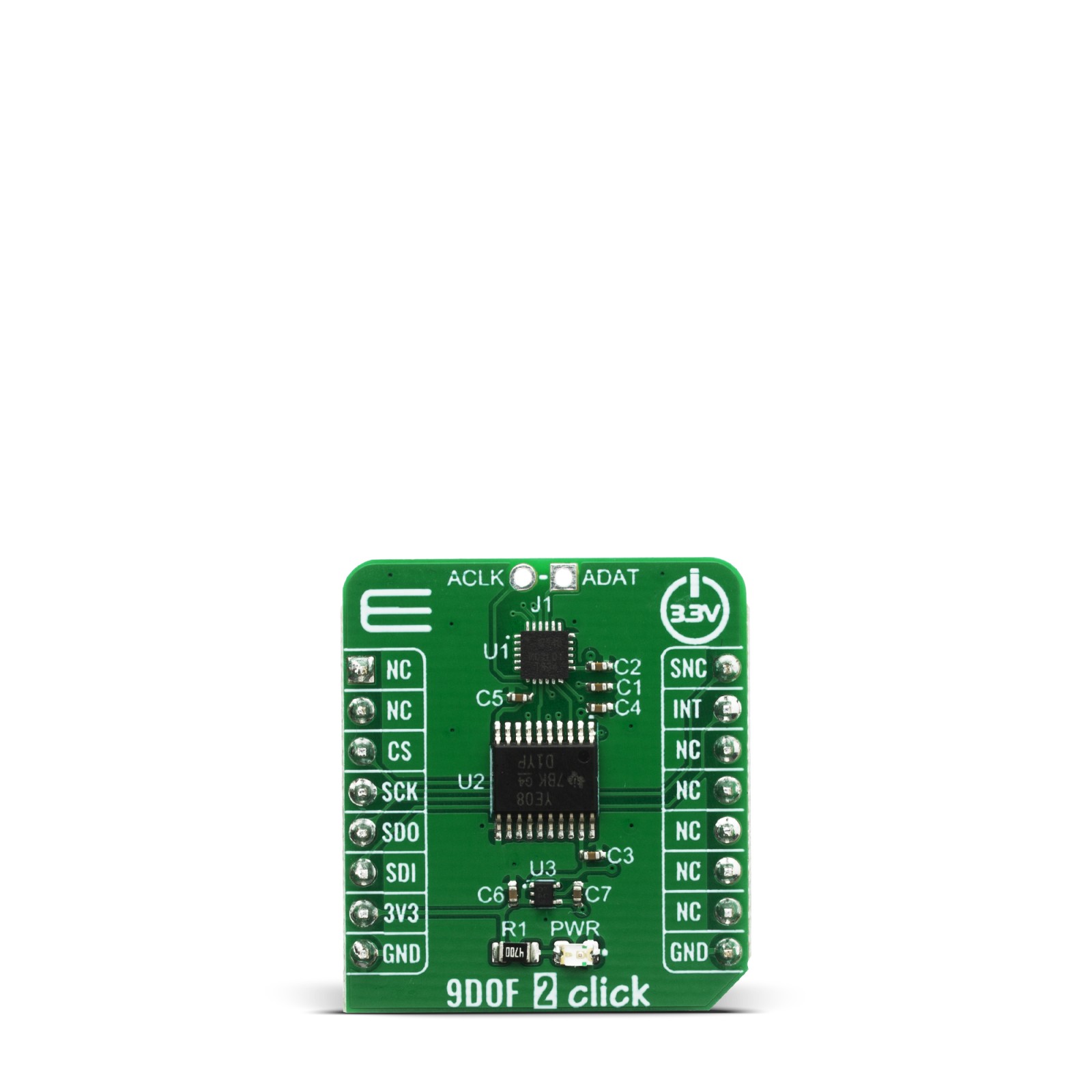

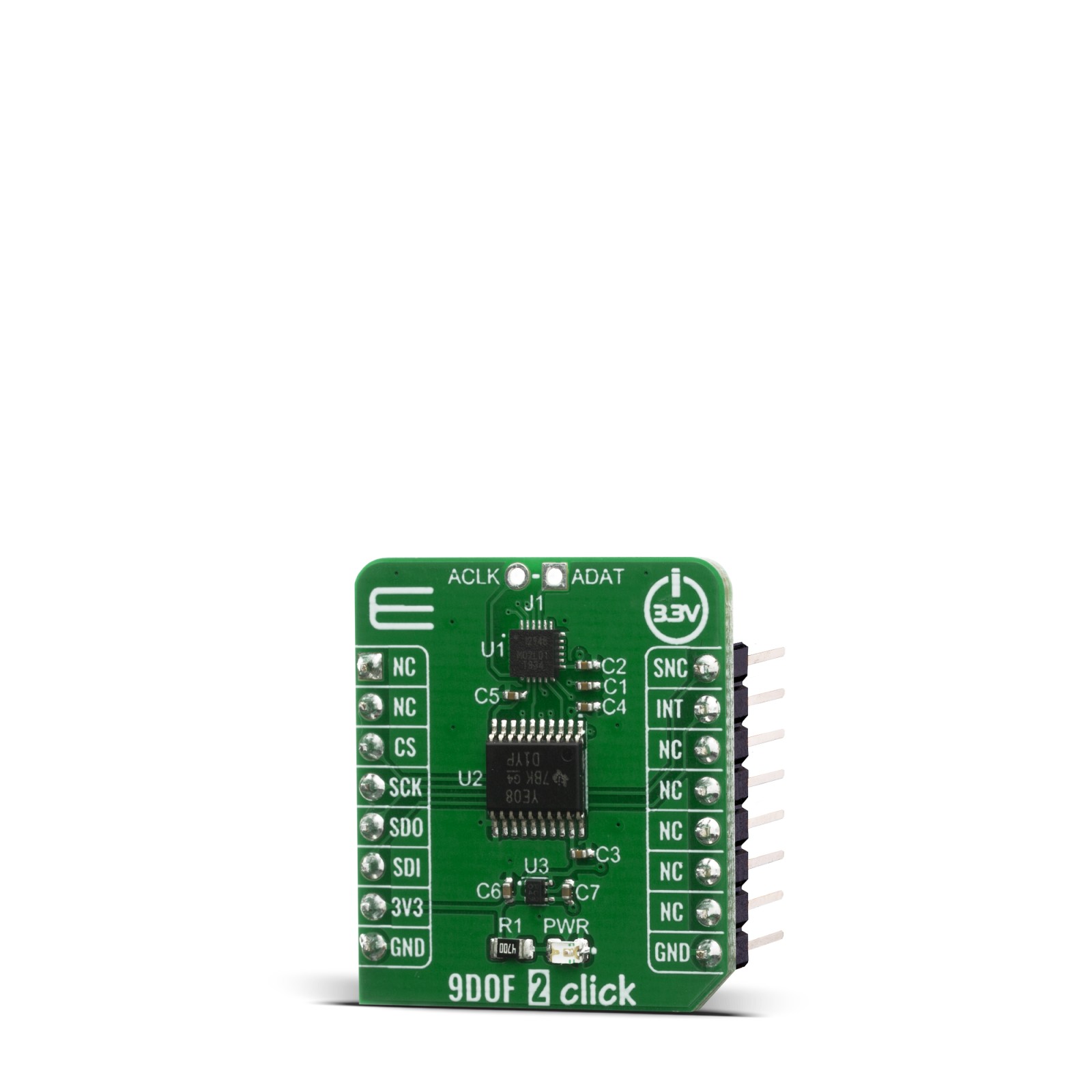

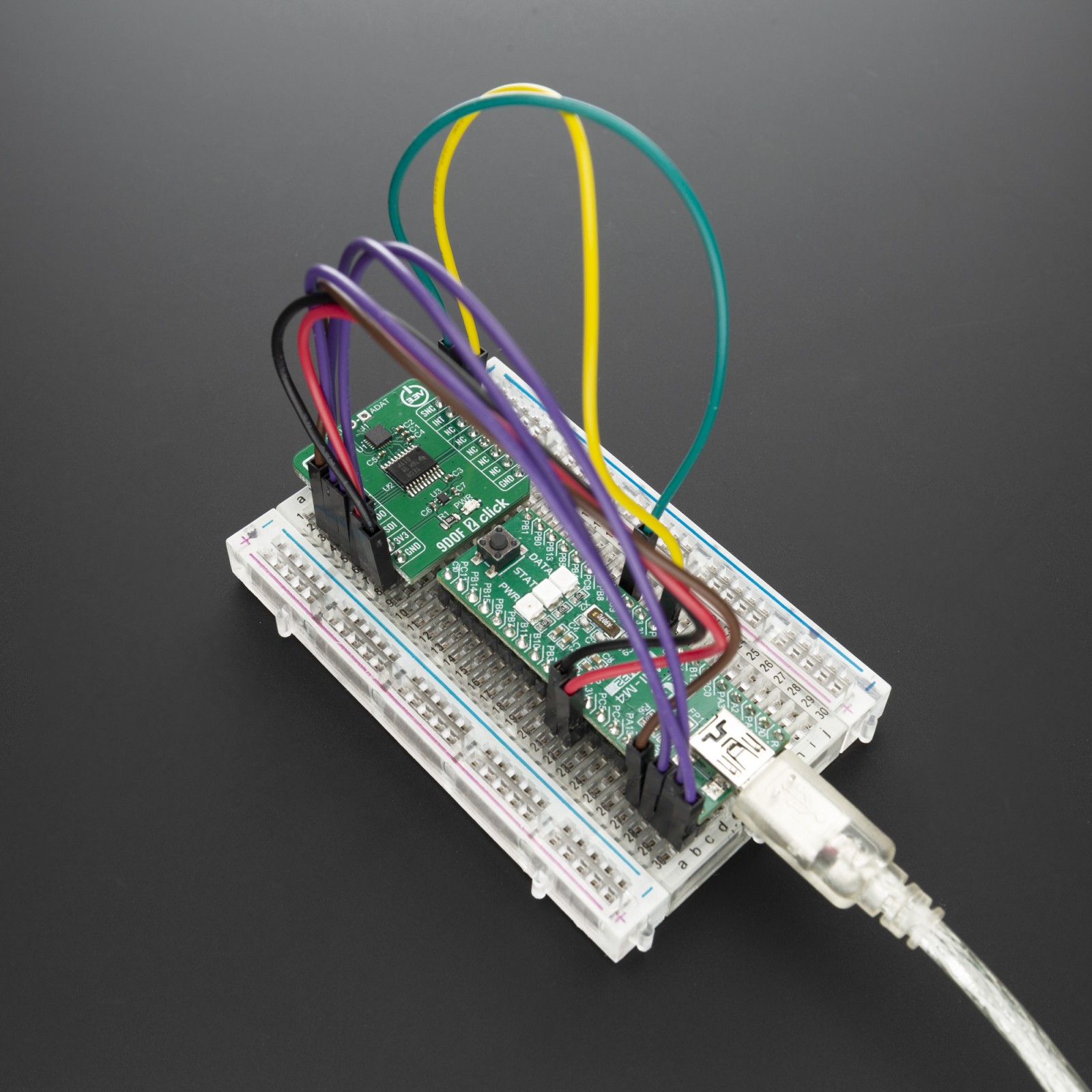

9DOF 2 Click

R425.00 ex. VAT

9DOF 2 Click is a compact add-on board for applications which require lowest power motion tracking and magnetometer functionality. This board features the ICM-20948 a 9-axis MotionTracking™ sensor from TDK Invensense, which consist of two sensors combined into one package for universal 9DOF solution. In this package we have 3-axis gyroscope, a 3-axis accelerometer, 3-axis magnetometer, combined with Digital Motion Processor™ (DMP) and run-time calibration firmware. All this features makes 9DOF 2 Click excellent choice for manufacturers looking for a product to eliminate the costly and complex selection, qualification, and system level integration of discrete devices, guaranteeing optimal motion performance for consumers. Its also ideally suited for wearable sensors and IoT applications needed low power motion tracking device expandable with additional I2C sensors.

