Diff pressure Click

R1,250.00 ex. VAT

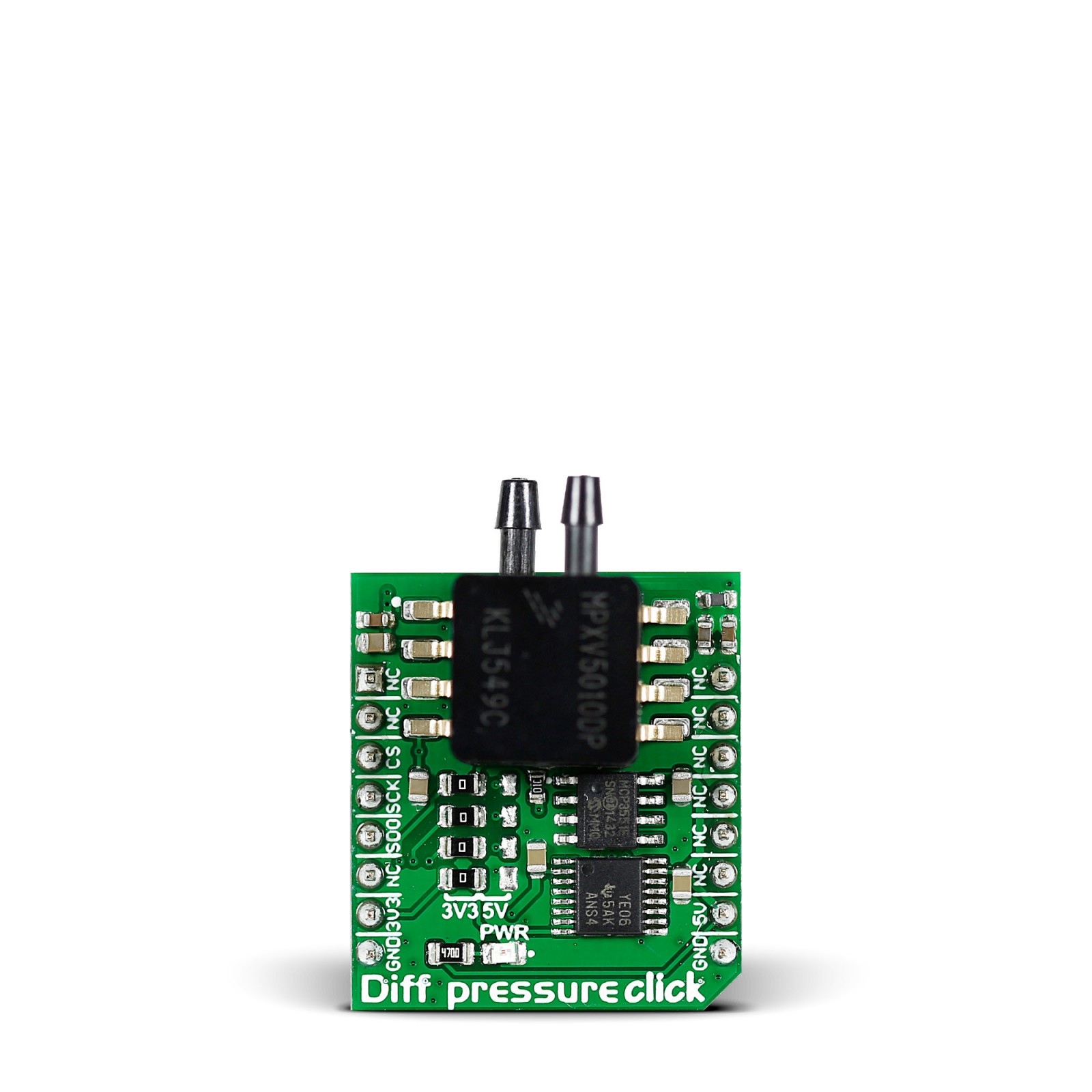

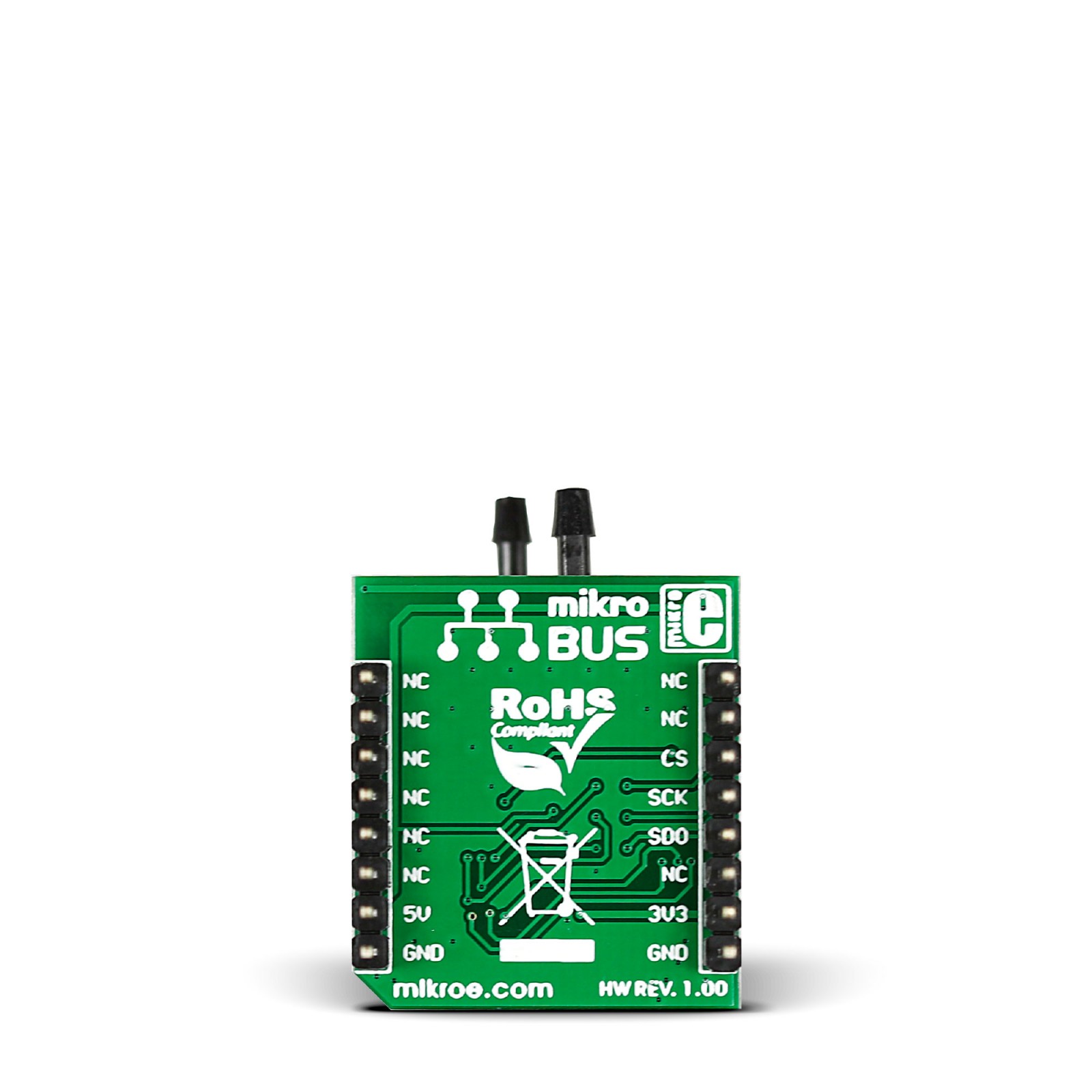

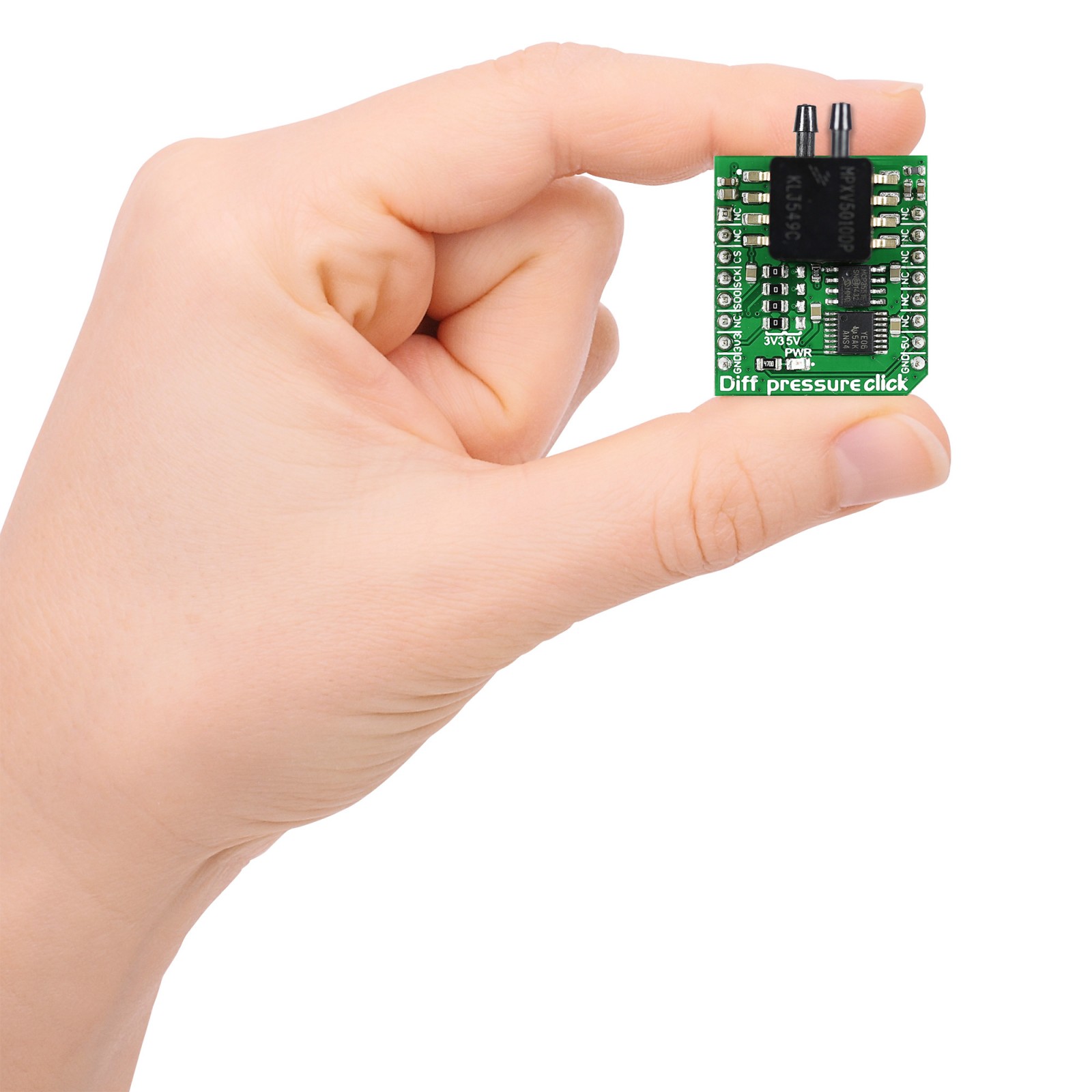

Diff Pressure Click is a compact add-on board that contains a differential pressure sensor. This board features the MPXV5010DP, an integrated silicon pressure sensor on-chip signal conditioned, temperature compensated, and calibrated from NXP Semiconductor. The sensor features two axial ports to accommodate industrial-grade tubing. It is designed for comparing two pressure measurements, such as the difference in the pressure of gasses in a variable flow tube. This Click board™ makes the perfect solution for the development of applications based on differential pressure measurement for controlling industrial processes, hospital beds, HVAC, respiratory systems, washing machine water levels, and more.

