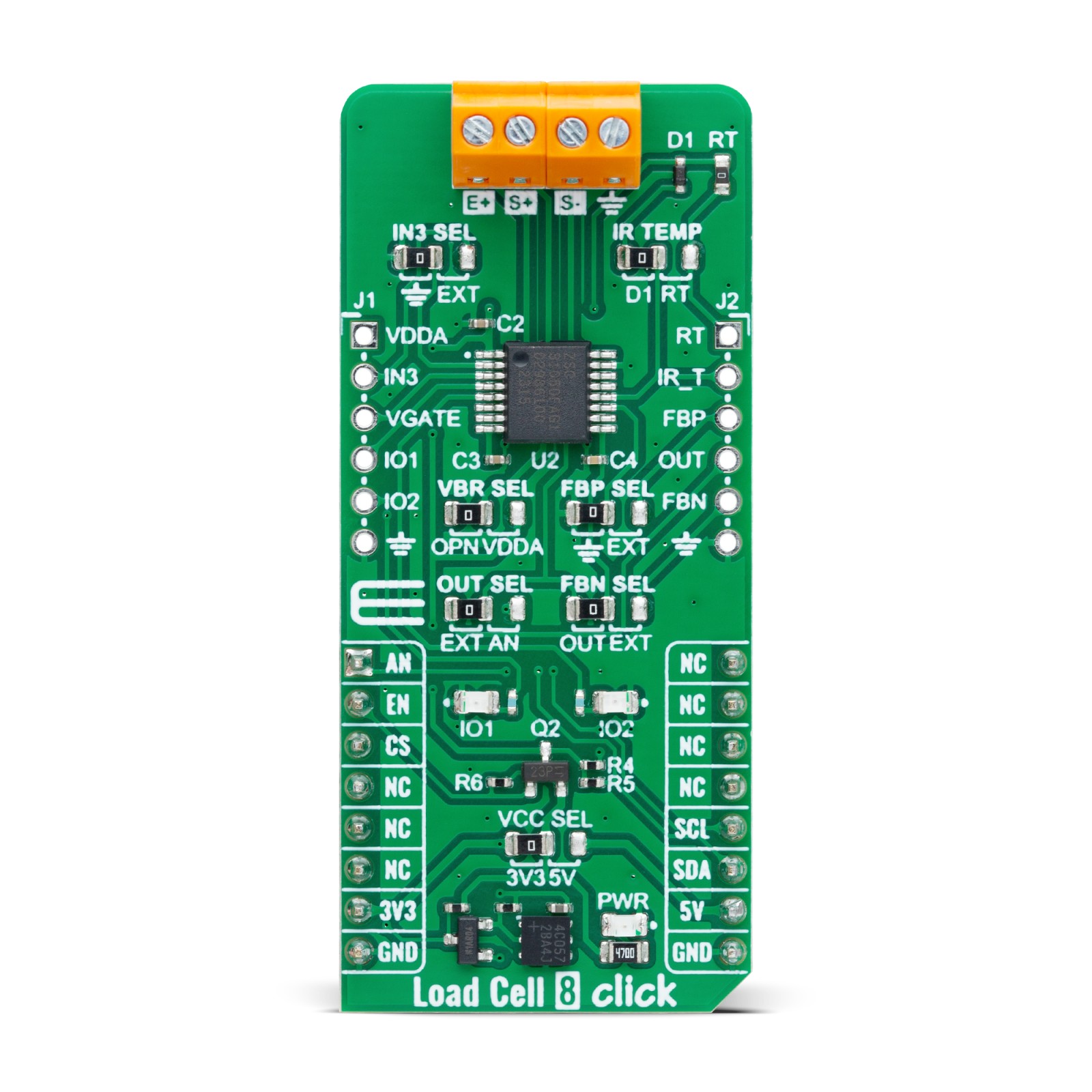

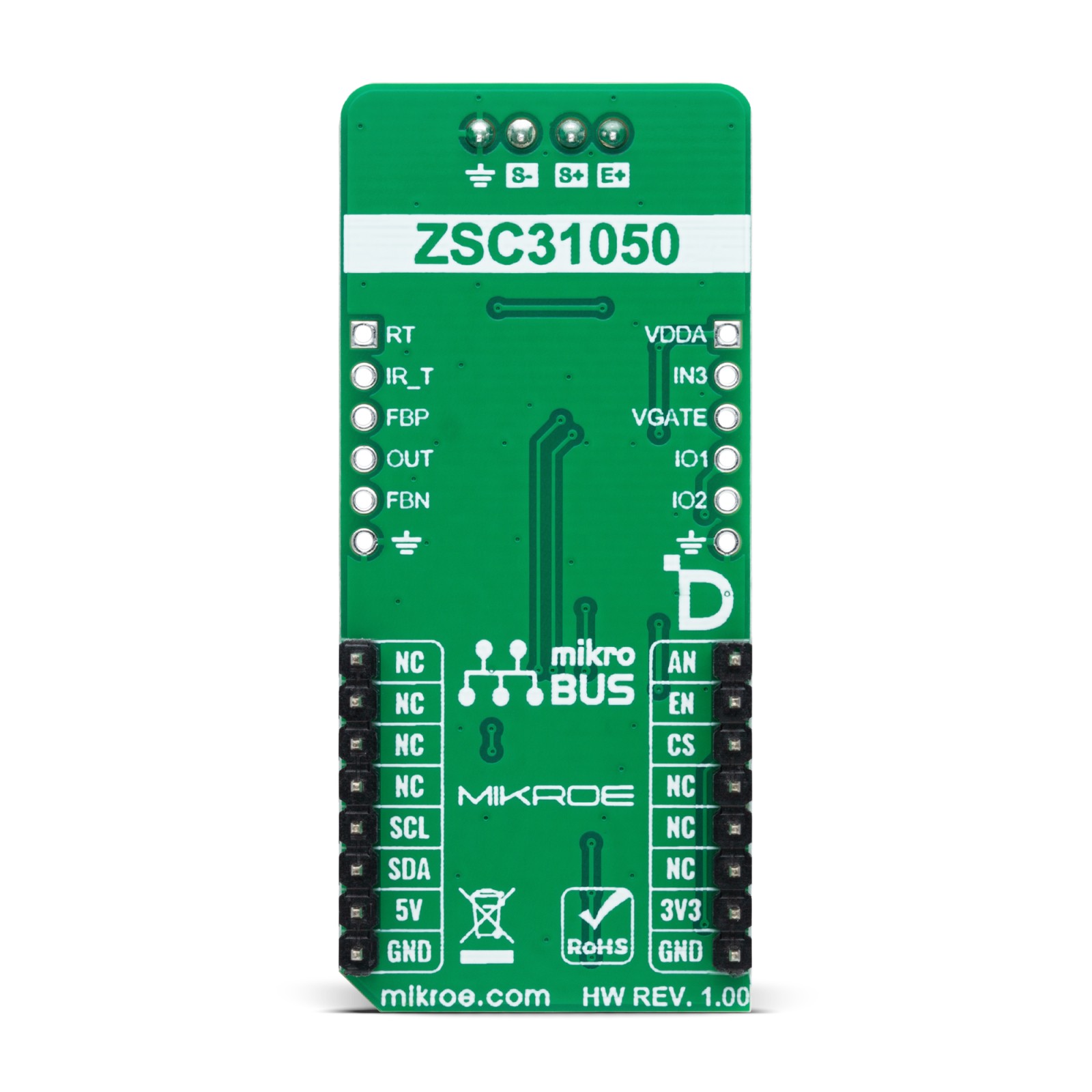

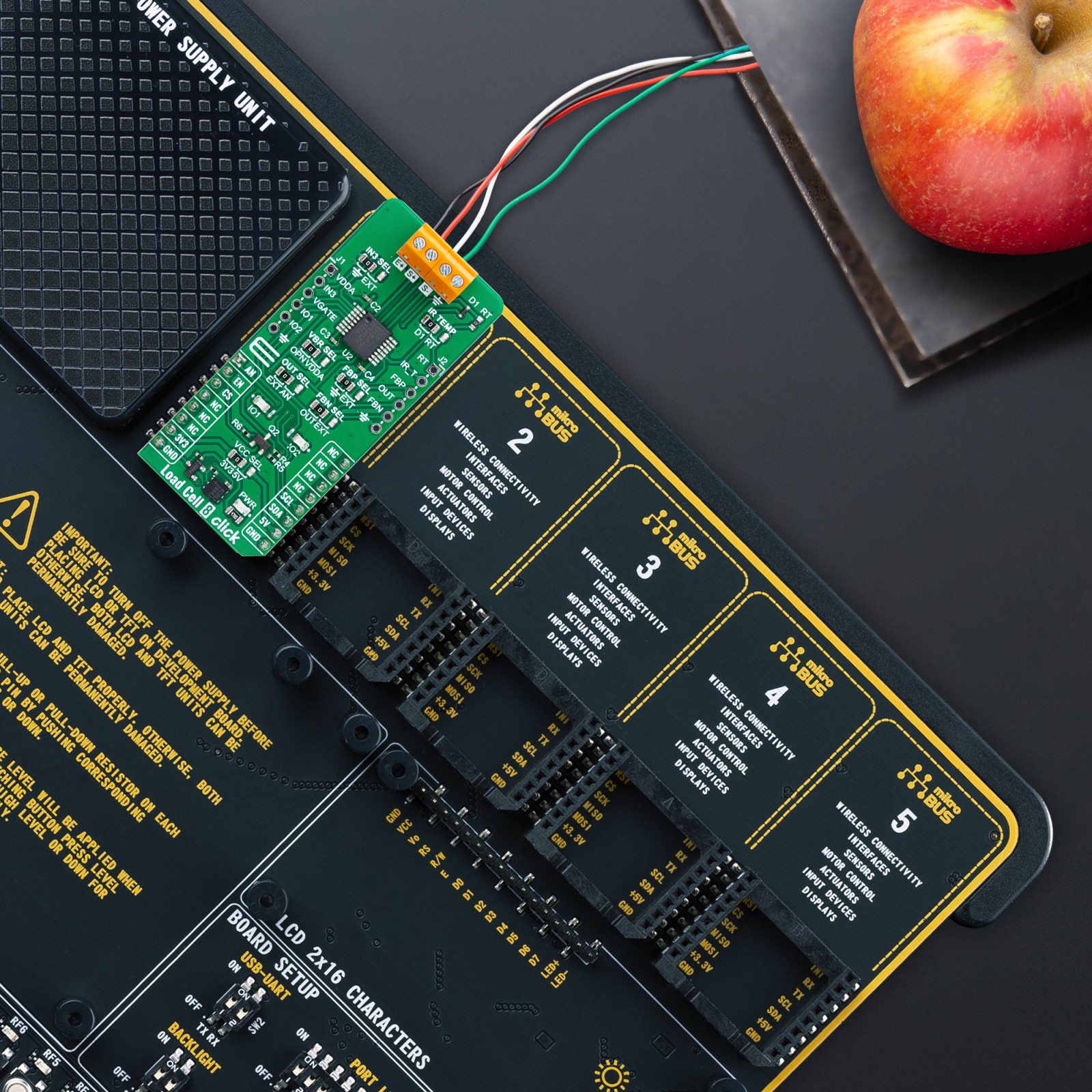

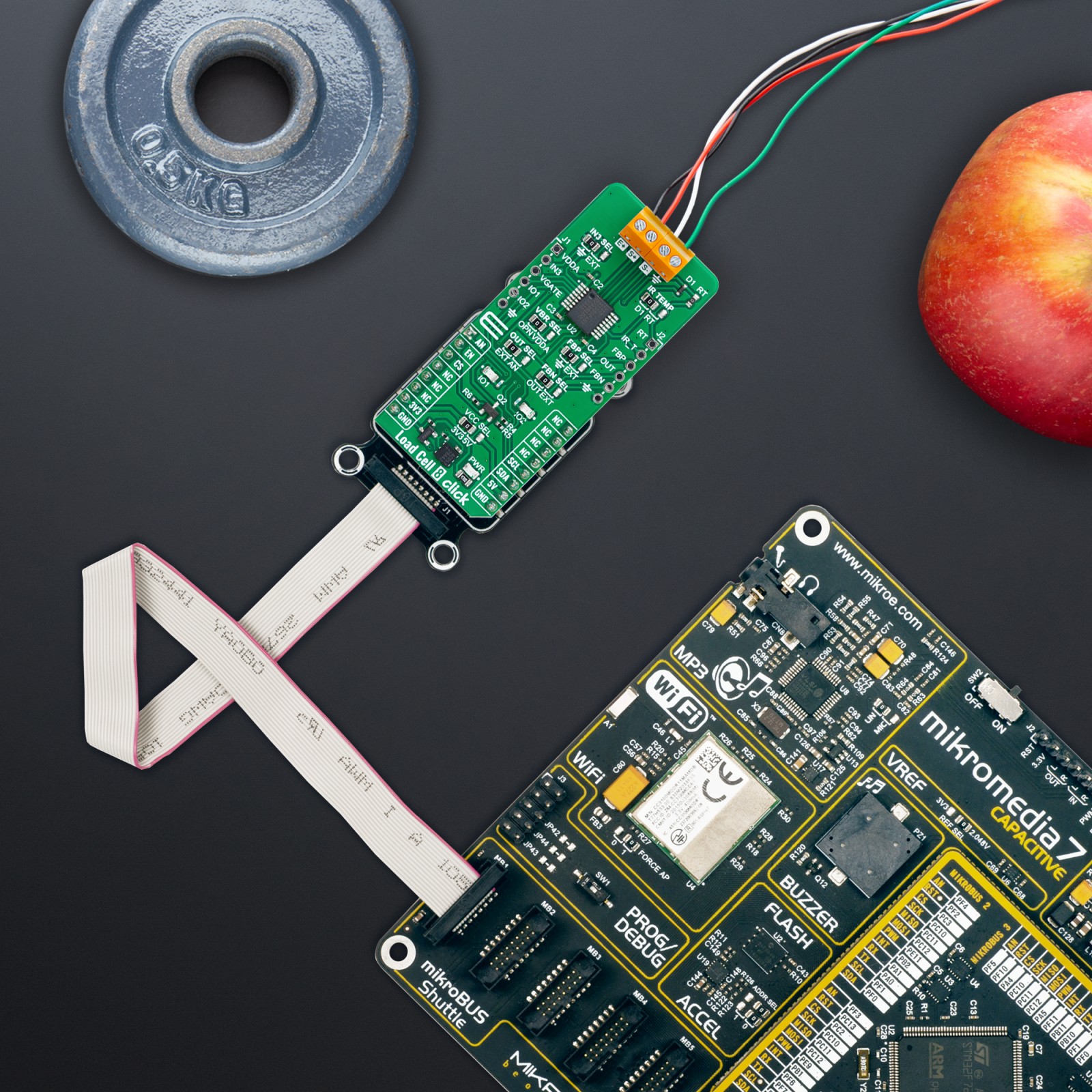

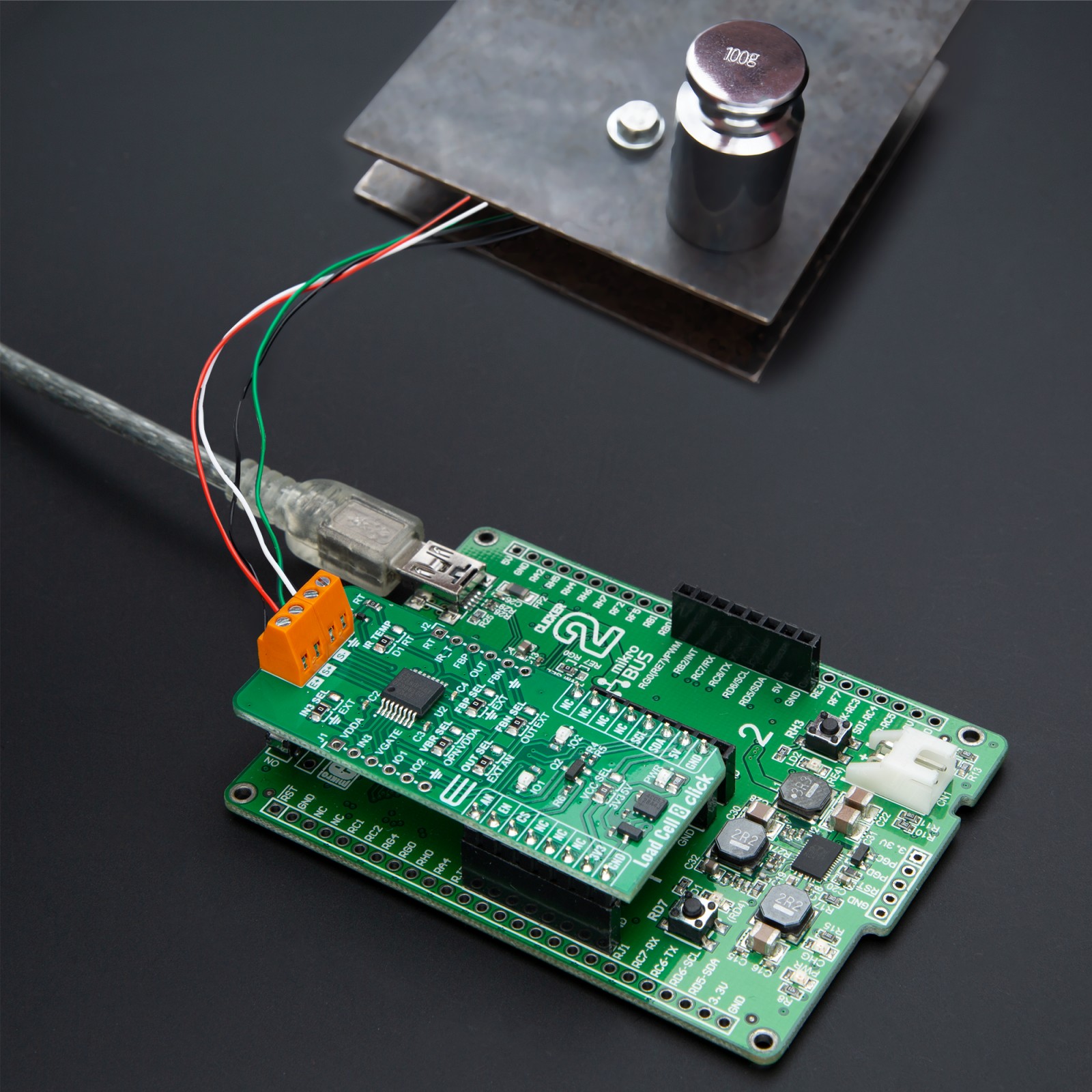

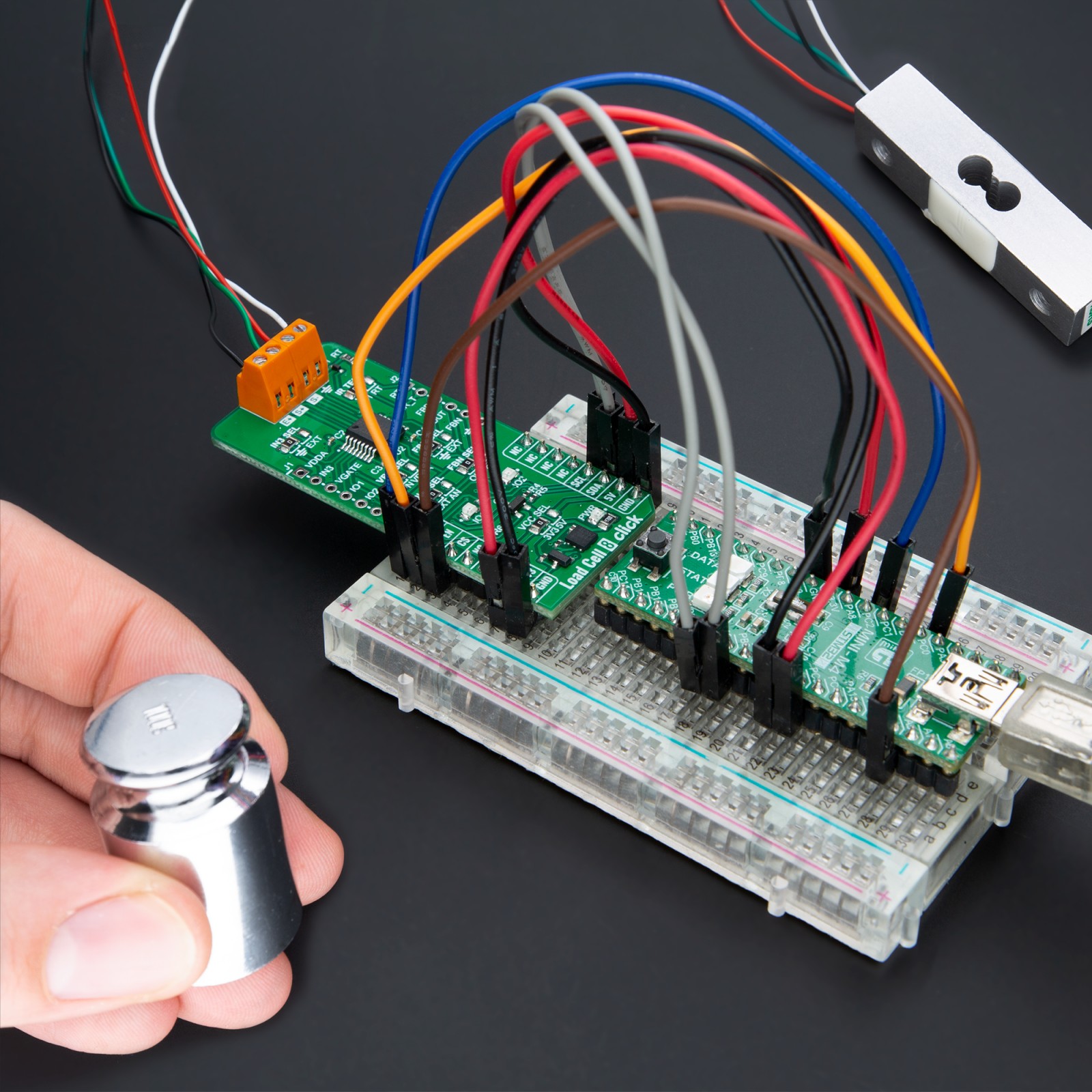

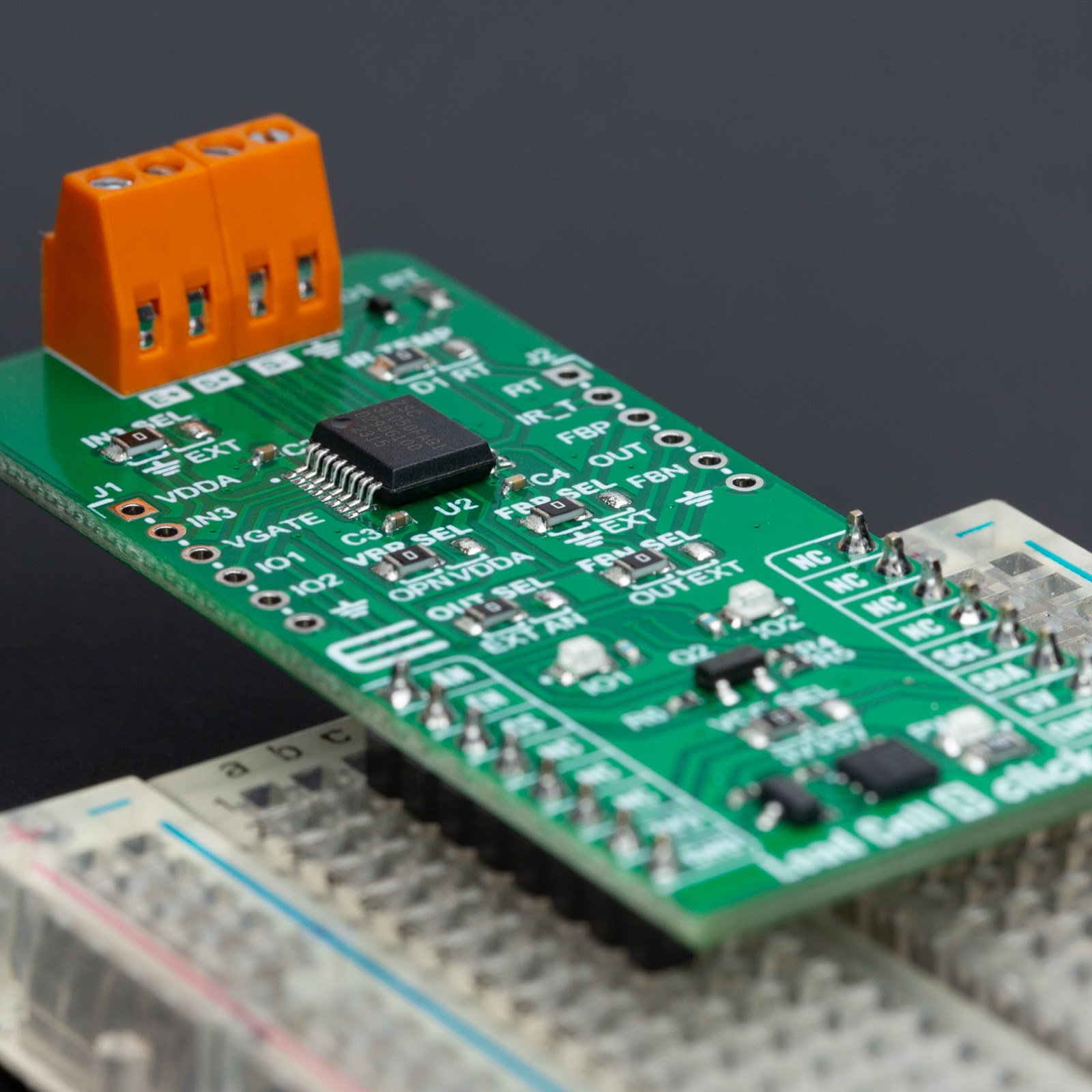

