DIGI POT 3 Click

R440.00 ex. VAT

DIGI POT 3 click is a versatile and feature-rich digital potentiometer click with 1024 steps and an internal non-volatile memory (EEMEM), which can be used for storing the wiper position, but also for storing various user data. The user EEMEM area has 14 words, each with 16bit length. The Click board™ can be used with both unipolar and bipolar signals, selectable by onboard SMD jumpers. The wiper position can be increased or decreased linearly or by the logarithmic scale (6db/step) with a single command. A special scratch register allows direct programming of the wiper position. It can be stored to the non-volatile memory and on the power on, it is automatically restored. This means that the device restores its last position after the power on – just like its mechanical counterpart.

Stock: Lead-time applicable.

| 5+ | R418.00 |

| 10+ | R396.00 |

| 15+ | R374.00 |

| 20+ | R359.92 |

DIGI POT 3 click is a versatile and feature-rich digital potentiometer click with 1024 steps and an internal non-volatile memory (EEMEM), which can be used for storing the wiper position, but also for storing various user data. The user EEMEM area has 14 words, each with 16bit length. The Click board™ can be used with both unipolar and bipolar signals, selectable by onboard SMD jumpers. The wiper position can be increased or decreased linearly or by the logarithmic scale (6db/step) with a single command. A special scratch register allows direct programming of the wiper position. It can be stored in the non-volatile memory and on the power on, it is automatically restored. This means that the device restores its last position after the power on – just like its mechanical counterpart.

The main advantage of the digital potentiometers over the mechanical ones is that they can never wear out. The wiper position can be precisely programmed, and the wiper contact with the resistive coating can never be compromised by the influence of dirt or moisture. Due to its low THD and good bandwidth, it can be used for digital volume control or a precise gain and offset adjustment. It can also be used as the LCD digital contrast control, and generally – whenever a precise digital potentiometer is required.

How does it work?

