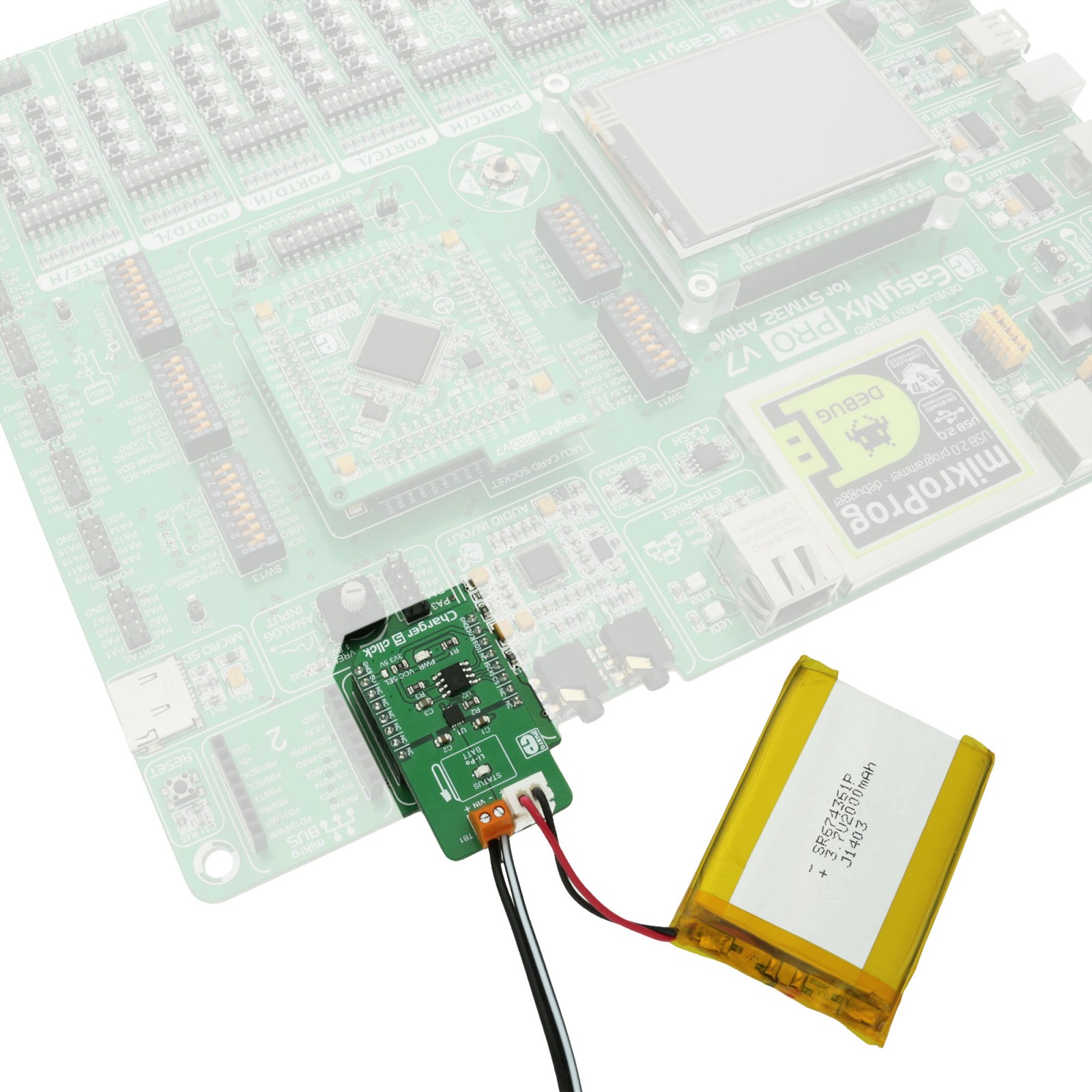

Charger 5 Click

R345.00 ex. VAT

Charger 5 click is designed to charge Lithium-Ion and Lithium-Polymer batteries. Besides the overvoltage and undervoltage protection, reverse discharge and overtemperature protection, automatic recharge and end of charge safety timer, the click also introduces the fast charging feature to the line of click board™ charger products. Charger 5 click uses a programmable digital potentiometer for adjusting the fast charging constant current, which can be set from 100 mA to 950 mA, via the SPI interface.

Stock: Lead-time applicable.

| 5+ | R327.75 |

| 10+ | R310.50 |

| 15+ | R293.25 |

| 20+ | R282.21 |

Charger 5 click carries the MCP73113, a single-cell Li-Po/Li-Ion battery charge IC from Microchip, along with the digital potentiometer chip labeled as MCP4161, from the same company. This click can be used to easily and securely charge and fast-charge batteries on many different devices that use 3.7V Li-Po/Li-Ion batteries.

How does it work?

Charger 5 click features two integrated circuits, both made by Microchip. One of them is the MCP73113, a single-cell battery charger equipped with many features, optimized for charging of the Li-Po/Li-Ion batteries. The constant charging current on the MCP73113 device is set by a resistor, connected between the PROG pin and the VCC, but instead using the conventional resistor, Charger 5 click employs the MCP4161 digital potentiometer IC, which allows setting the constant charging current via the SPI interface. This way, the constant charging current can be set from 100mA to 950mA.