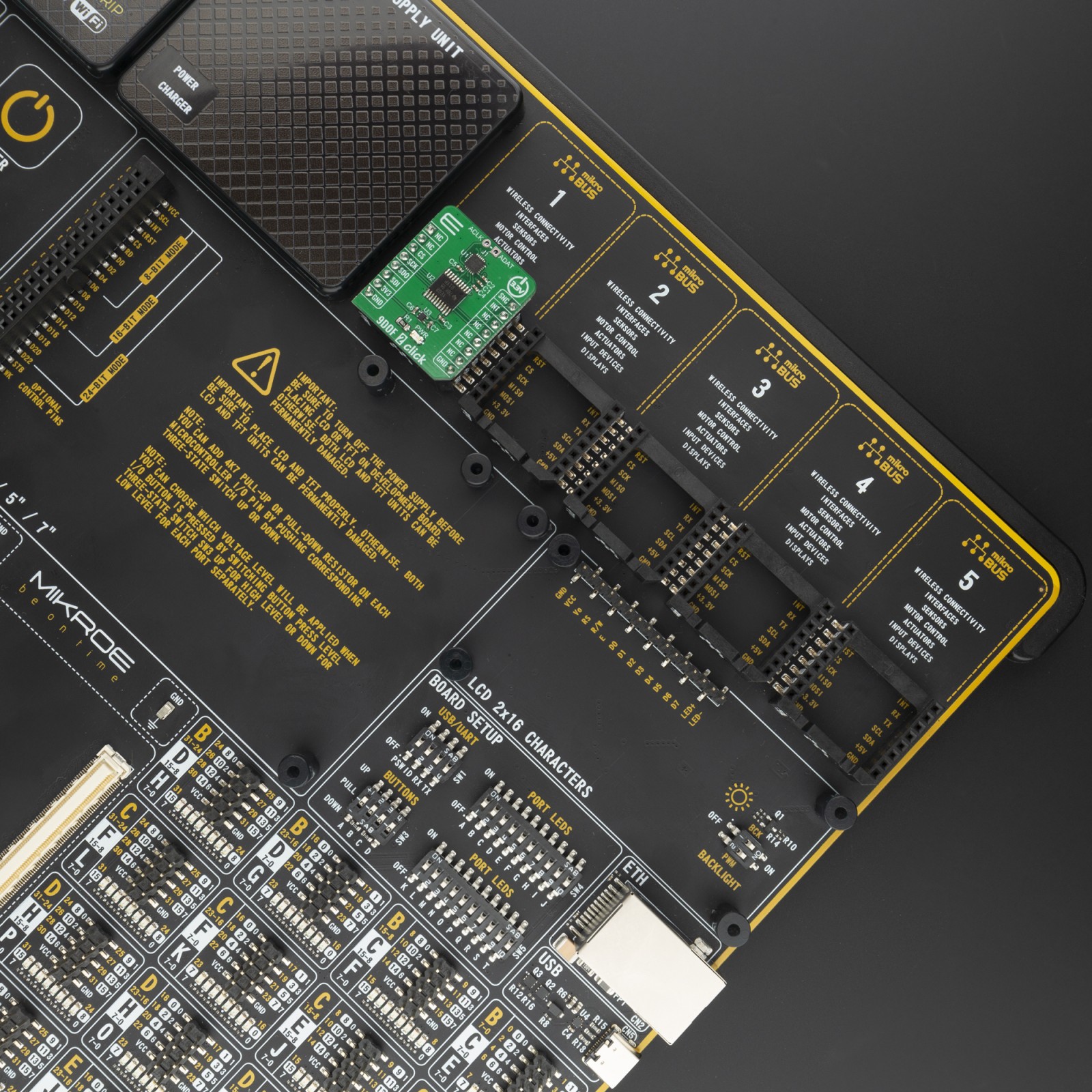

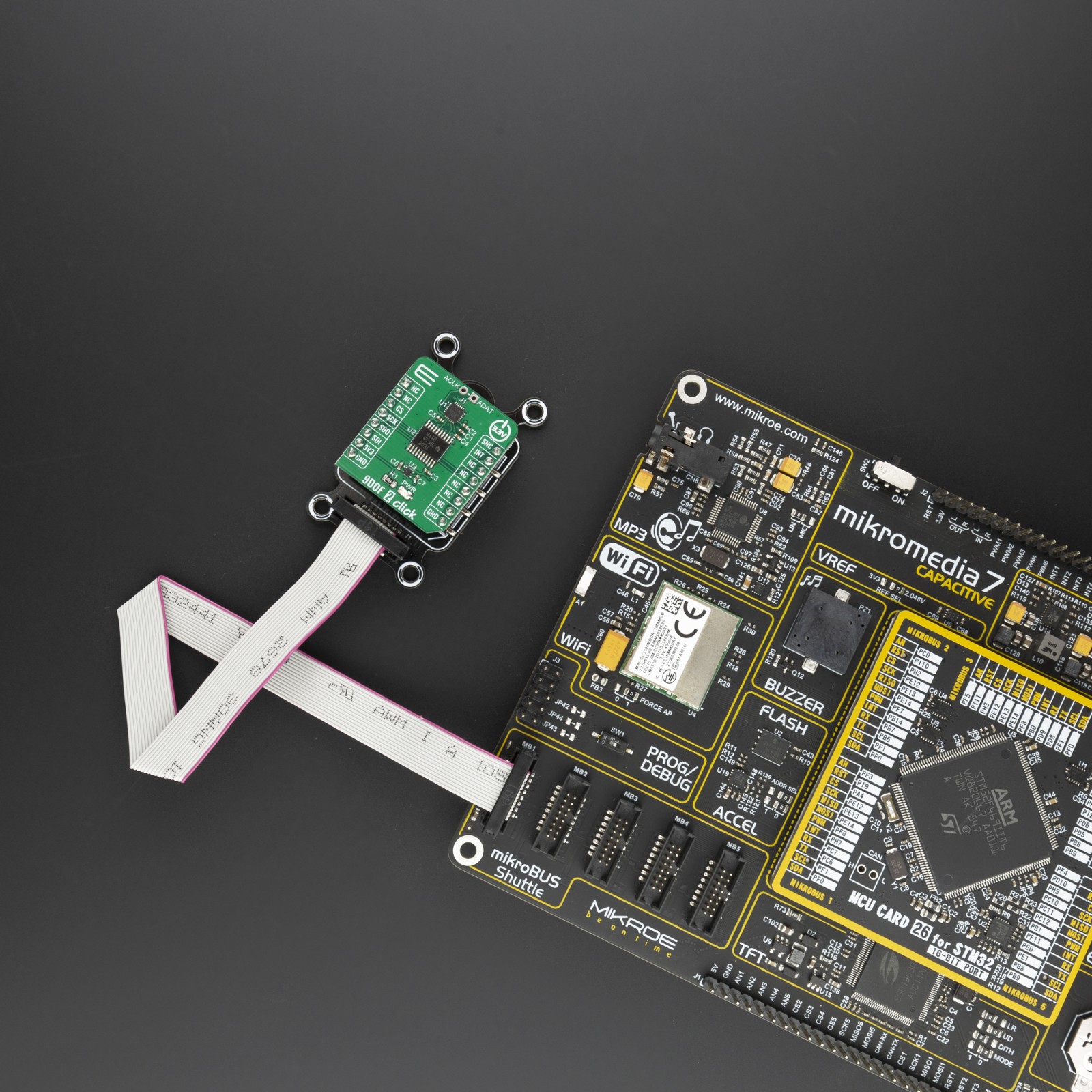

9DOF 2 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R403.75 |

| 10+ | R382.50 |

| 15+ | R361.25 |

| 20+ | R347.65 |