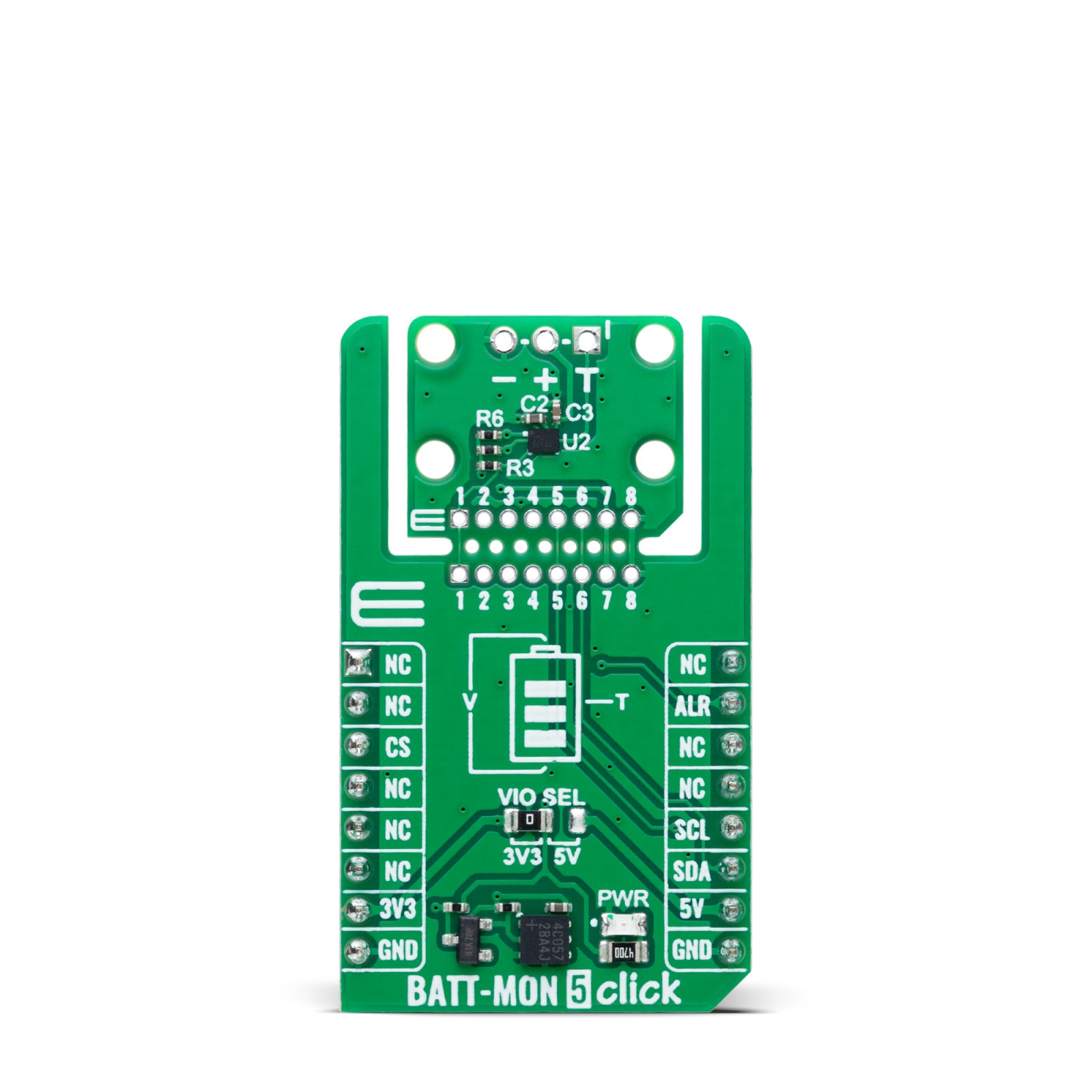

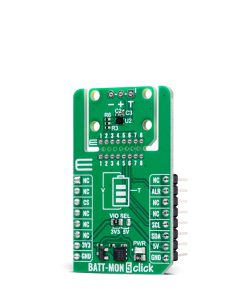

BATT-MON 5 Click

R285.00 ex. VAT

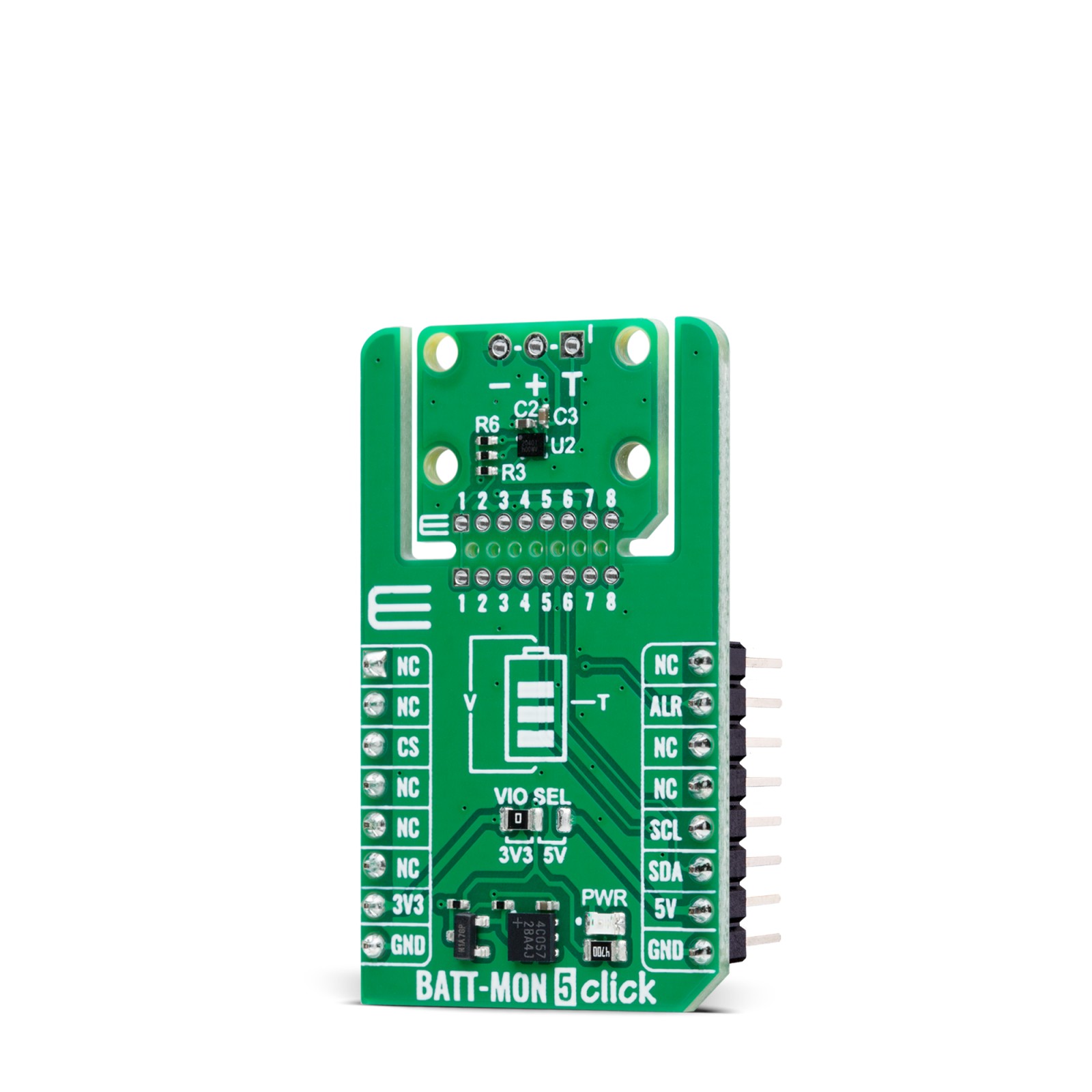

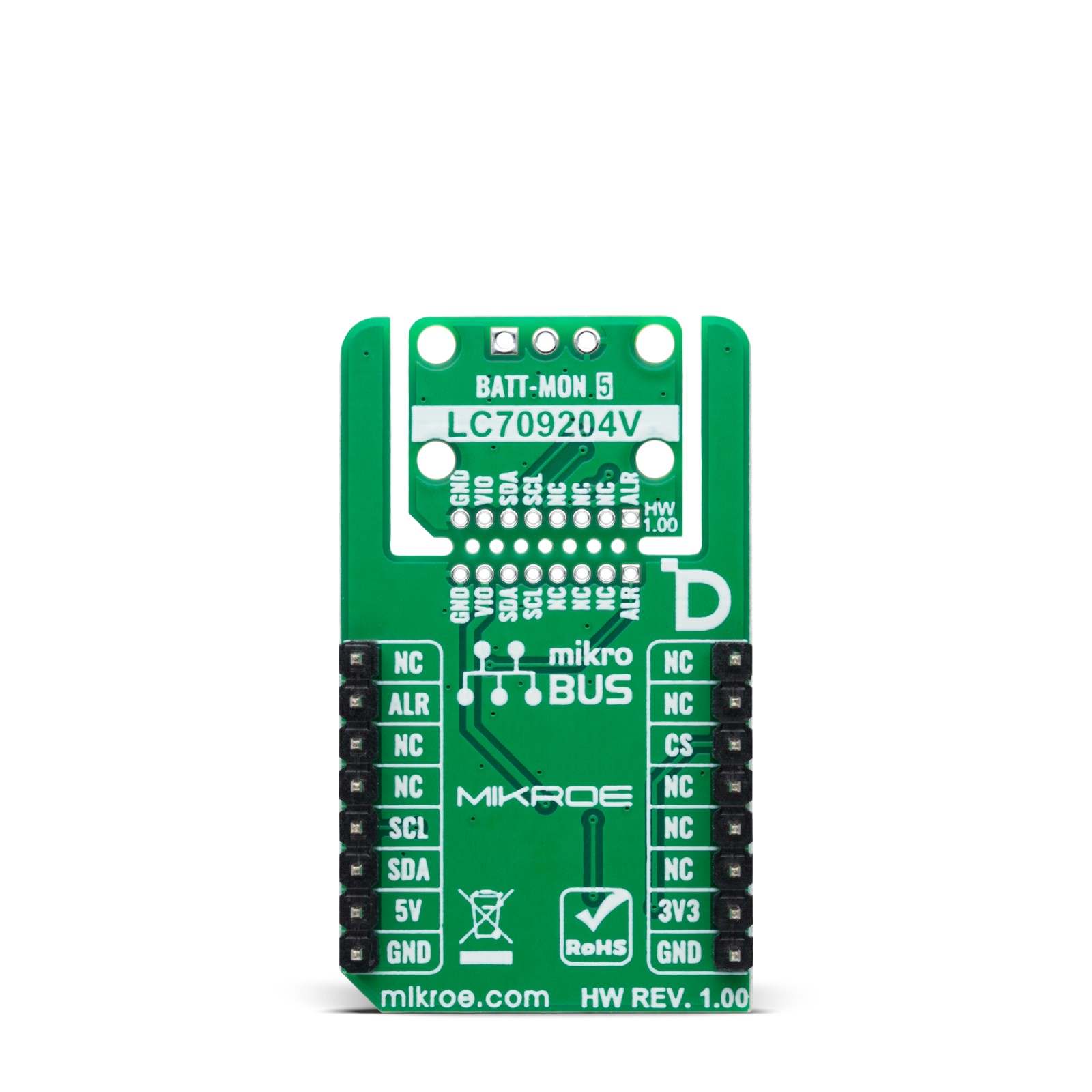

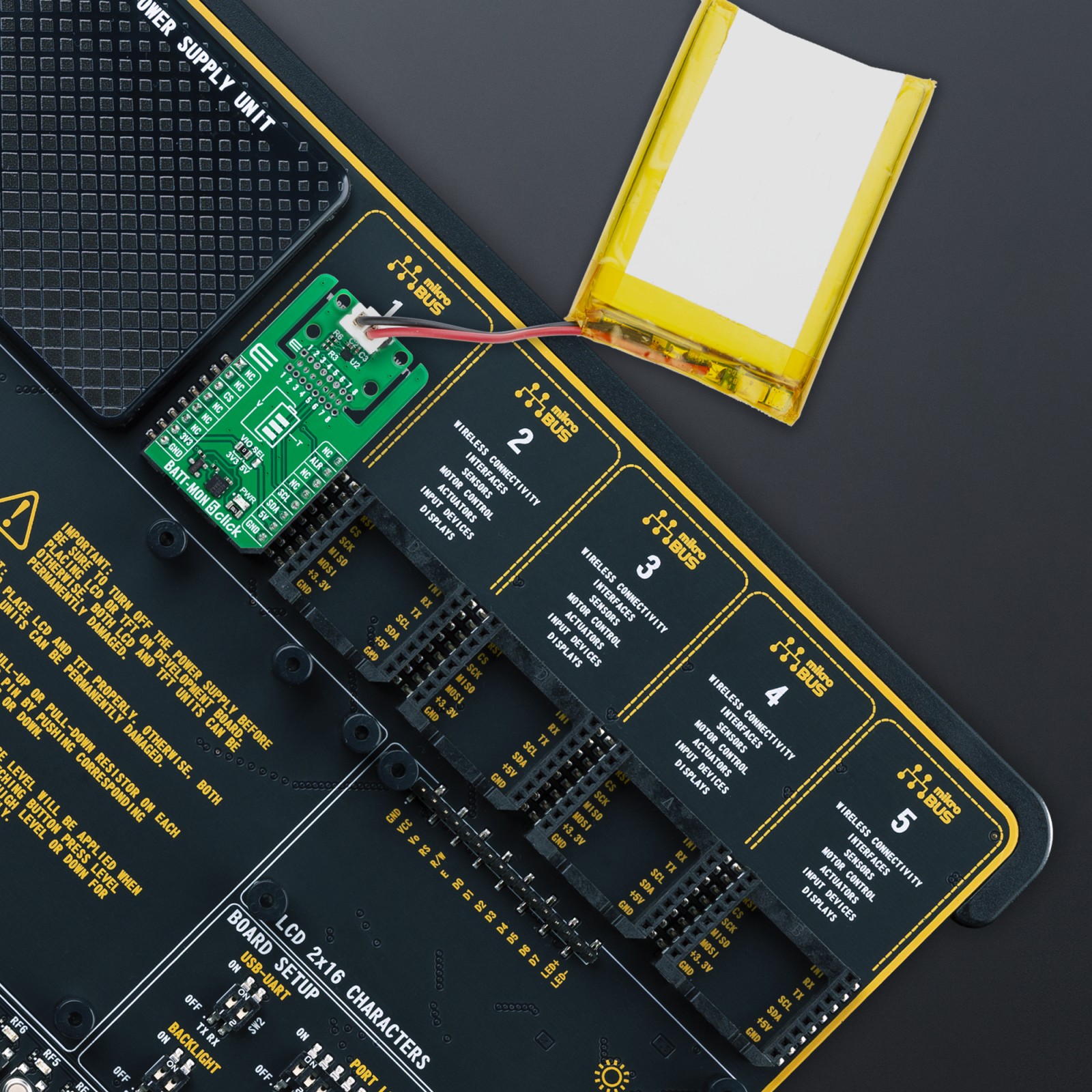