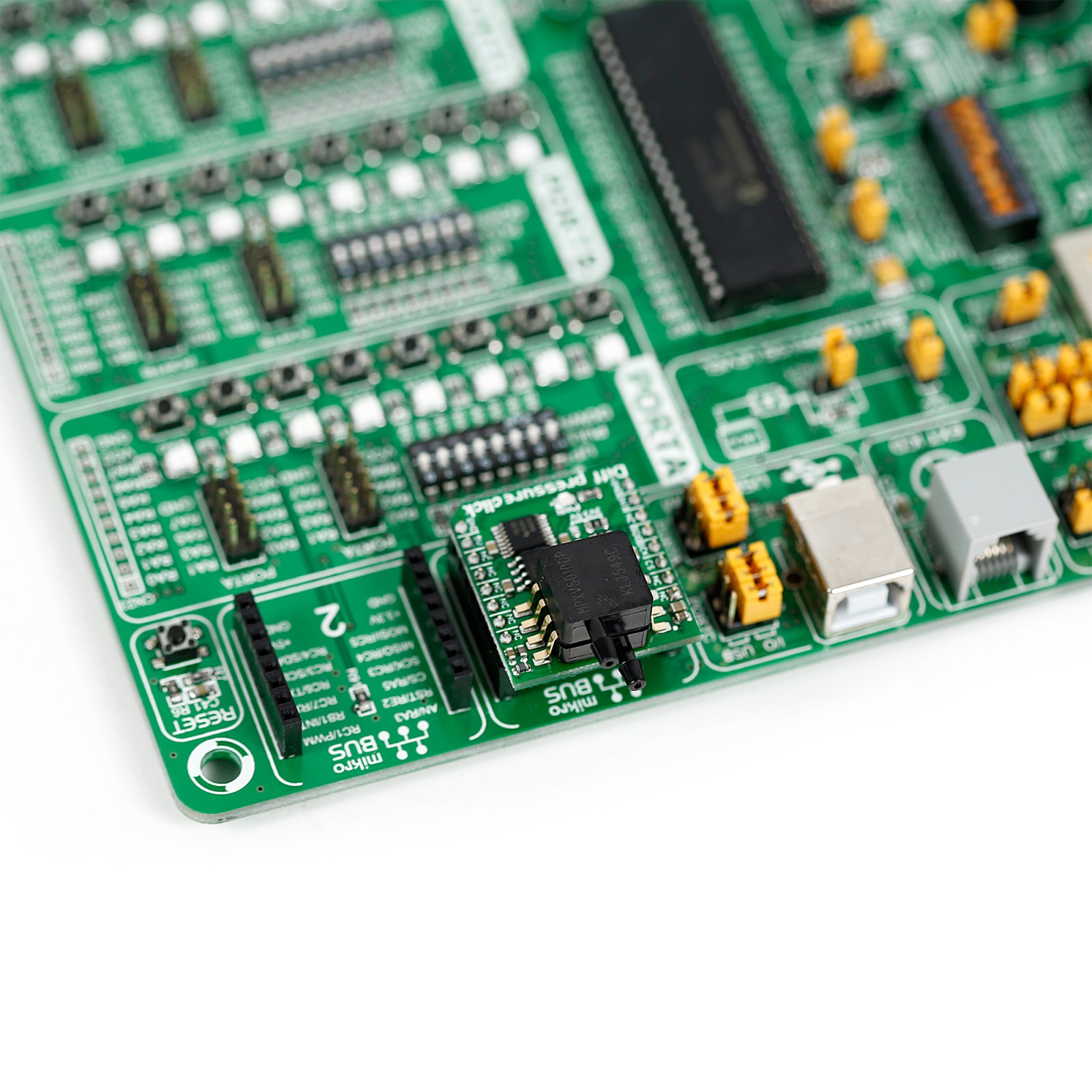

Diff Pressure Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R1,187.50 |

| 10+ | R1,125.00 |

| 15+ | R1,062.50 |

| 20+ | R1,022.50 |