Brushless Click

R820.00 ex. VAT

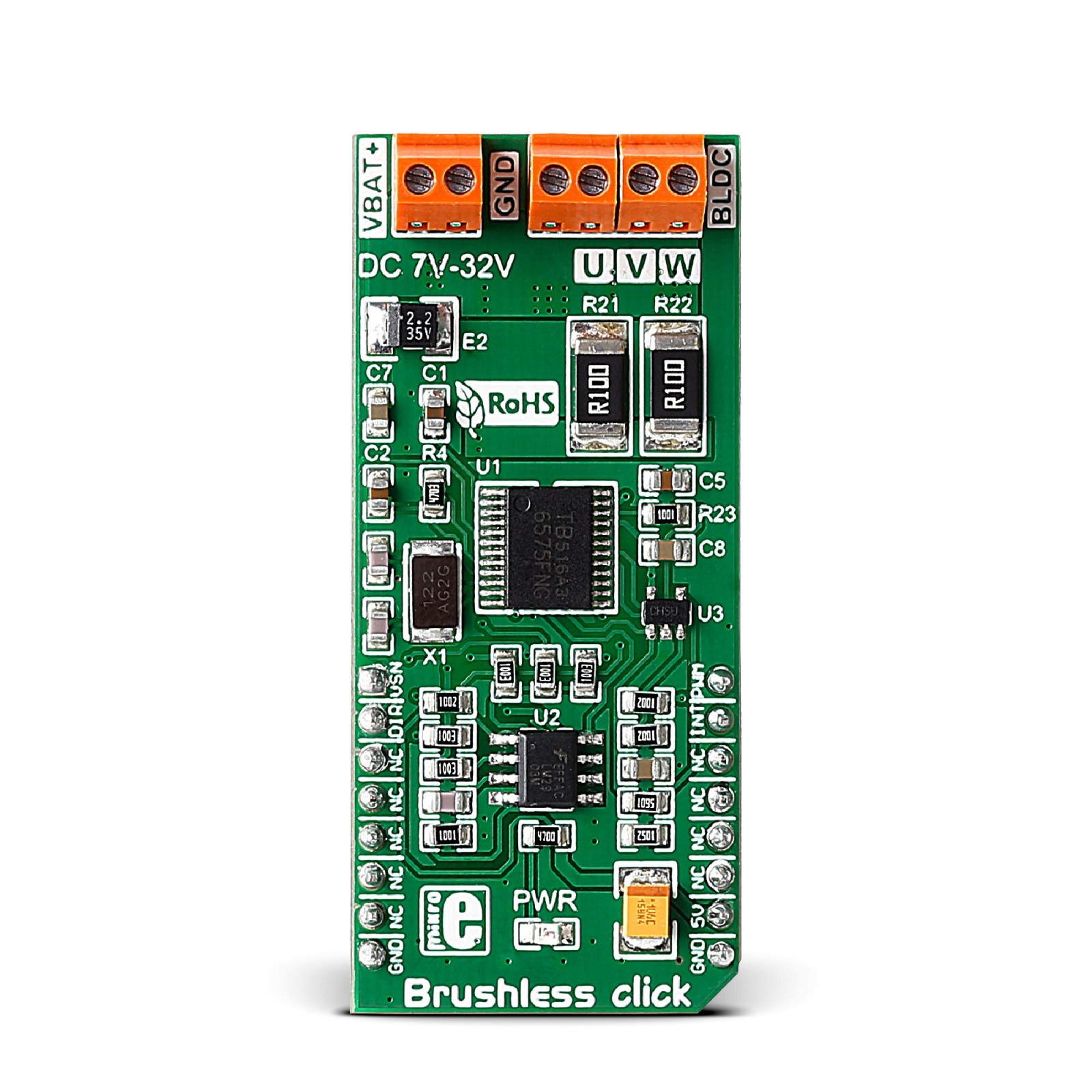

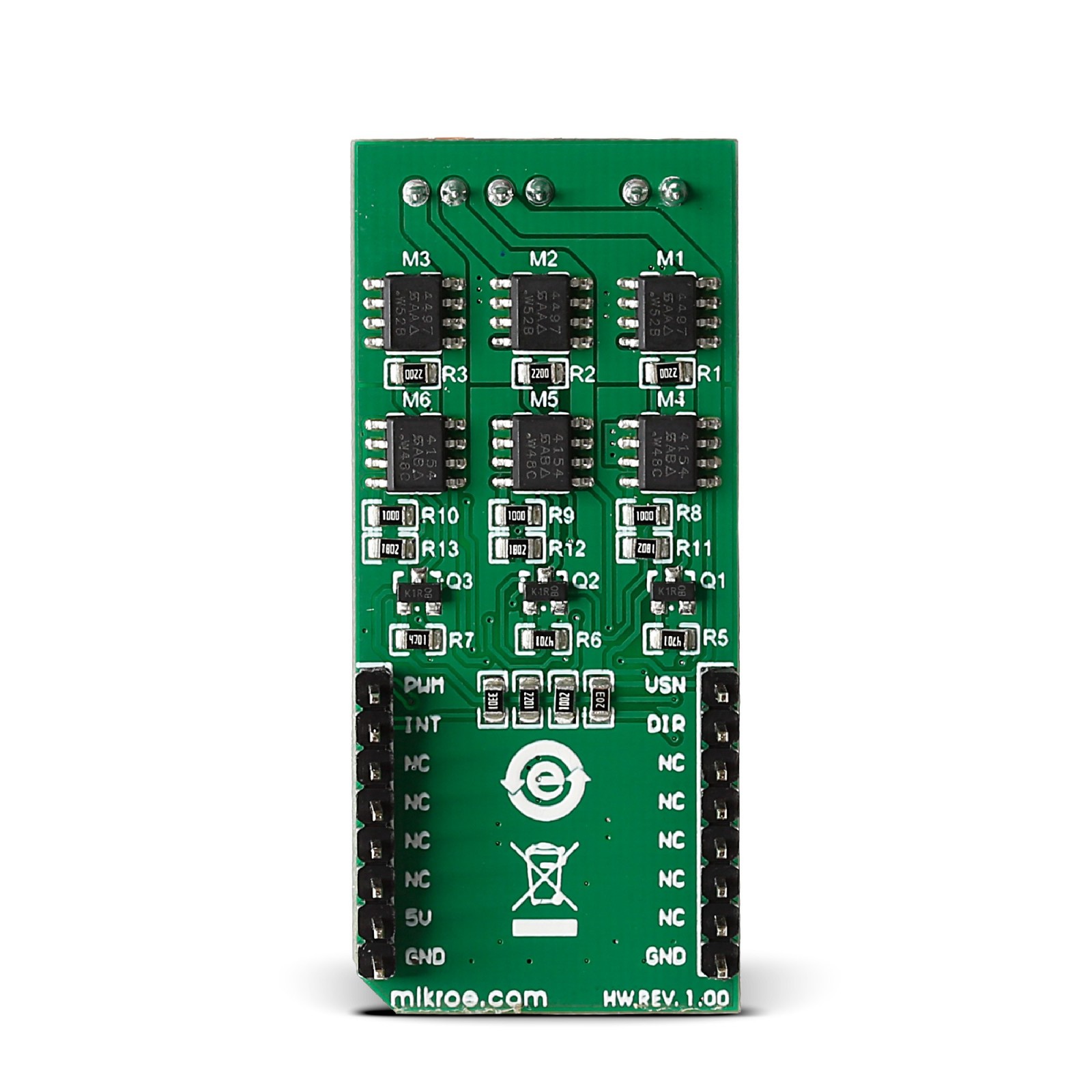

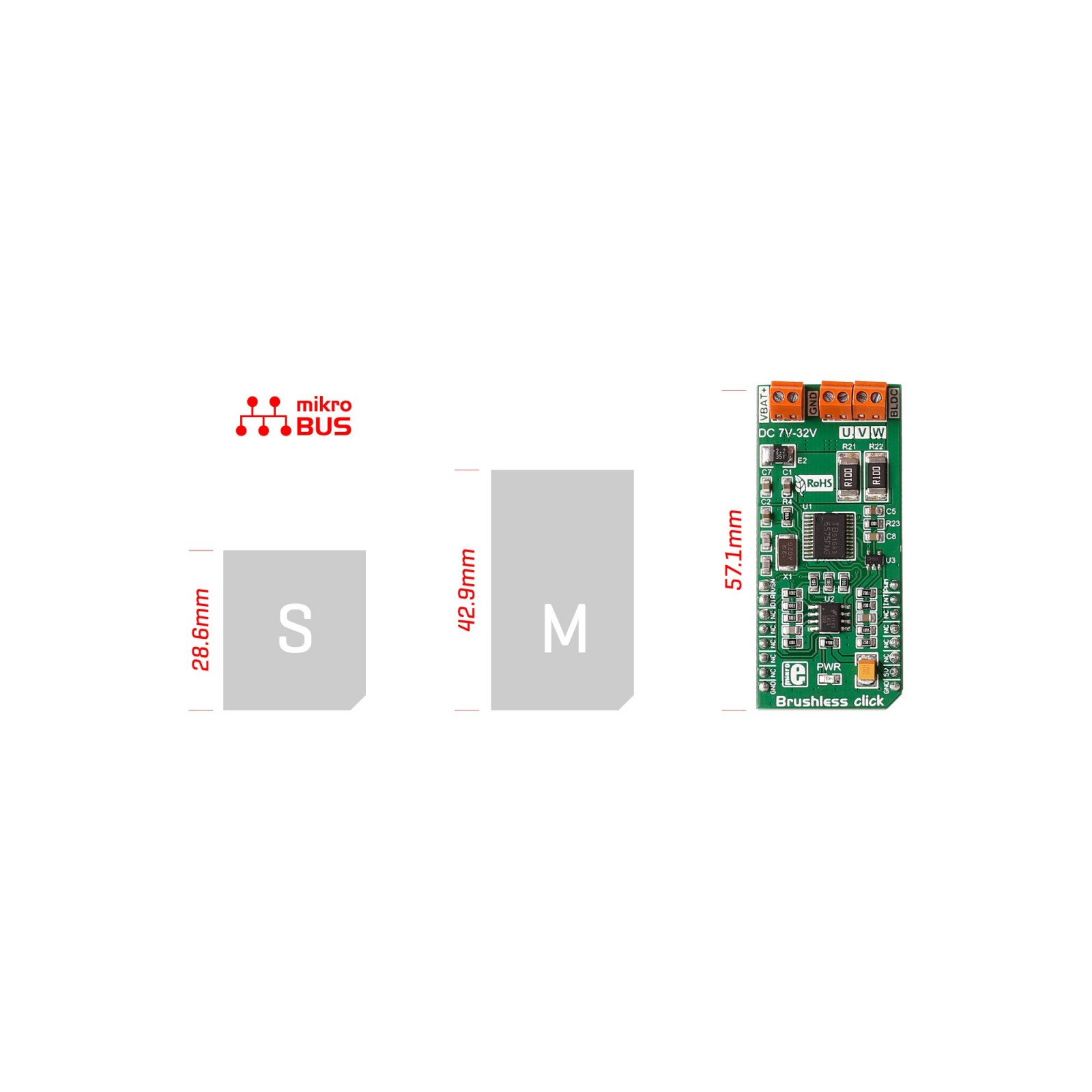

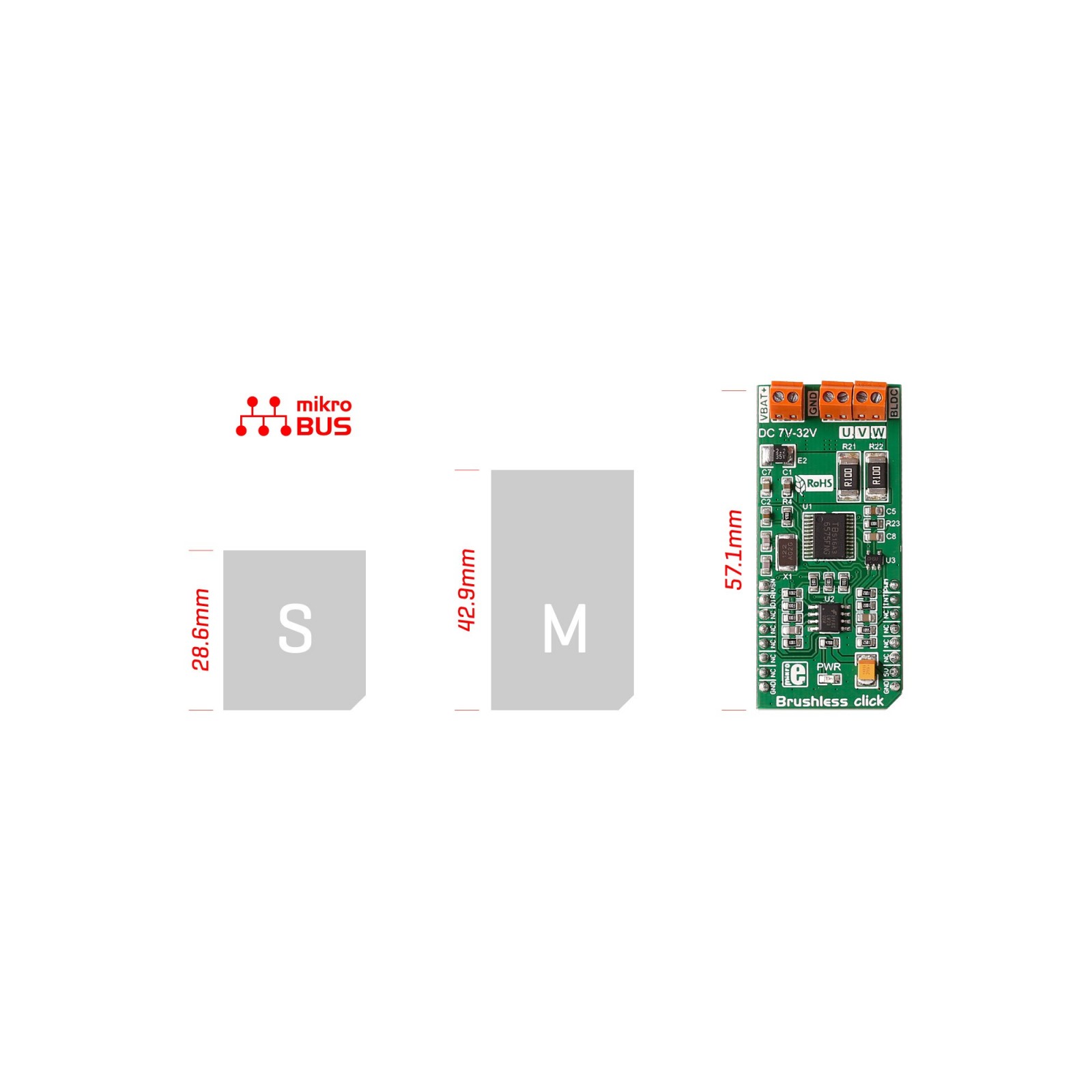

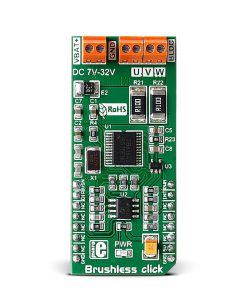

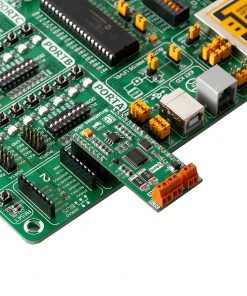

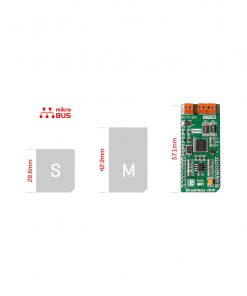

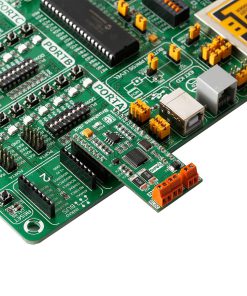

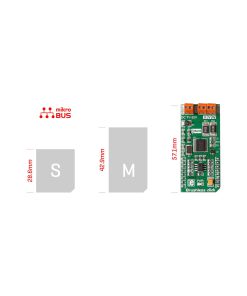

Brushless Click is a compact add-on board that controls brushless DC (BLDC) motors with any MCU. This board features the TB6575FNG, a PWM sensorless controller for three-phase full-wave BLDC from Toshiba Semiconductor. It provides three individually controllable drivers, where the rotation speed is controlled by changing a PWM duty cycle by analog voltage. Along with the rotation speed, the TB6575FNG features forward/reverse rotation control, lead angle control (7.5° and 15°), overlap commutation, and more. Besides, it has a wide operating voltage range from 7-32V DC and can safely drive external motors with up to 32V/2A, 20mA current sink capability on PWM output pins. This Click board™ makes the perfect solution for the development of driving three-phase brushless DC motors up to 2A output current rating.

