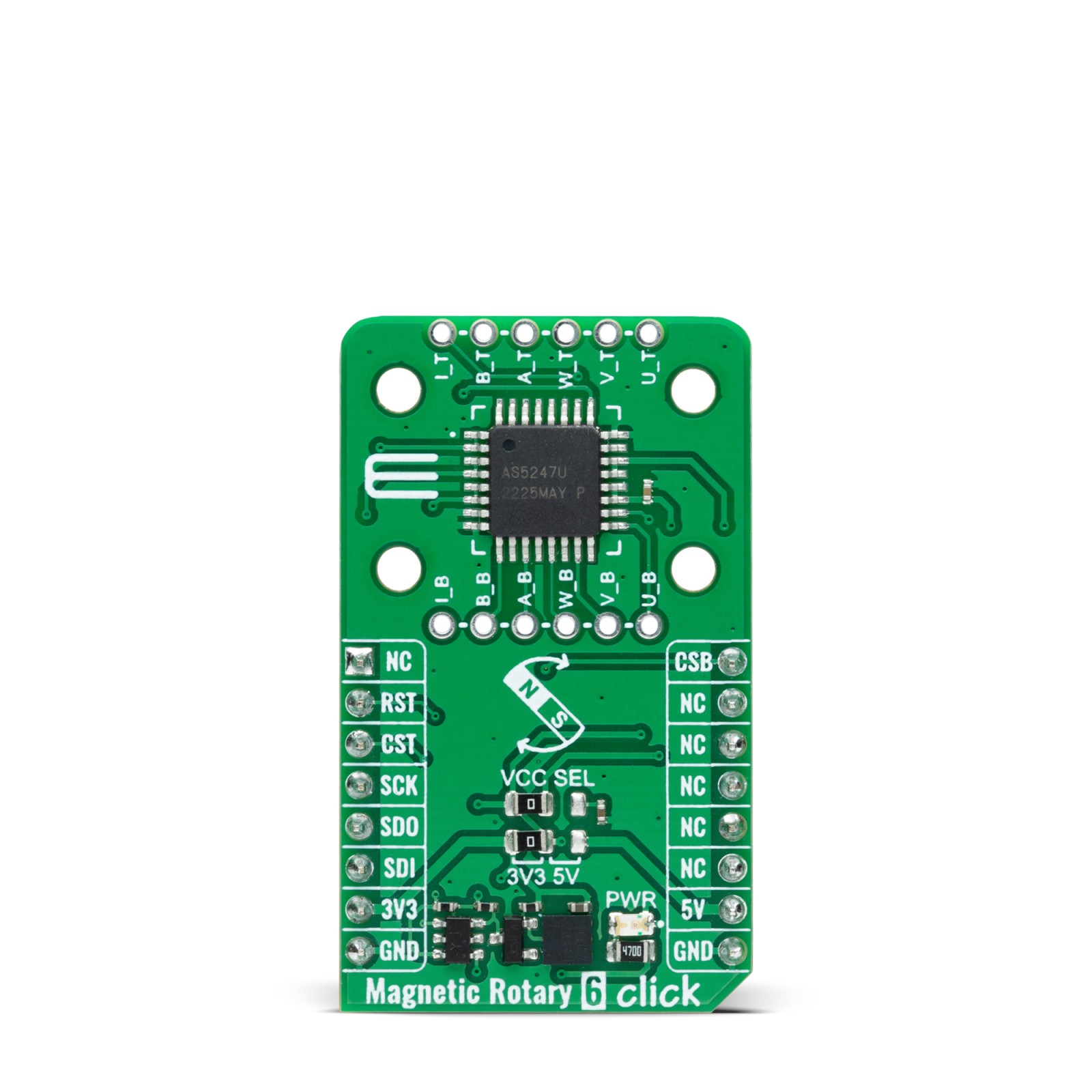

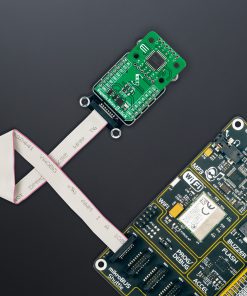

Magnetic Rotary 6 Click

R970.00 ex. VAT

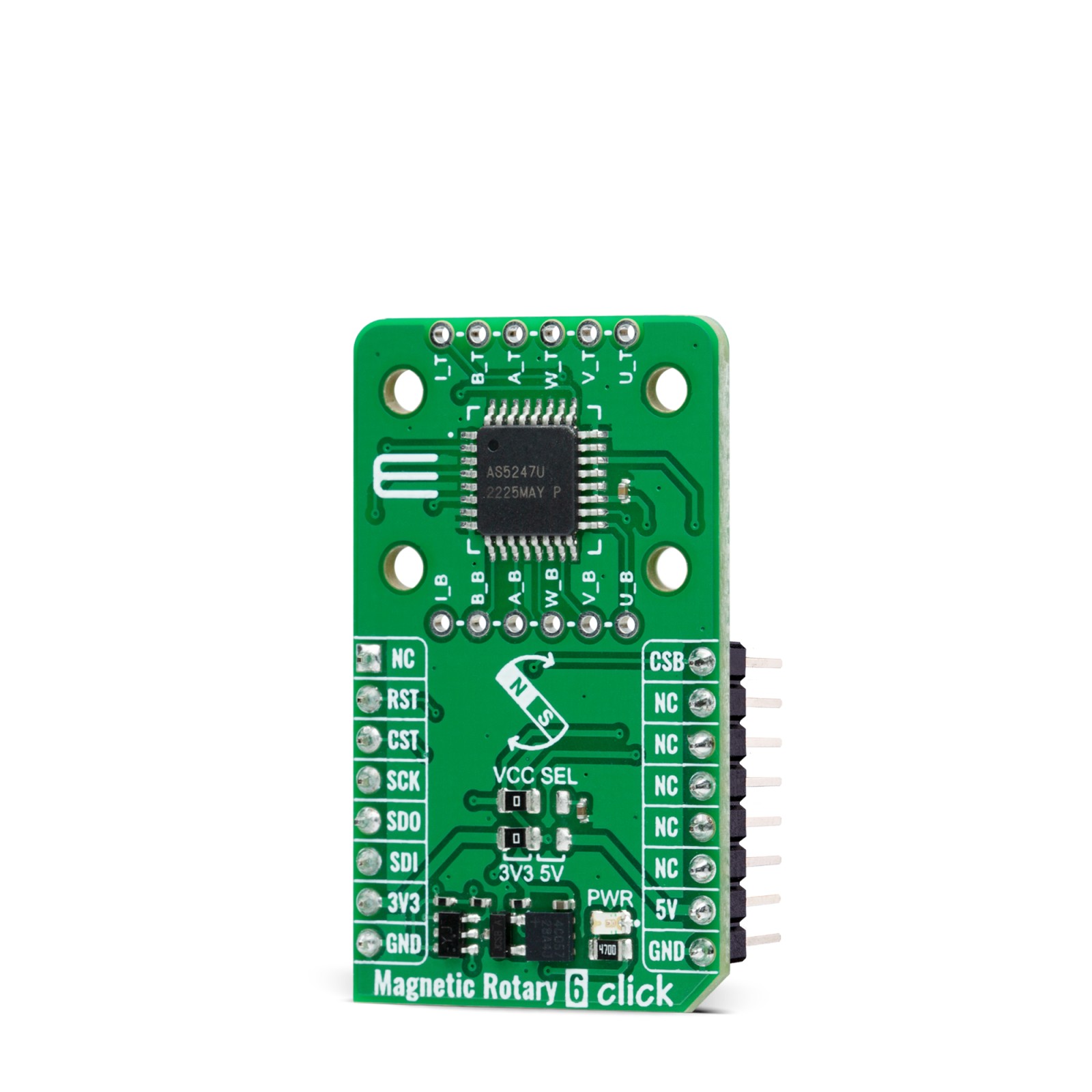

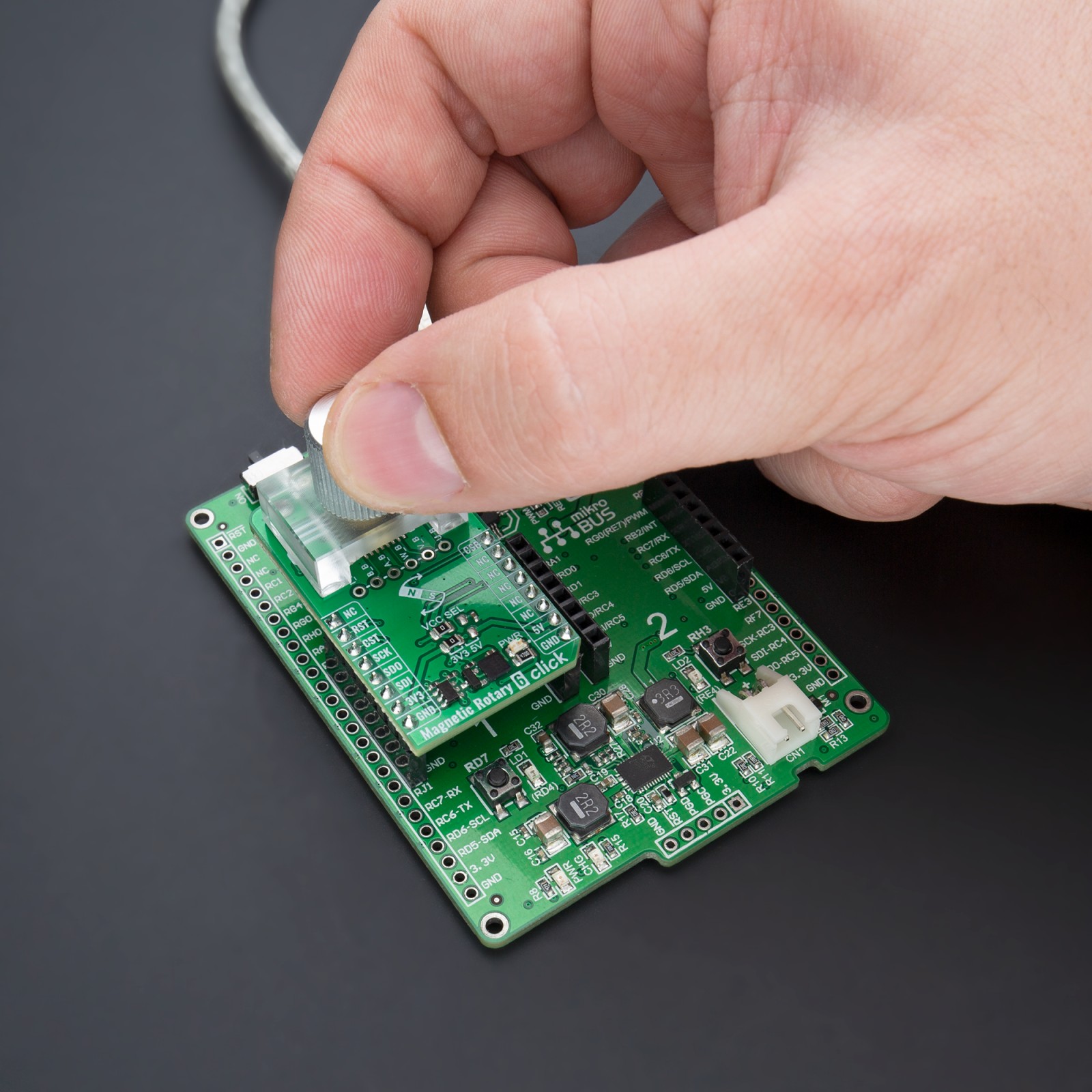

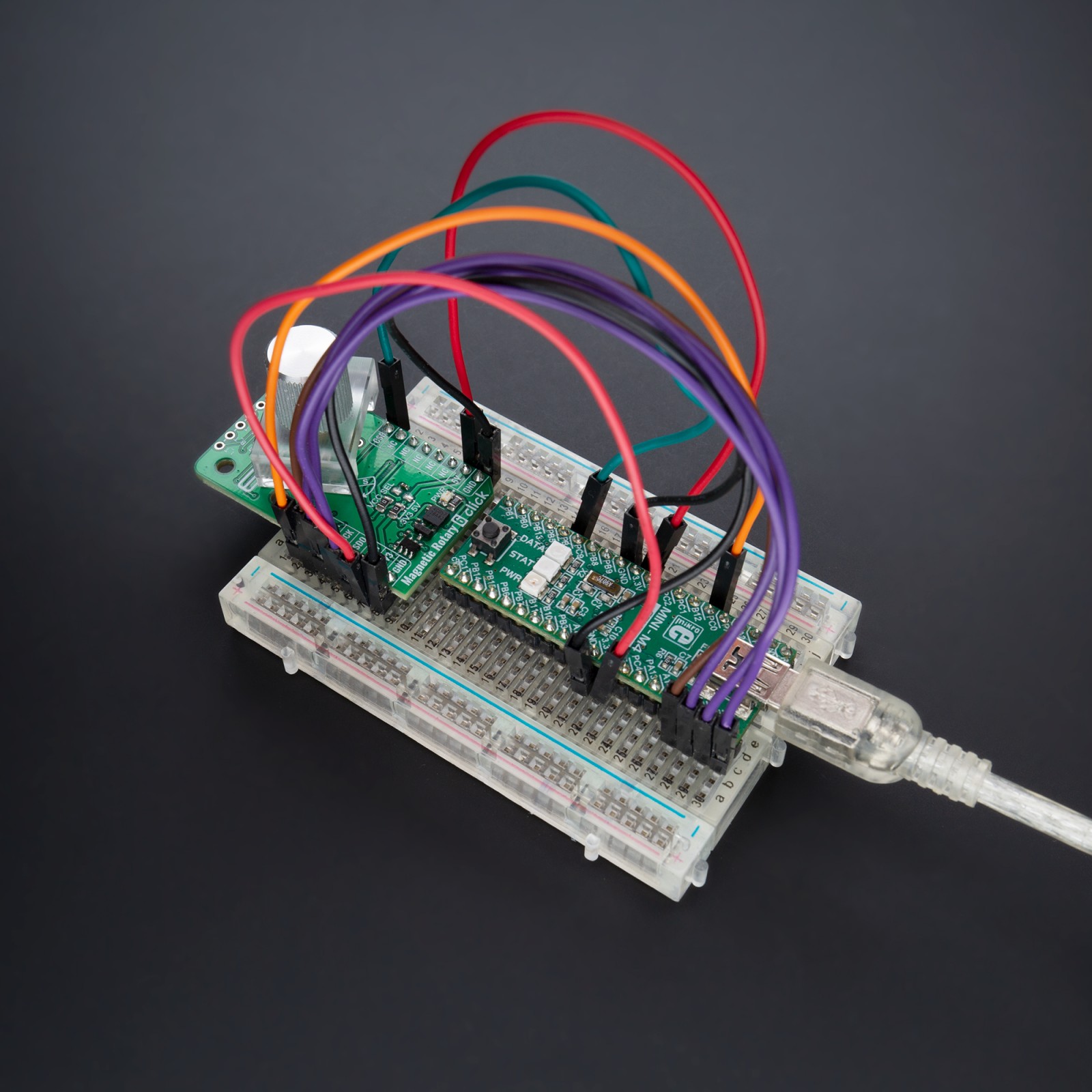

