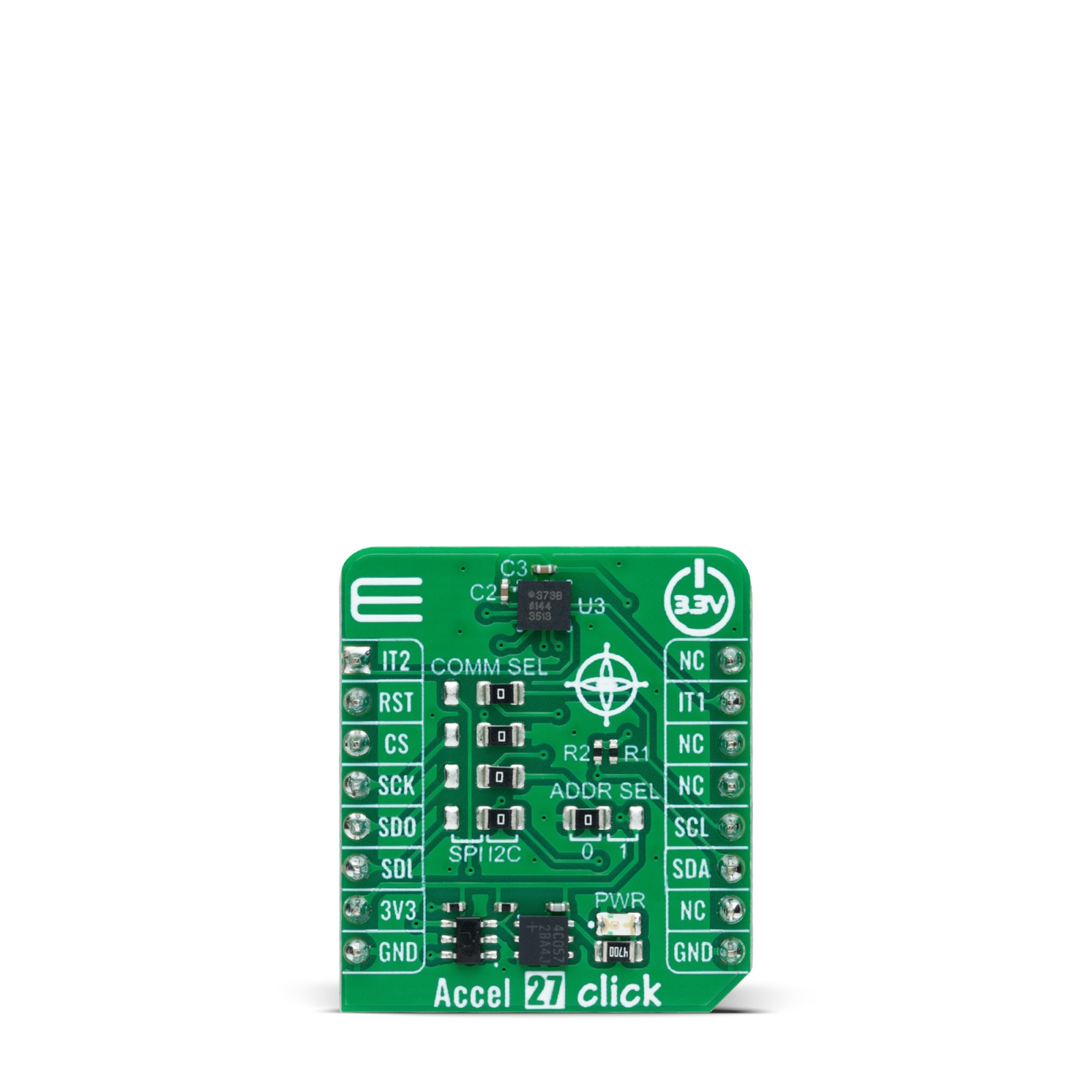

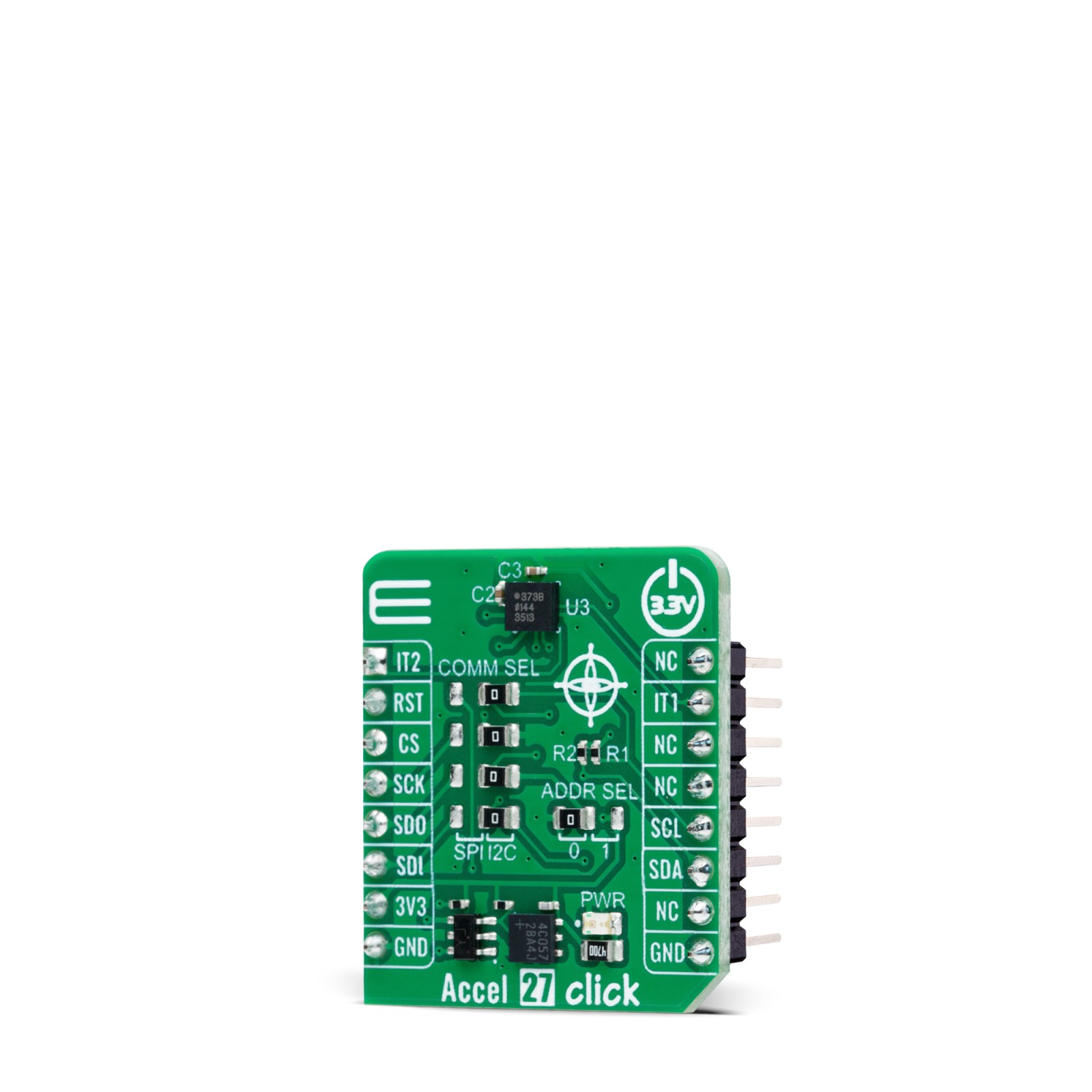

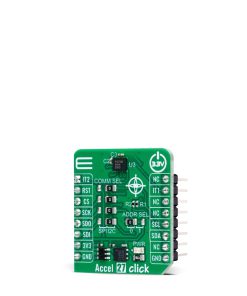

Accel 27 Click

R885.00 ex. VAT

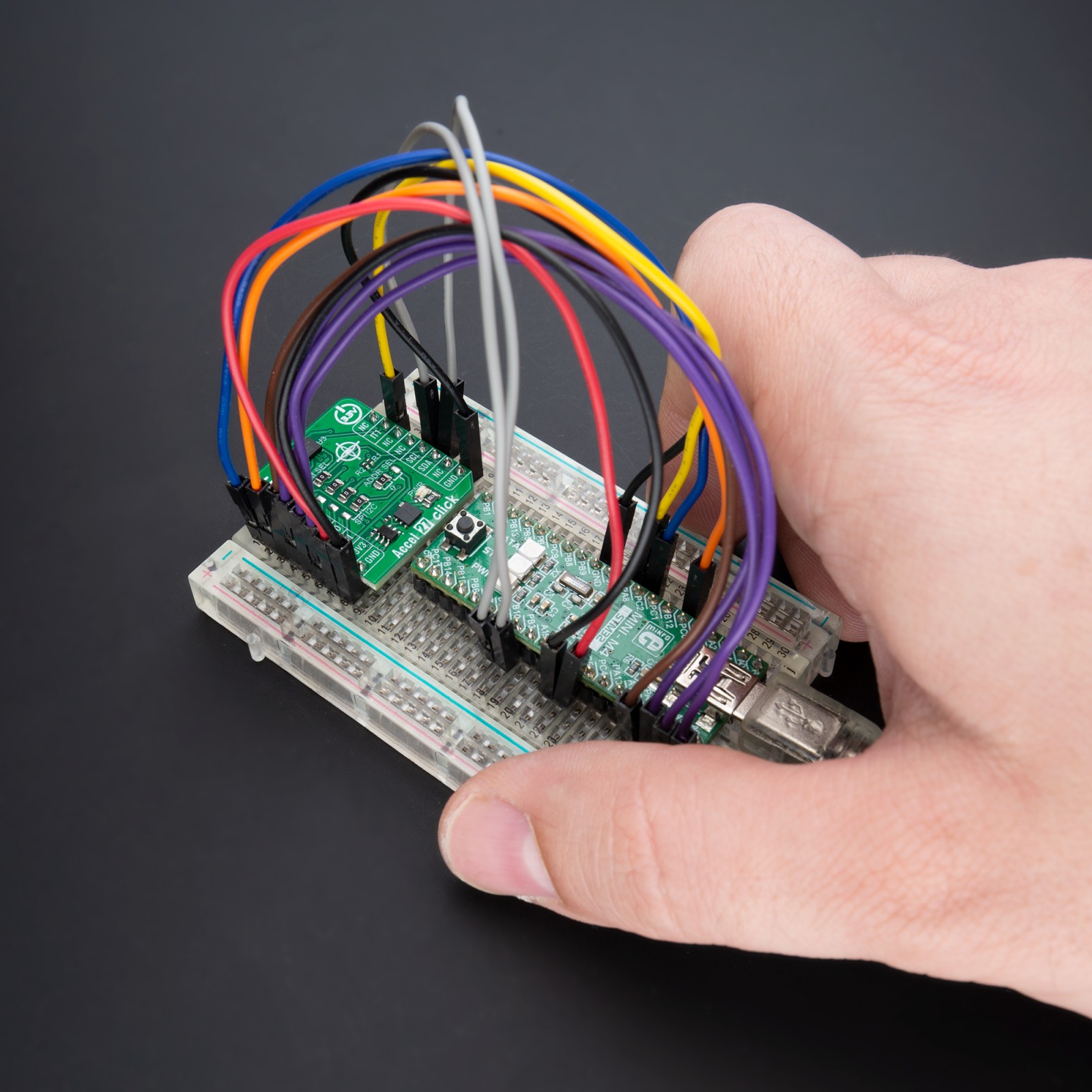

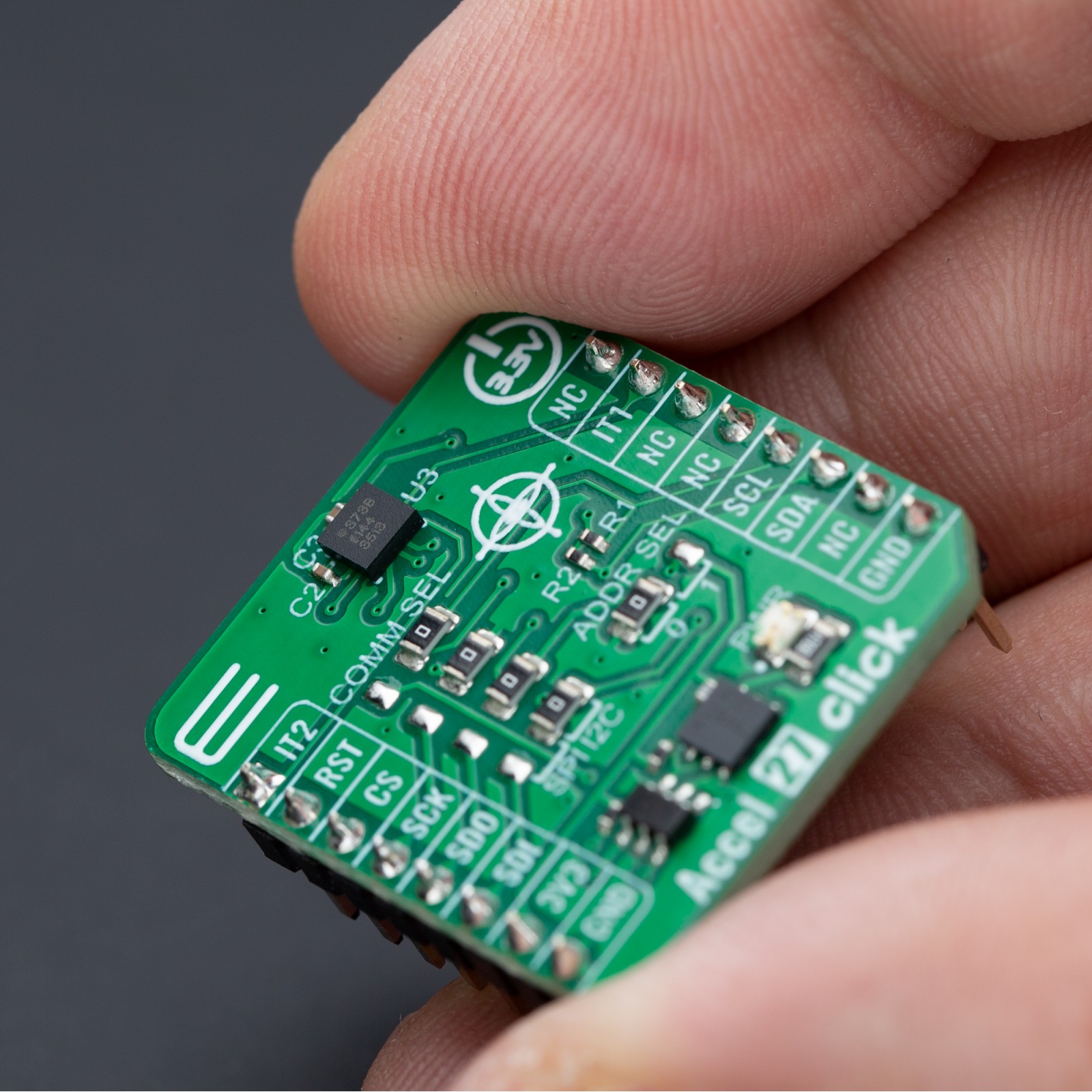

Accel 27 Click is a compact add-on board that contains an acceleration sensor. This board features the ADXL373, a three-axis MEMS ±400g accelerometer from Analog Devices. In addition to its ultra-low power consumption, the ADXL373 enables impact detection while providing system-level power reduction. It offers 12-bit output data at 200mg/LSB scale factor with a configurable host interface that supports SPI and I2C serial communication. This Click board™ is suitable for multiple applications such as motion-activated functions, impact, and shock detection, medical IoT applications that require ultra-low-power Wake-Up on the motion, and more.

