ADC2 Click

R515.00 ex. VAT

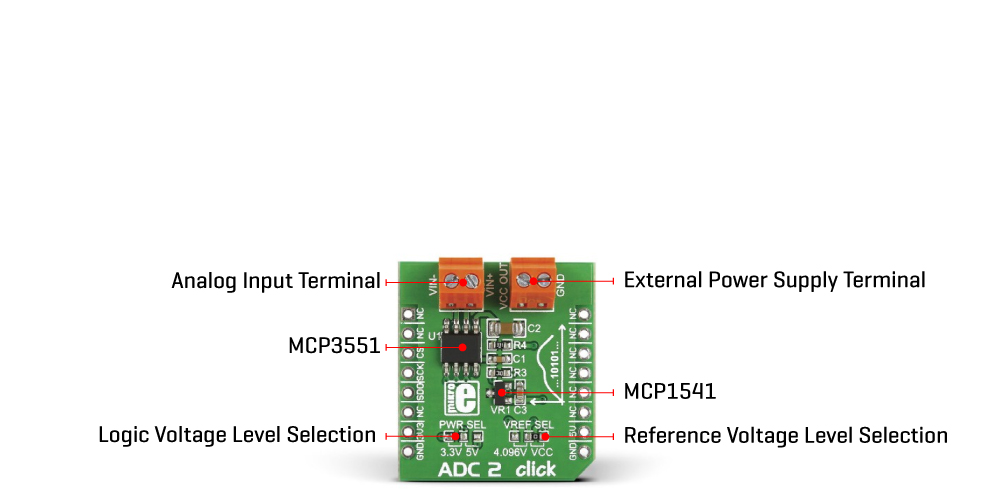

ADC 2 Click is a compact add-on board with a high-performance data converter. This board features the MCP3551, a 22-bit precision ΔΣ analog-to-digital converter with SPI compatible interface (read-only) from Microchip. The MCP3551 has fully differential analog input making it compatible with a wide variety of industrial or process control applications, offering high accuracy and low noise performance with an internal oscillator and high oversampling rate. Besides, the ADC 2 Click can select the value of the reference voltage and, thus, the precision of the converter itself. This Click board™ offers high accuracy for the most demanding applications, from general-purpose remote data acquisition to industrial applications.

ADC 2 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R489.25 |

| 10+ | R463.50 |

| 15+ | R437.75 |

| 20+ | R421.27 |