3D Hall Click

R550.00 ex. VAT

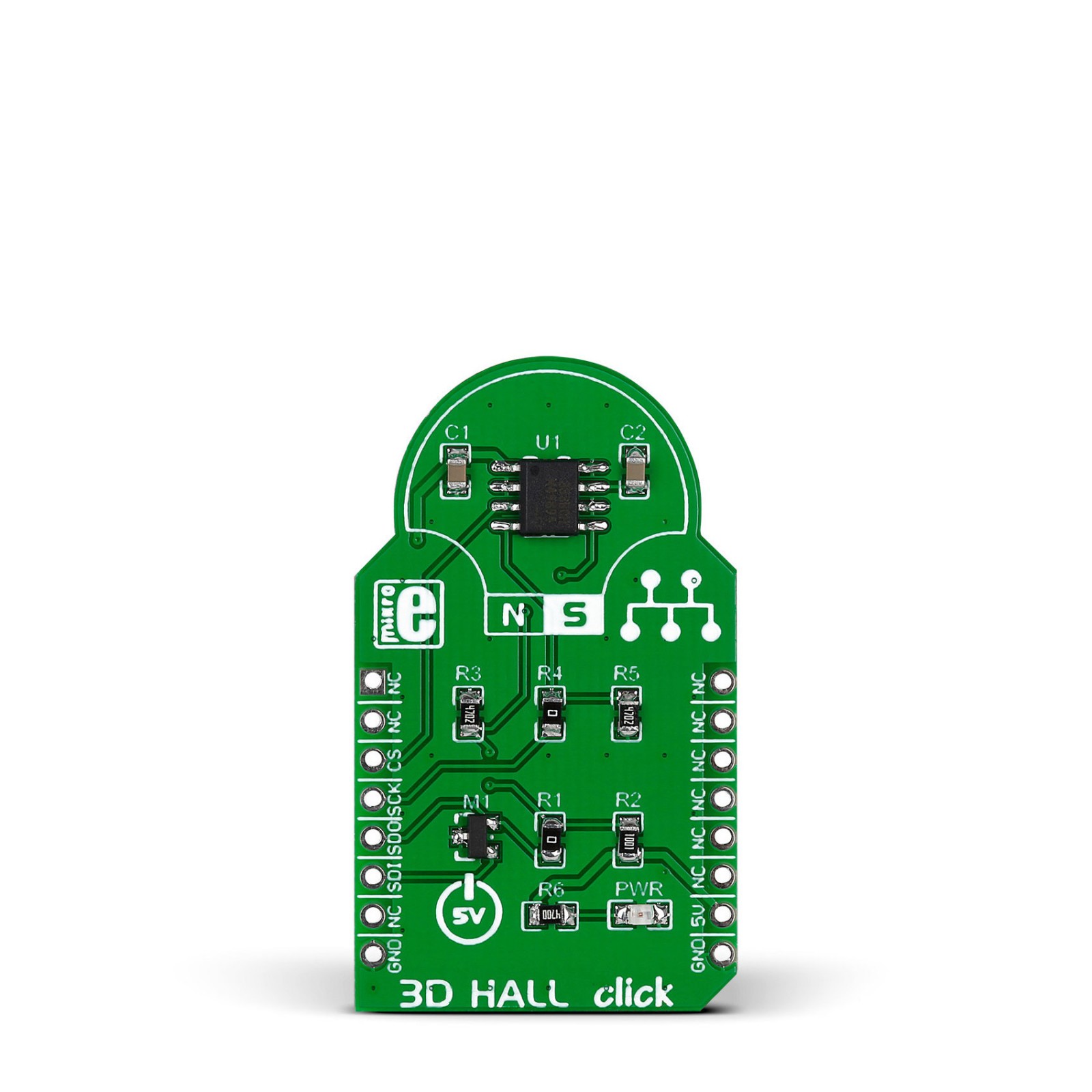

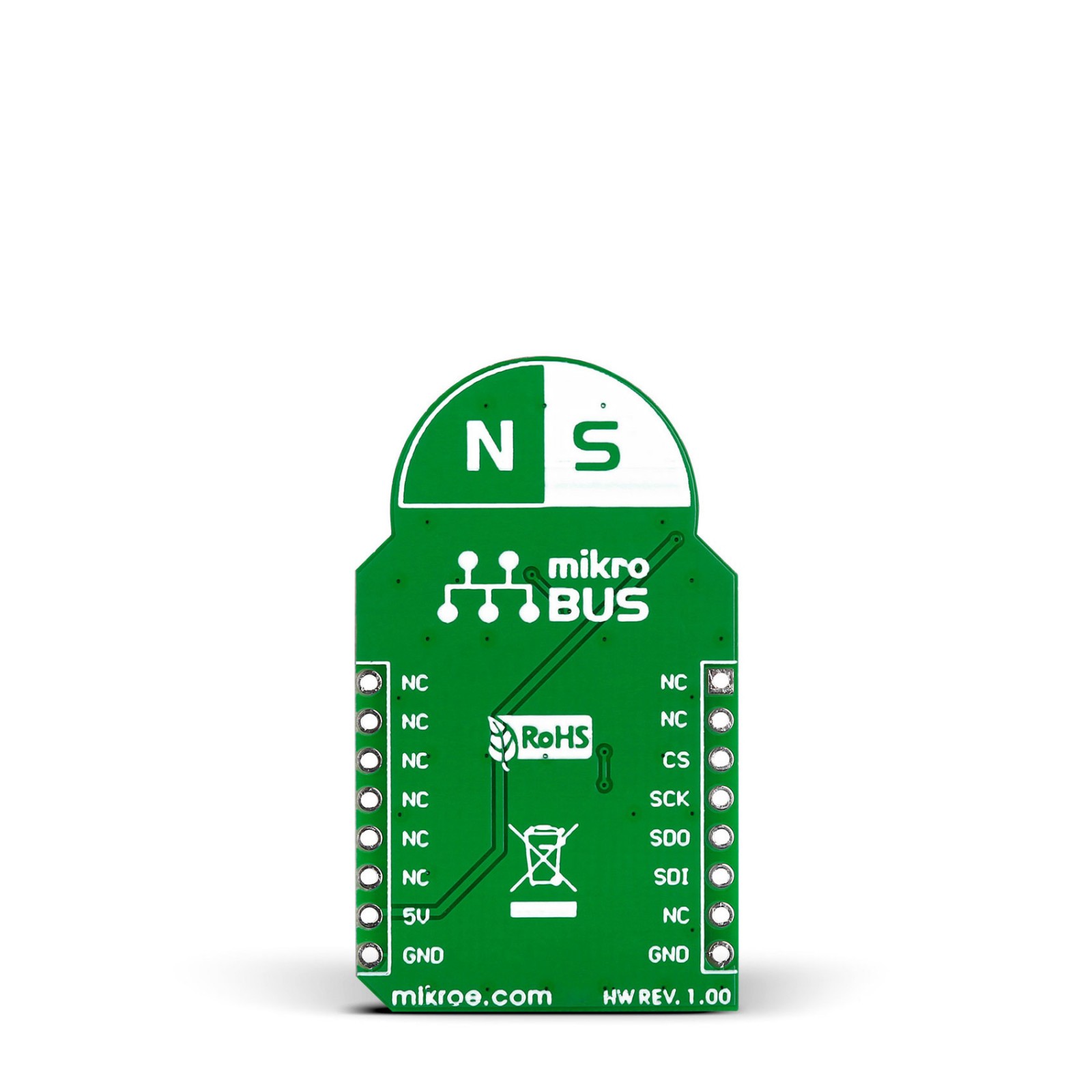

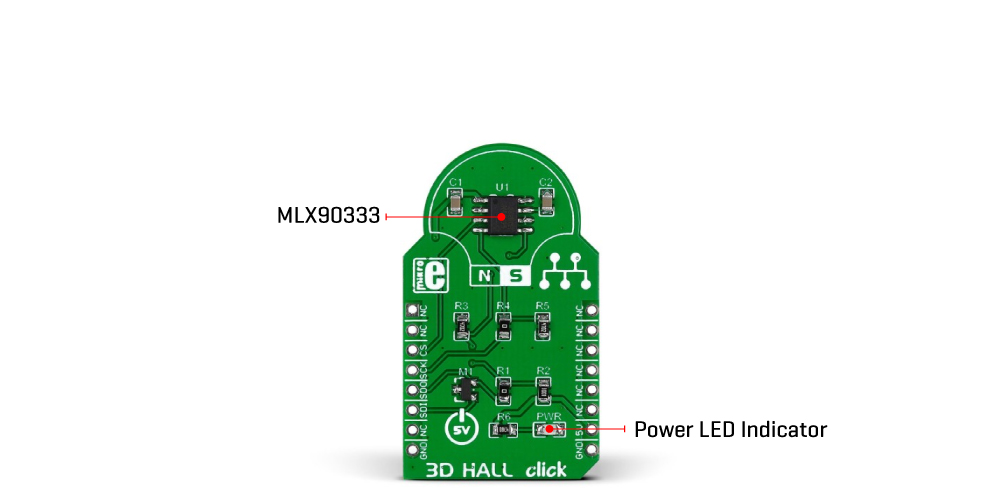

3D Hall Click is a compact add-on board used to detect the strength of a magnetic field in all three dimensions. This board features the MLX90333, a Triaxis® position sensor from Melexis Technologies. The MLX90333 can sense any magnet moving (rotational, linear, and 3D displacement with a high degree of precision) in its surrounding through the measurement and the processing of the three spatial components of the magnetic flux density vector via the SPI interface. Contactless coupling ensures resistance against wear and environmental contaminants such as dirt and dust. This Click board™ is suitable for rotary (through-shaft magnet), linear (magnet displacement parallel to the device surface), and 3D/joystick position sensing applications.