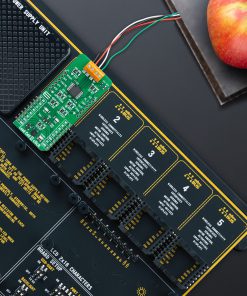

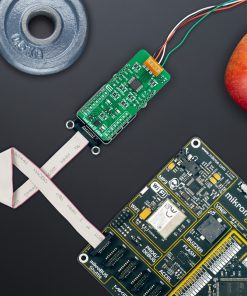

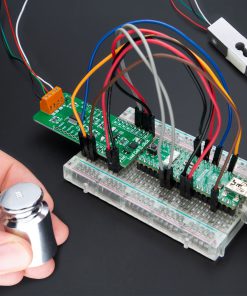

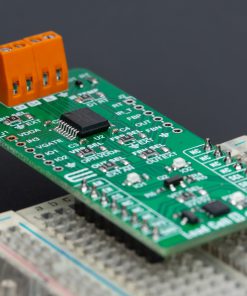

Load Cell 8 Click is a compact add-on board representing a weigh scale solution. This board features the ZSC31050, an advanced differential sensor signal conditioner from Renesas designed for high-precision signal conditioning in applications requiring detailed sensor-specific corrections. It excels in processing differential sensor signals for various resistive bridge sensors. The ZSC31050 is capable of highly accurate amplification, offering