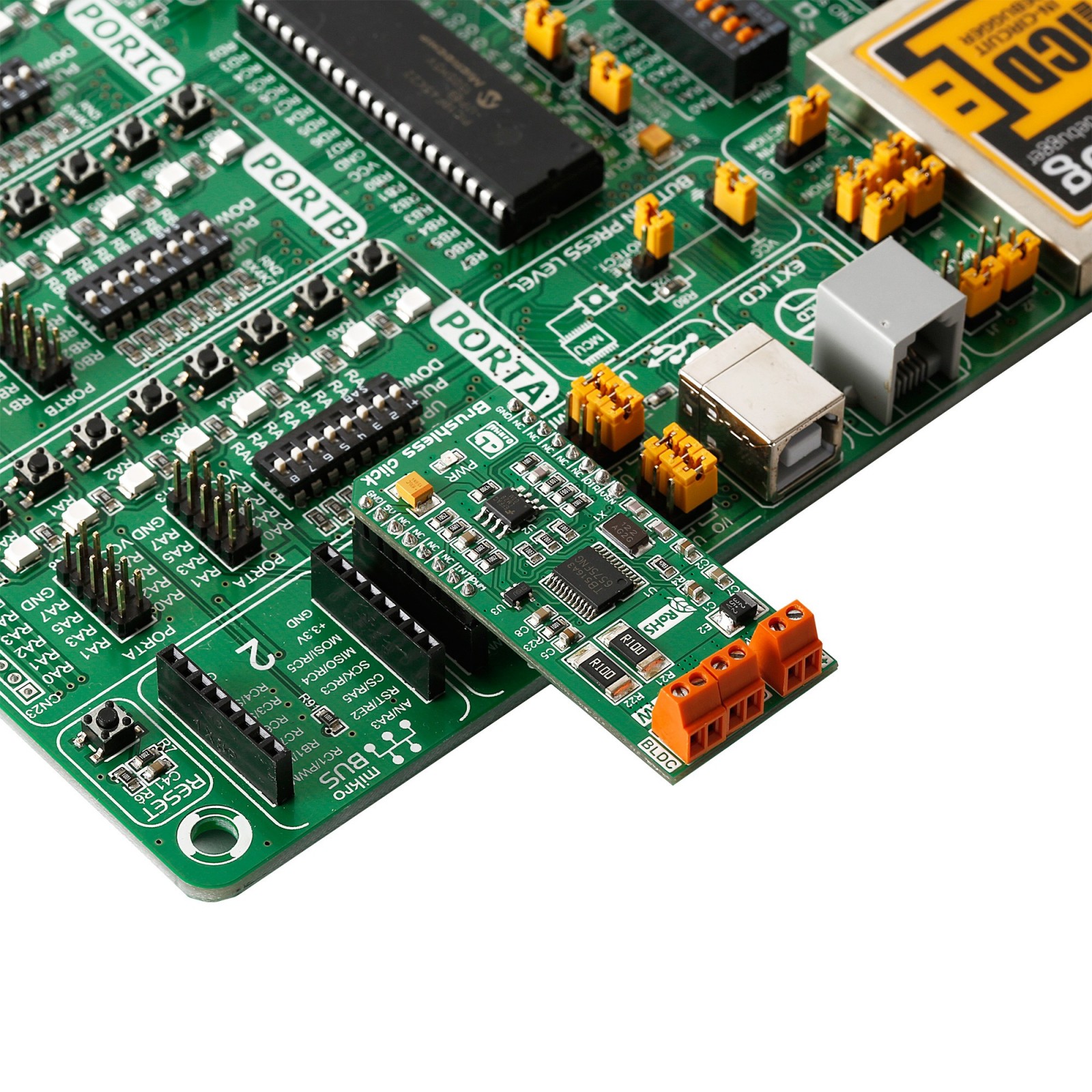

Brushless Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Stock: Lead-time applicable.

| 5+ | R779.00 |

| 10+ | R738.00 |

| 15+ | R697.00 |

| 20+ | R670.76 |