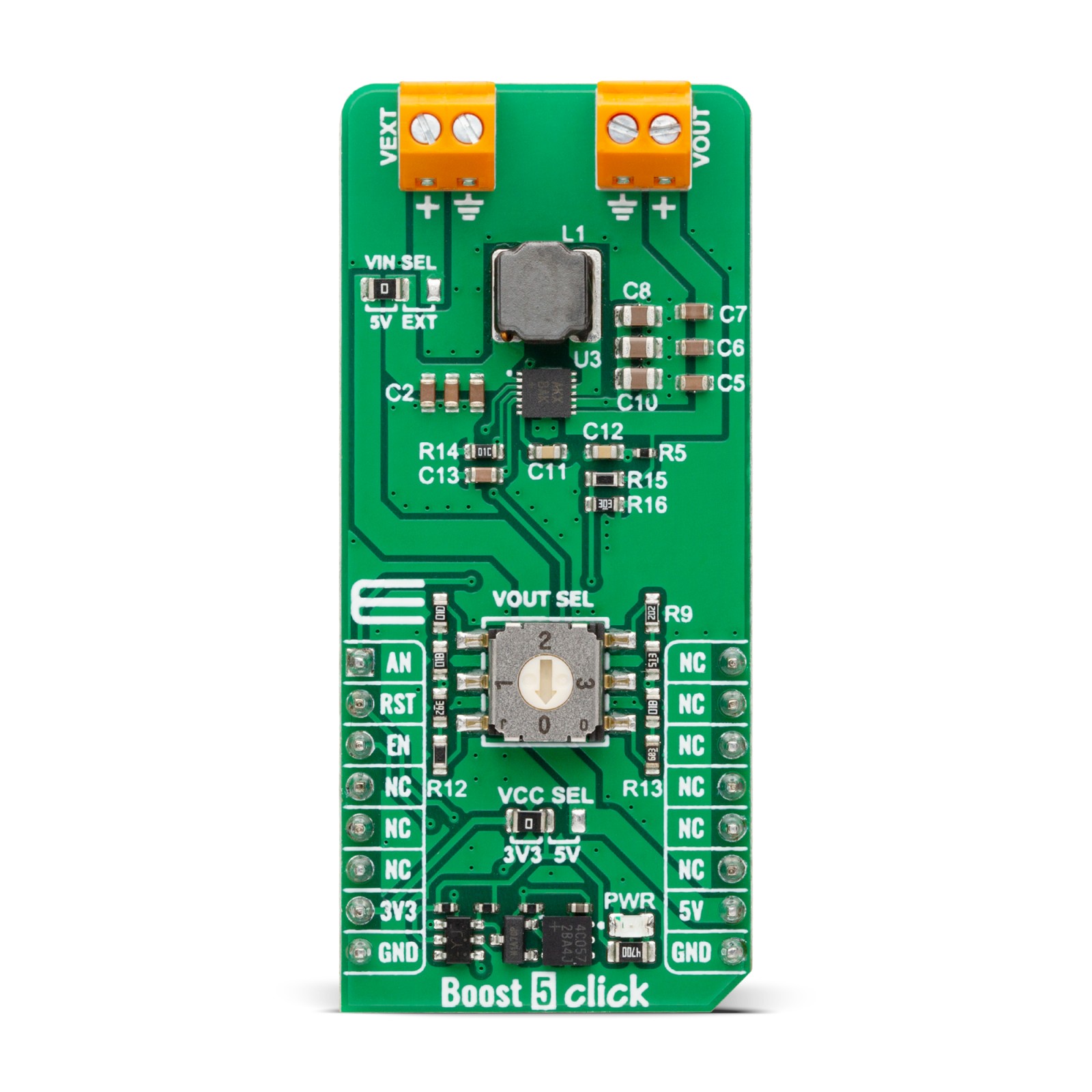

Boost 5 Click

R650.00 ex. VAT

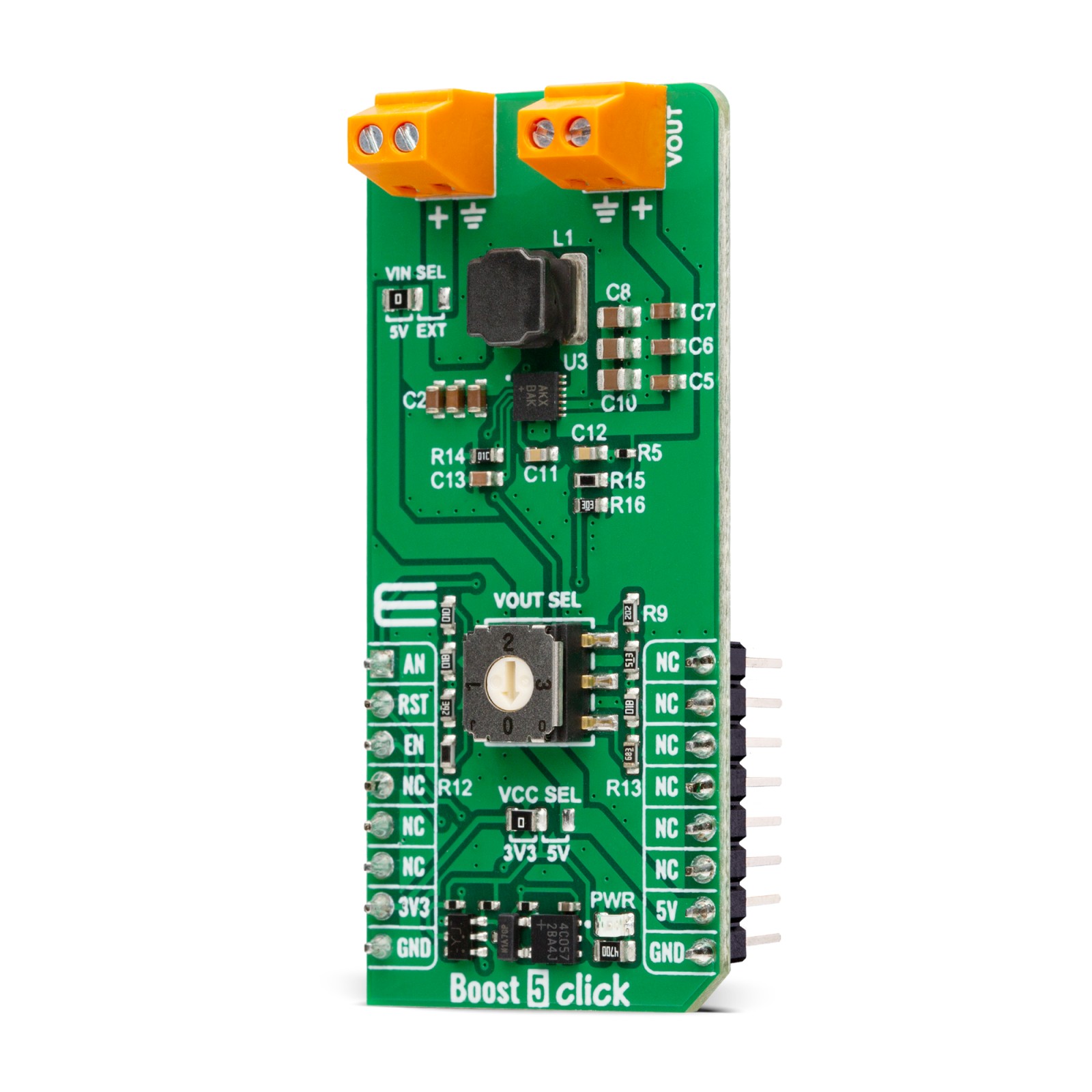

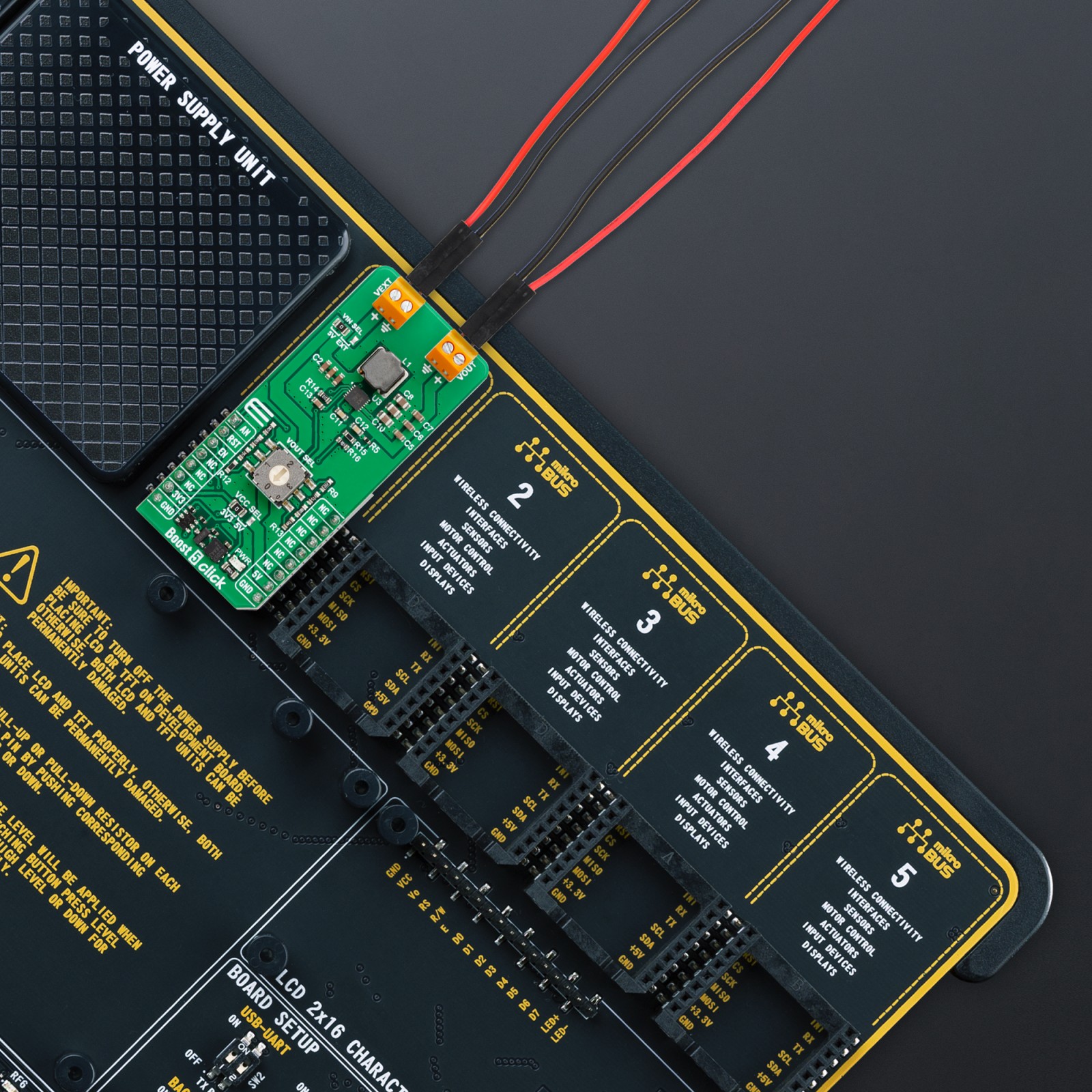

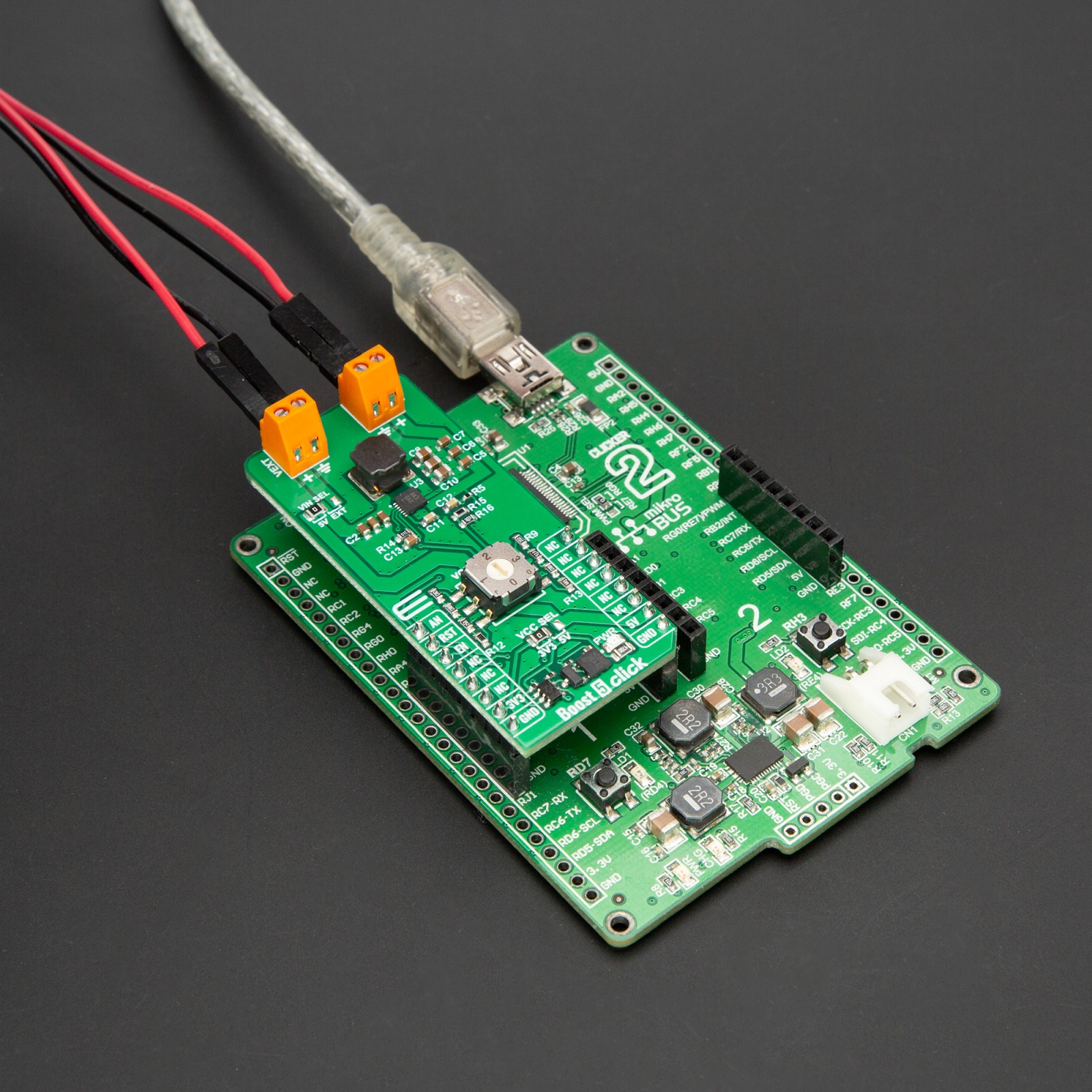

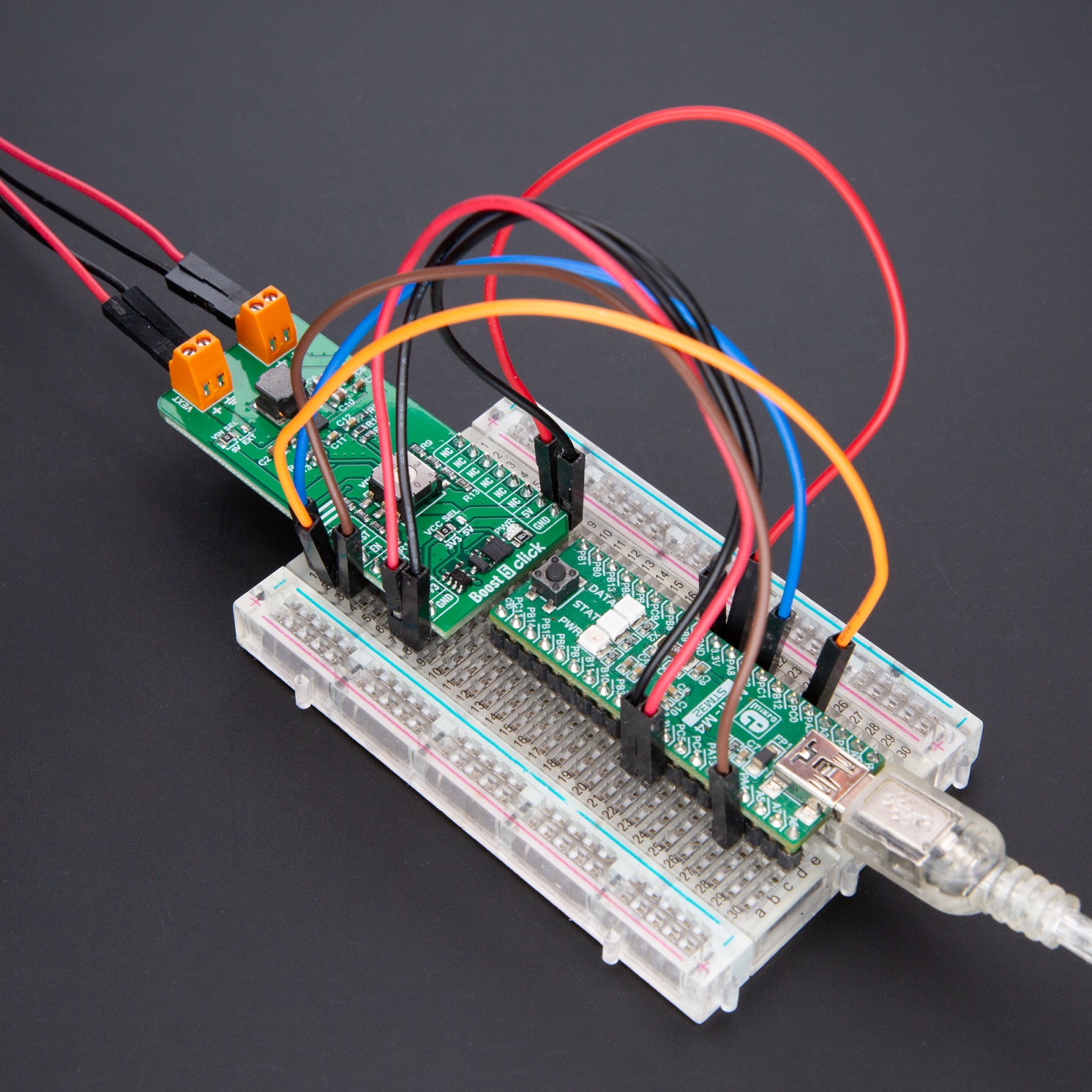

