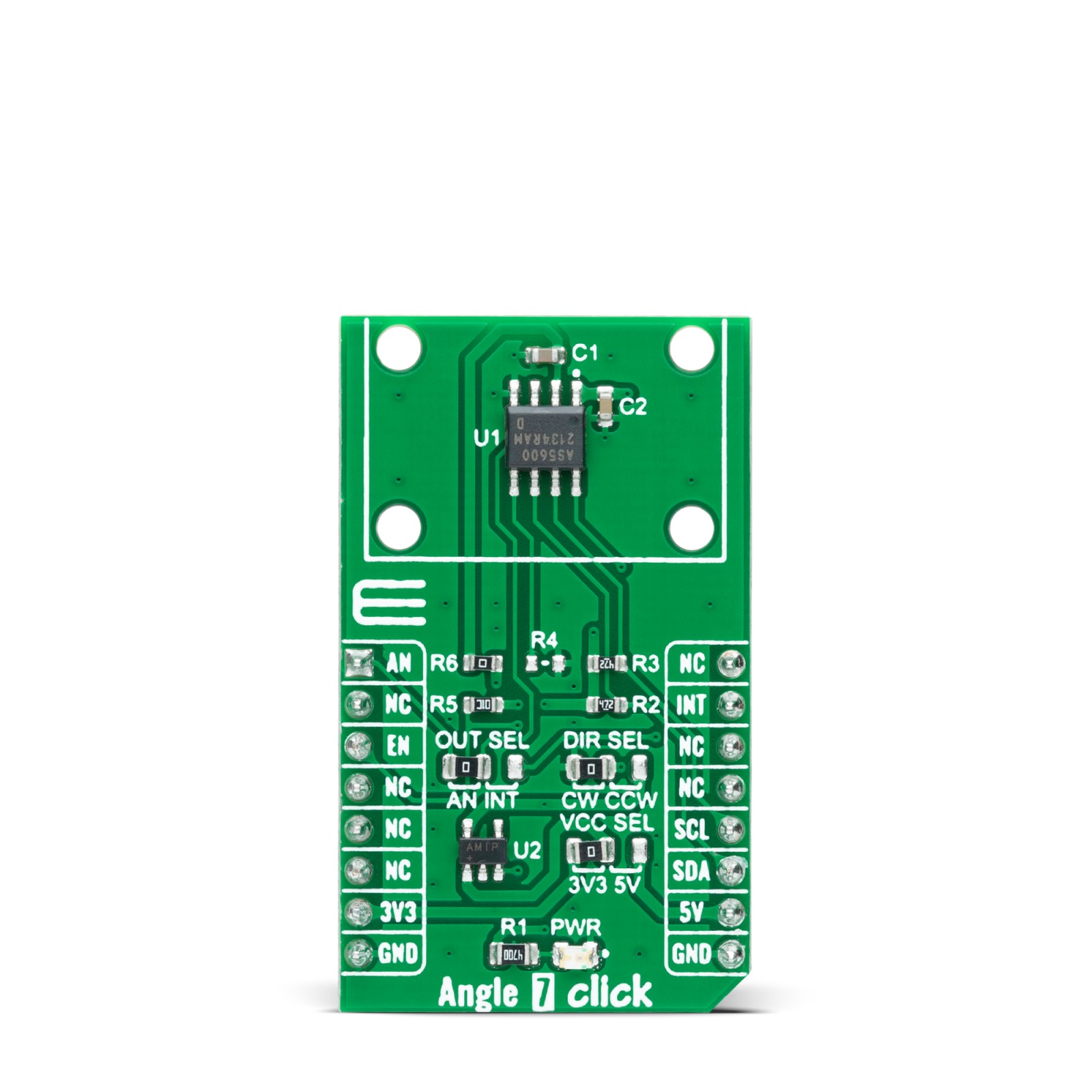

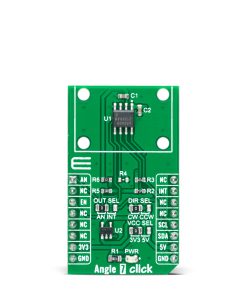

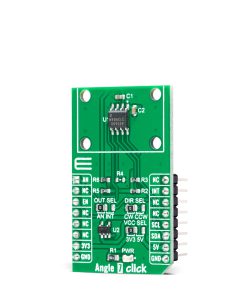

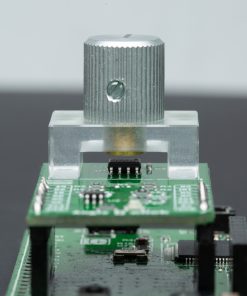

Angle 7 Click

R330.00 ex. VAT

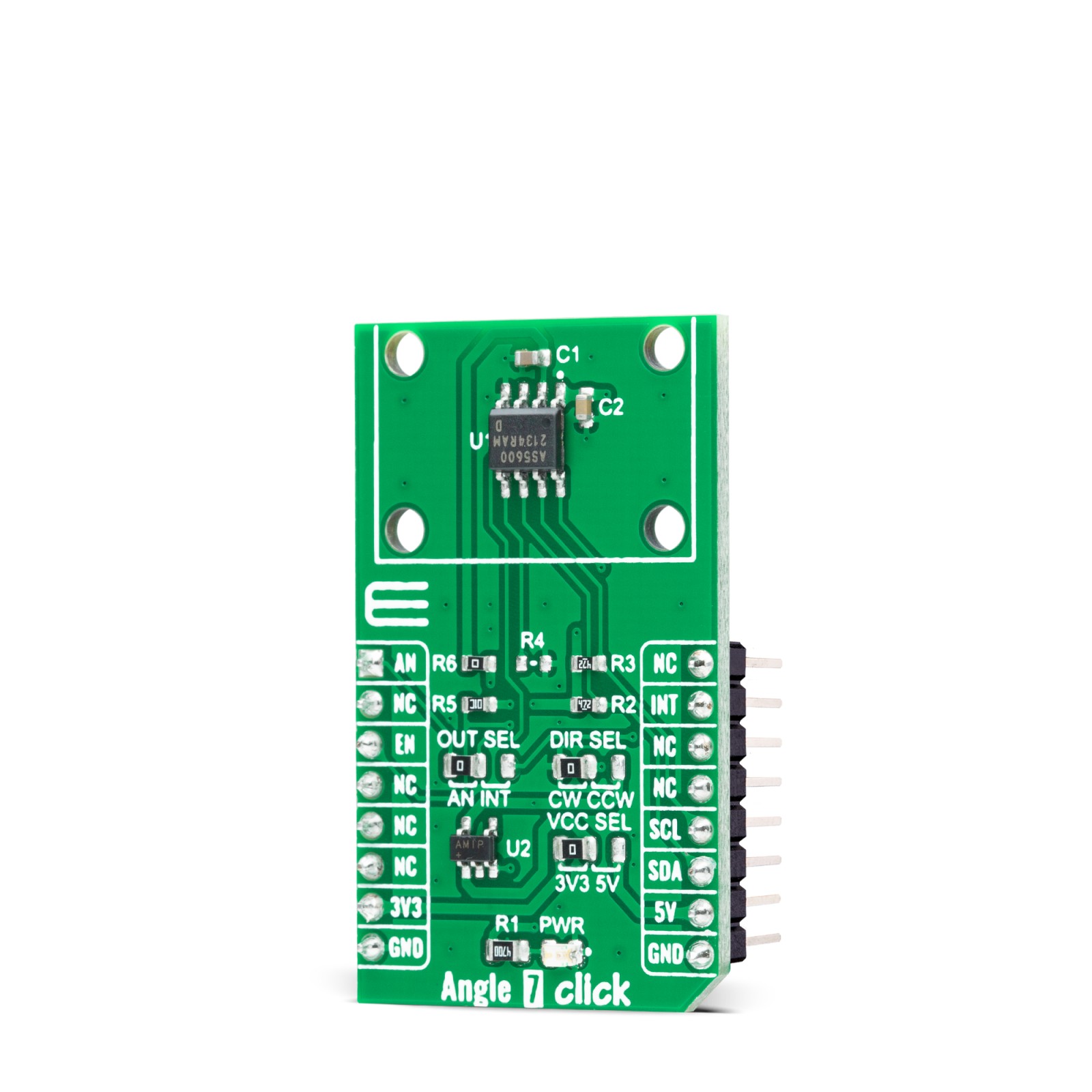