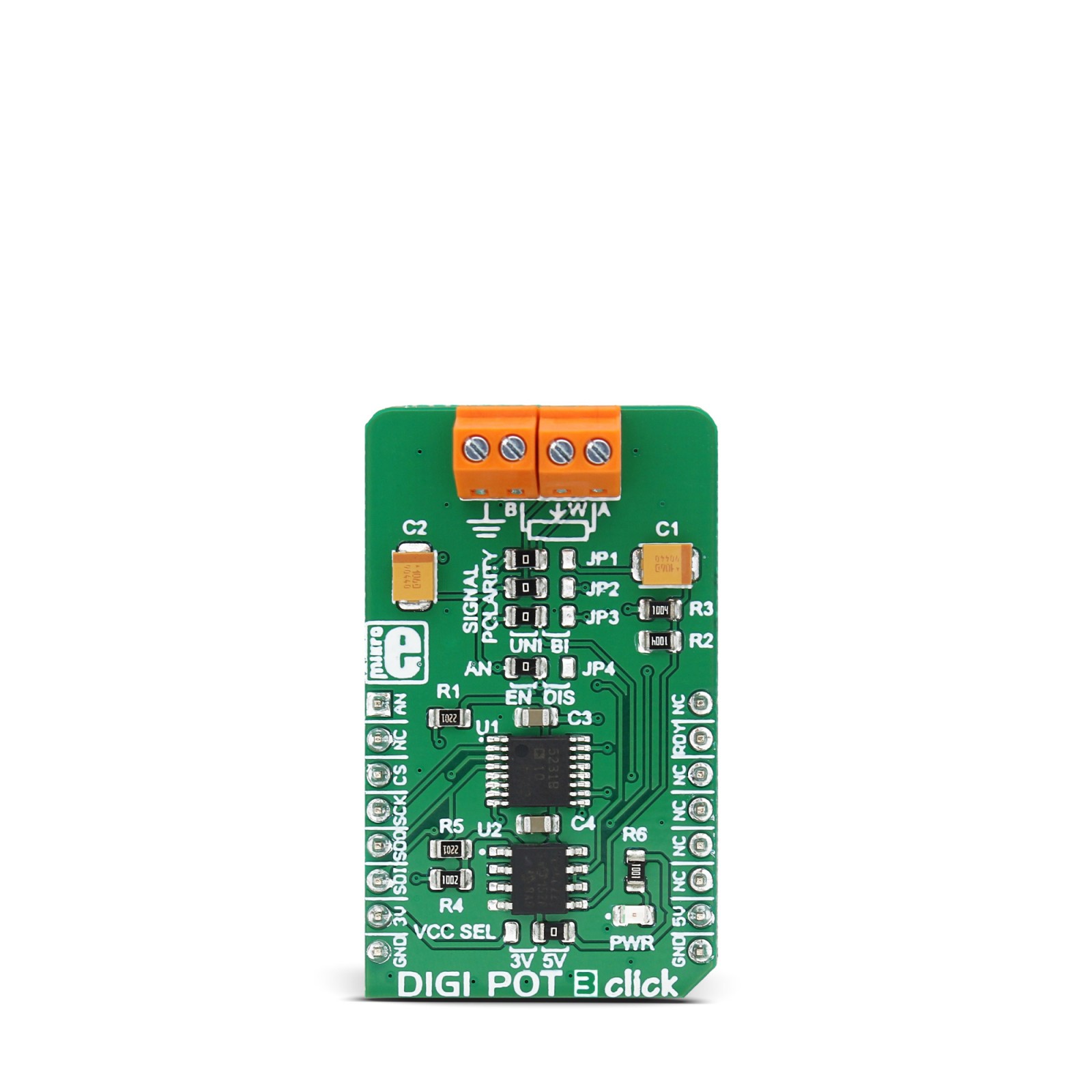

This Click board™ carries the AD5231, a 1024-position (10bit) digital potentiometer with a non-volatile memory (EEMEM), from Analog Devices. As already mentioned, this digital potentiometer has many features that make it a superior choice over the classic, mechanical potentiometers. It offers the solid state reliability, high precision, an additional storage non-volatile (NV) memory cells and most importantly – it can be digitally controlled by an MCU via the high-speed SPI interface, with its pins routed to the mikroBUS™. Analog Devices Inc. offer several sub-types of the same IC, but the DIGI POT 3 click uses the one labeled as AD5231BRUZ10, meaning that it has 10KΩ of resistance between the potentiometer end-points.

One of its distinctive features is to refresh its wiper register (called RDAC in the device datasheet) after the power on, making it possible to restore the wiper position on power-up, just like the mechanical counterpart. The wiper position register (RDAC) is not automatically written to the EEMEM because this type of memory has a limited number of write cycles, which is the limitation of the technology itself. For this reason, once the position has been established, it can be stored to EEMEM by a command (Command 0x2 – Store RDAC setting to EEMEM). The AD5231 IC is factory pre-programmed to set the wiper at the middle position after the power-on, but this can be overwritten by storing a custom position with the aforementioned command.

Besides storing the RDAC register to the EEMEM, it is possible to store 14 more words, each 16 bits long. This EEMEM area can be used for any purpose – lookup tables, data for other components, or system identification information. Writing to EEMEM takes some time, during which the AD5231 IC is non-responsive. This time is about 25ms and the end of this operation is signaled by the RDY pin of the AD5231 IC, routed to the INT pin of the mikroBUS™ – labeled as the RDY. When the read to, or write from EEMEM cycle is done, this pin pulses to a LOW logic level. It is otherwise pulled to a HIGH logic level by an on-board pull-up resistor.

For the complete list of commands and addresses, please refer to the AD5231 datasheet. However, MikroElektronika provides a library that contains functions compatible with the MikroElektronika compilers, which can be used for simplified programming of the DIGI POT 3 Click. The library also contains an example application, which demonstrates its use. This example application can be used as a reference for custom designs.