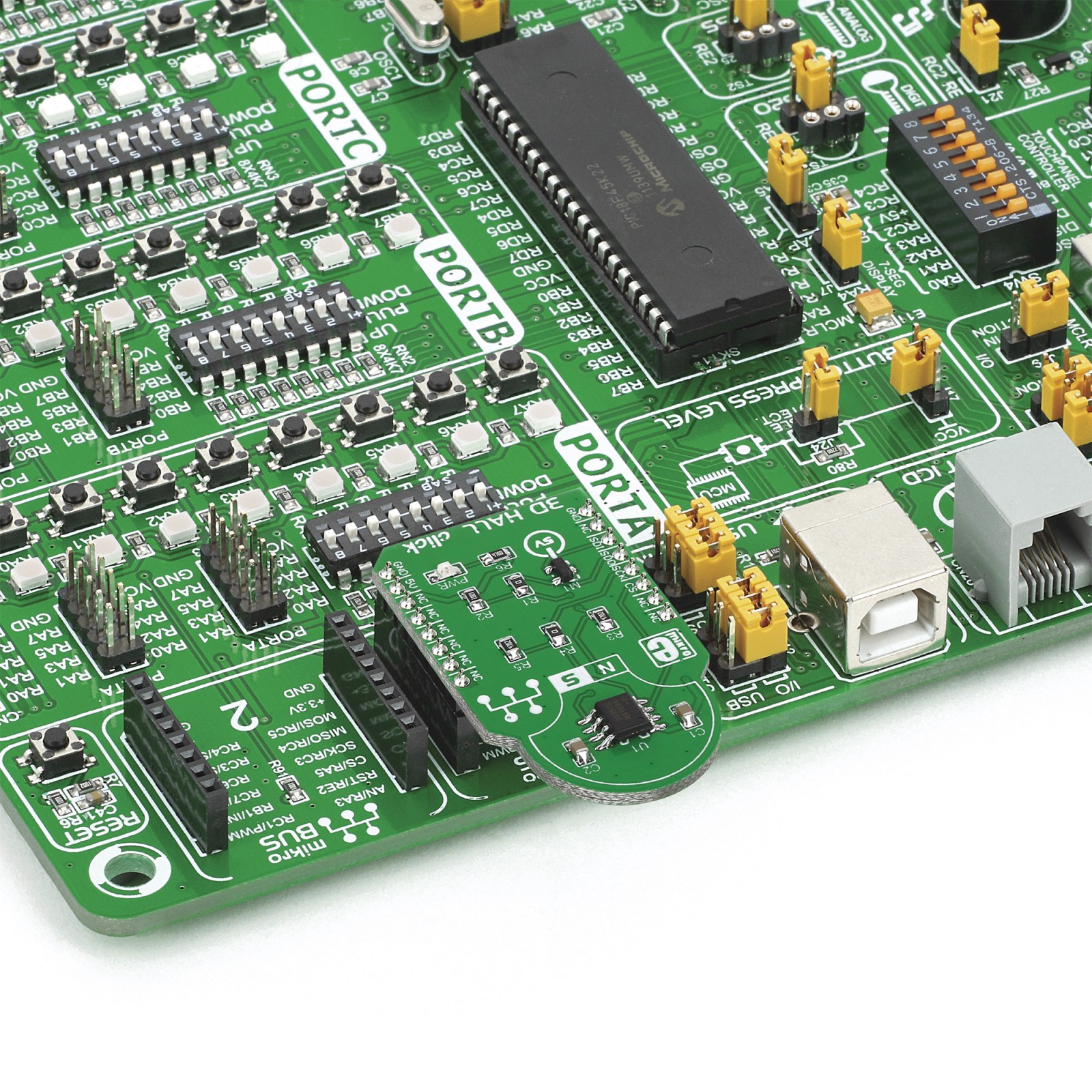

3D Hall Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R522.50 |

| 10+ | R495.00 |

| 15+ | R467.50 |

| 20+ | R449.90 |