PMIC Click

R515.00 ex. VAT

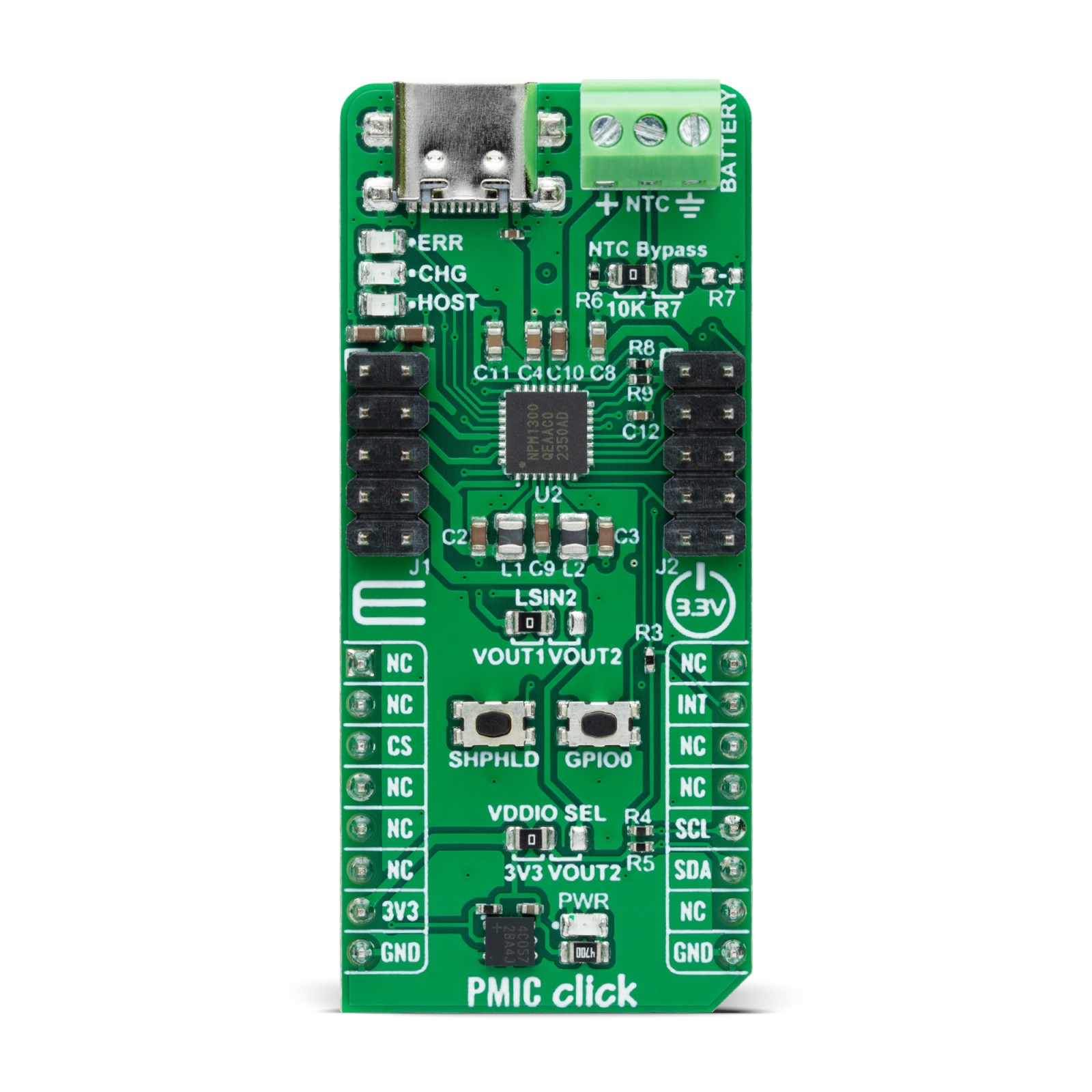

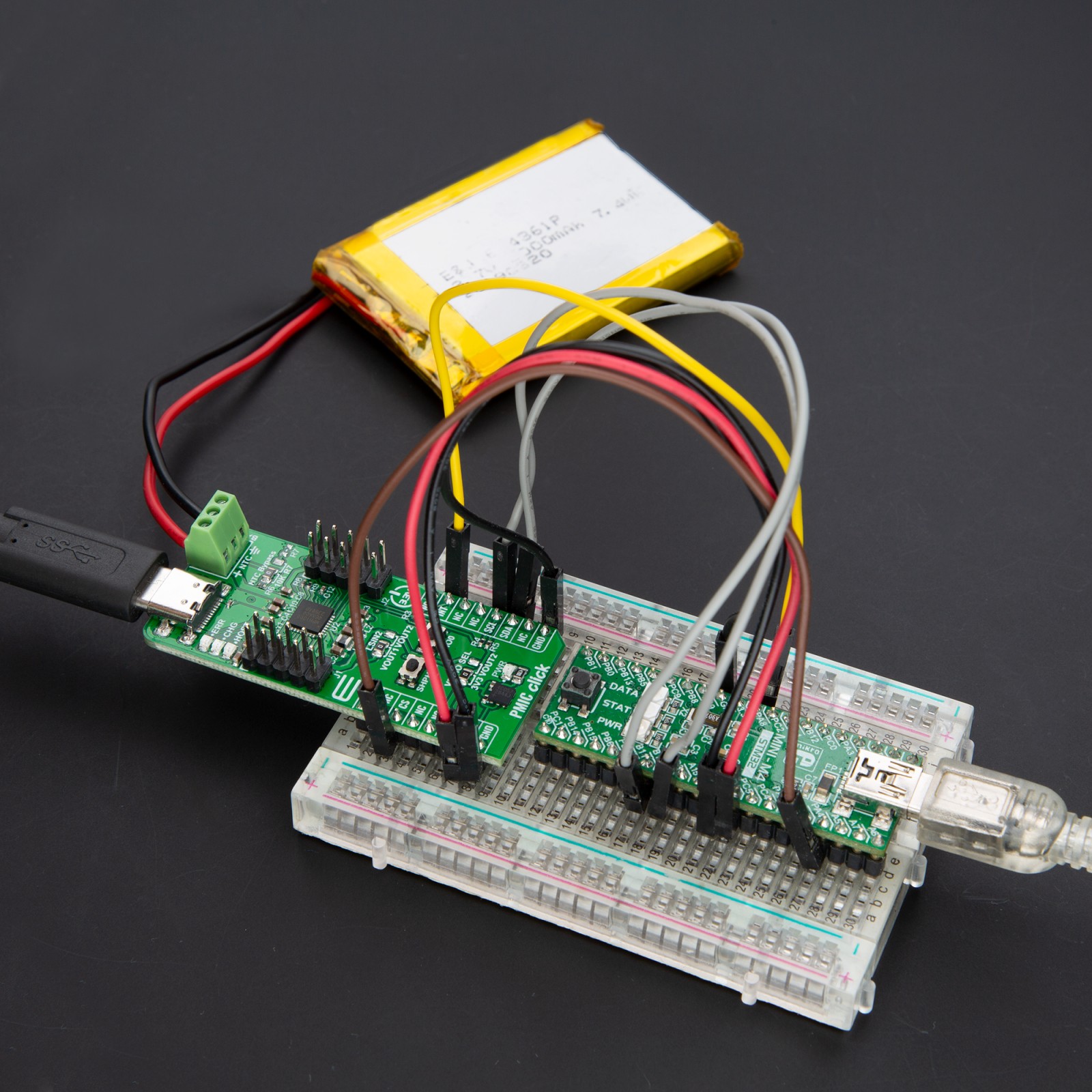

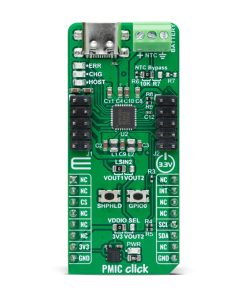

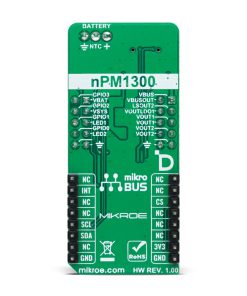

PMIC Click is a compact add-on board for efficient power management in rechargeable applications. This board features the nPM1300, an advanced Power Management Integrated Circuit (PMIC) from Nordic Semiconductor, offering integrated battery charging, fuel gauge, and advanced system power management features. The board includes an 800mA JEITA-compliant linear battery charger, two 200mA buck regulators, and configurable load switches, all housed in a compact QFN32 package. It provides flexible power distribution and system monitoring through an I2C interface with additional real-time feedback. This Click board™ is ideal for wearables, IoT devices, asset tracking, and interactive entertainment systems.