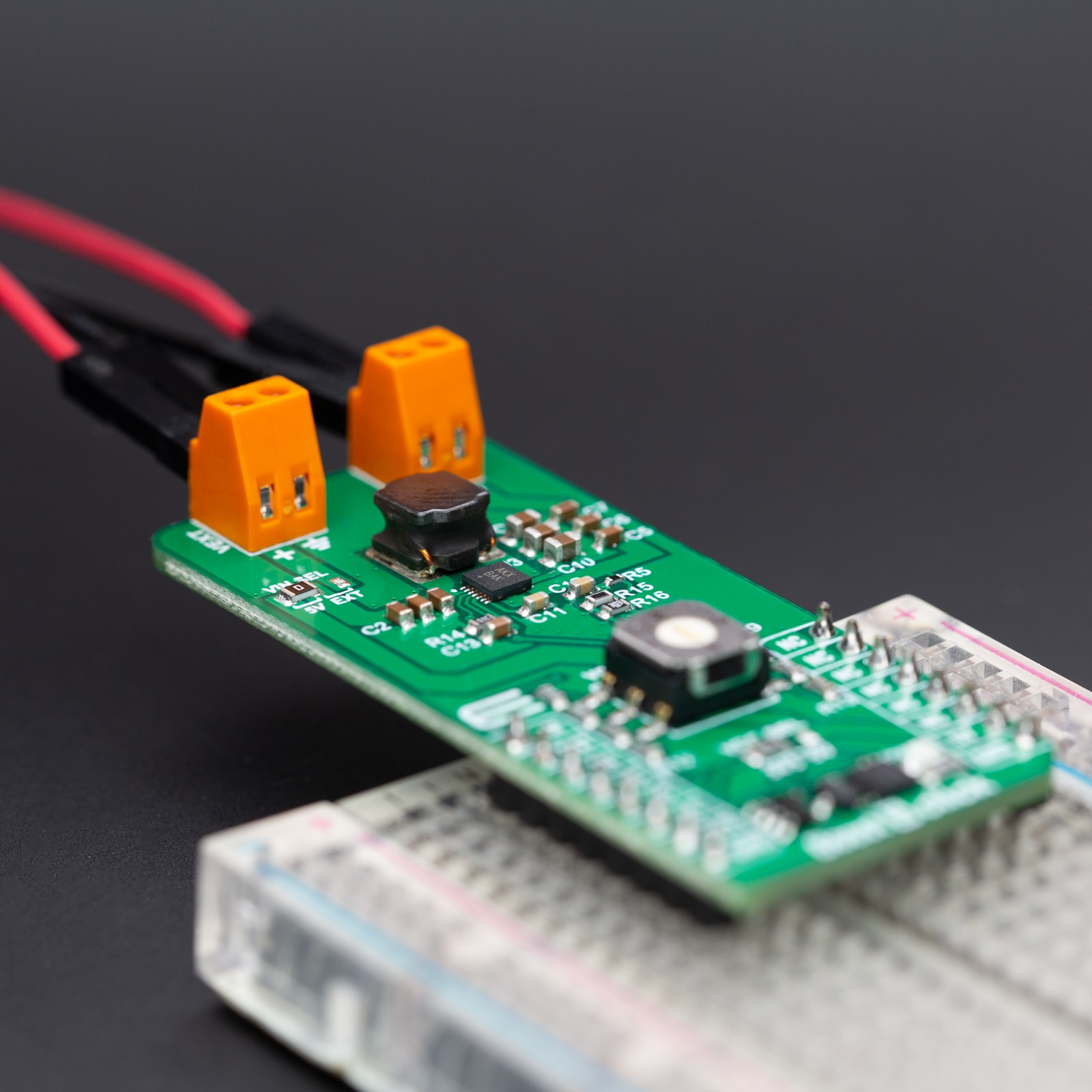

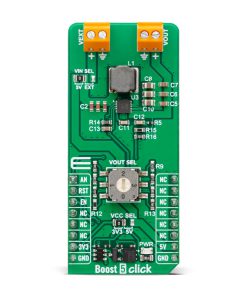

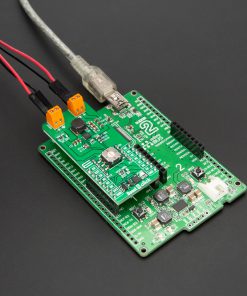

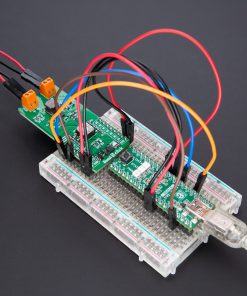

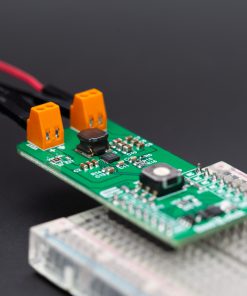

Boost 5 Click is a compact add-on board that boosts voltage for battery-powered and low-power applications. This board features the MAX17250, a high-efficiency synchronous boost converter from Analog Devices, featuring True Shutdown™ and ultra-low quiescent current operation. This Click board™ supports input voltages from 2.7V to 18V and delivers regulated output voltages of 8V, 10V, 12V, or 14V, selectable via an onboard switch with peak current limit of 3.5A. It includes short-circuit protection, Pulse Frequency Modulation (PFM) for minimal power consumption, and offers flexible power sourcing through a VIN SEL jumper, allowing users to choose between an internal mikroBUS™ 5V power rail or an external supply. Boost 5 Click is ideal for battery-powered IoT devices, single or dual-cell Li-Ion battery applications, display power supplies, and buzzer/alarm drivers where reliable and efficient voltage step-up is required.

Boost 5 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R617.50 |

| 10+ | R585.00 |

| 15+ | R552.50 |

| 20+ | R531.70 |