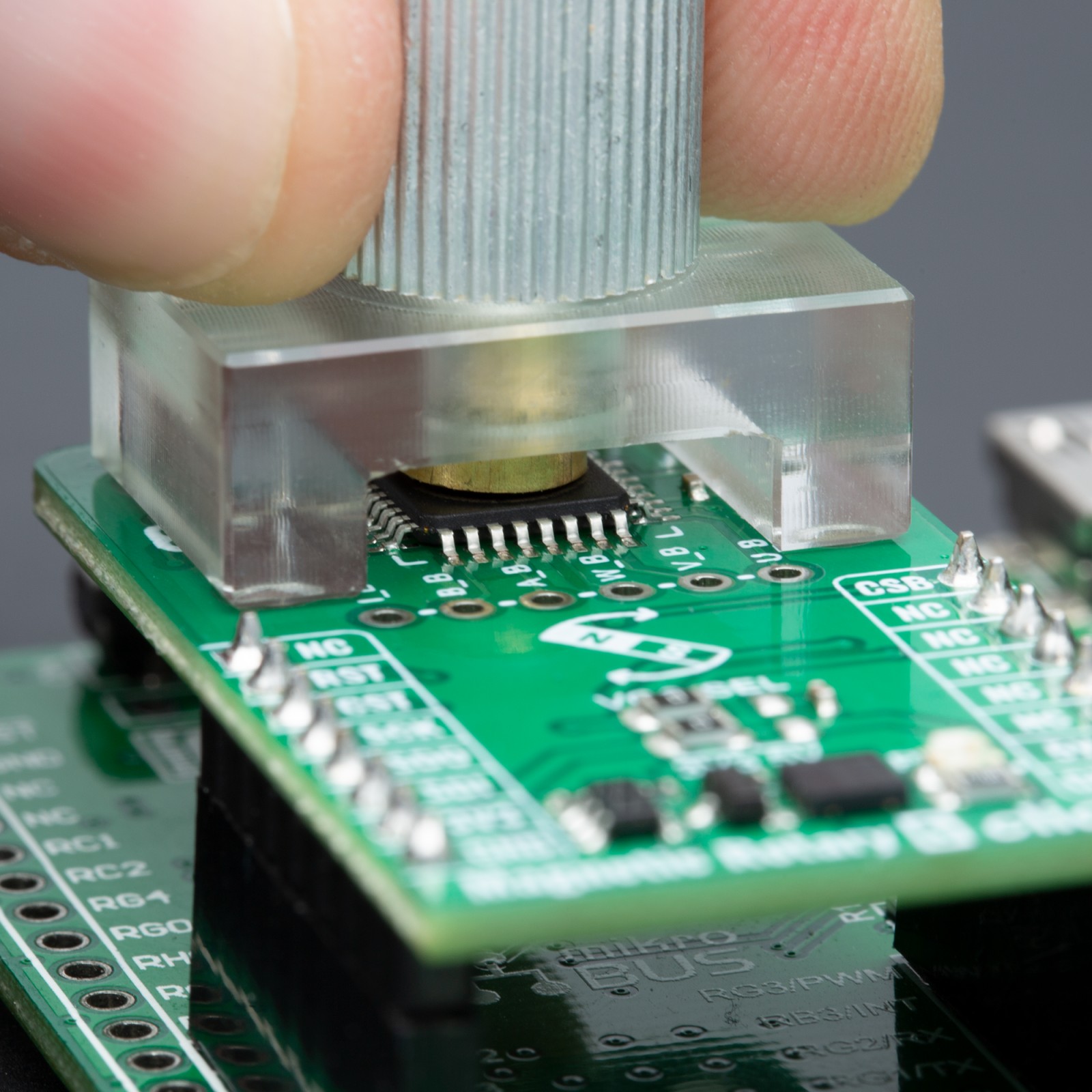

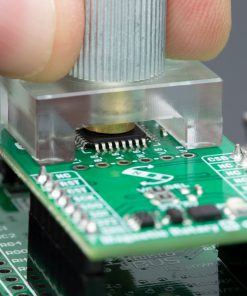

Magnetic Rotary 6 Click is a compact add-on board for accurate magnet-position sensing. This board features the AS5247U, an SPI-configurable high-resolution dual rotary position sensor for fast absolute angle measurement over a full 360-degree range from ams AG. The AS5047D is equipped with revolutionary integrated dynamic angle error compensation (DAEC™) with almost 0 latency and offers a robust design that suppresses the influence of any homogenous external stray magnetic field. It also comes with onboard headers reserved for incremental and commutation signals of their respective A/B/I and U/V/W signals, with a maximum resolution of 16384 steps / 4096 pulses per revolution, alongside embedded self-diagnostics features. This Click board™ has been designed to support BLDC motor commutation for the most challenging automotive and safety-critical applications.

