ML Vibro Sens Click

R460.00 ex. VAT

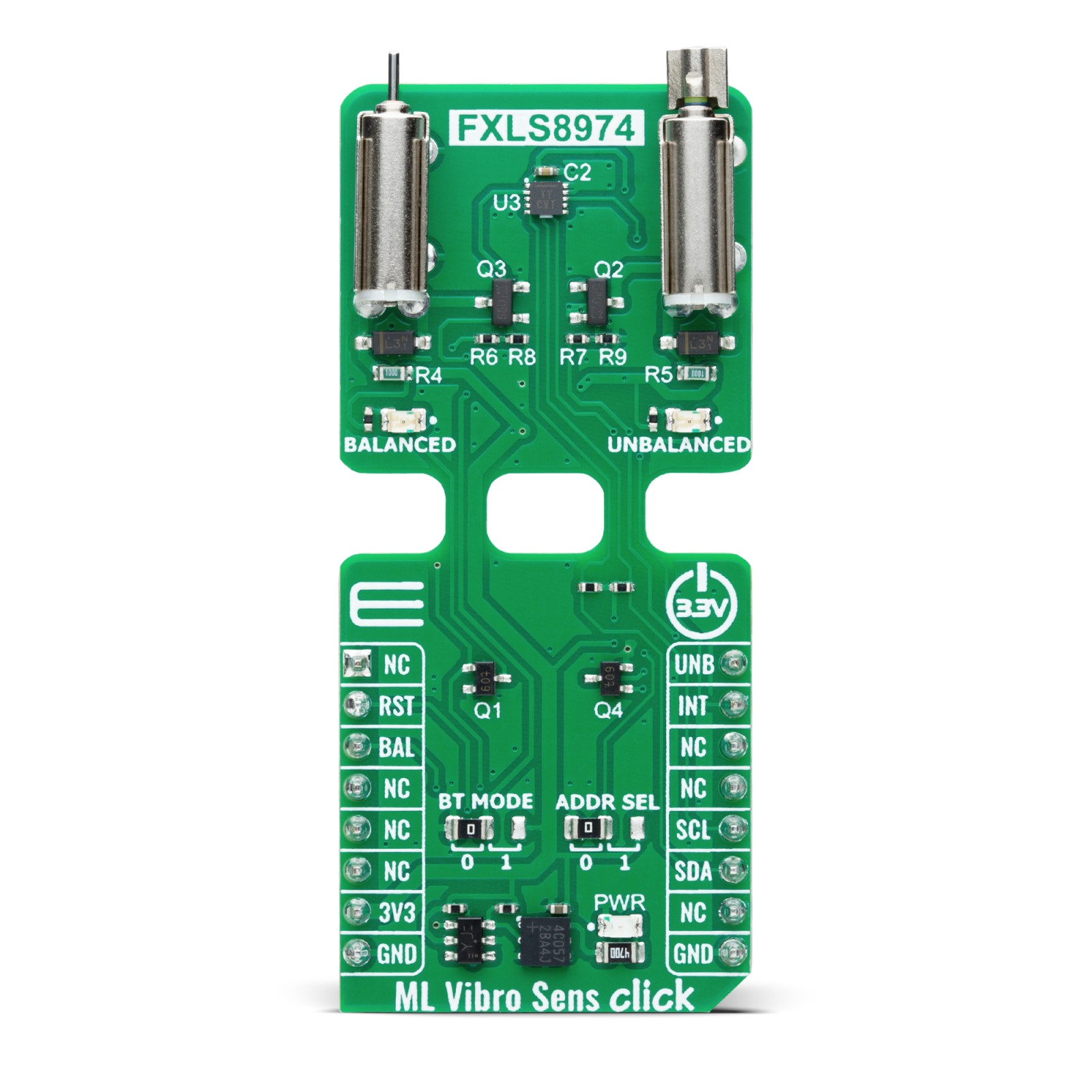

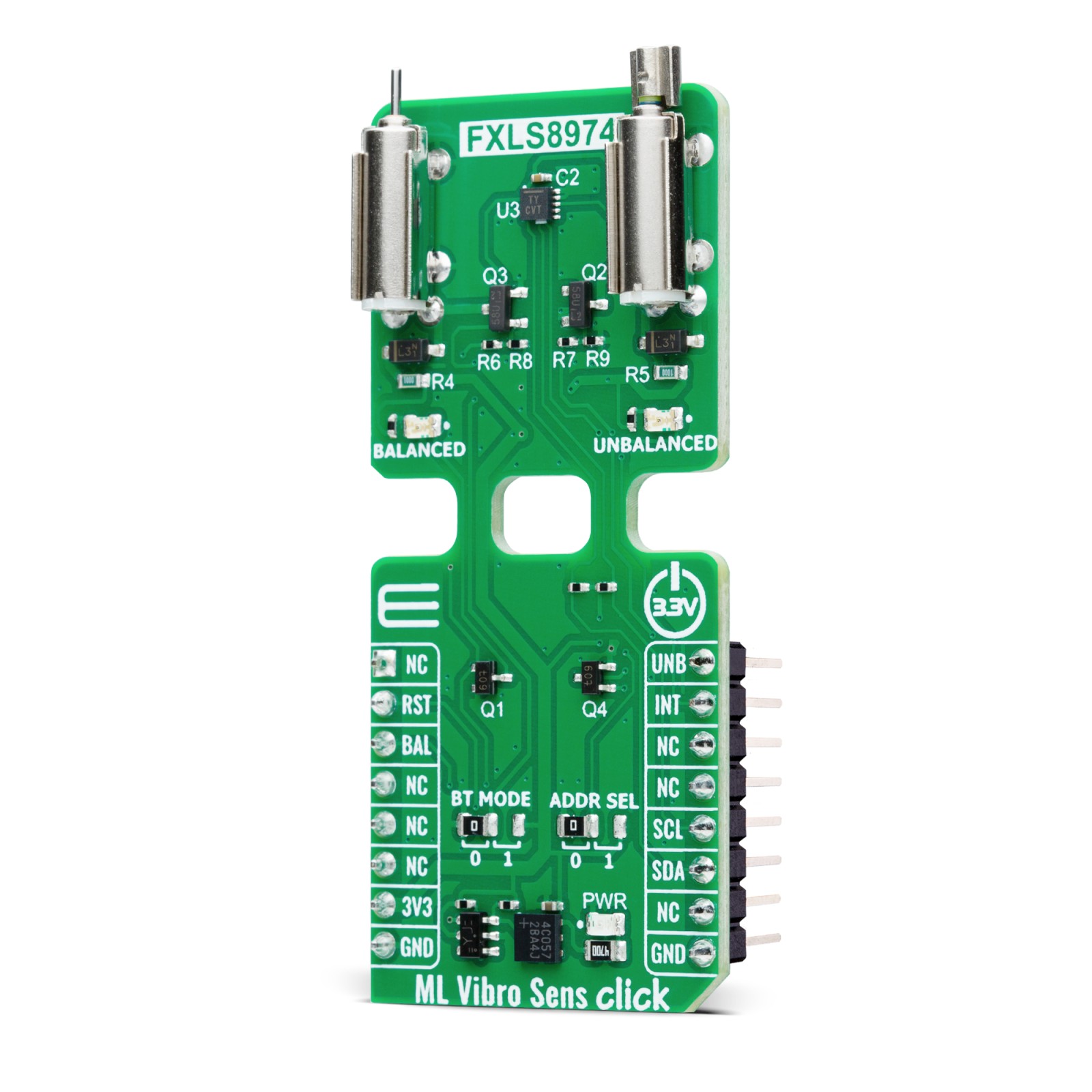

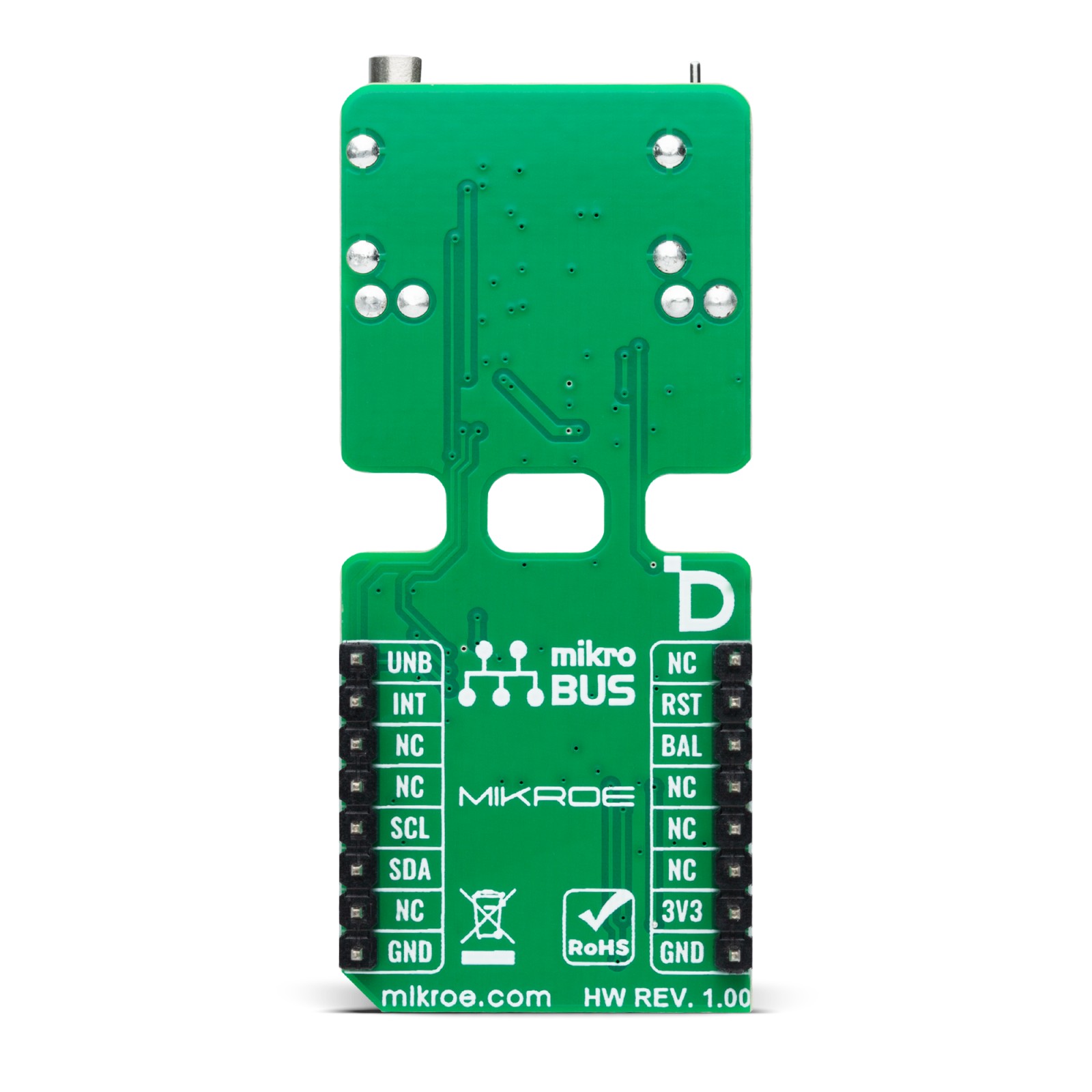

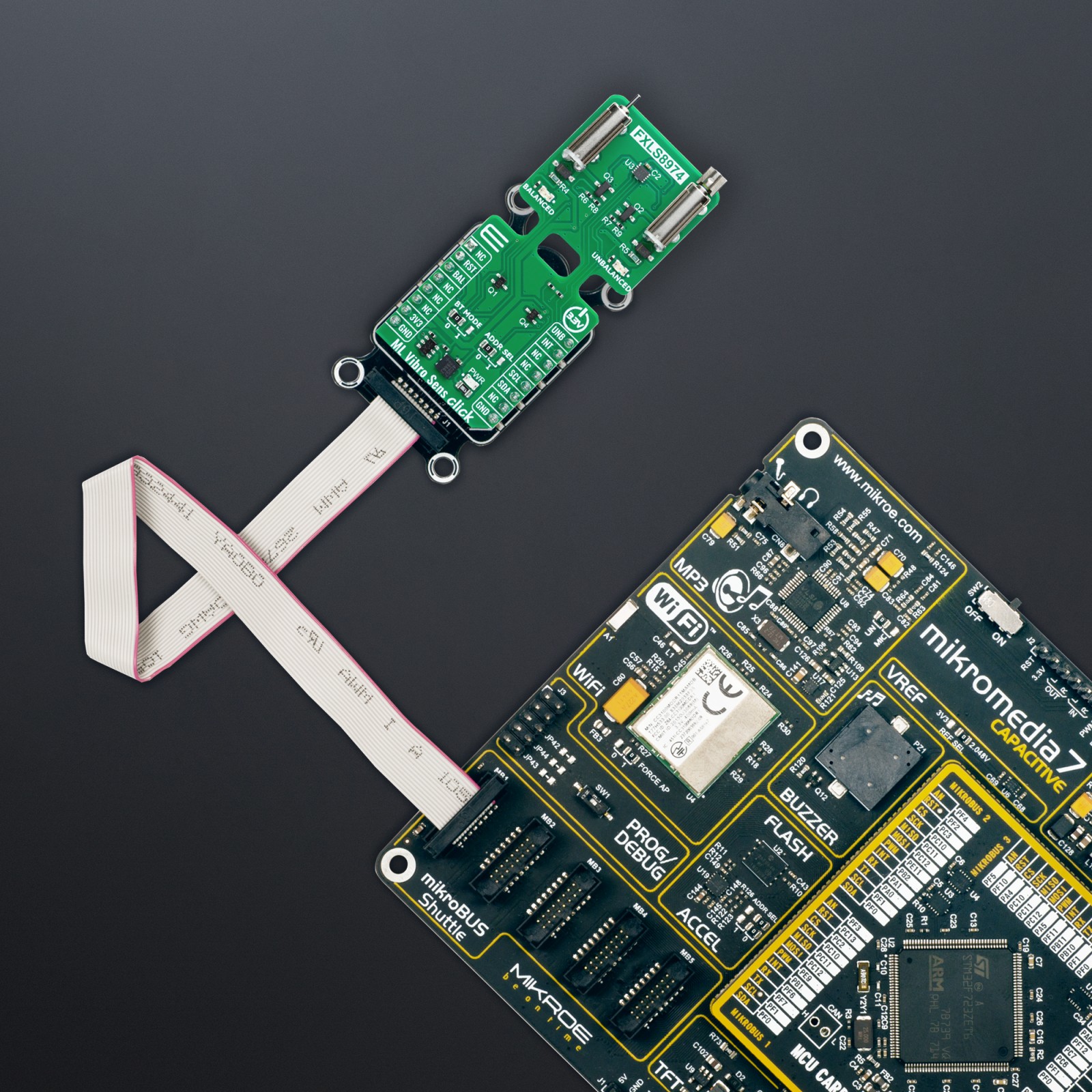

