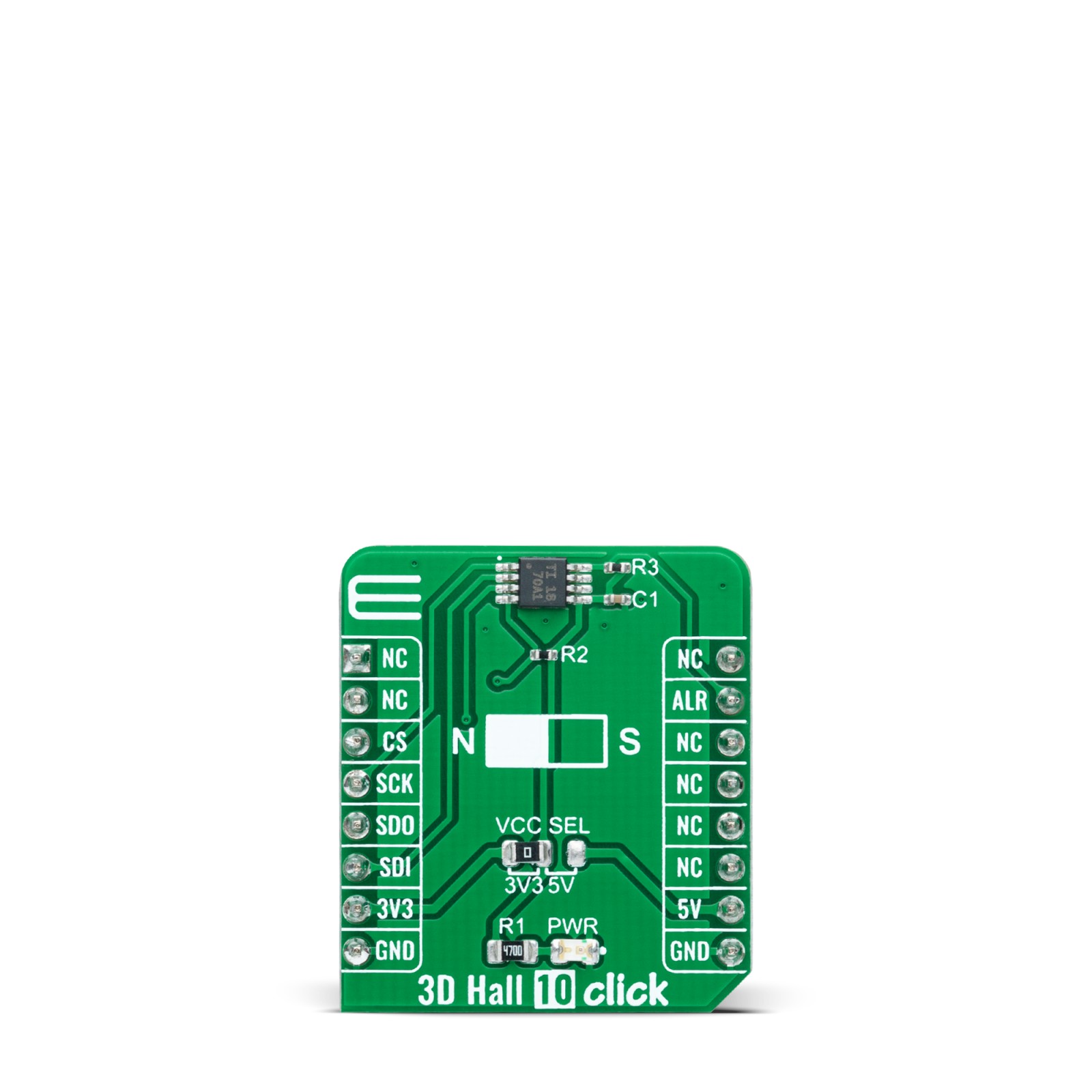

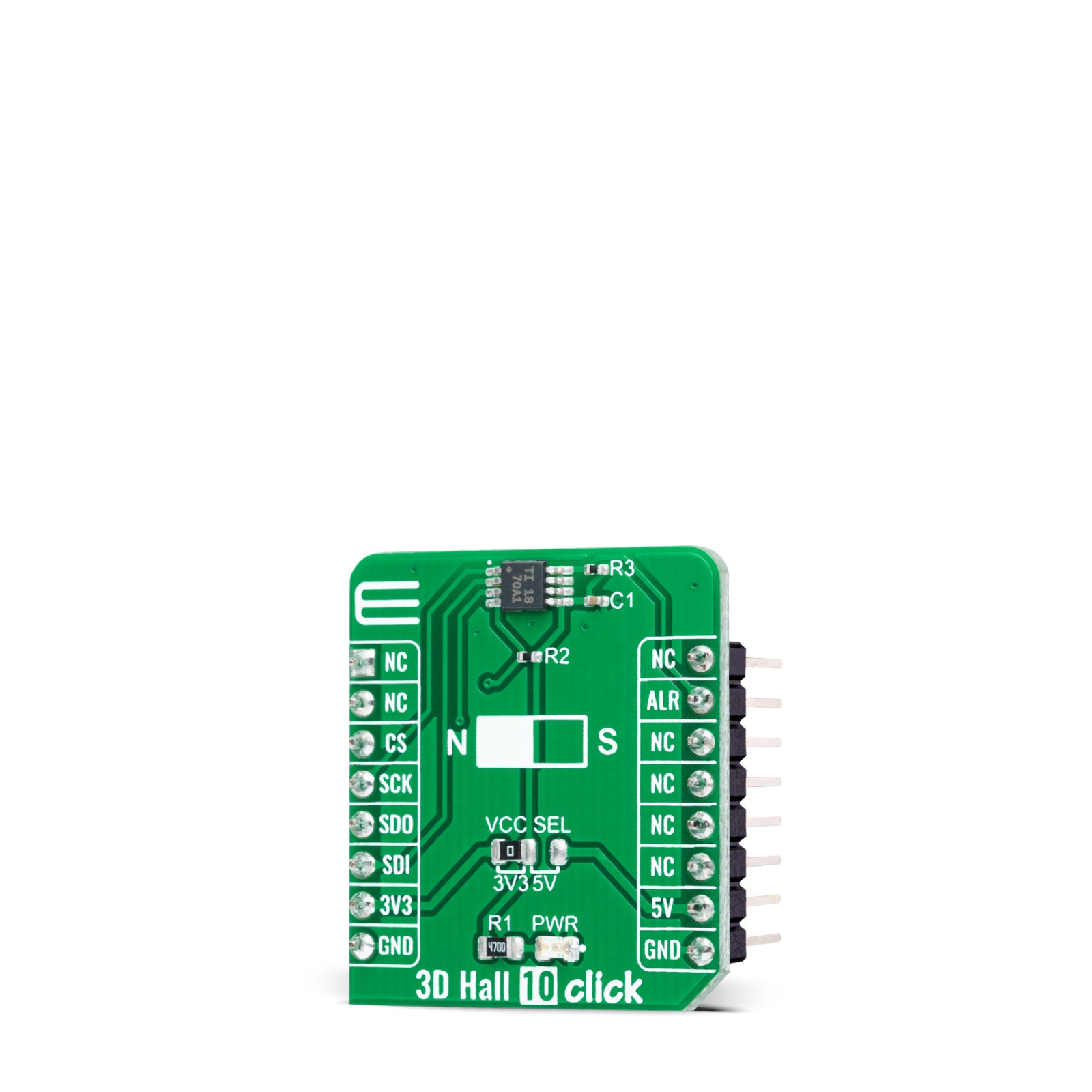

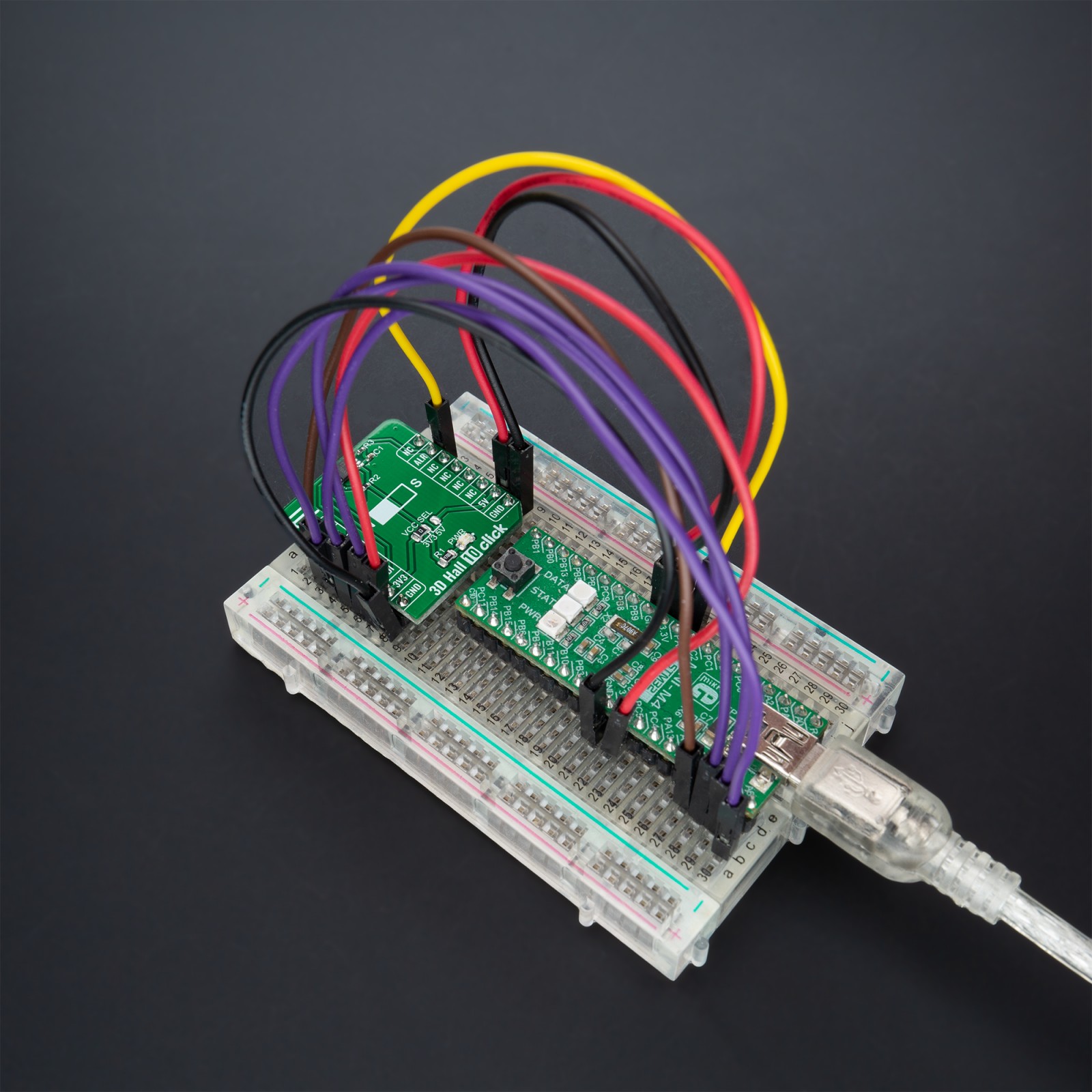

3D Hall 10 Click

R165.00 ex. VAT

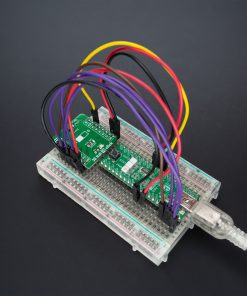

3D Hall 10 Click is a compact add-on board used to detect the strength of a magnetic field in all three dimensions. This board features the TMAG5170, a high-precision linear 3D Hall effect sensor from Texas Instruments. The TMAG5170 features an SPI interface for configuration by MCU. The measurement data is provided in digital format of 12-bits corresponding to the magnetic field measured in each X, Y, and Z axes. It can achieve ultra-high precision at speeds up to 20kSPS for faster and more accurate real-time control and offers multiple diagnostics features to detect and report both system and device-level failures. This Click board™ is designed for a wide range of industrial and personal electronics applications.

