Stepper 6 Click

R490.00 ex. VAT

Stepper 6 click is the complete integrated bipolar step motor driver solution. It comes with the abundance of features that allow silent operation and optimal working conditions for the connected motor. A specialized integrated driver chip on this Click board™ far exceeds the capabilities of similar, commonly used step motor drivers. It comes in the package which also includes the mikroSDK™ software, and a library with all the functions. The Click board™ comes as a fully tested and approved prototype, making it a reliable device ready to use on the development board. Stepper 6 click is a perfect solution for any application that requires an efficient and reliable motor driver. It can be used in 3D printers, laser printers, laser engravers, video security cameras, factory automatization, robotics, and other similar applications.

Stock: Lead-time applicable.

| 5+ | R465.50 |

| 10+ | R441.00 |

| 15+ | R416.50 |

| 20+ | R400.82 |

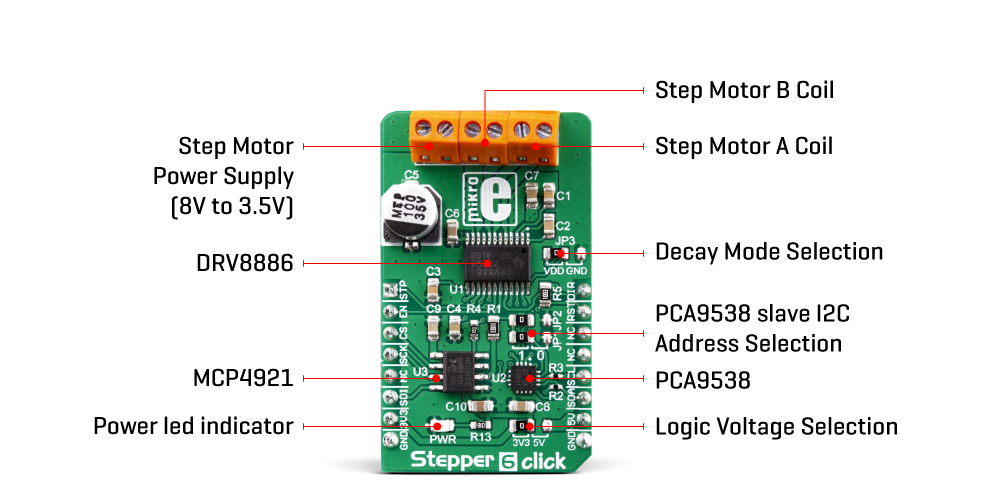

The DRV8886 step motor driver IC can deliver a reasonably high amount of current to the connected load. This IC uses a set of I/O pins, simplifying the control over the connected step motor. Since the DRV8886 IC offers so many options, an additional port expander IC is used to cover them all, offering the full control over the IC via the SPI interface, with no restrictions.

The DRV8886 IC also features a full set of protection features: overvoltage, thermal, overcurrent, and undervoltage protection schemes are all present on this IC, along with the fault indication pin. All these features make the Stepper 6 click a robust and versatile bipolar step motor driving solution. With its integrated current sensing, a microstepping ratio up to 1:16, a non-circular stepping mode for higher torque output, a high efficiency, and a reasonably high current it can deliver, the Stepper 6 click is a perfect solution for any application that requires an efficient and reliable motor driver. It can be used in 3D printers, laser printers, laser engravers, video security cameras, factory automatization, robotics, and other similar applications.

How does it work?

Stepper 6 click is equipped with the DRV8886, a highly integrated bipolar step motor driver with current sensing, from Texas Instruments. This integrated driver offers a simple interface, featuring a set of pins used to control the functions of the step motor. Since the number of pins exceeds the available mikroBUS™ general purpose pins, an additional port expander IC is used, exposing a 2-wire I2C interface for the communication with the host MCU. The port expander IC is the PCA9538, an 8-bit port expander with the I2C interface, an interrupt, and a reset, from NXP.

The high efficiency of the integrated N-Channel power MOSFET H-Bridges allows a high efficiency to be achieved: Stepper 6 click can withstand peaks of current up to 3A, while the internal current limiter is set to 1.4 A per bridge. The Click board™ can work with in the range from 8V up to 35V. However, when operated near the upper current and voltage limits, component heating is expected. If the temperature threshold of 150° is reached, a thermal protection will be engaged, while the fault condition will be indicated with the nFAULT pin of the DRV8886 IC. The nFAULT pin is routed to the port expander IC, allowing its state to be read over the I2C interface. The I2C interface bus of the PCA9538 is routed to the appropriate mikroBUS™ pins (SCA, SDL), allowing the host MCU to control it and read states of its pins.