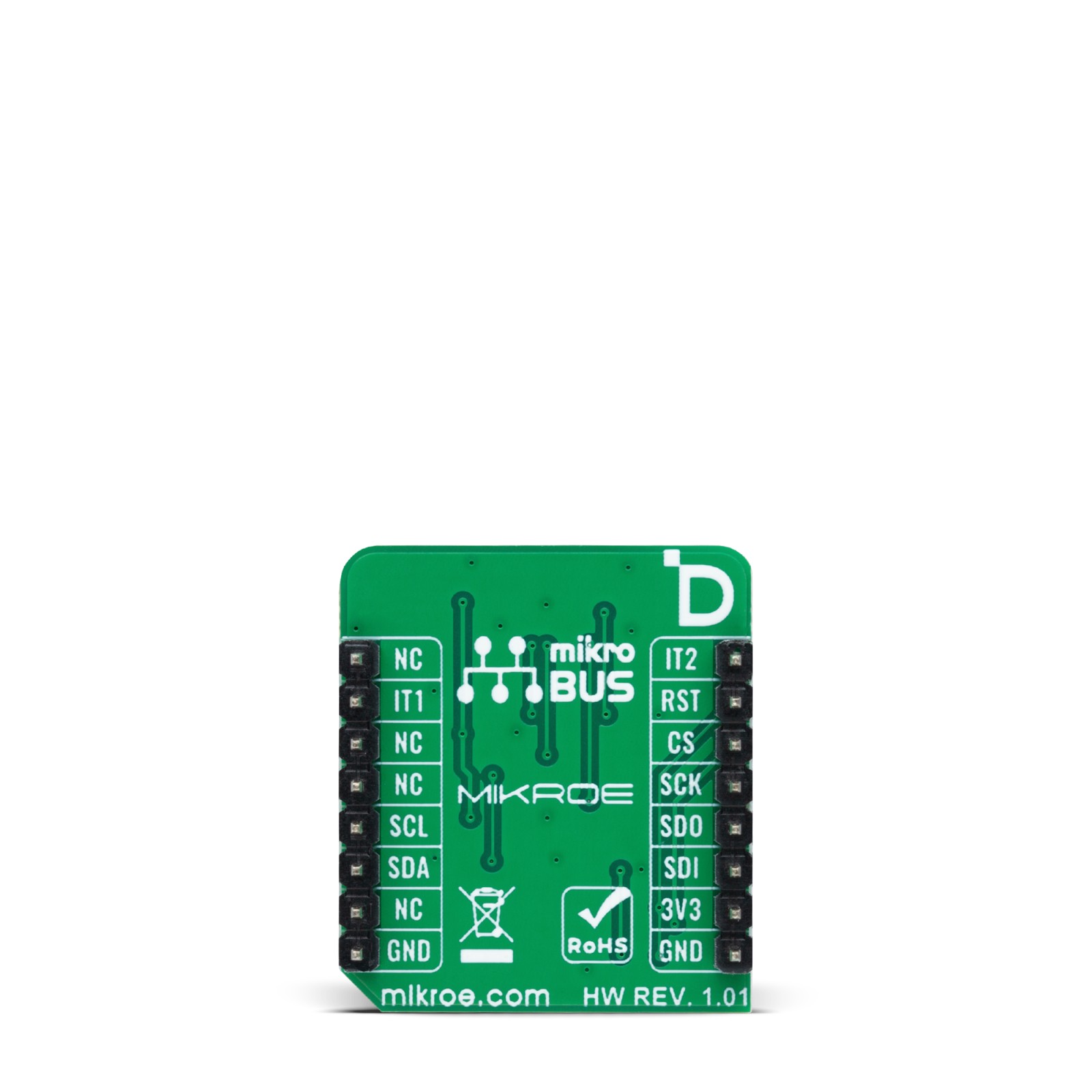

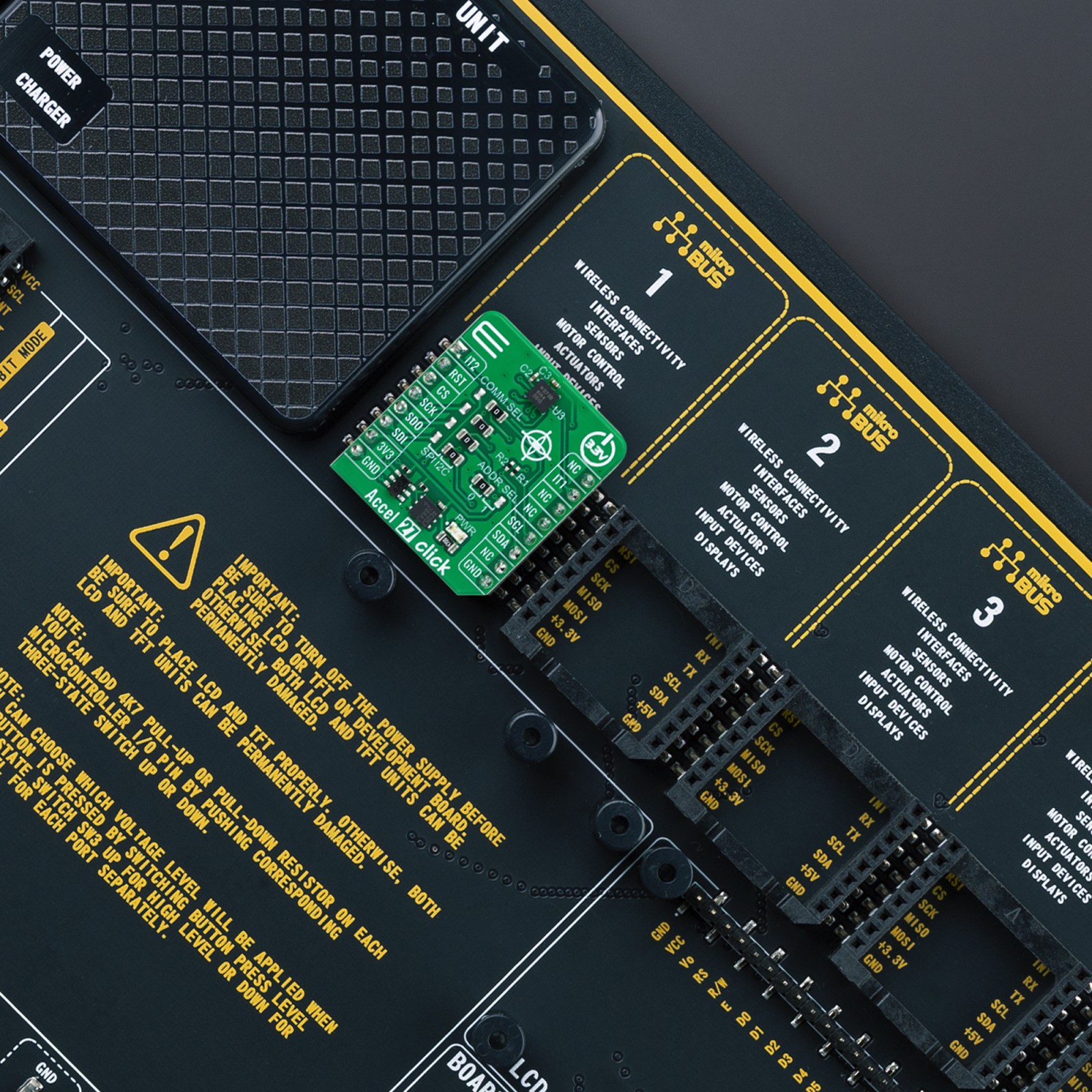