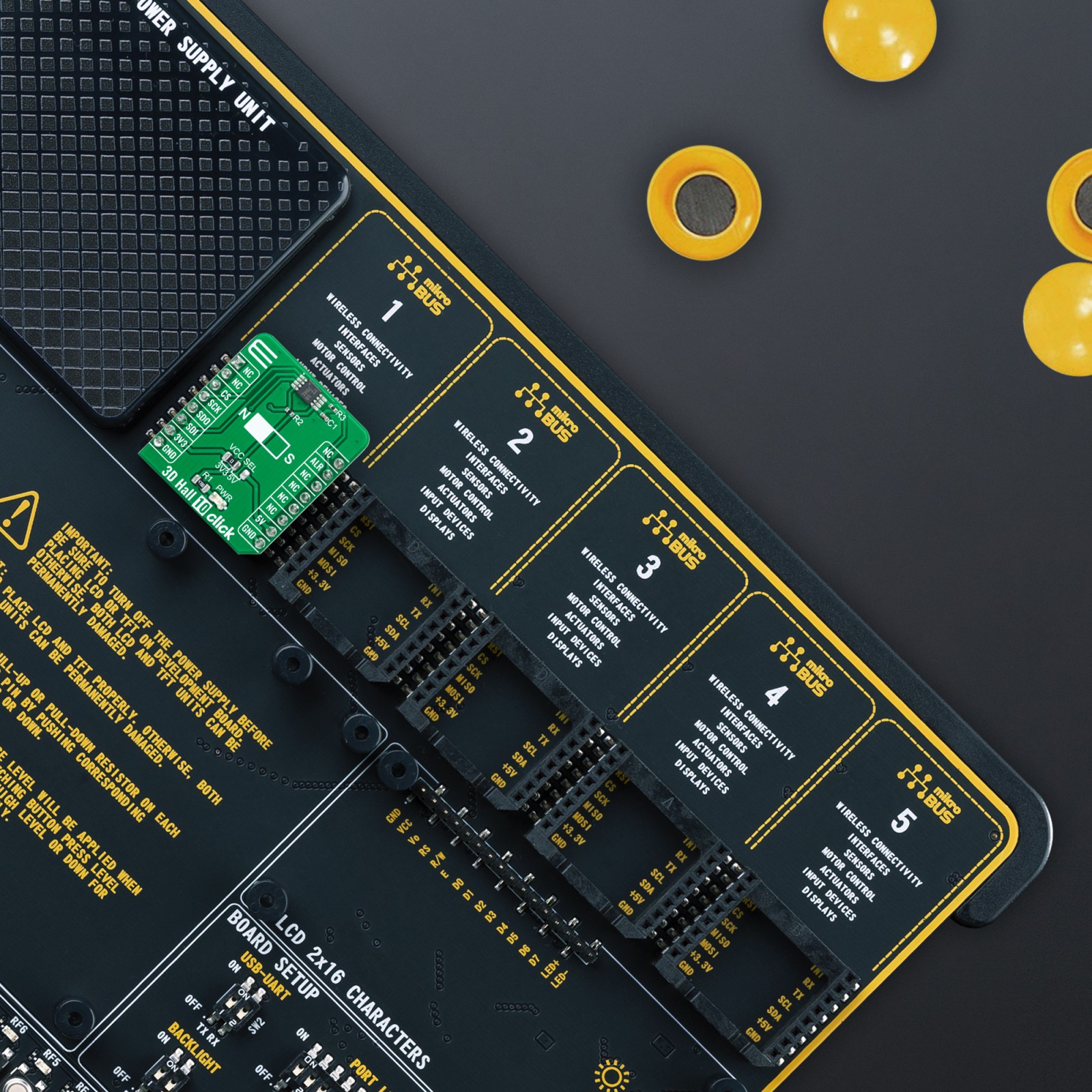

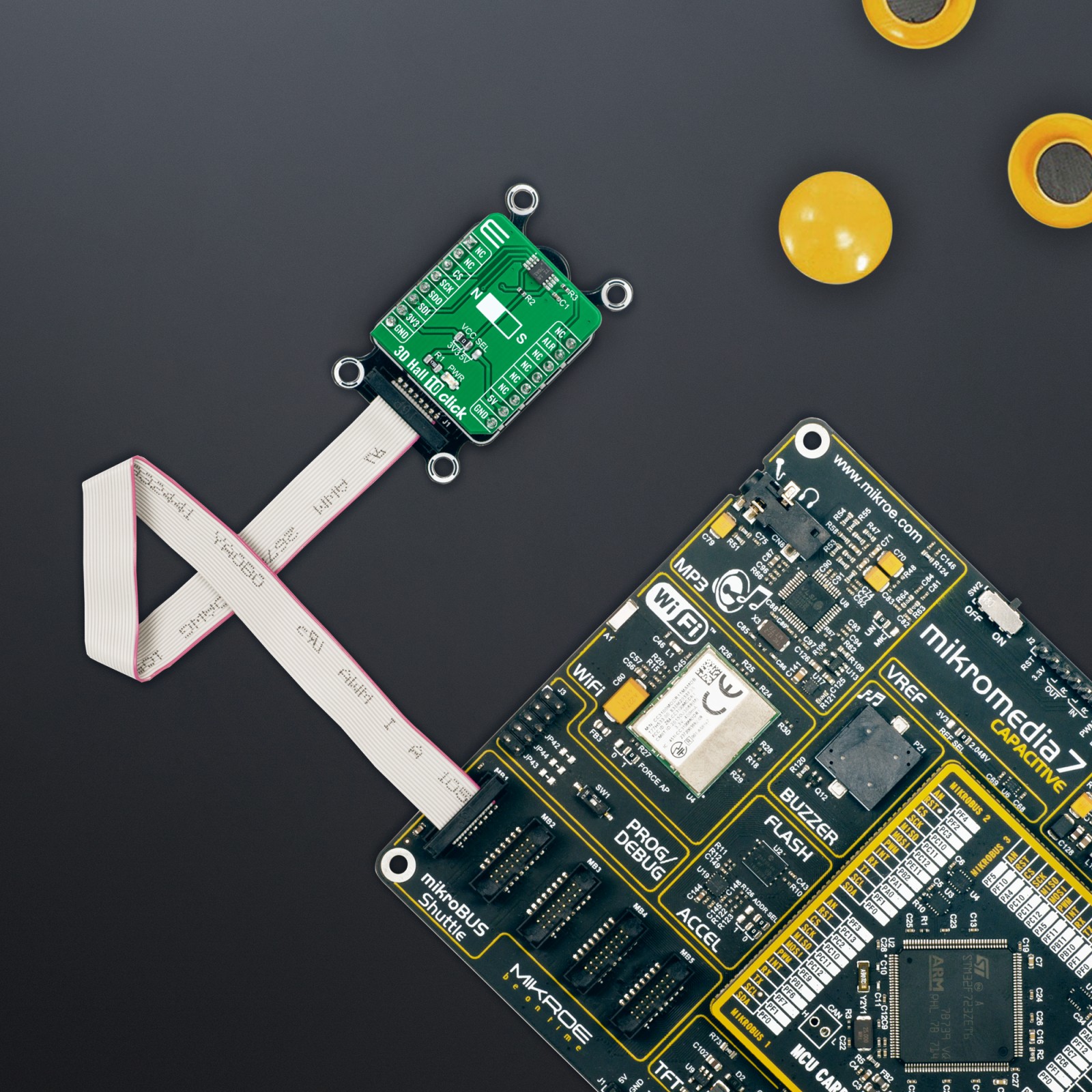

3D Hall 10 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R156.75 |

| 10+ | R148.50 |

| 15+ | R140.25 |

| 20+ | R134.97 |