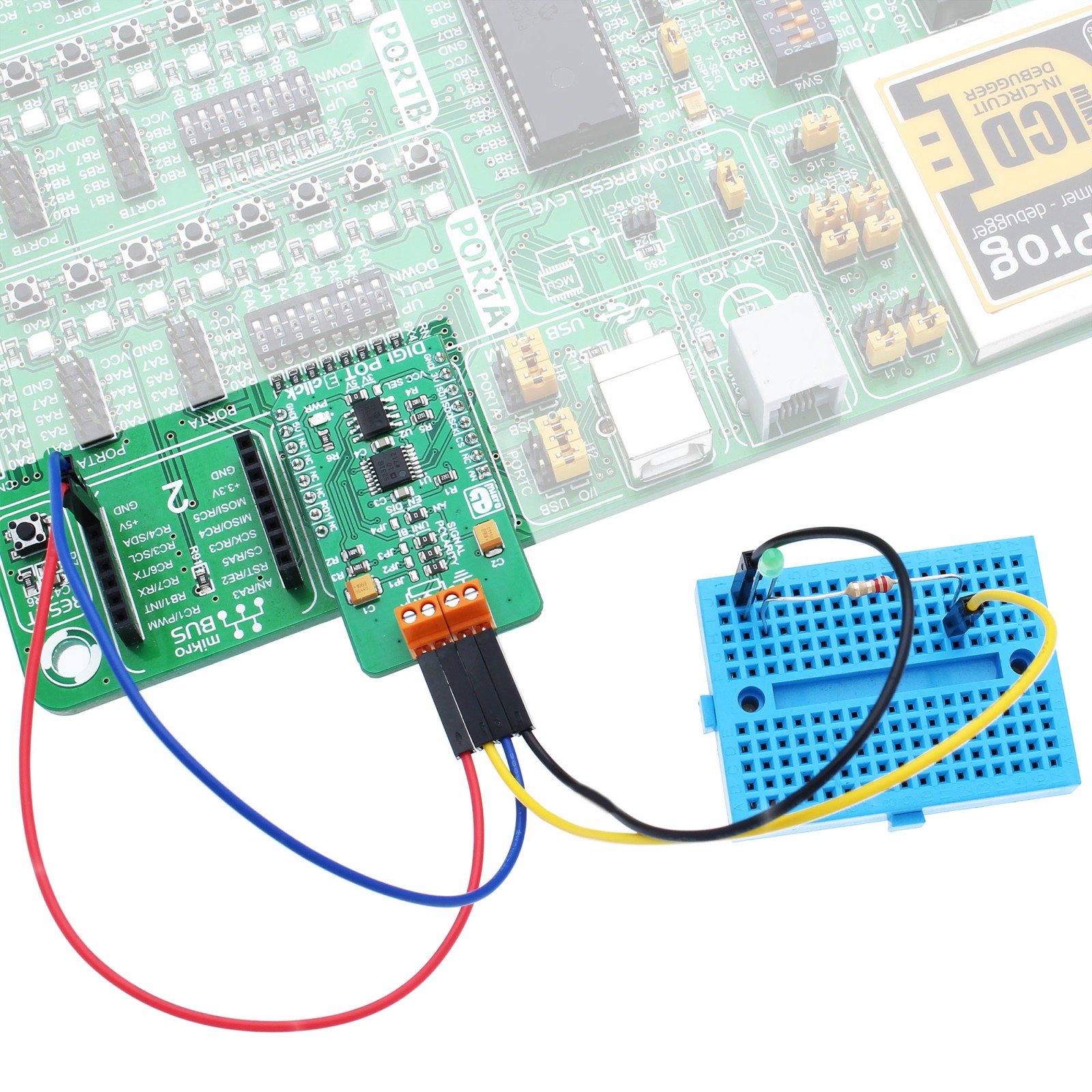

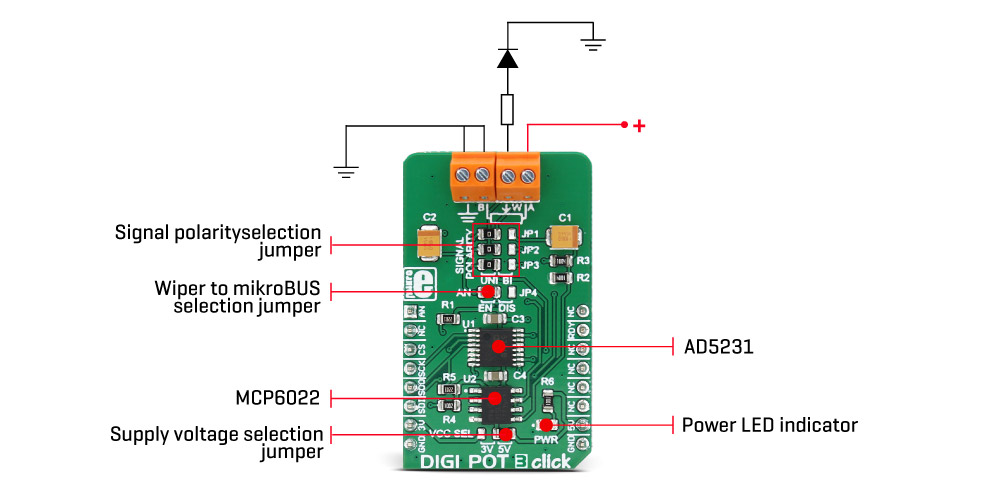

The Click board™ is equipped with an edge screw terminals, which are used to connect the Click board™ to the external electrical circuit. They offer a secure connection to the external electrical circuit. A small print of a potentiometer electrical symbol illustrates how to connect these terminals properly: Inputs labeled as A and B are the endpoints of the digital potentiometer, while W is the wiper. Lastly, the GND symbol is for connecting the ground of the circuit where the potentiometer will be used.

DIGI POT 3 click allows using of both unipolar and bipolar signals. The potential across the positive and the negative power supply pins define the boundary conditions for a proper digital potentiometer operation. Supply signals present on the A, B, and W terminals that exceed this range are clamped by the internal forward-biased diodes. Since this Click board™ is intended to be used on the mikroBUS™, the power supply voltage of the AD5231 is +3.3V or +5V, selectable by an onboard SMD jumper labeled as VCC SEL. This makes it possible to work with the voltage range between 0 and VCC. By utilizing an additional circuitry, it is also possible to work with the bipolar signals, which can be useful for interfacing the digipot to an audio source.

Since there are no negative power supplies available on the mikroBUS™, the Click board™ uses the MCP6022, a rail-to-rail, 10 MHz onboard operational amplifier from Microchip, in order to support operation with bipolar signals. It is used as a non-inverting amplifier with a unity gain – a buffer. There are several onboard SMD jumpers, used to route the signal