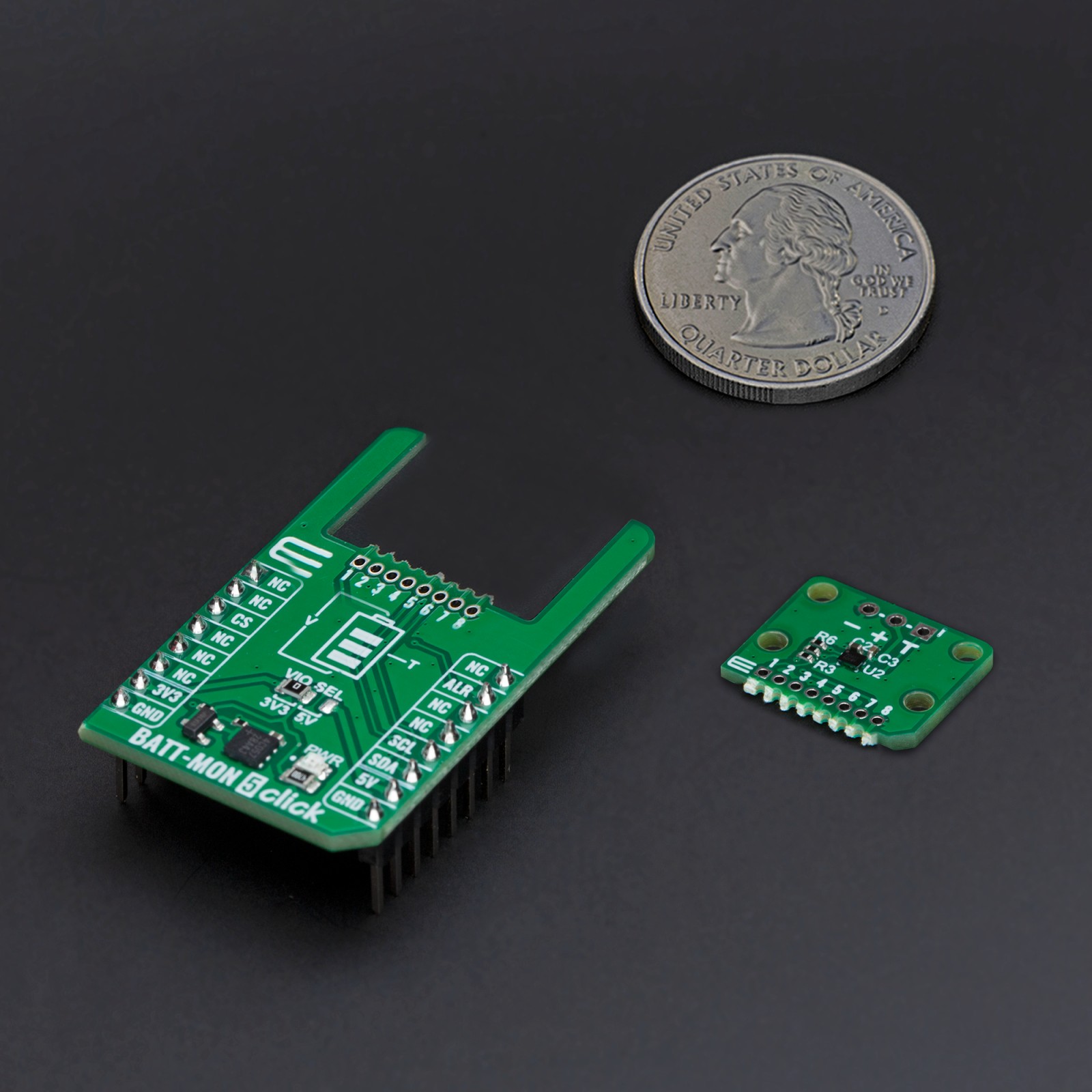

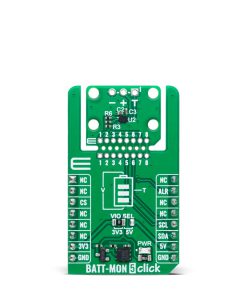

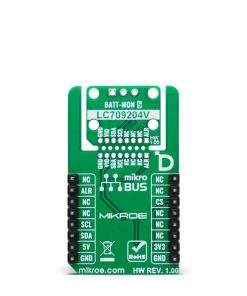

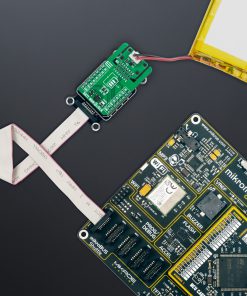

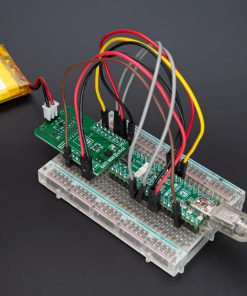

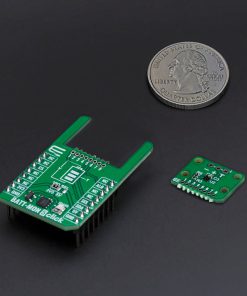

BATT-MON 5 Click is a compact add-on board designed for precise fuel gauging of 1-cell Lithium-ion/Polymer (Li+) batteries. This board features the LC709204V from onsemi based on the innovative HG-CVR2 algorithm to deliver accurate Relative State of Charge (RSOC) readings under varying conditions, such as temperature changes, load fluctuations, and battery aging. It features low power consumption, easy integration with simple parameter configuration, and integrated safety alarms for monitoring critical battery conditions like low voltage, abnormal temperature, and over-discharge risks. Ideal for portable devices, wearables, PDAs, and USB-powered systems applications, this Click board™ ensures reliable battery performance and extended device operating time, making it an essential tool for modern energy management.