The PCA9538 is also connected to some other pins: both M0 and M1 pins are routed to this IC, allowing the microstepping configuration over the I2C interface. These two pins are used to set the microstepping size in the range from 1 to 1/6 of a step. The current through the coils is indexed and depends on a position, so the angle of 0° will allow 100% of the current to run through the coil, scaling it down to 0% for the 90°. These current values change with the step position and the microstepping current on an H-Bridge output is a sine function. An additional non-circular half-stepping mode is also available when more torque is required at higher motor RPM. The current in this mode is simply switched from 0% to 100% with no indexed values in between. One of the key features of the DRV8886 IC is the integration of the sensing resistors, which reduces the design complexity.

The current decay through the coil for the circular microstepping modes is controlled by the DRV8886 IC, which offers three different decaying modes: slow decay, slow-mixed decay, and all mixed decay. The correct decay mode is necessary to prevent loss of the current regulation through the coil which might degrade the efficiency of the stepper motor control. The DECAY pin offers the control over the decay mode, and it is routed to the SMD jumper JP3, allowing it to be either pulled up (to the DVDD) or to the GND. The DRV8886 offers detailed information about the decay modes and how to set this pin for each.

The maximum current is limited by setting the current through the RREF pin. A DAC converter is used to set the voltage at this pin. The pin is typically used with the resistor connected to the GND, but the Stepper 6 click uses the MCP4921, a dedicated 12-bit DAC with SPI interface, from Microchip. This way, it is possible to change the maximum current limit by the firmware. The SPI interface of the MCP4921 is routed to the mikroBUS™, allowing the host MCU to take control over the maximum current limit. To find about the current limiting by using the DAC, please visit the DRV8886 datasheet. It offers all the necessary formulas to calculate the required DAC value for a certain current limit. However, the Click board™ comes with the library that contains functions which allow operational parameters of the Click board™ to be forwarded as the simple function arguments.

The maximum current is additionally scaled down by the TRQ pin, which can have three different states. A logic LOW state on this pin will not scale the current limit, at all. A logic HIGH will scale the current limiting factor down to 50%. If the pin is in the HIGH-Z mode (floating), the current limiting factor will be set to 75%. The current limiting formulas in the DRV8886 datasheet do take into the account the scaling factor set by the TRQ pin. This pin is routed to the port expander IC and is available to be controlled over the I2C interface.

The STEP, DIR, and EN pins of the DRV8886 are directly routed to the mikroBUS™ pins AN, PWM, and RST, respectively. These pins comprise the basic stepper motor driving interface, typically used on many similar devices: a rising edge on the STEP input pin will advance the internal sequencer (indexer) for one step; the DIR pin sets the direction, while the EN pin enables the output drives. A LOW logic level on this pin disables the H-Bridges at the output, leaving the logic section operational. A rising edge on the STEP input will still advance the internal sequencer, yet the connected motor will not act, as the H-Bridges are disabled.

Stepper 6 click has additional SMD jumpers that are used to set up the I2C slave address for the PCA9538 port expander (JP1 and JP2), as well as the logic voltage level selection SMD jumper, which allows selecting either 3.3V or 5V, allowing interfacing with a wide range of different MCUs. The motor power supply, as well as the two coils of a bipolar stepper motor (A and B), are connected to the Click board™ via the screw terminal block, according to the labeling on the bottom side of the Click board™, beneath the terminal.