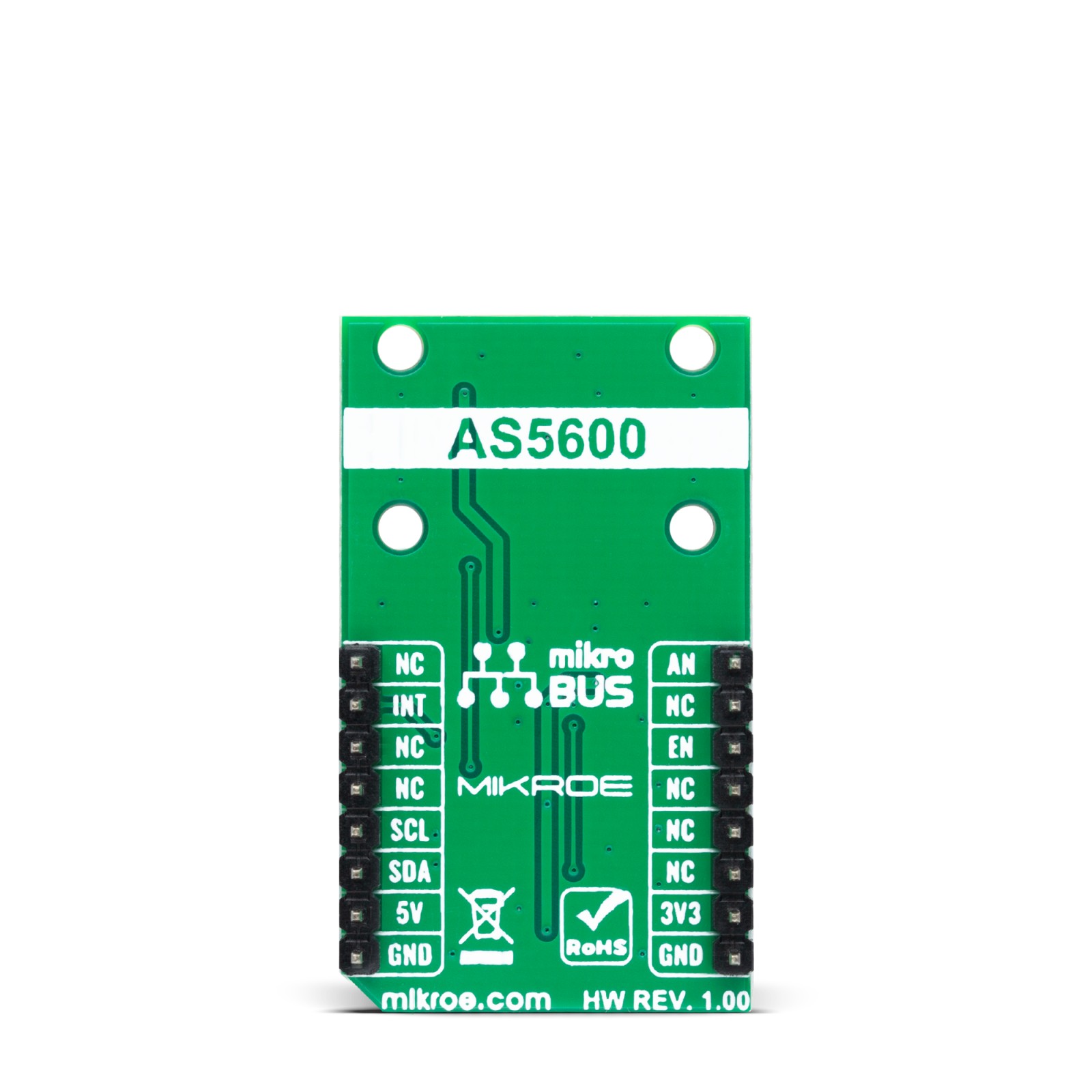

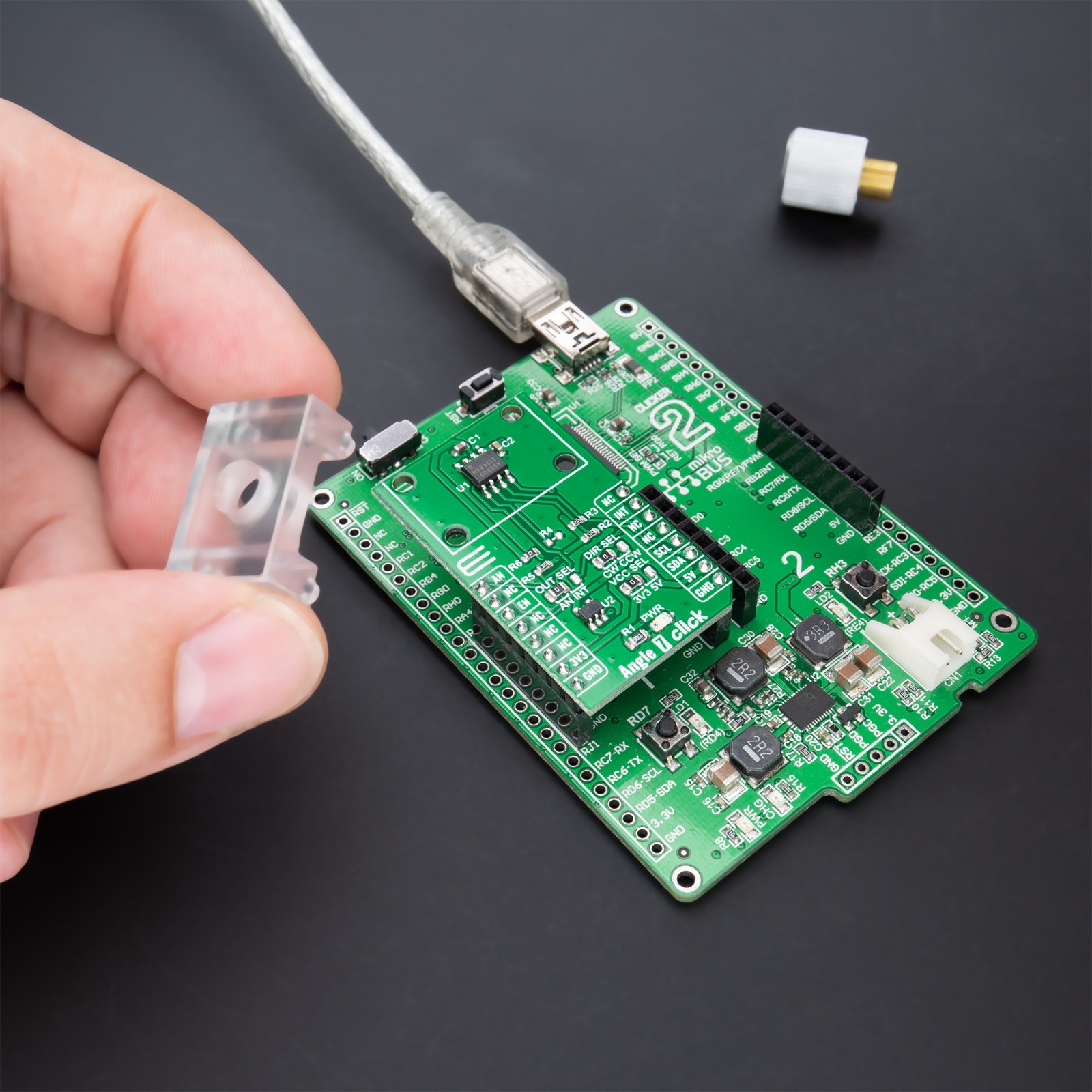

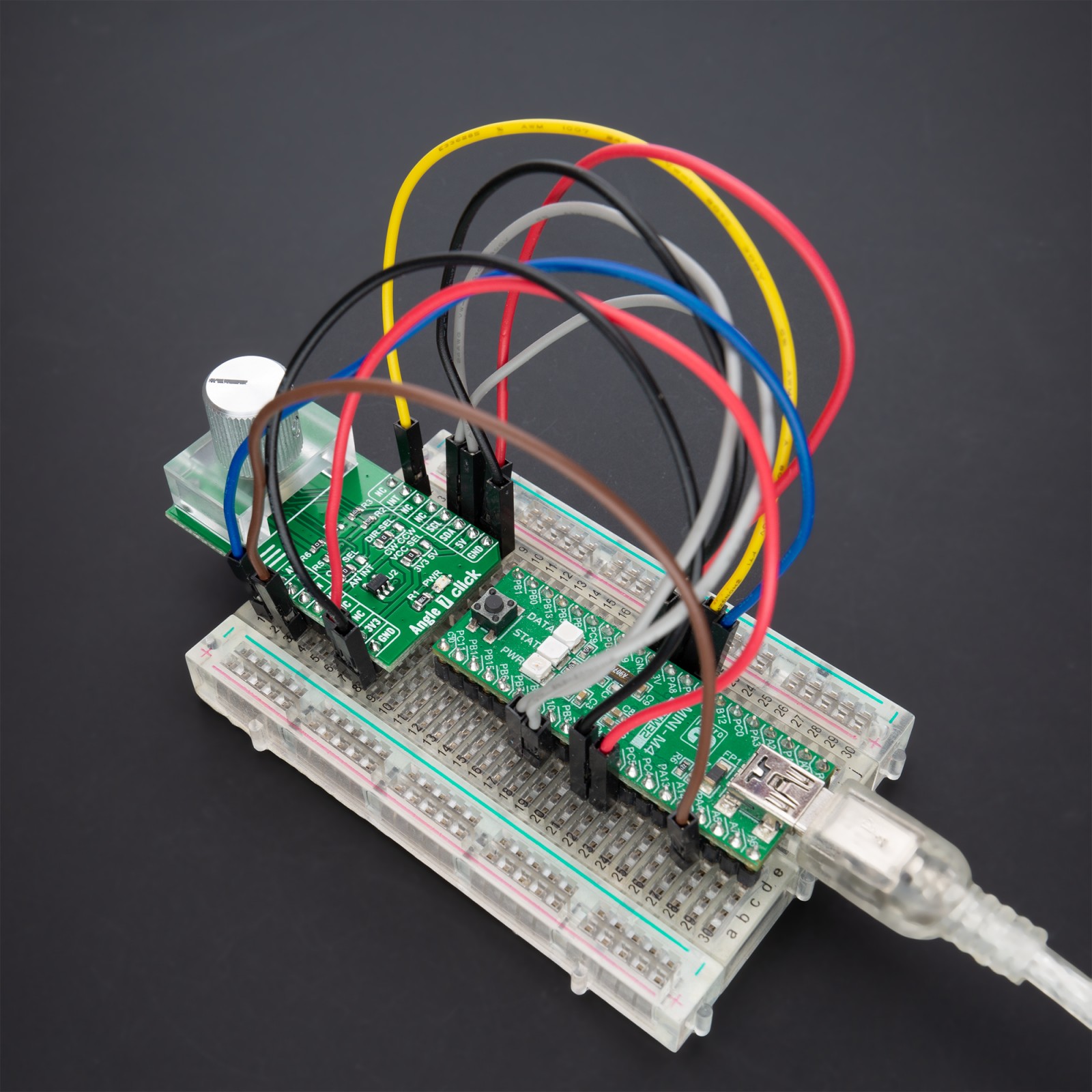

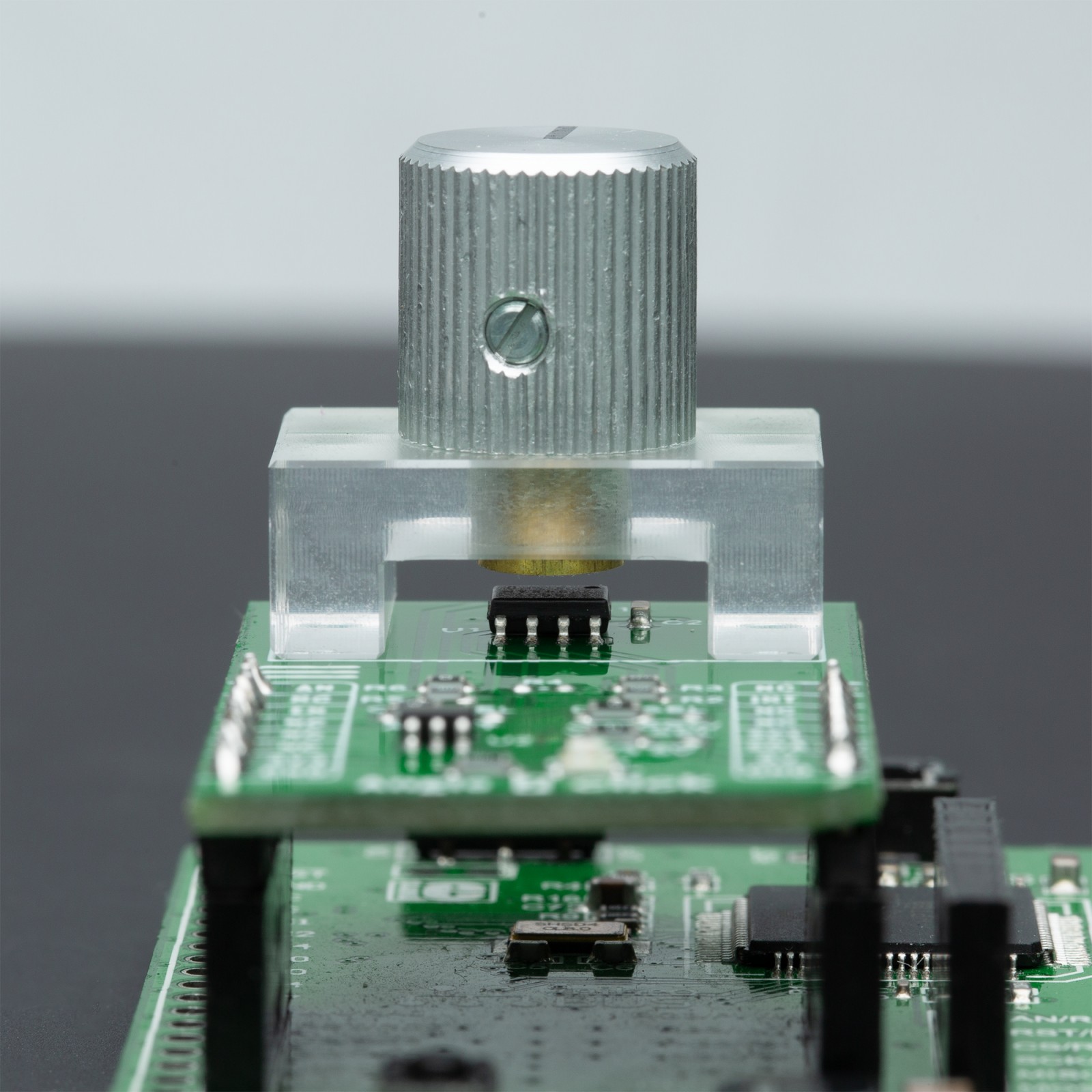

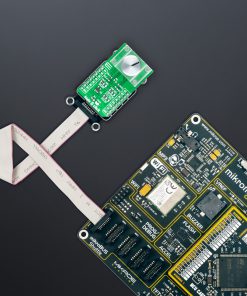

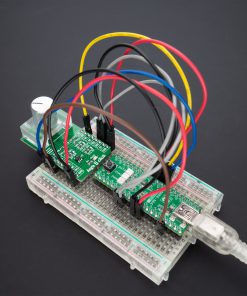

Angle 7 Click is a compact add-on board that detects the absolute angular position of a permanent magnet. This board features the AS5600, a programmable Hall-based rotary magnetic position sensor with a high-resolution 12-bit analog or PWM output from ams AG. Based on planar Hall technology, this sensor measures the orthogonal component of the flux density (Bz) from an external magnet while rejecting stray magnetic fields. The default range of the output is from 18 to 360 degrees, where the full resolution of the device can be applied to a smaller range by programming a zero angle (start position) and a maximum angle (Stop position) through the I2C interface used for configuration and user programming of non-volatile parameters. This Click board™ is suitable for contactless potentiometers, contactless knobs, RC servos, and other angular position measurement solutions.