so it passes through the buffer, instead of being fed directly to the AD5231 IC. A group of SMD jumpers labeled as SIGNAL POLARITY is used to patch the signal to a proper route: setting all these jumpers to the LEFT position will connect the terminal inputs directly to the AD5231 IC, allowing unipolar signals ranging from 0 to VCC to be connected. Moving all these jumpers to the RIGHT position will route the input signal through the decoupling capacitor and the buffer, allowing bipolar signals to be used, introducing an offset of VCC/2. This allows signal to swing between VCC/2 and GND for the negative half-cycle, and between VCC/2 and VCC for the positive half-cycle. The offset is then removed by a decoupling capacitor at the W terminal. The SMD jumpers should be all moved either to the LEFT or to the RIGHT position, as leaving some of them in the opposite position than the others may render the device unresponsive.

The AN pin can be used as an auxiliary wiper output if routing of the wiper back to the mikroBUS™ is required. This pin can be completely disconnected from the mikroBUS™ by moving the appropriate SMD jumper, labeled as AN to the RIGHT position. This will not affect the presence of the wiper output on the output terminal.

Specifications

Type

Digital potentiometer

Applications

It can be used for digital volume control or a precise gain and offset adjustment. It can also be used as the LCD digital contrast control, and generally – whenever a precise digital potentiometer is required.

On-board modules

AD5321, a 1024-position digital potentiometer with non-volatile memory (EEMEM), from Analog Devices; MCP6022, a R2R input/output, 10 MHz Op Amp, from Microchip.