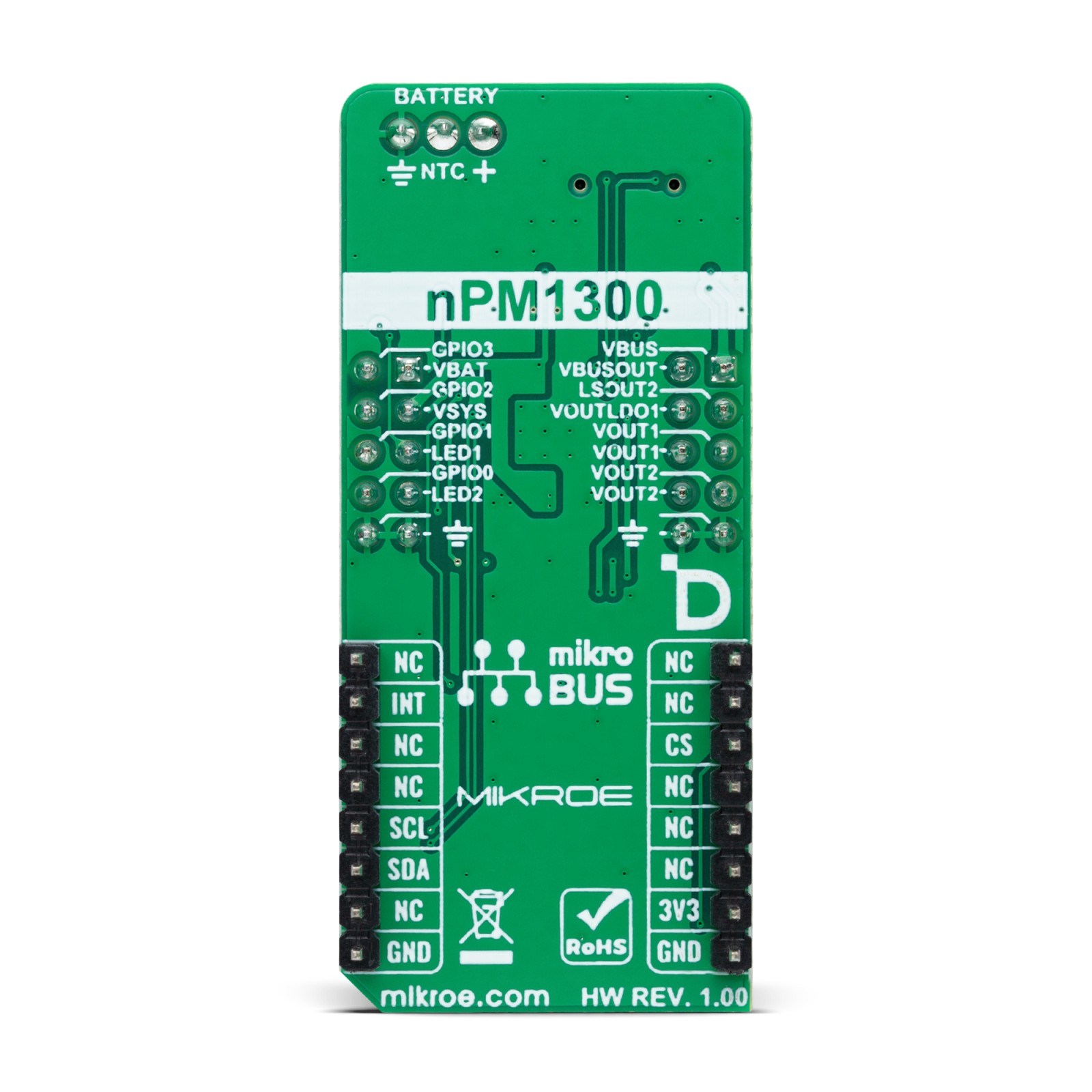

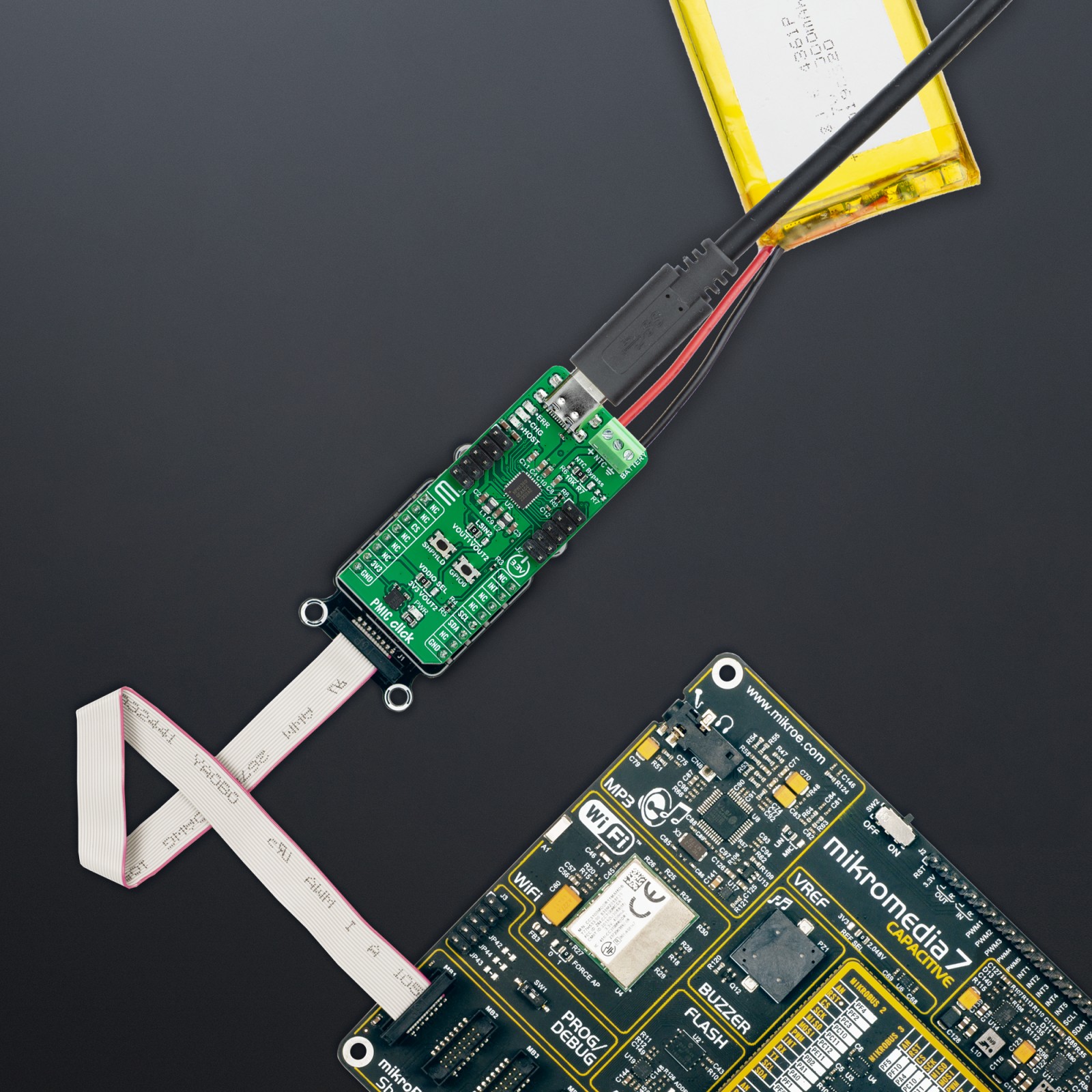