digital compensation of sensor offset, sensitivity, temperature drift, and non-linearity. It supports a broad signal range from 1mV/V to 275mV/V, making its use across industrial, medical, and consumer applications. It uses a standard I2C interface for communication, allows multiple output modes, and provides various jumper selections for many features, such as output signal routing, external reference voltage adjustments, and more. Ideal for measuring pressure, force, torque, and position, this Click board™ finds extensive use in monitoring and control systems.

Load Cell 8 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to seamlessly and automatically detect and identify this add-on board.

LPG Click

1 × R325.00

LPG Click

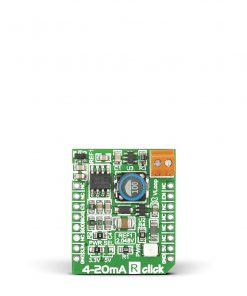

1 × R325.00  4-20mA R Click

1 × R470.00

4-20mA R Click

1 × R470.00  EXPAND Click

1 × R255.00

EXPAND Click

1 × R255.00  RN4678 Click

1 × R835.00

RN4678 Click

1 × R835.00  GSM/GNSS Click

1 × R1,650.00

GSM/GNSS Click

1 × R1,650.00  tRF Click

1 × R1,050.00

tRF Click

1 × R1,050.00  ccRF2 Click

1 × R780.00

ccRF2 Click

1 × R780.00  GSM-GPS Click

1 × R1,300.00

GSM-GPS Click

1 × R1,300.00