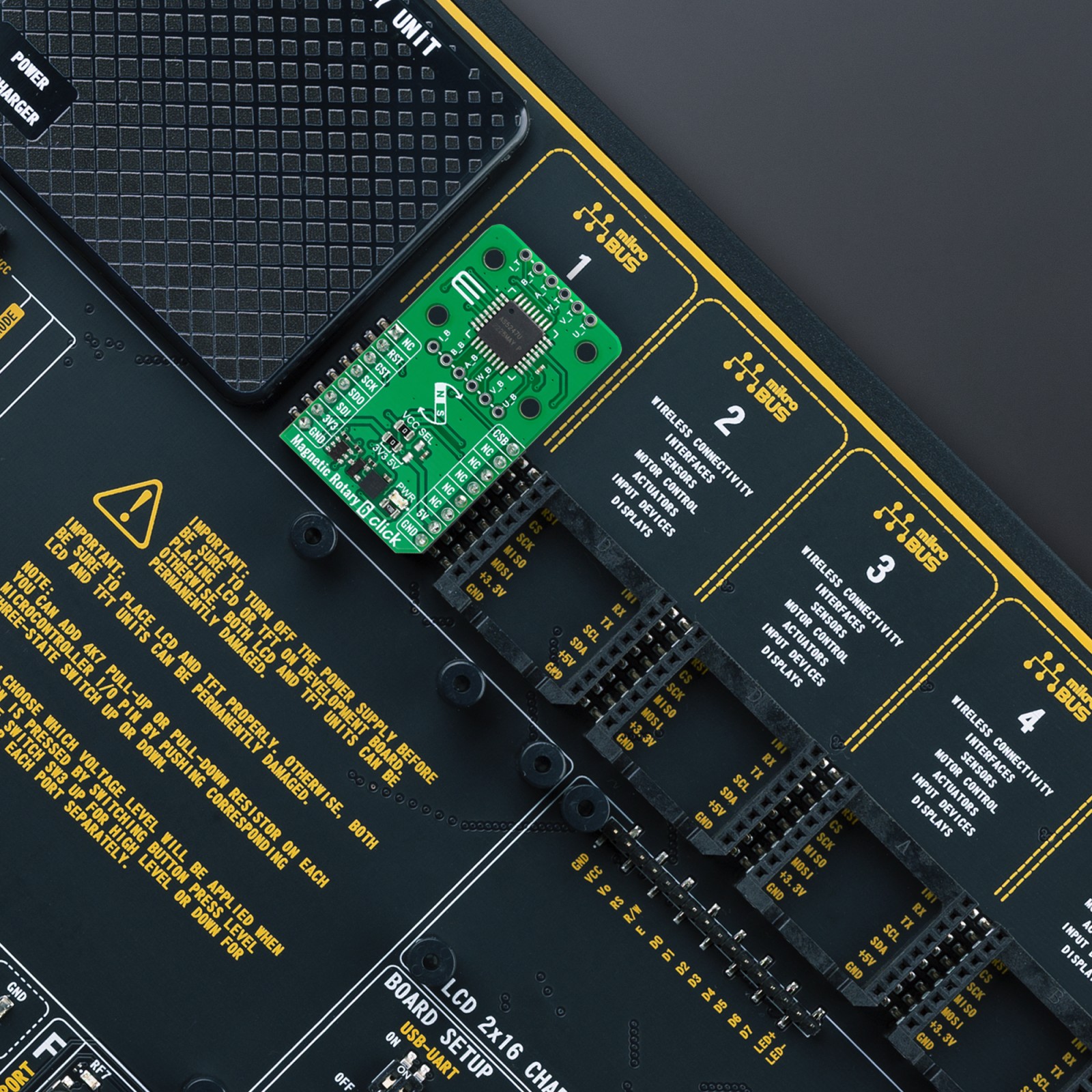

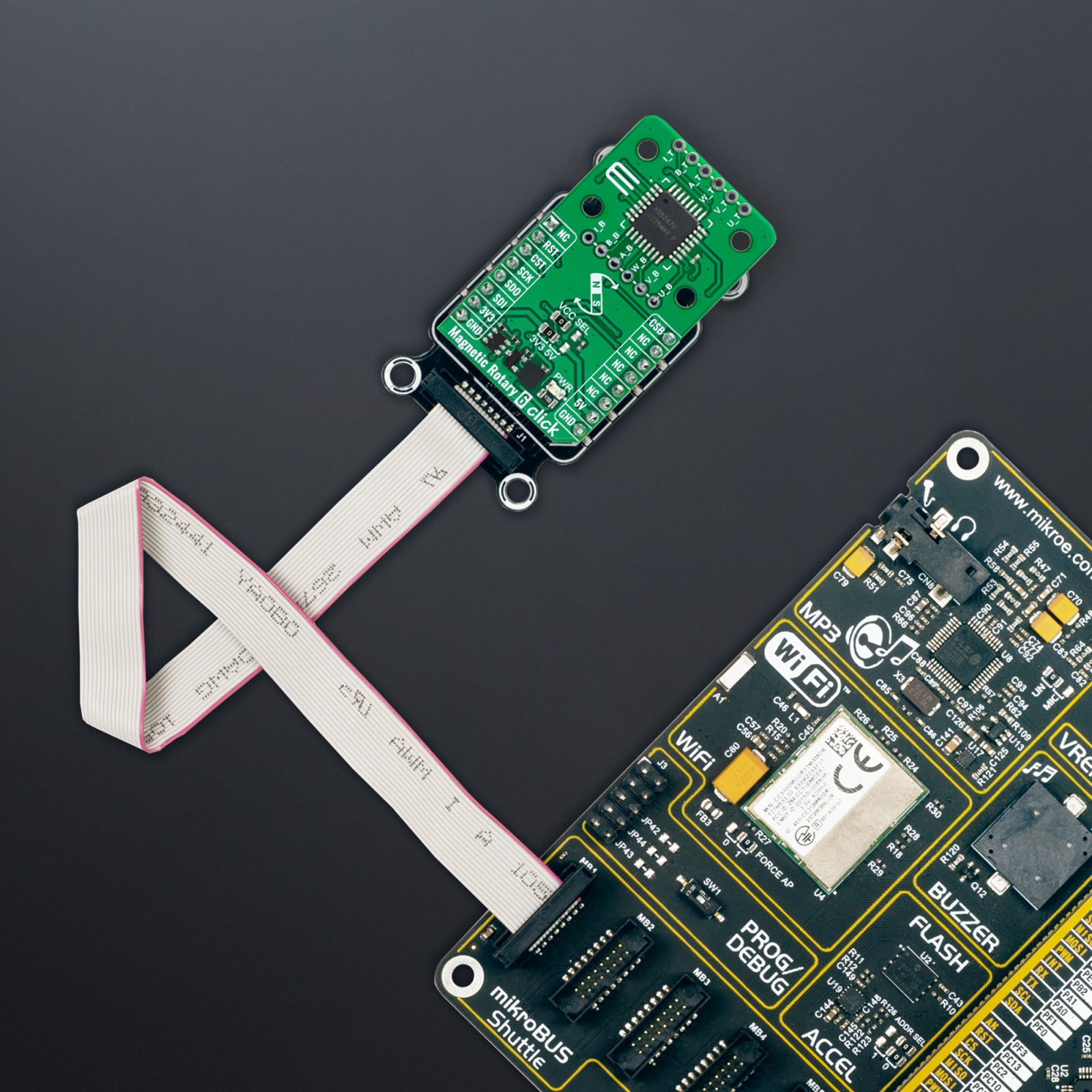

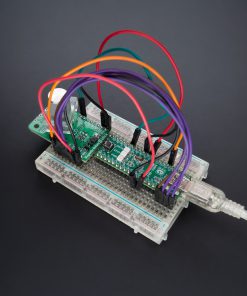

Magnetic Rotary 6 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

Stock: Lead-time applicable.

| 5+ | R921.50 |

| 10+ | R873.00 |

| 15+ | R824.50 |

| 20+ | R793.46 |