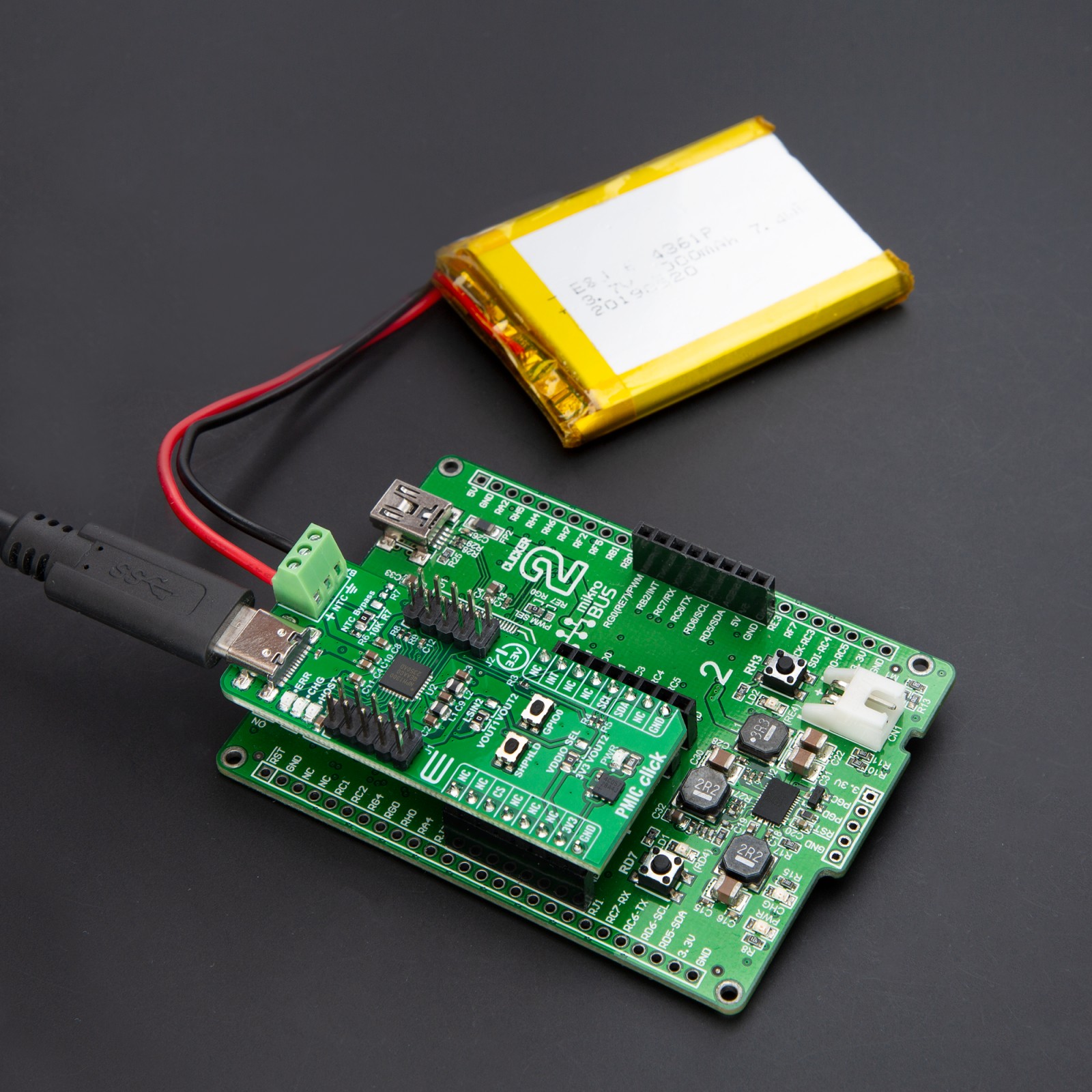

PMIC Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R489.25 |

| 10+ | R463.50 |

| 15+ | R437.75 |

| 20+ | R421.27 |

How does it work?

