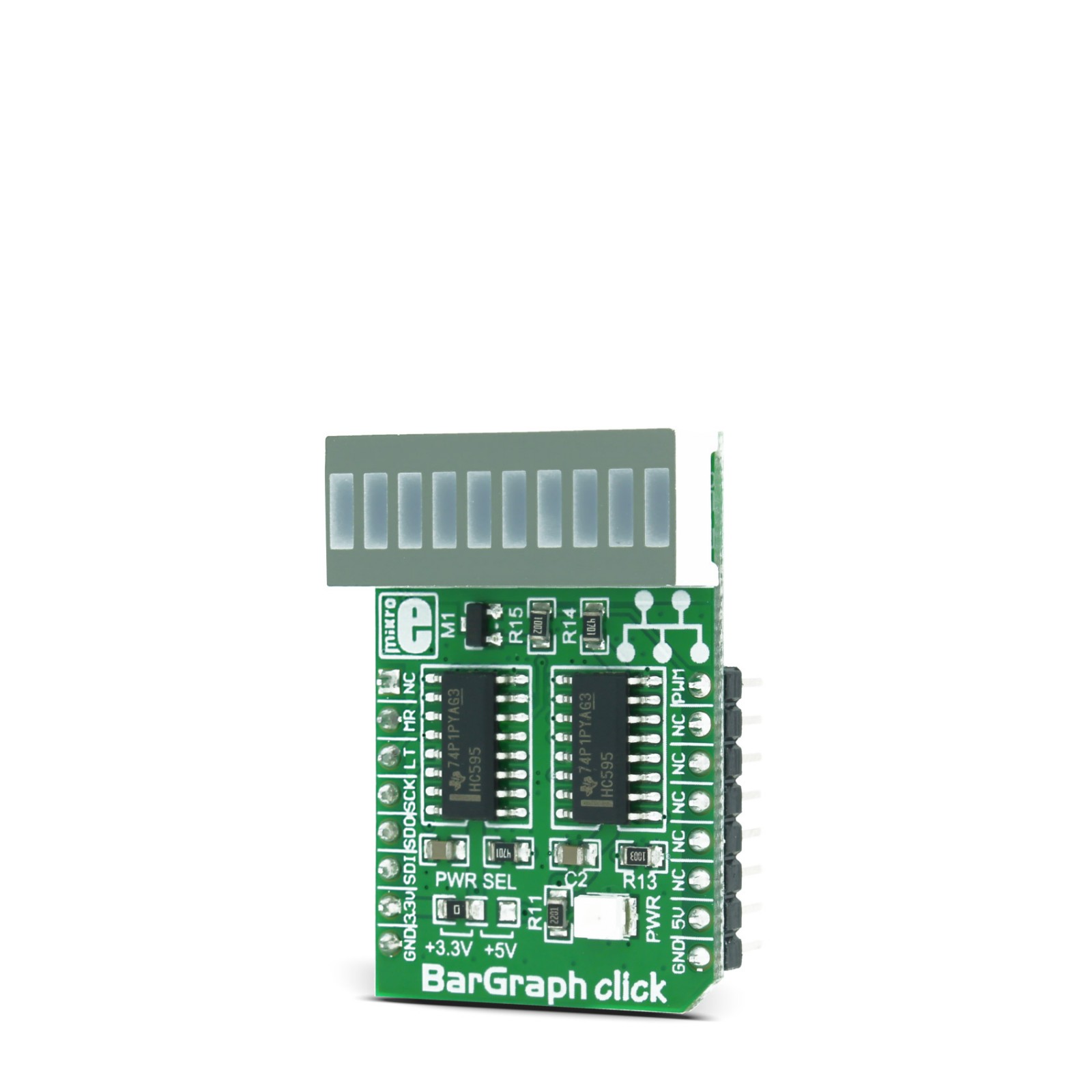

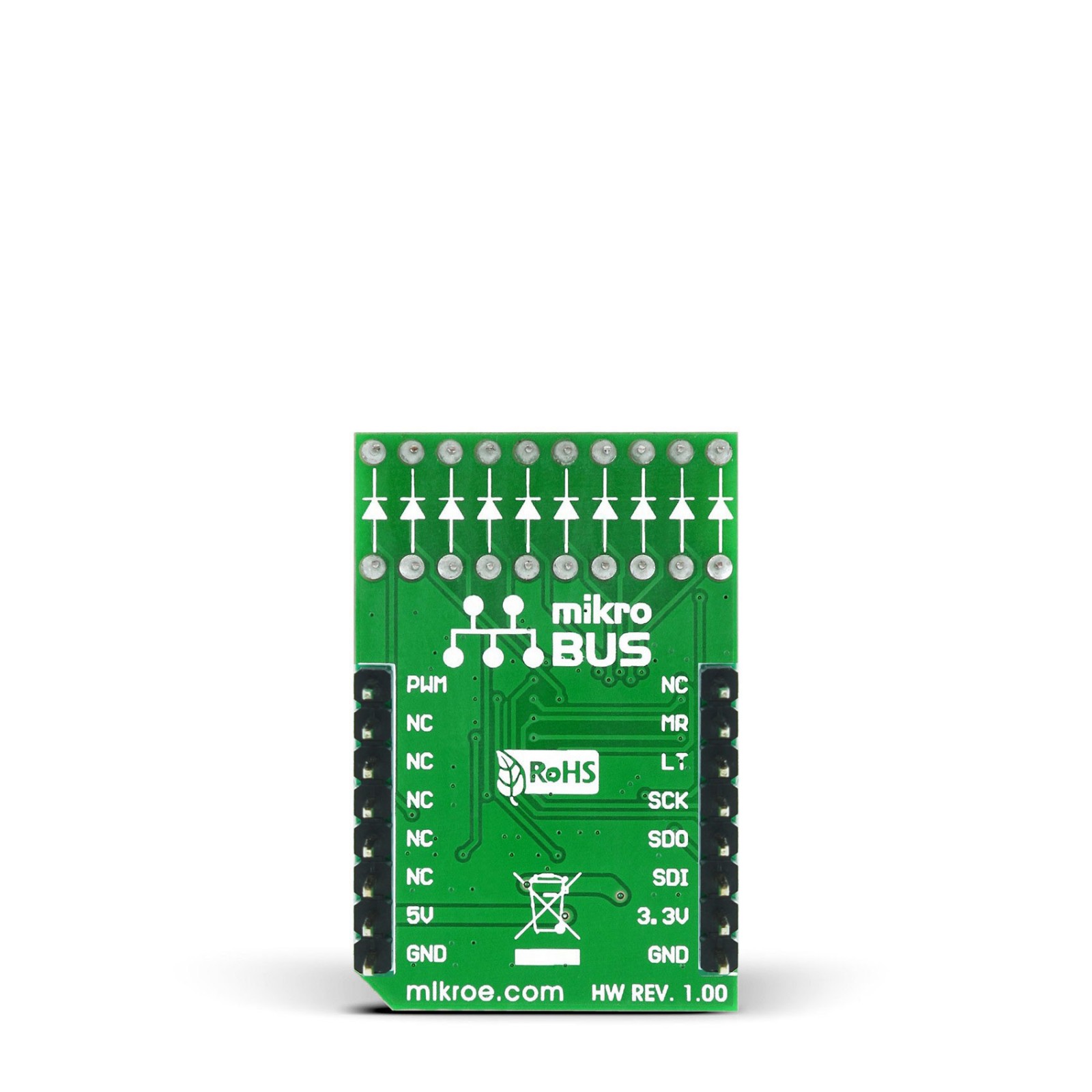

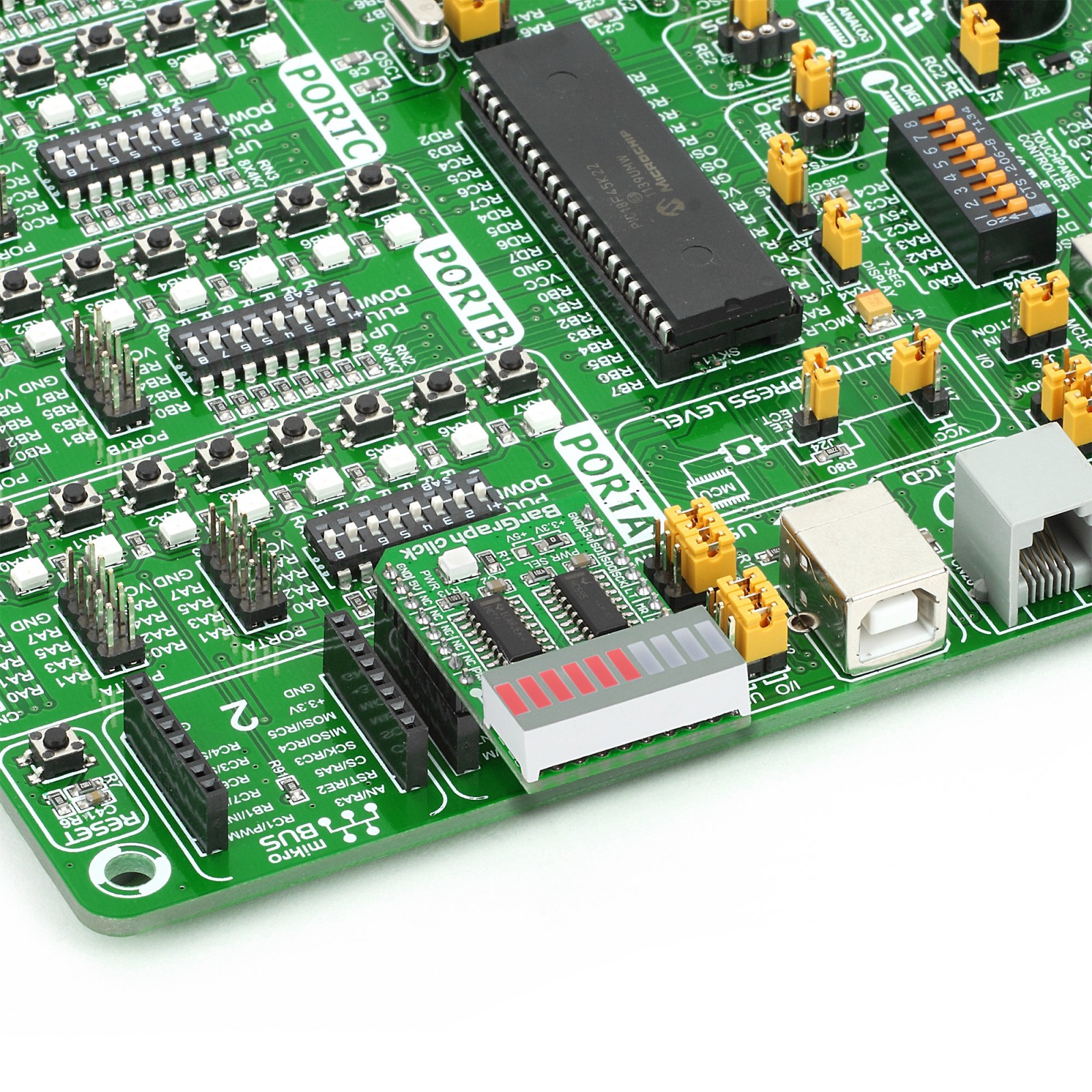

BarGraph Click is a compact add-on board with an LED bar graph display. This board features two SN74HC595Ds, 8-bit shift registers with 3-state output registers from Texas Instruments. The LED bar graph display consists of 10 red LEDs, and you can control each LED separately, including the light intensity. The segments of the onboard bar graph LED display are bright and uniformly colored, providing pleasant and clean visual feedback. This Click board™ makes the perfect solution for displaying various signal or status properties, building VU-meters, and various types of gauges and signal indicators, whether it be an audio level, current/voltage level, the position of the encoder, or any other property that can be displayed in the form of a bar graph.

BarGraph Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R232.75 |

| 10+ | R220.50 |

| 15+ | R208.25 |

| 20+ | R200.41 |