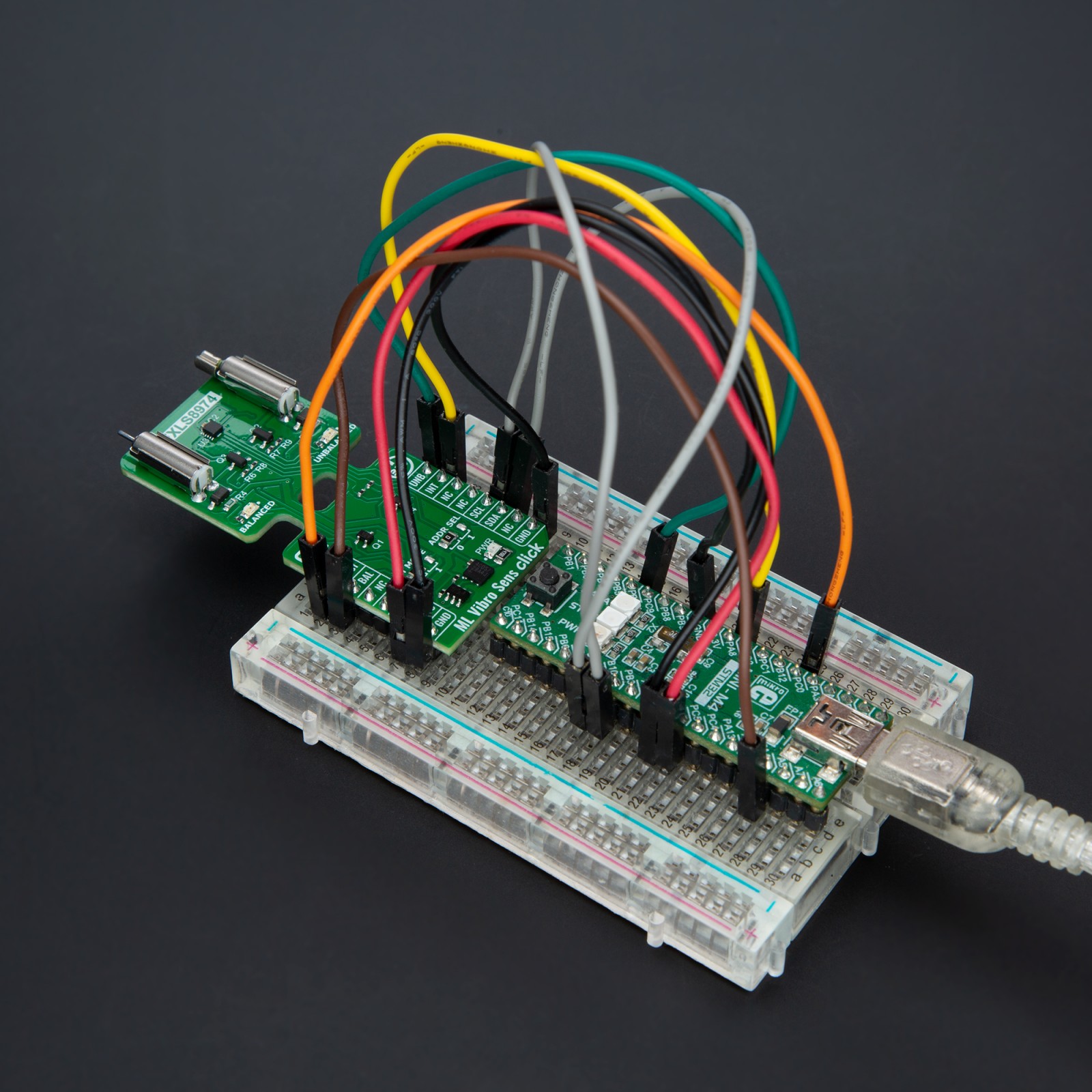

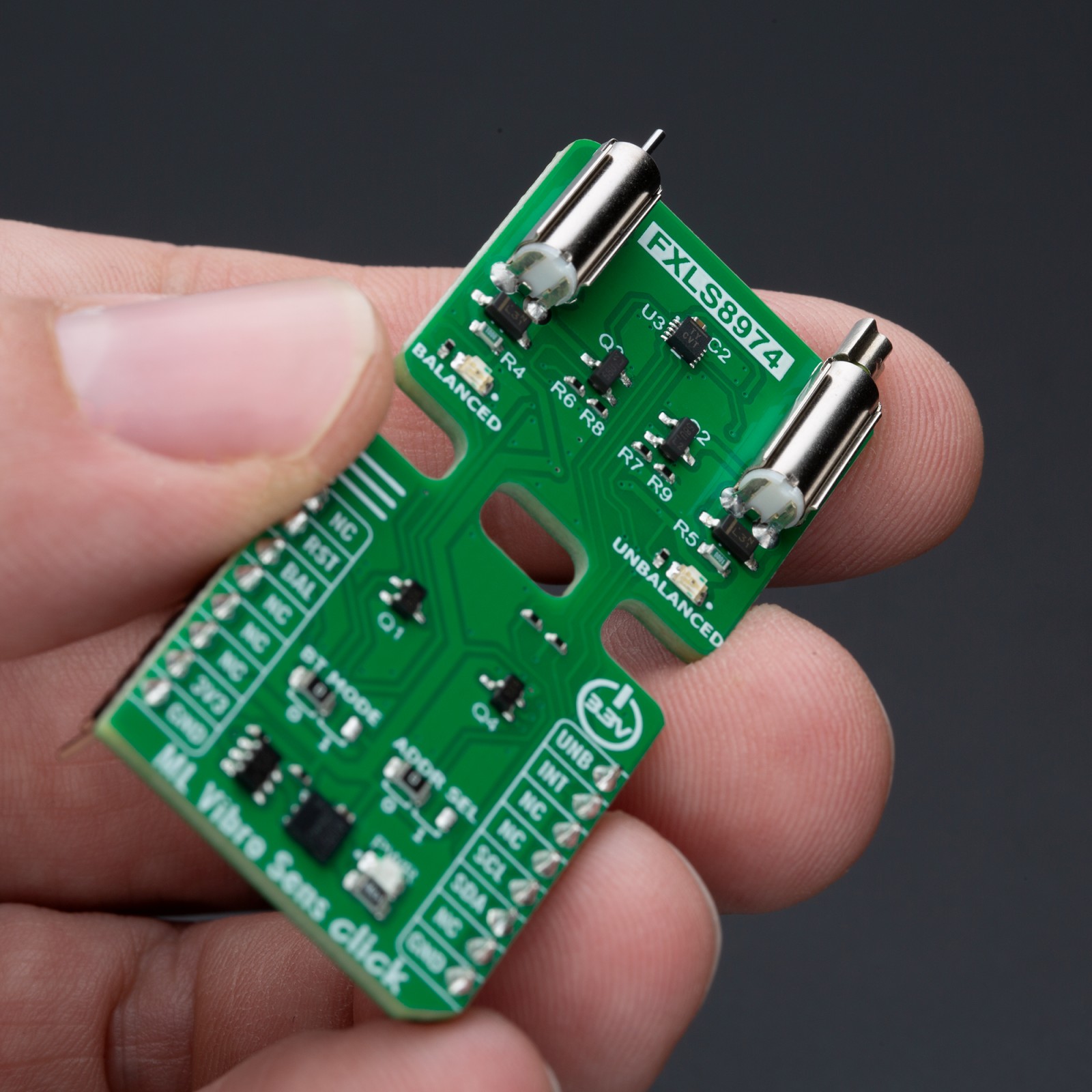

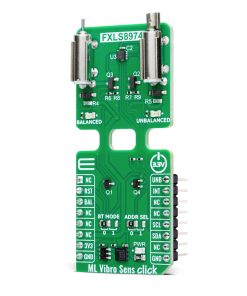

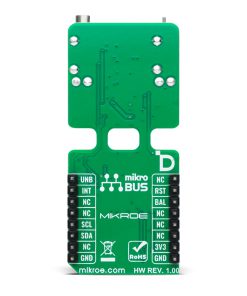

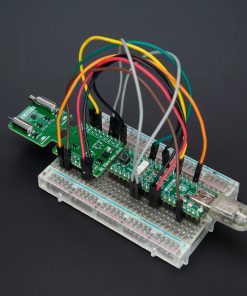

ML Vibro Sens Click is a compact add-on board for motion sensing and vibration analysis. This board features the FXLS8974CF, a 3-axis low-g 12-bit digital accelerometer from NXP designed for precise motion detection and data collection. This Click board™ represents a machine learning training tool that communicates with the host MCU over an I2C interface, with selectable addresses and dual operating modes for interrupt signaling or motion detection. It features two DC motors – a balanced motor for generating steady baseline vibrations and an unbalanced motor for customizable vibration patterns controlled via PWM or PDM signals. Ideal for industrial diagnostics, IoT systems, wearable devices, and environmental monitoring, ML Vibro Sens Click provides reliable motion data for training ML algorithms in diverse applications.