Specifications

Type

Stepper

Applications

A perfect solution for building various applications that require precise and reliable stepper motor control, such as the movement control of beds, heads, and assemblies of various CNC plotting, milling and 3D printer designs, industrial automatization, security cameras…

On-board modules

DRV8886, a bipolar step motor driver with current sensing, from Texas Instruments; PCA9538, an 8-bit port expander with the I2C interface, from NXP; MCP4921, a 12-bit DAC with SPI interface, from Microchip

Key Features

Integrated current sensing, high efficiency, overcurrent, thermal and undervoltage with fault indication pin, simple motor control interface, up to 1:16 microstepping, wide voltage range, programmatically controlled current limiting, torque scaling, operational mode, step size, and more

Interface

GPIO,I2C,SPI

Feature

No ClickID

Compatibility

mikroBUS™

Click board size

M (42.9 x 25.4 mm)

Input Voltage

3.3V or 5V

Pinout diagram

This table shows how the pinout on Stepper 6 Click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

Onboard jumpers and connectors

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | – | Power LED indicator |

| JP1 – JP2 | JP1 – JP2 | Left | PCA9538 slave I2C address selection: left position HIGH (1), right position LOW (0) |

| JP3 | VCC SEL | Left | Decay mode selection: left position – DECAY pin connected to VDD, right position – DECAY pin connected to GND |

| JP4 | V-, V+, L | Left | Logic voltage level selection: left position – 3.3V; right position – 5V |

| TB1 | AOUT1, AOUT2 | – | Stepper motor coil A connector |

| TB2 | BOUT1, BOUT2 | – | Stepper motor coil B connector |

| TB3 | 8 – 35V | – | Stepper motor power supply input |

Stepper 6 click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| External power supply voltage | 8 | – | 35 | V |

| Motor RMS current [1] | – | – | 1.4 | A |

| Step size (without the interpolation feature) | 1 | – | 1:16 | step |

Note: Power dissipation should be monitored. An additional heat sink might be required for high current operation

Microstep resolution configuration

| Step Size | 1:1 | 1:2 | 1:4 | 1:8 | 1:16 | 1:2 [*] |

|---|---|---|---|---|---|---|

| M0 | 0 | 0 | 1 | Hi-Z | 1 | Hi-Z |

| M1 | 0 | 1 | 1 | 0 | 0 | 1 |

Software Support

We provide a library for the Stepper 6 Click as well as a demo application (example), developed using MIKROE compilers. The demo can run on all the main MIKROE development boards.

Package can be downloaded/installed directly from NECTO Studio Package Manager (recommended), downloaded from our LibStock™ or found on MIKROE github account.

Library Description

This library contains API for Stepper 6 Click driver.

Key functions

-

stepper6_set_directionThis function sets the motor direction by setting the DIR pin logic state. -

stepper6_set_step_modeThis function sets the step mode resolution settings. -

stepper6_drive_motorThis function drives the motor for the specific number of steps at the selected speed.

Example Description

This example demonstrates the use of the Stepper 6 Click by driving the motor in both directions for a desired number of steps.

void application_task ( void )

{

log_printf ( &logger, " Move 200 full steps clockwise, speed: slowrnn" );

stepper6_set_direction ( &stepper6, STEPPER6_DIR_CW );

stepper6_set_step_mode ( &stepper6, STEPPER6_MODE_FULL_STEP );

stepper6_drive_motor ( &stepper6, 200, STEPPER6_SPEED_SLOW );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf ( &logger, " Move 200 half steps counter-clockwise, speed: mediumrnn" );

stepper6_set_direction ( &stepper6, STEPPER6_DIR_CCW );

stepper6_set_step_mode ( &stepper6, STEPPER6_MODE_HALF_STEP );

stepper6_drive_motor ( &stepper6, 200, STEPPER6_SPEED_MEDIUM );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf ( &logger, " Move 400 quarter steps counter-clockwise, speed: fastrnn" );

stepper6_set_direction ( &stepper6, STEPPER6_DIR_CCW );

stepper6_set_step_mode ( &stepper6, STEPPER6_MODE_QUARTER_STEP );

stepper6_drive_motor ( &stepper6, 400, STEPPER6_SPEED_FAST );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

The full application code, and ready to use projects can be installed directly from NECTO Studio Package Manager (recommended), downloaded from our LibStock™ or found on MIKROE github account.

Other MIKROE Libraries used in the example:

- MikroSDK.Board

- MikroSDK.Log

- Click.Stepper6

Additional notes and informations

Depending on the development board you are using, you may need USB UART click, USB UART 2 Click or RS232 Click to connect to your PC, for development systems with no UART to USB interface available on the board. UART terminal is available in all MIKROE compilers.

mikroSDK

This Click board™ is supported with mikroSDK – MIKROE Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

Resources

Downloads

| Weight | 21 g |

|---|---|

| Brand | MikroElektronika |