Key Features

Accurate positioning of the wiper via the 1024 different steps, non-volatile EEPROM memory used for recalling the wiper position and custom data storage, simple commands for linear/logarithmic wiper control, can accept both bipolar and unipolar signals.

Interface

Analog,SPI

Feature

No ClickID

Compatibility

mikroBUS™

Click board size

M (42.9 x 25.4 mm)

Input Voltage

3.3V or 5V

Pinout diagram

This table shows how the pinout on DIGI POT 3 click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | – | Power LED indicator |

| JP5 | VCC SEL | Right | LED driver voltage selection: left position 3.3V, right position 5V |

| JP1 – JP3 | SIGNAL POLARITY | Left | Signal polarity selection: left position unipolar, right position bipolar |

| JP4 | AN | Left | AN pin routing selection: left position AN pin routed to the wiper, right position AN pin not connected |

DIGI POT 3 click electrical characteristics

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Power supply voltage (VCC) | 3.3 | 5 | 5 | V |

| Voltage at the input terminals | 0 | – | VCC | V |

Software support

We provide a library for DIGI POT 3 Click on our Libstock page, as well as a demo application (example), developed using MikroElektronika compilers. The demo application can run on all the main MikroElektronika development boards.

Library Description

The library performs the check procedure for the desired outputs (IN1 – IN4). For more details check the documentation.

Key functions:

uint8_t digipot3_sendCommand( uint8_t commandByte )– The function executes the desired command.uint8_t digipot3_storeEEMEM( uint8_t location_address, uint16_t transfer_data )– The function stores 16-bit data to the desired

EEMEM (non-volatile) memory location.uint8_t digipot3_writeDAC( uint16_t valueDAC )– The function writes a 10-bit value to DAC register and determines the wiper position.void digipot3_readDAC( uint16_t *dataOut )– The function reads a 10-bit value from DAC register (wiper position).

Examples Description

The demo application is composed of three sections:

- System Initialization – Initializes peripherals and pins.

- Application Initialization - Initializes SPI driver and restores the wiper position value from EEMEM (non-volatile) memory to the DAC register, if this value does not already exist in the DAC register.

- Application Task – (code snippet) – Increments the wiper position by 6dB every 2 seconds. When the wiper position reaches the desired value (0x0200), then the wiper position is decremented by 6dB every 2 seconds, until position value reaches the new desired value (0x0002). After that, the new position value will be stored in the EEMEM memory, if that value does not already exist in the EEMEM memory.

void applicationTask()

{

while (digitalValue < 0x0200)

{

digipot3_sendCommand( _DIGIPOT3_INCREMENT_RDAC_6DB_COMM );

digipot3_readDAC( &digitalValue );

WordToStr( digitalValue, text );

mikrobus_logWrite( "DAC value is: ", _LOG_TEXT );

mikrobus_logWrite( text, _LOG_LINE );

Delay_ms( 2000 );

}

while (digitalValue > 0x0002)

{

digipot3_sendCommand( _DIGIPOT3_DECREMENT_RDAC_6DB_COMM );

digipot3_readDAC( &digitalValue );

WordToStr( digitalValue, text );

mikrobus_logWrite( "DAC value is: ", _LOG_TEXT );

mikrobus_logWrite( text, _LOG_LINE );

Delay_ms( 2000 );

}

if (eememValue != digitalValue)

{

digipot3_sendCommand( _DIGIPOT3_STORE_RDAC_TO_EEMEM_COMM );

eememValue = digitalValue;

}

}

The full application code, and ready to use projects can be found on our Libstock page.

mikroE Libraries used in the example:

- Conversions

- SPI

- UART

Additional notes and information

Depending on the development board you are using, you may need USB UART click, USB UART 2 click or RS232 click to connect to your PC, for development systems with no UART to USB interface available on the board. The terminal available in all MikroElektronika compilers, or any other terminal application of your choice, can be used to read the message.

mikroSDK

This click board is supported by mikroSDK - MikroElektronika Software Development Kit. To ensure proper operation of mikroSDK compliant click board demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

Resources

Downloads

| Weight | 20 g |

|---|---|

| Brand | MikroElektronika |