PMIC Click is based on the nPM1300, an advanced Power Management Integrated Circuit (PMIC) from Nordic Semiconductor designed for rechargeable applications. The nPM1300 integrates a variety of power and system management functionalities, offering a compact and efficient solution for managing power in devices. It supports battery charging for lithium-ion (Li-Ion), lithium-polymer (Li-Poly), and lithium iron phosphate (LiFePO4) batteries, using a flexible power regulation system. Housed in a space-saving QFN32 package, the nPM1300 is made for high efficiency and is fully configurable via an I2C interface, making it ideal for wearables, peripherals, asset tracking, interactive entertainment, IoT applications, and much more.

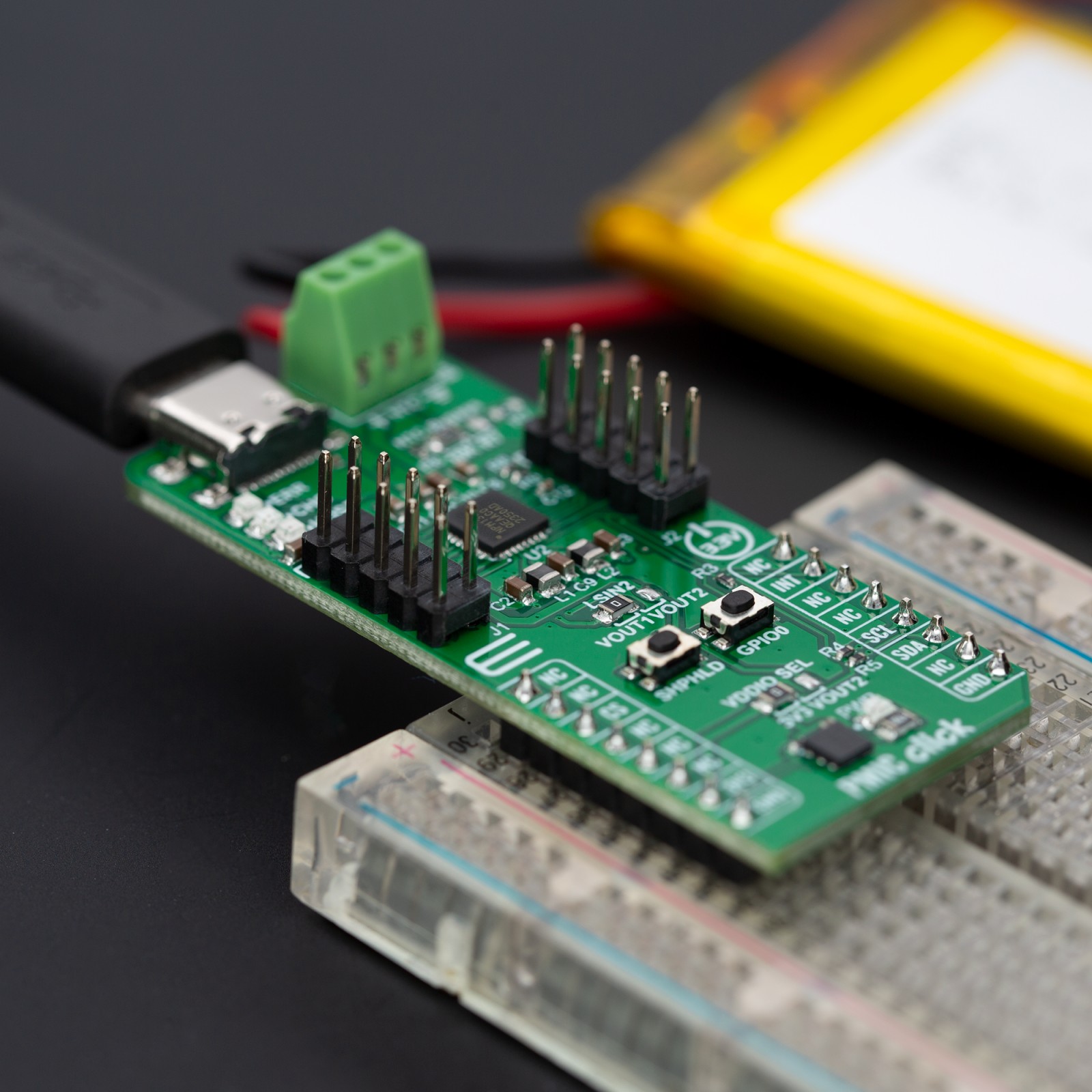

The nPM1300 features an integrated 800mA linear battery charger that ensures safe and efficient charging by adhering to the JEITA standards, which adjusts the charging process based on temperature to protect the battery and extend its lifespan. A battery can be connected to a connector in the upper right corner that supports the integration of an NTC thermistor for precise battery temperature monitoring. If the used battery pack already includes an NTC, the NTC terminal on the BATTERY connector can be left unconnected. For scenarios where a battery without an NTC thermistor is used, the board provides options to bypass this requirement by using onboard resistors. An integrated 10K resistor is available by default, or you can customize the value via an empty resistor footprint (R7 0603) to match specific needs. This feature can be selected via an onboard NTC Bypass jumper.

Besides the battery charger, the nPM1300 also provides two 200mA buck regulators, two 100mA load switches or 50mA Low Dropout Regulators (LDOs). These load switches offer flexibility in managing power distribution across your device. Control of these load switches is achieved through I2C registers or GPIO pins, providing flexibility to tailor the power configuration to your application’s requirements. A notable feature is the ability to select the input source for a second load switch via the LSIN2 jumper, allowing you to choose between the output voltage of one of the buck regulators (VOUT1 or VOUT2).

The regulated outputs, VOUT1 and VOUT2, are currently configured to output 1.8V, and VOUT2 is set to 3.3V. These configurations are achieved through specific resistor settings – R8 for VOUT1 and R9 for VOUT2, where VOUT1 can be adjusted within a range of 0V to 2.7V, while VOUT2 from 0V to 3.3V, depending on the selected resistor values. Unregulated output VBUSOUT is directly tied to the VBUS input, offering an unregulated power source that can be used for additional system needs, while VSYS serves as another unregulated output derived from the system’s overall power supply.