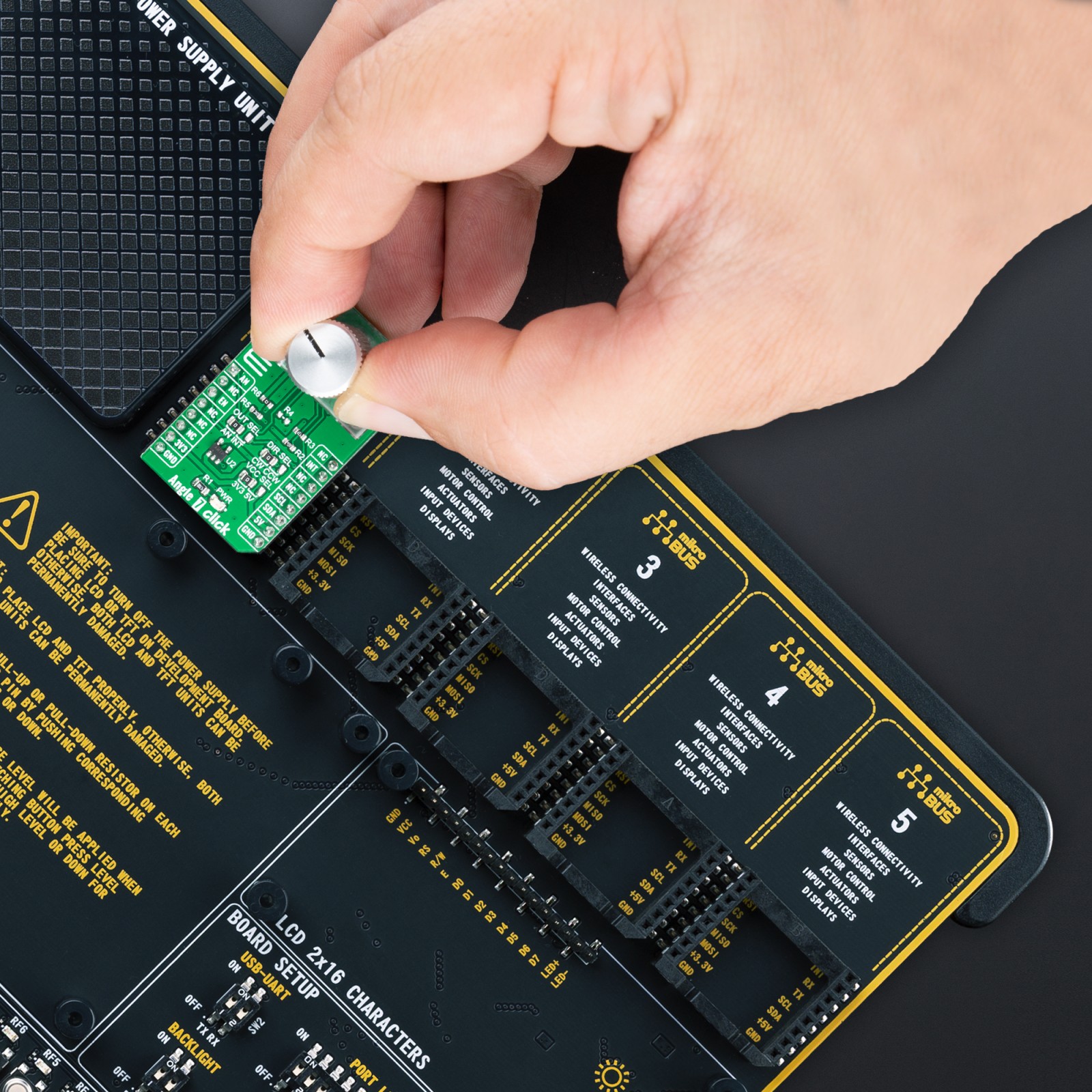

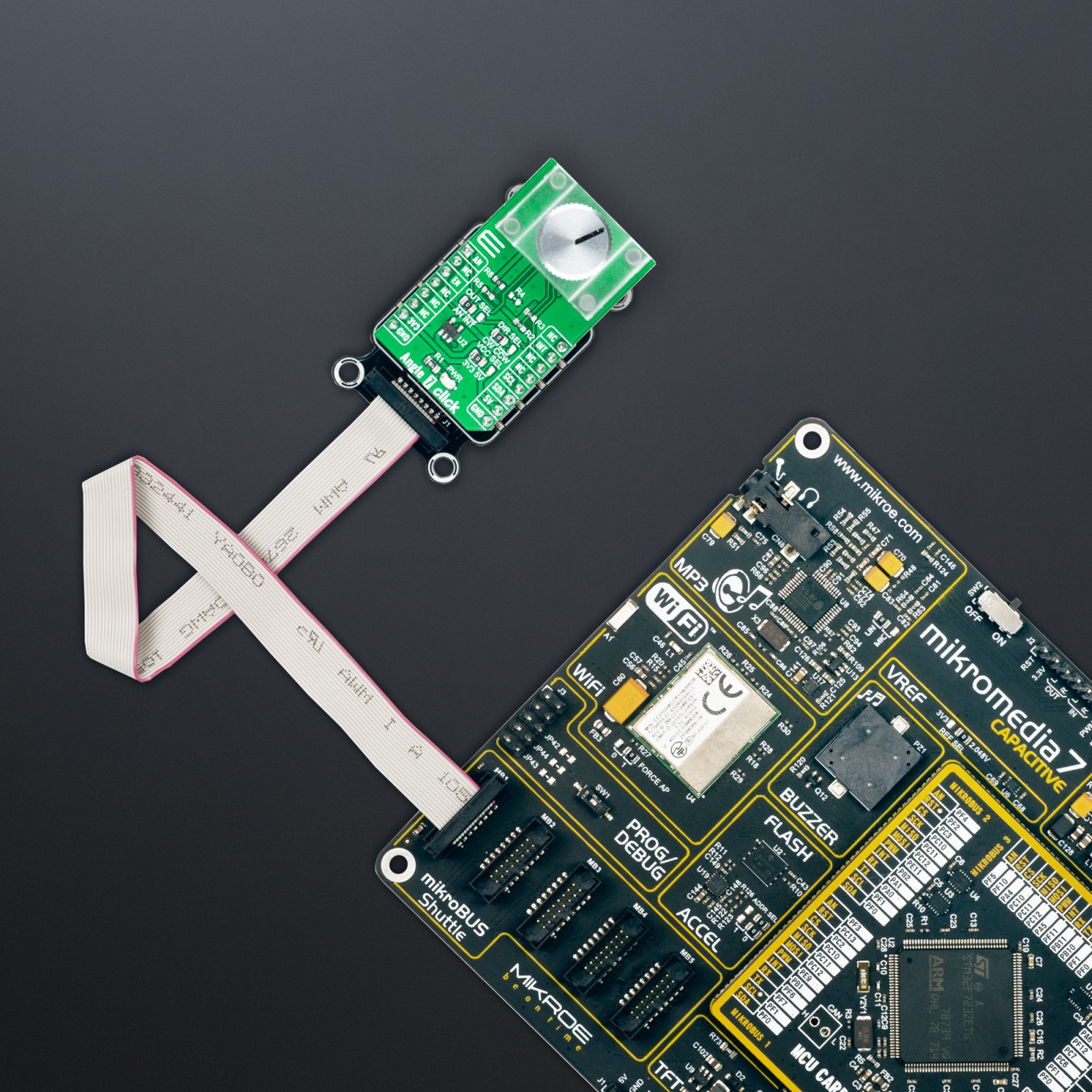

Angle 7 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R313.50 |

| 10+ | R297.00 |

| 15+ | R280.50 |

| 20+ | R269.94 |