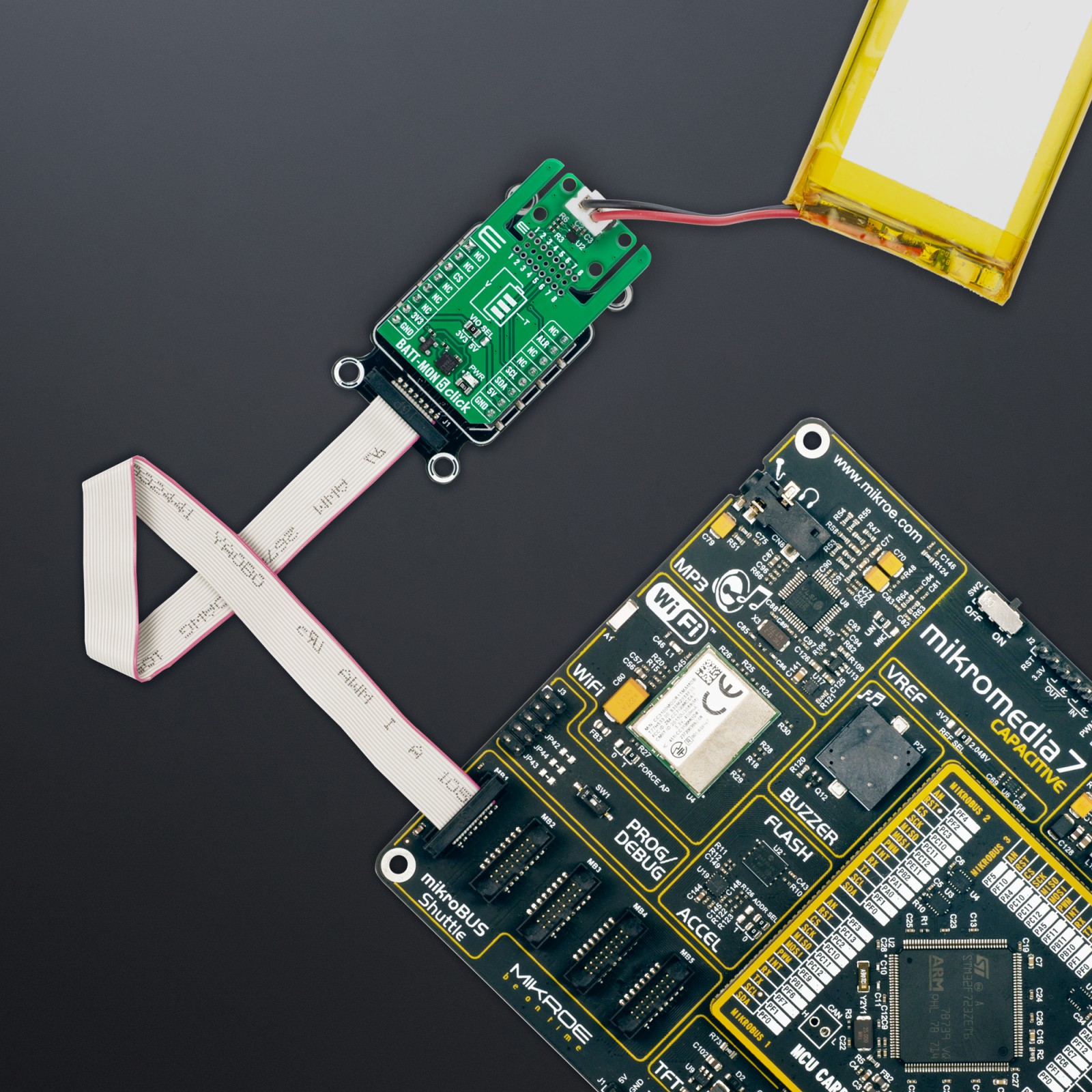

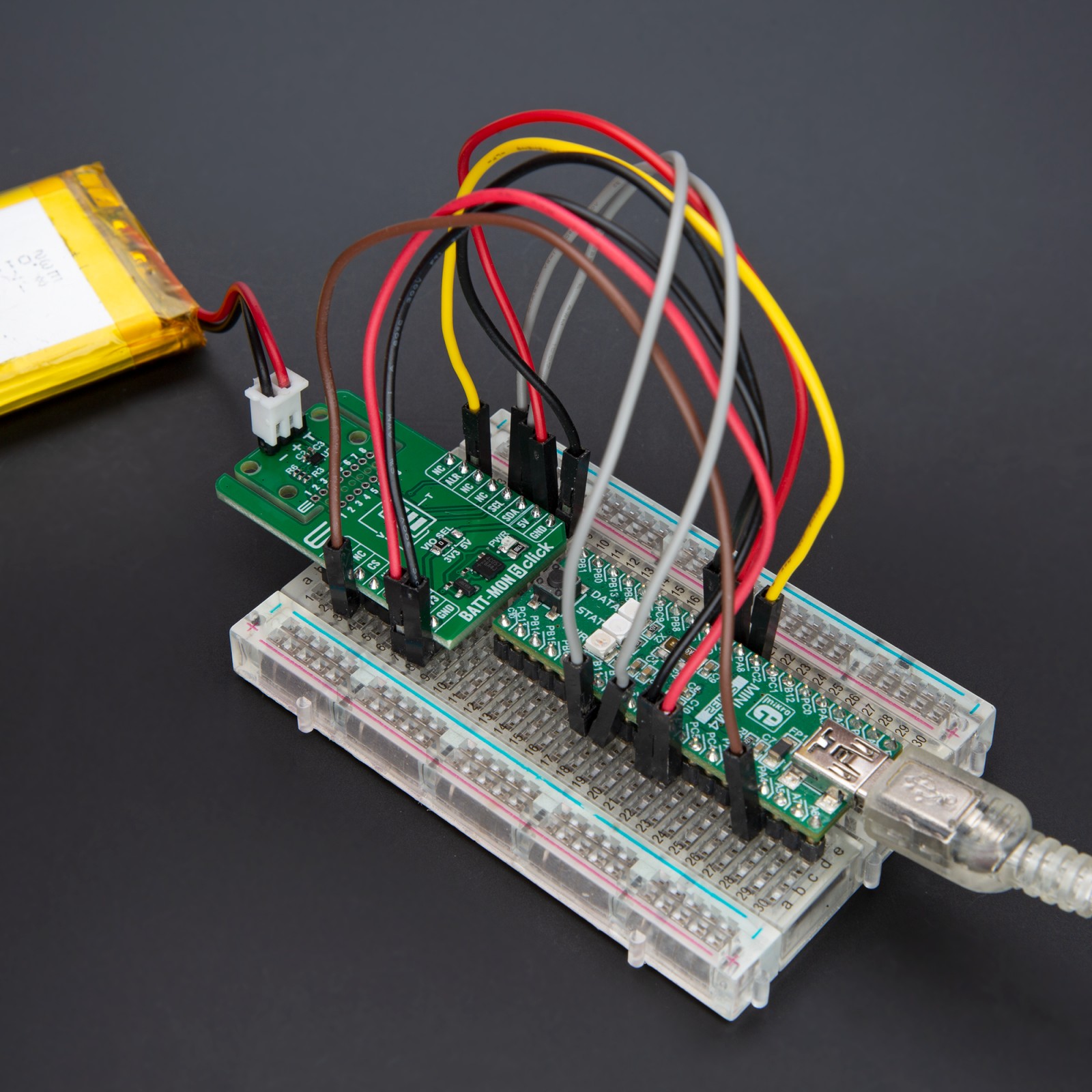

BATT-MON 5 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board, alongside a Click Snap feature introducing a new level of flexibility and ease of use.

Stock: Lead-time applicable.

| 5+ | R270.75 |

| 10+ | R256.50 |

| 15+ | R242.25 |

| 20+ | R233.13 |