The primary power supply for the nPM1300 PMIC is provided by the VBUS connection, which is a dedicated USB Type-C input. Alongside VBUS, the complementary power supply is VBAT, which also acts as the output for the battery charger, ensuring that the connected battery is charged while maintaining a stable power supply to the system. In addition, the nPM1300 also enhances system reliability with a watchdog that resets the system if it becomes unresponsive, failed-boot recovery for system integrity, battery fuel gauging, and an intelligent power-loss warning to prevent data loss or failure.

PMIC Click uses a standard 2-wire I2C interface for communication with the host MCU, supporting a clock frequency of up to 400kHz in Standard mode. Besides interface pins, the board also features an interrupt (INT) pin providing real-time alerts to the host system for immediate action. To manage the power states, PMIC Click includes a SHPHLD button to exit Ship and Hibernation mode – two of the lowest quiescent current states available. These modes disconnect the battery from the system, reducing the quiescent current to extend the battery life. Hibernate mode, in particular, can be used during normal operation, as the device can automatically wake up after a preconfigured timeout, maximizing battery efficiency. The SHPHLD button also allows users to reset or power cycle the nPM1300.

For additional control, the board is equipped with a GPIO0 button, which directly manages the nPM1300’s GPIO0 pin. Three LED indicators provide visual feedback: a red ERR LED that signals errors during operation, a green CHG LED that indicates the charging status, and a yellow HOST LED that shows host activity. These LEDs offer clear and immediate visual cues, making monitoring the board’s status and troubleshooting any issues easier.

Two headers, J1 and J2, provide easy access to power and control functions. The J1 header grants access to the PMIC’s voltage outputs, VOUT1 and VOUT2, as well as the USB VBUS voltage through the VBUS pin and VBUSOUT from the nPM1300, allowing you to power external devices directly from the main IC. The J2 header serves multiple purposes, primarily enabling connections to PMIC GPIO pins located in the right column. These GPIOs, configured as inputs with weak pull-downs by default, can be used for custom workflows, standard GPIO functions, or as control pins for the board’s buck regulators and load switches. Additionally, the J2 header supports connections for external LEDs and includes the previously mentioned VSYS pin, a system voltage output.