The MCP73113 charger IC features a number of different battery charging protection and optimization schemes so that the charging process remains perfectly safe and efficient. The undervoltage protection shuts the charger circuit down in case the connected input voltage is below the threshold value. The overvoltage protection will also put the device in the shutdown mode if the input voltage is greater than the threshold value. Also, the connected input voltage should be 150mV greater than the battery voltage or else it will remain in power down state. This prevents the battery draining in case there’s no input voltage. Therefore, the input voltage range should stay between 5V and 6.5V. The device is resistant to voltage spikes up to 18V on its input connector, but for a proper operation, the input voltage should stay in the recommended voltage range.

The connected battery voltage is constantly monitored. If it drops below the charging threshold and if all the other input voltage charging conditions are met, the charging process will start. When the battery is charged to the factory set threshold, the charging will be stopped to prevent battery overcharging. Charging threshold for the MCP73113 charger IC used on this click is set to 4.2V.

If a Li-Ion battery is discharged to below 3V, it has to be pre-charged with around 10% of the full charge current. This means that the charging current, in this case, will be 10% of the fast charging current set by the MCP4161 digital potentiometer.

Charger 5 click detects short circuit on the battery connector. The short circuit is also reported in case of a faulty battery cell. If such event occurs, the charger will enter the shutdown mode. The MCP73113 charger IC features thermal management too, which regulates the charging current, based on the die temperature. If the IC die is heated over 150°C, the device will be shut down.

The onboard SMD jumper selector is used to select voltage for the digital potentiometer IC and SPI logic levels. There are also two onboard connectors. One connector is a screw terminal used to connect the external power supply (5V to 6.5V). The other connector is the Li-Po/Li-Ion battery 2.54mm header connector. This is the standard battery connector used for easy connection of Li-Po/Li-Ion batteries, like batteries that can be found in the MikroElektronika shop.

Specifications

Type

Battery charger

Applications

Charger 5 click can be used for fast and secure charging Li-Po/Li-ion 3.7V batteries, used in wide range of battery powered applications.

On-board modules

MCP 73113, a single-cell Li-Ion/Li-Polymer battery charge management controller with input overvoltage protection, MCP 4161, an 8-bit SPI digital POT with non-volatile memory

Key Features

Charger 5 click features many different options and algorithms optimized for safe and efficient charging of the Li-Po and Li-ion batteries. It has the fast charging feature, with user defined fast charging constant current, up to 950mA.

Interface

SPI

Feature

No ClickID

Compatibility

mikroBUS™

Click board size

M (42.9 x 25.4 mm)

Input Voltage

3.3V or 5V

Pinout diagram

This table shows how the pinout on Charger 5 click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

Charger 5 click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Input Voltage Range | 4 | 5 | 6.5 | V |

| Current Output | 100 | 950 | mA | |

| Operating Ambient Temperature | -40 | 85 | °C |

Note: The maximum input voltage that the click can withstand is 16V, but it won’t operate over 6.5V.

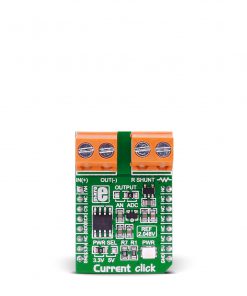

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | – | Power LED indicator |

| LD2 | STATUS | – | Battery charging status LED |

| J1 | BAT | – | Battery connector |

| TB1 | VIN | – | Input voltage connector |

| JP1 | VCC SEL | Left | Power supply voltage selection: Left position 3V3, right position 5V |

Software support

We provide a library for Charger 5 click on our LibStock page, as well as a demo application (example), developed using MikroElektronika compilers. The demo can run on all the main MikroElektronika development boards.

Library description

Key functions:

uint8_t charger5_writeReg(uint8_t register_address, uint16_t transfer_data)– Function writes to the click’s registers

uint16_t charger5_readReg(uint8_t register_address)– Function reads from click’s registers

uint8_t charger5_incrementWiper(uint8_t register_address, uint8_t numberOfSteps)– Function increments value of the click’s registers

uint8_t charger5_decrementWiper(uint8_t register_address, uint8_t numberOfSteps)– Function decrements value of the click’s registers

uint8_t charger5_setCurrent(uint8_t register_address, uint16_t transfer_data)– Function sets current value of the selected wiper to both, volatile and not volatile, memory locations

Example description

- System Initialization – Initializes peripherals and pins.

- Application Initialization – Initializes click driver.

- Application Task – Demonstrates the use of driver functions. It will set the charging current up to 500 mA, then decrements that value, and then increments it.

applicationTask()

{

mikrobus_logWrite( "Setting value of current to 500mA", _LOG_LINE );

charger5_setCurrent(_CHARGER5_WIPER0_VOL, _CHARGER5_500MA_CURRENT);

Delay_ms(2000);

mikrobus_logWrite( "Decrementing value of wiper by 5 steps", _LOG_LINE );

charger5_decrementWiper(_CHARGER5_WIPER0_VOL, _CHARGER5_5_STEPS);

Delay_ms(2000);

mikrobus_logWrite( "Incrementing value of wiper by 2 steps", _LOG_LINE );

charger5_incrementWiper(_CHARGER5_WIPER0_VOL, _CHARGER5_2_STEPS);

}

The full application code, and ready to use projects can be found on our LibStock page.

Additional notes and information

Depending on the development board you are using, you may need USB UART click, USB UART 2 click or RS232 click to connect to your PC, for development systems with no UART to USB interface available on the board. The terminal available in all MikroElektronika compilers, or any other terminal application of your choice, can be used to read the message.

mikroSDK

This click board is supported with mikroSDK, the MikroElektronika Software Development Kit. To download mikroSDK visit LibStock. For more information about SDK, visit the official page.

Resources

Downloads

| Weight | 19 g |

|---|---|

| Brand | MikroElektronika |