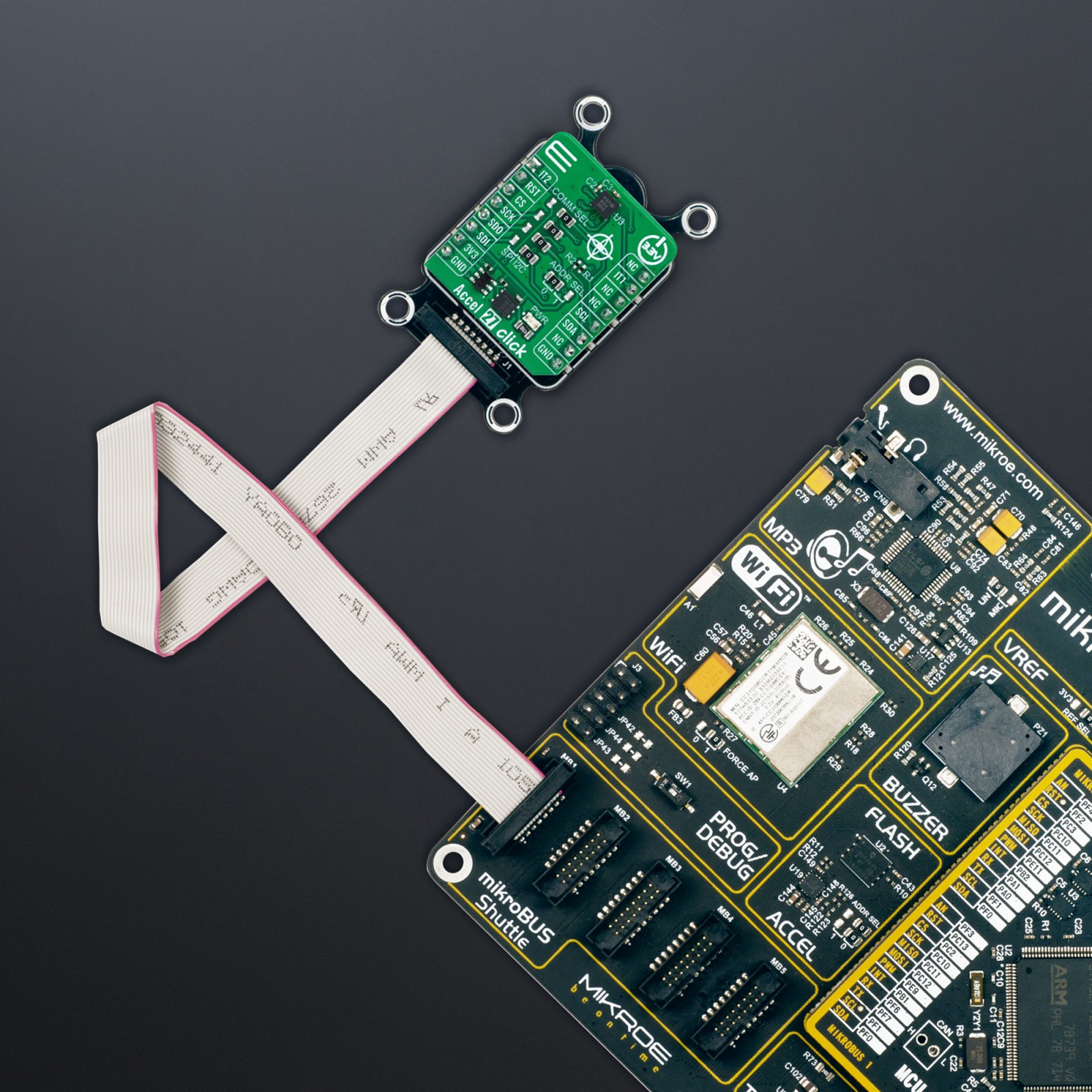

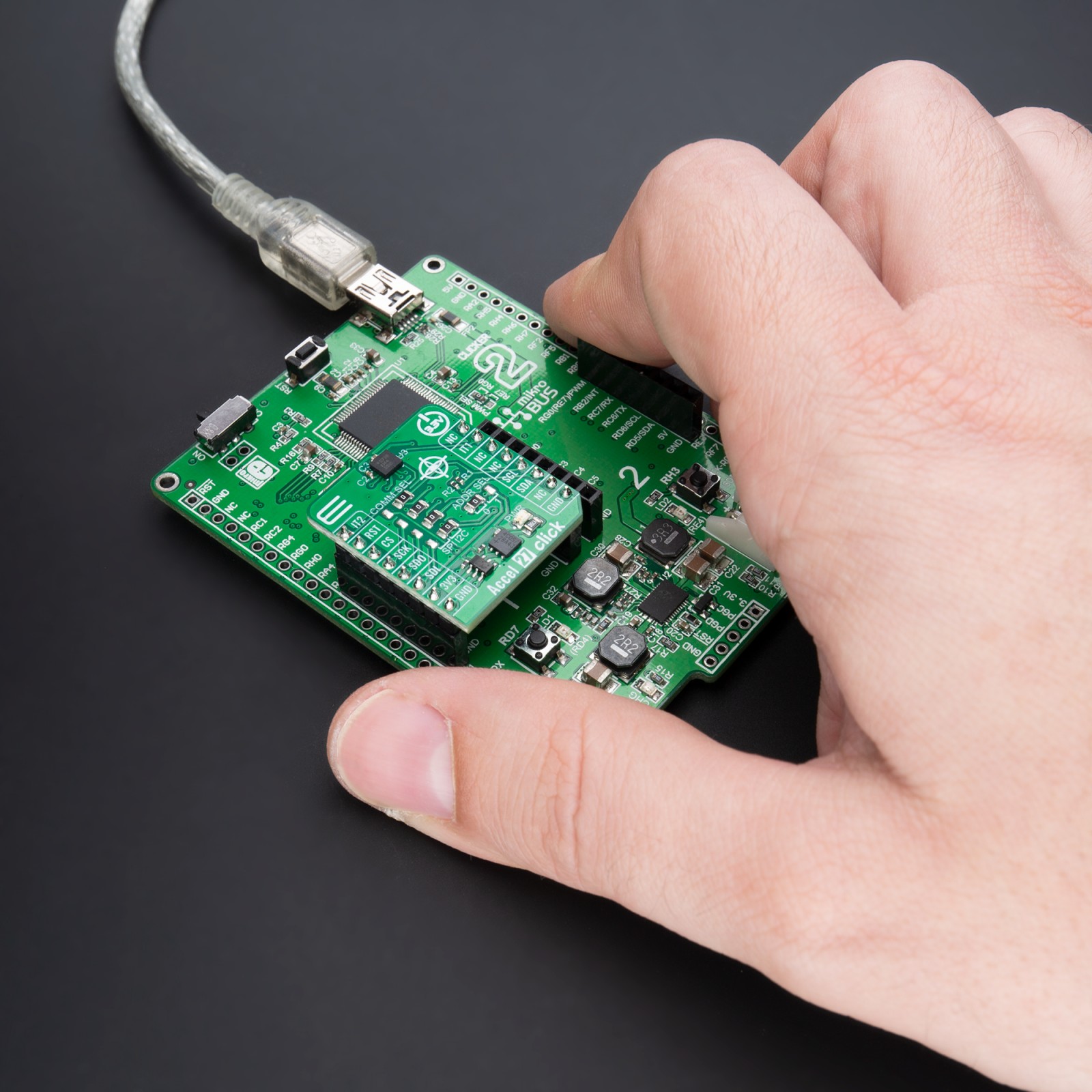

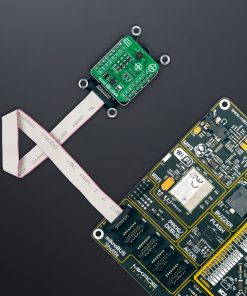

Accel 27 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R840.75 |

| 10+ | R796.50 |

| 15+ | R752.25 |

| 20+ | R723.93 |