This Click board™ can operate with either 3.3V or 3.3V provided from VOUT2 regulated PMIC output selected via the VDDIO SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Specifications

Type

Battery charger

Applications

Ideal for for wearables, IoT devices, asset tracking, and interactive entertainment systems

On-board modules

nPM1300 – Power Management Integrated Circuit (PMIC) from Nordic Semiconductor

Key Features

JEITA-compliant linear charger, two 200mA buck regulators, two 100mA load switches or 50mA LDOs configurable via I2C or GPIO, fuel gauge, system watchdog and failed-boot recovery, Ship and Hibernation modes for ultra-low power consumption, status LED indicators, and more

Interface

I2C

Feature

ClickID

Compatibility

mikroBUS™

Click board size

L (57.15 x 25.4 mm)

Input Voltage

3.3V,External

Pinout diagram

This table shows how the pinout on PMIC Click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | – | Power LED Indicator |

| LD2 | HOST | – | Host Activity LED Indicator |

| LD3 | CHG | – | Charging Status LED Indicator |

| LD4 | ERR | – | Error LED Indicator |

| JP1 | VDDIO SEL | Left | Logic Voltage Level Selection 3V3/VOUT2: Left position 3V3, Right position VOUT2 |

| JP2 | LSIN2 | Left | Load Switch 2 Suppy Source Selection VOUT1/VOUT2: Left position VOUT1, Right position VOUT2 |

| JP4 | NTC Bypass | Left | NTC Bypass Selection 10K/R7: Left position 10K, Right position R7 |

| T1 | SHPHLD | – | Ship/Hibernation Mode Exit Button |

| T1 | GPIO0 | – | GPIO0 Control Button |

PMIC Click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage | – | 3.3 | – | V |

| Charging Current | – | – | 800 | mA |

| Regulated Voltage VOUT1 | 0 | 1.8 | 2.7 | V |

| Regulated Voltage VOUT2 | 0 | 3 | 3.3 | V |

Software Support

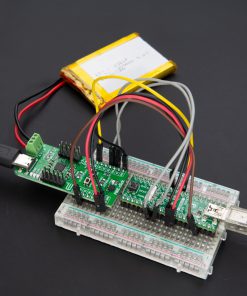

We provide a library for the PMIC Click as well as a demo application (example), developed using MIKROE compilers. The demo can run on all the main MIKROE development boards.

Package can be downloaded/installed directly from NECTO Studio Package Manager (recommended), downloaded from our LibStock™ or found on MIKROE github account.

Library Description

This library contains API for PMIC Click driver.

Key functions

-

pmic_get_vbatThis function reads the VBAT measurement results in millivolts. -

pmic_get_vbusThis function reads the VBUS measurement results in millivolts. -

pmic_get_vsysThis function reads the VSYS measurement results in millivolts.

Example Description

This example demonstrates the use of PMIC Click board™ by enabling battery charging and displaying the charging status.

void application_task ( void )

{

uint16_t vbat = 0, vbus = 0, vsys = 0;

if ( PMIC_OK == pmic_get_vbat ( &pmic, &vbat ) )

{

log_printf( &logger, " VBAT : %u mVrn", vbat );

}

if ( PMIC_OK == pmic_get_vbus ( &pmic, &vbus ) )

{

log_printf( &logger, " VBUS : %u mVrn", vbus );

}

if ( PMIC_OK == pmic_get_vsys ( &pmic, &vsys ) )

{

log_printf( &logger, " VSYS : %u mVrnn", vsys );

}

pmic_display_charger_status ( &pmic );

Delay_ms ( 1000 );

}

The full application code, and ready to use projects can be installed directly from NECTO Studio Package Manager (recommended), downloaded from our LibStock™ or found on MIKROE github account.

Other MIKROE Libraries used in the example:

- MikroSDK.Board

- MikroSDK.Log

- Click.PMIC

Additional notes and informations

Depending on the development board you are using, you may need USB UART click, USB UART 2 Click or RS232 Click to connect to your PC, for development systems with no UART to USB interface available on the board. UART terminal is available in all MIKROE compilers.

mikroSDK

This Click board™ is supported with mikroSDK – MIKROE Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

Resources

Downloads

| Weight | 22 g |

|---|---|

| Brand | MikroElektronika |