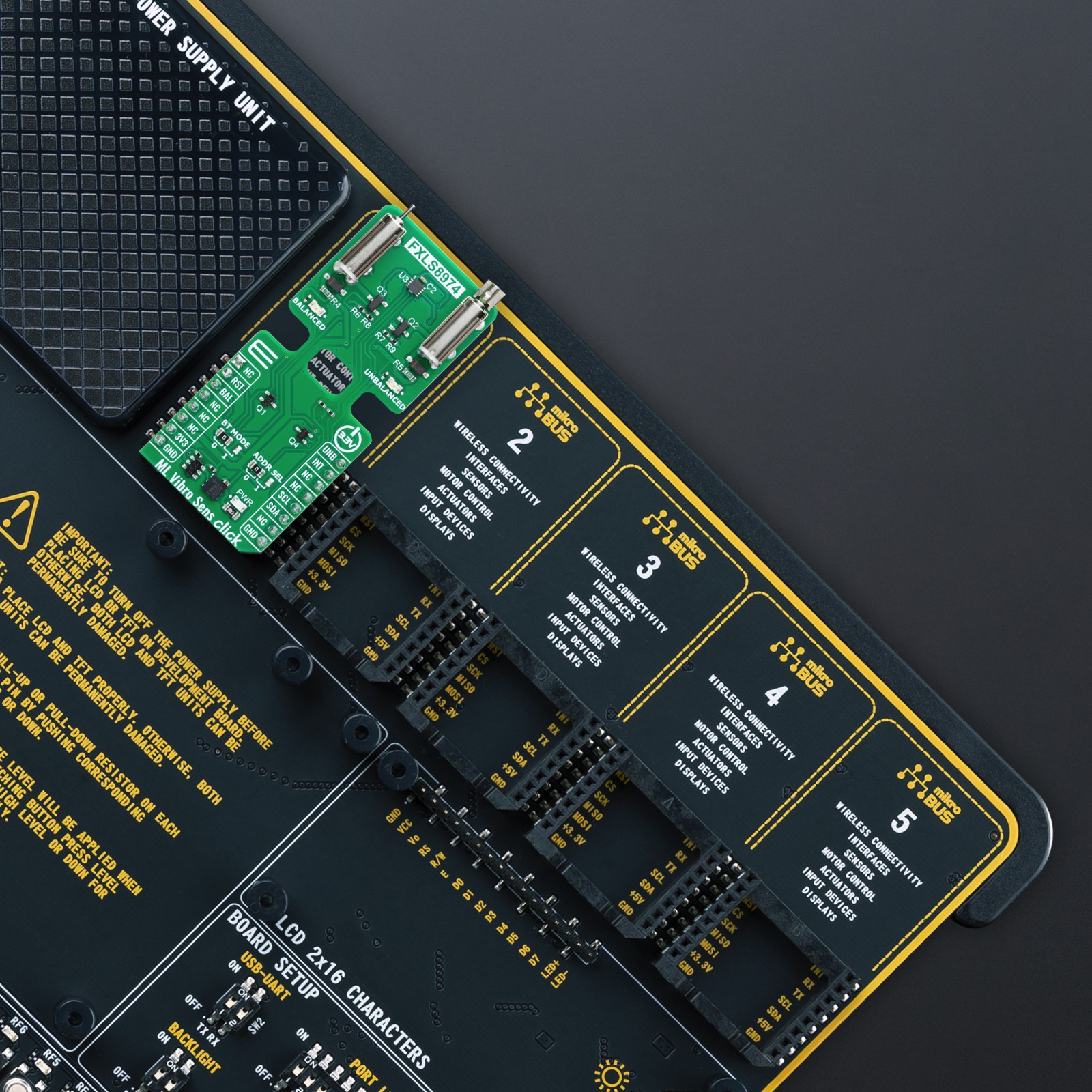

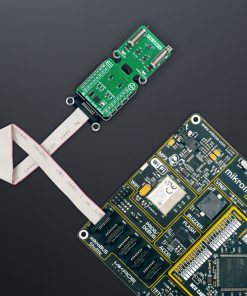

ML Vibro Sens Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R437.00 |

| 10+ | R414.00 |

| 15+ | R391.00 |

| 20+ | R376.28 |